In the world of padel, quickly judging the build quality of a racket comes down to a detailed check of its materials, construction precision, balance, and finish. By focusing on these key parameters, procurement managers and product developers can efficiently assess whether a racket meets the standards of performance and durability required in high-level play.

When evaluating a padel racket, the main challenge lies in balancing technical inspection with practical performance indicators. As the market grows, quality variations among manufacturers can significantly affect player performance. For professionals, knowing how to quickly assess these differences saves time and ensures only the best rackets are sourced.

A thorough evaluation should cover several areas, including:

- Materials Used: The use of fiberglass, 3k, 12k, or 18k carbon fiber1 can dramatically influence performance and lifespan.

- Manufacturing Consistency: Consistency in production techniques and quality assurance reflects the overall reliability of the product line.

- Design Characteristics: Factors such as weight, balance, shape, and surface texture directly impact a player's feel and control.

- Customization and Finishing Details: Features like custom prints, grip quality, and handle design might also indicate the level of craftsmanship.

By conducting a detailed inspection focused on these features, B2B professionals can quickly identify the quality level of any padel racket.

Below is a list of critical indicators you can use as a checklist when assessing padel racket build quality:

-

Material Quality and Composition:

- Look at the materials used in the construction. High-end rackets are typically made with advanced composites like 12k or 18k carbon fiber that offer enhanced durability and performance.

- Compare the carbon fiber grade to fiberglass options if comfort and ease of use are more critical.

-

Manufacturing and Production Techniques:

- Assess whether the racket is produced using advanced techniques like Automated Layering Process2 or hand-crafting procedures.

- Evaluate the consistency in production by comparing multiple rackets from the same batch.

