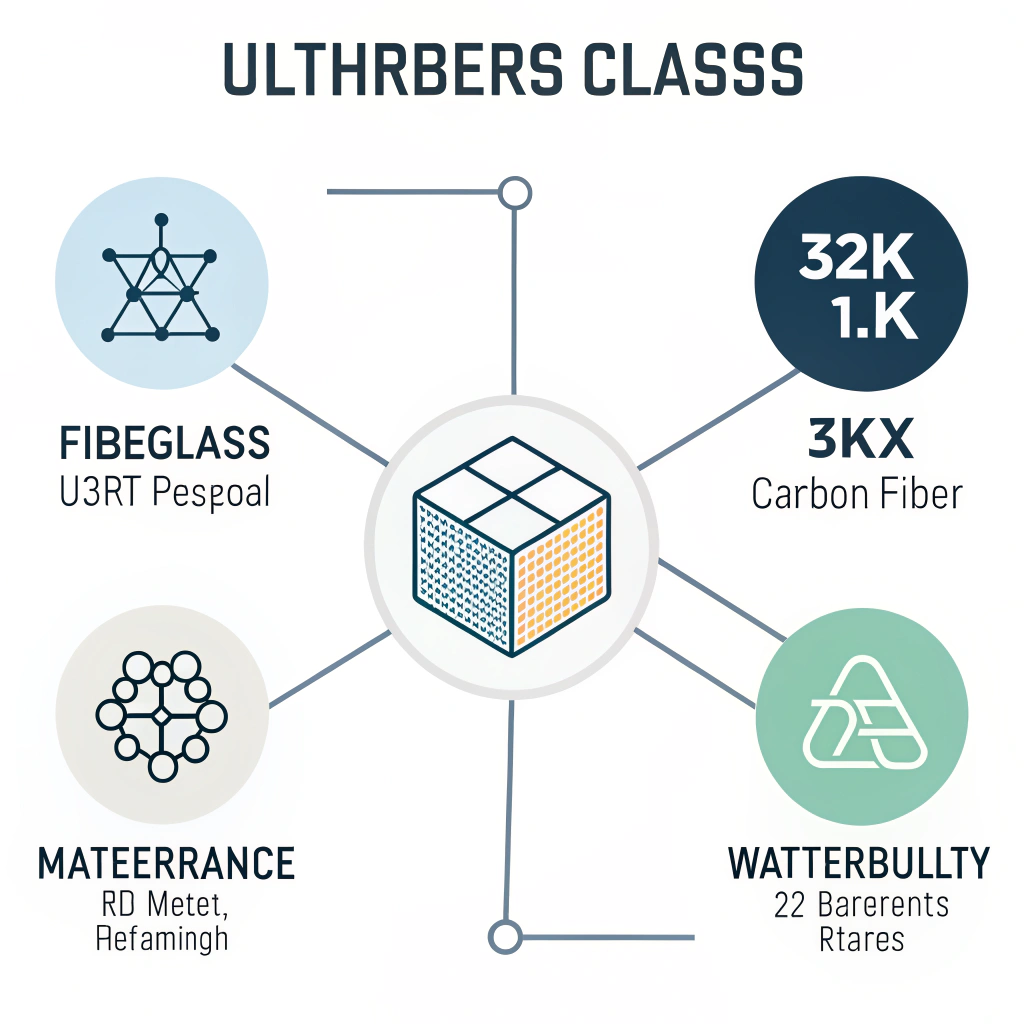

Advanced materials such as carbon fiber1 variants and fiberglass2 can significantly enhance padel racket performance by optimizing weight, durability, and precision. In this article, we explore technical challenges, analyze the causes, and provide a deep dive into advanced material selection for high-performance padel rackets, offering clear solutions and actionable guidance for product managers and technical directors.

In today’s competitive sports equipment market, manufacturers face increasing pressure to deliver high-performance products while ensuring production efficiency and cost-effectiveness. One major challenge lies in selecting the appropriate composite materials3 that not only enhance the racket’s performance characteristics but are also adaptable to precision manufacturing4 processes. Traditional materials often fall short in terms of durability or performance consistency over time, which may lead manufacturers to explore advanced materials like different grades of carbon fiber and fiberglass.

Due to the complexity of the production process and the variability in material properties, many product managers struggle to determine which composite materials offer the best balance between weight, strength, and cost. For instance, materials such as 3k, 12k, and 18k carbon fiber each bring unique properties that can either enhance or hamper racket performance if not selected appropriately. Additionally, production challenges such as quality control, consistency in material supply, and the integration of custom designs further complicate the material selection process.

Understanding the causes behind material selection challenges requires an appreciation of several key factors:

-

Material Properties Variability

- Carbon Fiber Grades: The different grades of carbon fiber—3k, 12k, and 18k—each have distinct tensile strengths, stiffness, and weight characteristics. This variability demands precise knowledge about how each grade will perform under specific conditions.

- Fiberglass: While less expensive, fiberglass may not always match the performance reliability of carbon fiber. Its mechanical properties vary depending on the weave and resin used.

-

Manufacturing Process Limitations

- Precision Manufacturing: Achieving a consistent shape with full customization (i.e., Diamond, Round, Teardrop) requires advanced production techniques. Manufacturers must balance between production speed, dimensional accuracy, and the physical limits of each material type.

- Technique Integration: The success of a composite product heavily relies on how aptly the manufacturing process translates technical material properties into the final product. The transition from raw material to finished racket entails multiple stages where material mismanagement can occur.

-

Industry Expectations and Customization Needs

- Customization Demand: Modern sports equipment buyers demand personalized products with custom printing, color variations, and additional accessories such as hand grips with logo customization.

- Quality Control and Durability: Ensuring durability over extensive play while maintaining aesthetic excellence requires rigorous quality control. Manufacturing batches that incorporate small design changes must all meet the high-performance standards expected from advanced materials.

-

Cost versus Performance Trade-offs

- Budget Constraints: Material quality always competes with cost. High-performance carbon fibers are more expensive, requiring an informed decision regarding performance benefit relative to market price and production costs.

- Supply Chain Consistency: Reliable and stable supply of advanced composite materials is essential. Any fluctuations in material quality or availability can disrupt production schedules.

To overcome these challenges, manufacturers can leverage the following technical strategies and materials:

Below is a table comparing key advanced materials used in padel racket manufacturing:

| Material Type | Characteristics | Advantages | Considerations |

|---|---|---|---|

| Fiberglass | Lower cost, moderate strength | Enhanced flexibility, cost-effective | Less stiffness; subject to wear |

| 3k Carbon Fiber | Fine weave, balanced strength and weight | Improved handling and control | Requires precise layup techniques |

| 12k Carbon Fiber | Coarser weave, high-performance stiffness | Greater power and stiffness | Higher cost; may need reinforcement |

| 18k Carbon Fiber | Ultra-high stiffness, premium performance | Superior durability, optimal energy transfer | Best suited for elite competitive use |

This table succinctly captures the performance trade-offs and technical benefits associated with each material option.

-

Enhanced Durability and Strength

- The use of high-grade carbon fiber, such as 18k carbon fiber, markedly increases the racket's durability. Its stiffness directly contributes to more precise energy transfer during ball impact, essential for reaching high levels of play.

- For manufacturers targeting a broader market, 3k and 12k carbon fibers offer a balanced performance where cost efficiency and durability can be maintained.