-

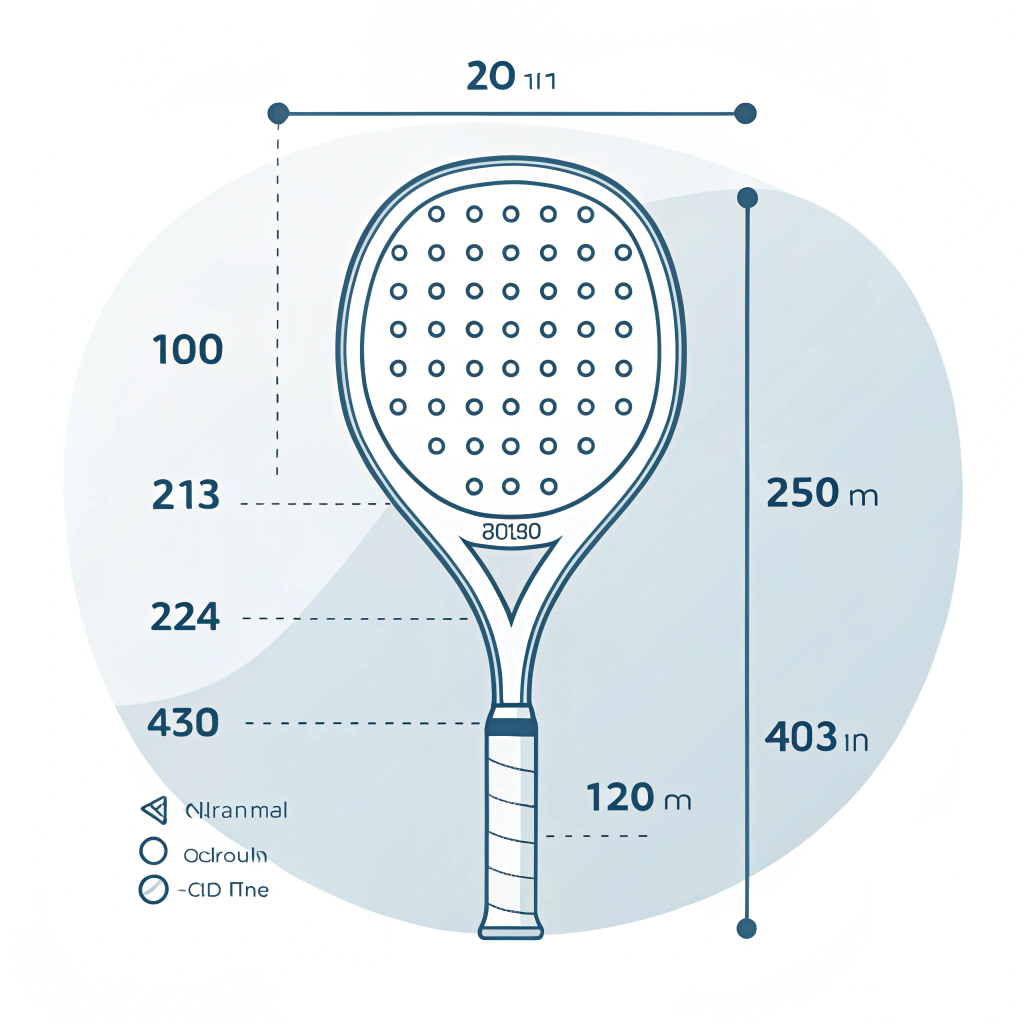

Weight and Balance:

- Verify that the racket's weight is within the optimal range (typically between 340 and 375 grams) to suit different play styles.

- Balance is essential; a well-disciplined racket should offer an even distribution of weight to control maneuverability and power.

-

Shape and Design Features:

- The racket's head shape (Diamond, Round, or Teardrop) should align with the intended playing style.

- Handle design, including grip size and length, plays a crucial role in comfort and control.

-

Surface Texture and Finish:

- A consistent surface texture not only improves spin and control but also indicates high-quality finishing in the production process.

- Check for any irregularities, excess glue, or uneven painting that might lower performance.

Materials form the backbone of any high-performance padel racket. Here’s how to break it down:

- Fiberglass vs. Carbon Fiber:

Fiberglass offers a smoother feel and is often preferred for entry-level rackets, while carbon fiber provides superior strength and stiffness. Different grades such as 3k, 12k, and 18k carbon fibers deliver varying levels of rigidity and responsiveness. - Carbon Fiber Grades Comparison Table:

| Carbon Fiber Grade | Characteristics | Suitability |

|---|---|---|

| 3k Carbon | Lightweight; moderate durability | Beginner to intermediate players |

| 12k Carbon | Improved strength and stiffness | Intermediate players needing balance |

| 18k Carbon | High performance; maximum durability | Advanced players requiring top performance |

Selecting the right composite ensures that the racket will maintain its integrity during prolonged game play, minimizing the risk of fractures or performance degradation.