-

Precision in Production

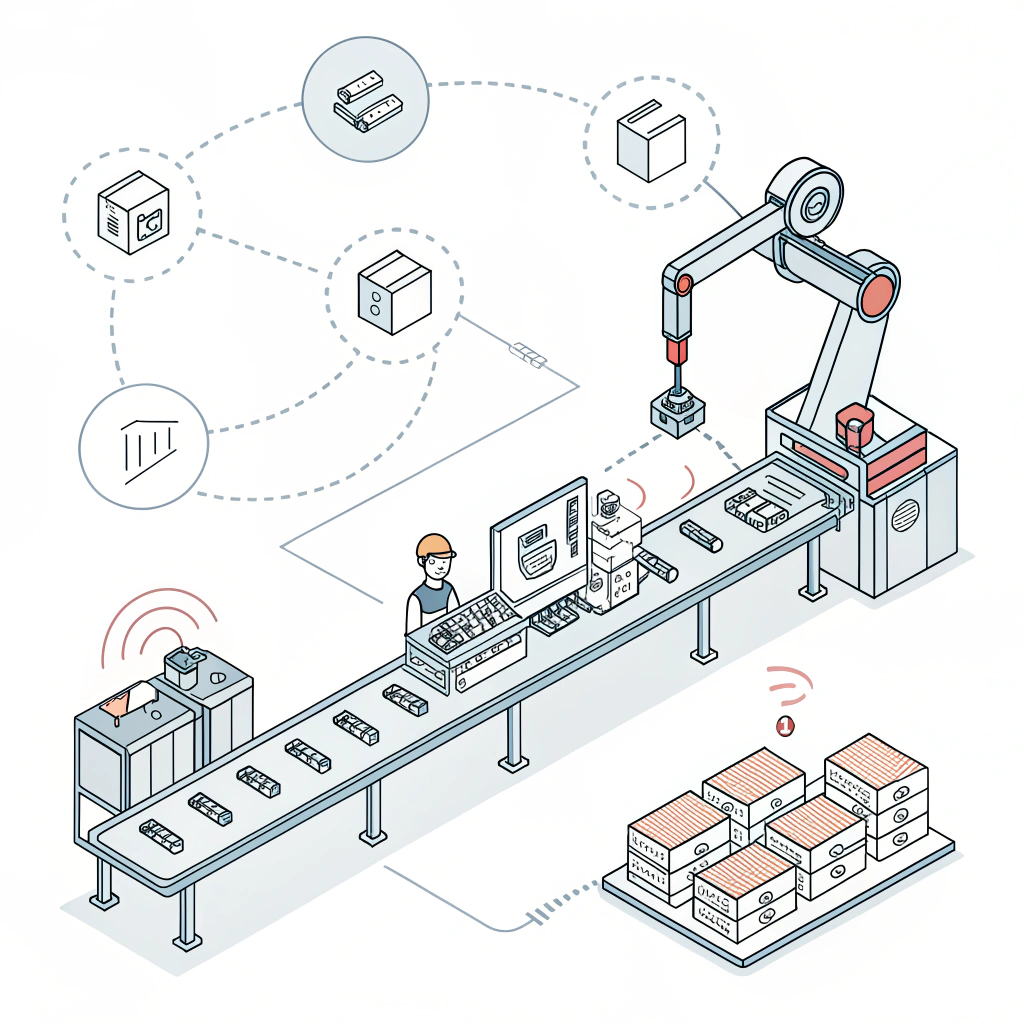

- Advanced material characteristics such as fiber alignment and weave pattern play a crucial role during the production process. Integrating digital quality control systems5 within the production line helps maintain consistency.

- Our partnership with renowned brands like Hirostar, Reebok, and Starvie offers a testament to how integrating precision engineering with advanced materials can yield outstanding performance records and reduced production error rates.

-

Customization and Aesthetics

- Whether opting for the classic Diamond, Round, or Teardrop shapes, the versatility of composite materials allows for full customization tailored to both performance and aesthetic preferences.

- Custom printing and color variations are more effectively integrated with carbon fibers given their uniform surface properties during molding.

-

Optimized Weight and Responsiveness

- The incorporation of lightweight materials like carbon fiber improves the overall handling and speed of the racket. It proves beneficial in fast-paced rallies where split-second responsiveness is critical.

- The strategic balance between weight reduction and energy transfer gives players a competitive edge, especially in intense match scenarios.

Implementing the right production strategies ensures that the chosen materials translate their technical benefits into high-performance rackets effectively.

-

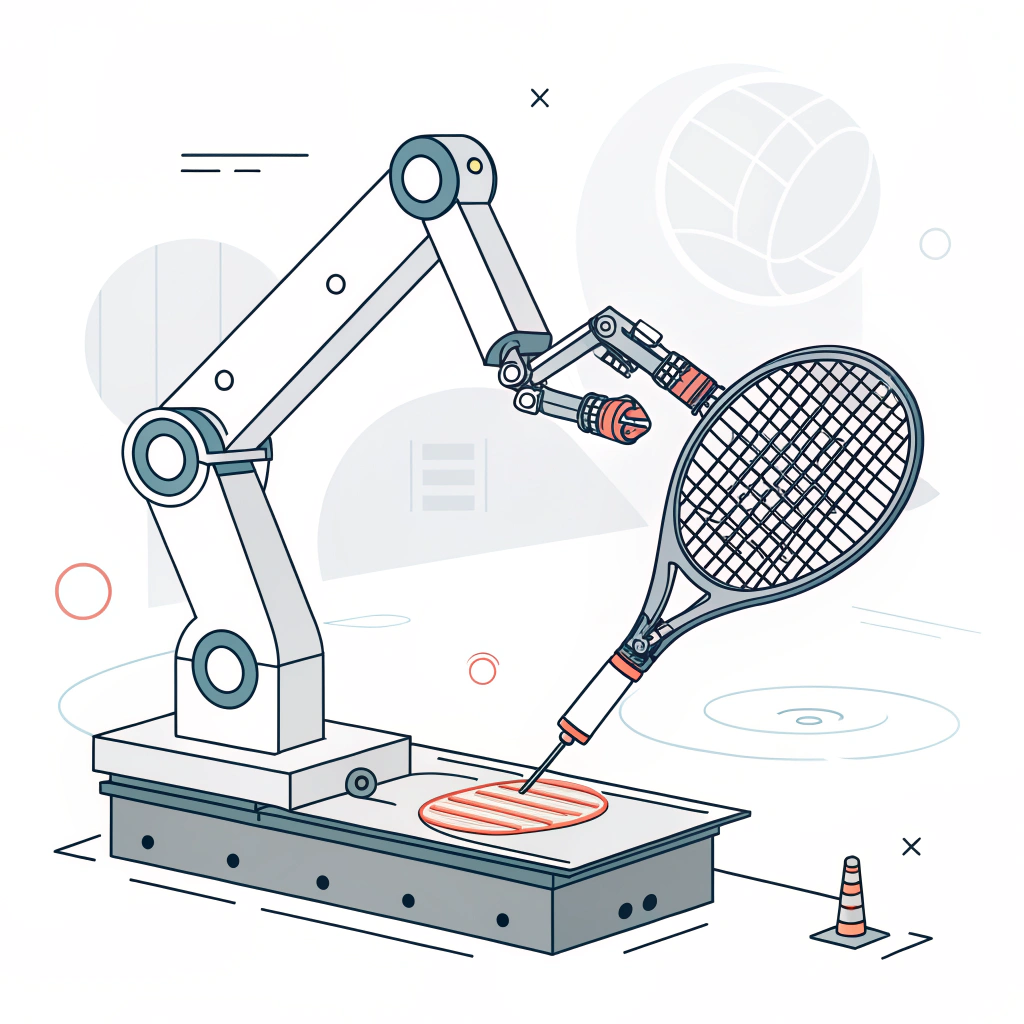

Precision Manufacturing:

Utilizing robotic layup systems and automated cutting tools can reduce human error in fiber alignment. Technologies like 3D laser scanning for mold verification ensure that each racket meets the design dimension requirements accurately. -

Custom Molding Capabilities:

Our processes support tailor-made shapes and custom designs, enabling manufacturers to switch between different racket profiles smoothly. Life cycle analysis tools integrated within our production line track material performance in real time, providing a feedback loop that further refines product quality. -

Data-Driven Production Adjustments:

Advanced sensors and diagnostic equipment allow for minute adjustments during production. Batch testing and material strength analysis performed in controlled environments contribute to an overall increase in product durability.

-

Material Cost vs. Benefit Analysis:

Although high-grade carbon fibers such as 18k offer the best performance, a mixture of 3k and 12k fibers can achieve a similar performance profile at a substantially lower cost. Manufacturers can conduct in-house experiments to determine the ideal fiber composition that balances performance and budget constraints. -

Supply Chain Partnerships:

It is critical to source materials from reliable suppliers to maintain consistency. Our established partnerships with trusted material suppliers ensure that only the highest quality composites are used. This commitment is integral to producing rackets that perform optimally under competitive conditions.

-

Integrated Production Workflow:

A well-integrated production line is paramount. Minimizing delays between raw material processing, molding, curing, and quality checks creates a seamless workflow that helps preserve the integrity of advanced materials. -

Technological Upgrades:

Continuous investment in state-of-the-art machinery and training for technical staff can significantly improve efficiency. The trend in the padel racket industry is towards smart manufacturing, where real-time data analytics support better decision-making in production. -

Maintenance of Equipment:

Frequent calibration of production tools, automated monitoring, and preventive maintenance contribute to a reduction in defects. With high-performance materials, even slight deviations can lead to compromised performance, which is why rigorous maintenance regimes are essential.