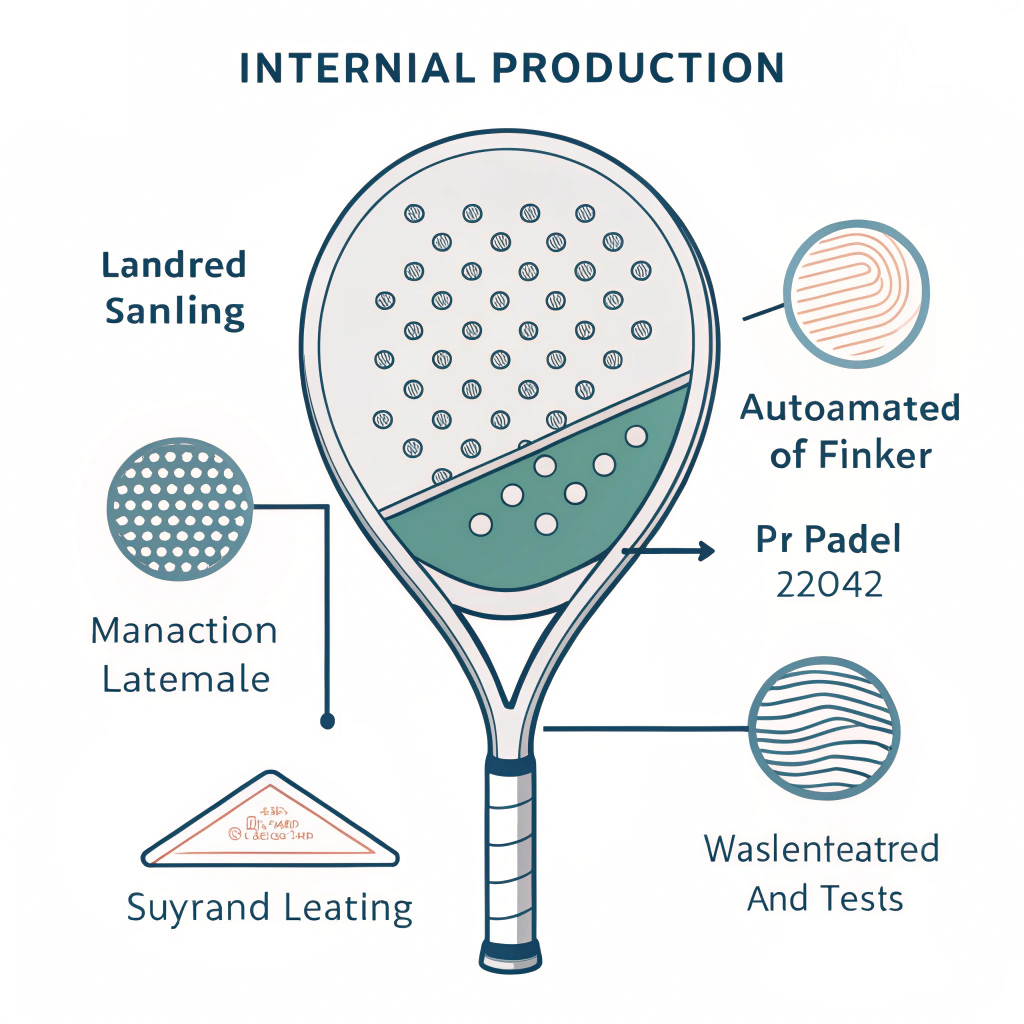

Modern padel racket manufacturing involves a blend of machinery and artisanal techniques:

- Automated Layering Process2: Advanced machinery ensures uniformity in material layers, reducing the risk of weak points.

- Handcrafted Finishing:

Skilled technicians provide the final touches, ensuring that each racket exhibits a high level of detail and refinement. - Quality Assurance3: Continuous testing during production—from weight consistency to balance calibration—ensures that every unit meets predefined technical standards.

Our experience at NEX Padel, with rapid prototyping and quality monitoring, emphasizes these production steps. By focusing on these technical metrics, you can judge the build quality quickly and accurately.

Here are actionable methods and tests to quickly assess the build quality of a padel racket:

-

Visual Inspection:

- Check the surface finish for consistency. Look for any signs of uneven painting, bubbles, or imperfections.

- Inspect the edge details and handle finishes. A well-finished racket typically has smooth transitions and high-quality grips.

-

Tactile Evaluation:

- Run your hand along the racket’s surface. Real high-quality materials usually offer a uniform texture without rough transitions.

-

Weight Check:

- Use a precision scale to confirm the weight. Compare the measured weight against the published specifications (usually between 340 and 375 grams).

- A slight variation in weight across similar models can indicate inconsistencies during manufacturing.

-

- Use a balance beam or a simple home-made pendulum test to determine the center of gravity.

- A well-balanced racket provides more control and power, crucial for performance in competitive play.

-

Flexibility and Stiffness Test:

- Apply gentle pressure to assess the flex characteristics. The degree of flexibility not only affects power distribution but also indicates the impact resistance of the material.

-

Customization Options Review:

- If available, check for customization quality such as printed logos or color consistency. This reflects the manufacturer’s attention to detail and their willingness to cater to bespoke client requirements.

Incorporating these functional tests into your quality inspection process will help you make quick, informed decisions. They bridge the gap between technical evaluation and practical performance, essential for B2B purchasers in the sports equipment industry.