NEX Padel has successfully implemented advanced material strategies in our manufacturing process, setting a benchmark in the padel racket industry. Through our experience working with top-tier brands, we have refined our production techniques to include:

-

Rapid Prototyping:

Our in-house design team leverages advanced CAD modeling and simulation tools to iterate quickly. This not only reduces lead times but also ensures that the advanced composite materials are thoroughly tested for performance before mass production. -

Custom Material Optimization:

By experimenting with different fiber combinations, we have been able to tailor racket properties to meet specific playing styles. For instance, players requiring more control may prefer a composition leaning towards 3k carbon, while players opting for power might benefit from a higher ratio of 12k or 18k fibers. -

Enhanced Quality Assurance:

We implemented rigorous quality control protocols, including stress testing and durability analysis, which are integrated with our manufacturing workflow. These measures have allowed us to maintain a high level of consistency, regardless of customizations in design or print. -

Customer Feedback Integration:

Continuous feedback from our B2B partners and end-users supports ongoing improvements. The data collected from gameplay performance is invaluable in fine-tuning material selection and adjusting manufacturing protocols.

The comprehensive approach adopted by NEX Padel illustrates how blending advanced materials, precise manufacturing, and practical strategies leads to superior product performance and customer satisfaction.

In conclusion, the selection of advanced materials such as various grades of carbon fiber and fiberglass is paramount for producing high-performance padel rackets. The key points include:

- Understanding the unique properties of each composite material.

- Maintaining precision in manufacturing through advanced production techniques and integrated quality control.

- Balancing cost, durability, and performance through data-driven choices.

- Leveraging customization to meet the market’s evolving aesthetic and performance needs.

For product managers and technical directors aiming to elevate their padel racket offerings, our recommendations are:

- Conduct thorough material comparisons and pilot studies to determine the best composite mix for your production needs.

- Invest in precision manufacturing equipment and integrate real-time quality control systems.

- Collaborate with reliable suppliers and continuously integrate user feedback into your design and manufacturing cycles.

- Consider full customization capabilities to differentiate your products and meet specific market demands.

Taking these actions can provide a competitive advantage, ensuring that your products not only meet industry standards but excel in delivering superior performance on the court.

People Also Ask

Q1: How do advanced composite materials improve padel racket performance?

A1: Advanced composite materials like carbon fiber and fiberglass enhance padel racket performance by offering a balanced mix of durability, lightweight properties, and optimal energy transfer. This ensures better handling, precise ball control, and increased overall racket longevity.

Q2: What factors should be considered when choosing between 3k, 12k, and 18k carbon fiber in racket manufacturing?

A2: When selecting between 3k, 12k, and 18k carbon fibers, factors such as tensile strength, stiffness, weight, cost constraints, and the intended performance profile of the racket must be considered. Each fiber grade offers unique advantages that align with different performance and price points.

Q3: What manufacturing techniques are essential to ensure the quality of high-performance padel rackets?

A3: Essential manufacturing techniques include precision cutting, automated robotic layup, real-time quality control, integrated data analytics, and rigorous testing procedures. These techniques help maintain consistent material properties, minimize defects, and produce rackets that meet high industry standards.

-

carbon fiber: Learn about carbon fiber properties and its applications in high-performance products, including how its strength-to-weight ratio can improve product durability and performance. ^Return ↩

-

fiberglass: Discover the benefits and limitations of fiberglass in manufacturing, its cost-effectiveness, and why it may be chosen as an alternative to carbon fiber in specific applications. ^Return ↩

-

composite materials: Understand composite materials, their composition, and how they are engineered to balance performance, durability, and cost in advanced manufacturing environments. ^Return ↩

-

precision manufacturing: Explore the methods and technologies behind precision manufacturing processes that ensure consistent quality, dimensional accuracy, and optimal performance in product production. ^Return ↩

-

digital quality control systems: Read about digital quality control systems and how integrating advanced sensors, data analytics, and automation can help maintain high manufacturing standards and reduce production errors. ^Return ↩