Understanding how rackets stack up against industry benchmarks is essential. Here’s why these numbers matter:

-

Weight Range:

A racket’s weight must fall within a narrow spectrum influenced by design and material choices. Consistent weights indicate controlled manufacturing processes. -

Balance Point:

The balance should ideally align with the intended design type (e.g., a teardrop shape for power or a round shape for control). A mismatch in the balance can result in performance issues. -

Durability Metrics:

Stress Tests5 such as impact absorption and repeated flex cycles help determine long-term durability. Typically, a perfectly engineered padel racket will withstand hundreds of repetitive impacts without significant performance degradation.

Employing these benchmarks when comparing suppliers like NEX Padel provides a structured approach for decision-making. These data points help distinguish top-tier products from those that only appear robust superficially.

Below is a consolidated checklist for quickly judging padel racket build quality:

| Aspect | What to Check | Quality Indicators |

|---|---|---|

| Materials | Types of fiber used; grade (3k, 12k, 18k) | Consistent texture, clear composite layers |

| Construction | Precision of layering, bonding, and finishing | Smooth surface, even paint, secure handle attachment |

| Weight | Total weight vs. specification range | Within 340-375 grams for balance and control |

| Balance | Center of gravity, distribution of weight | Even or purpose-specific balance |

| Surface and Grip | Finishing quality, customization details | Uniform texture, precise logo printing |

| Flexibility | Resistance under pressure, durability | Measured response during stress testing |

For procurement managers, using this comprehensive checklist ensures that every vendor is held to the same high standards, minimizing the risk of subpar product performance.

In summary, the build quality of a padel racket can be rapidly judged by focusing on:

- The materials and grades used.

- Detailed examination of construction and finishing.

- Verification through functional testing like weight, balance, and flexibility assessments.

By using these criteria to quickly filter out products that do not meet the high-performance standards required, B2B buyers can make sound procurement decisions. The methodology provided not only emphasizes a technical approach but also aligns with industry benchmarks and best practices.

For organizations like NEX Padel, which specialize in highly precise manufacturing methods and cater to top-tier brands, such quality checks form the core of our product assurance process. Incorporating these tests into your standard evaluation routine will not only elevate your selection process but also ensure long-term value from each imported product.

We encourage procurement managers and industry professionals to integrate these practical guidelines and checklists into your quality assessment procedures. This will lead to a more consistent and transparent evaluation process while ultimately enhancing the performance outcomes on the court.

Q: How to tell a good padel racket?

A: A good padel racket is identified by its shape, optimal weight (typically 340-375 grams), well-balanced design, ergonomic handle, and high-quality materials. Additionally, a consistent surface texture and flawless finishing indicate superior craftsmanship.

Q: How much difference does a good padel racket make?

A: A well-made padel racket can deliver the right balance of power and maneuverability. Heavier rackets may offer increased power for aggressive play, while lighter ones enhance speed and control, ultimately affecting overall performance on the court.

Q: What are the best padel rackets made of?

A: The best padel rackets are commonly fabricated using high-quality materials. Fiberglass is often chosen for its comfort, whereas high-end rackets typically utilize various grades of carbon fiber—such as 12k and 18k for exceptional durability, strength, and performance.

-

carbon fiber: Read this article to understand the properties of carbon fiber, its various grades (3k, 12k, 18k), and why it is critical in high-performance sports equipment. ↩ ↩

-

Automated Layering Process: Click here to discover how automated layering ensures uniform composite structures and enhances product reliability. ↩ ↩ ↩2

-

Quality Assurance: Explore how robust quality assurance processes in manufacturing can minimize defects and ensure product consistency. ↩ ↩

-

Balance Assessment: Learn more about balance assessment techniques used to optimize weight distribution and enhance racket performance. ↩ ↩

-

Stress Tests: This article details the crucial stress tests that assess impact absorption and durability in high-performance sports gear. ↩ ↩