NEX Padel ensures consistent quality in every order by implementing advanced production techniques1, quality control measures2, and material selection processes3. This guarantees that each padel racket meets high-performance standards while providing operational efficiency and supply chain reliability4.

In today’s competitive sports equipment market, ensuring production consistency and high-quality output is critical for any manufacturer. At NEX Padel, we have addressed these challenges by establishing robust manufacturing processes and quality control checkpoints that deliver reliable performance across every order. In this post, we delve into our manufacturing methods, detailed quality assurance protocols, and how our rapid sampling5 and on-time delivery systems enable us to become a trusted partner for business buyers in the padel equipment industry.

Manufacturing consistent, high-performance padel rackets is crucial for meeting the demands of established sports brands and distributors. The primary challenges in the industry typically involve:

- Material variability due to the selection of different raw inputs (e.g., fiberglass vs. various carbon fiber grades such as 3k, 12k, and 18k)

- Production consistency, where even minor deviations in the process can affect the final product’s performance and durability

- Quality control gaps that might allow defects to reach the market

- Customized design requirements, including various racket shapes (Diamond, Round, and Teardrop) and branding design elements like custom prints and logos

These pain points compel manufacturers to adopt intricate control measures throughout the production process, ensuring that the final product meets stringent performance criteria.

Before exploring our solutions, it is important to understand why consistency issues arise in padel racket manufacturing:

-

Material Variability: Differences in raw materials (glass fiber vs. carbon fiber) can cause disparities in weight, stiffness, and durability. The choice of materials like 3k, 12k, and 18k carbon fibers significantly influences structural integrity.

-

Production Process Complexity: Custom designs and high-performance standards require precise cutting, layering, and curing processes. Even minor technical deviations or environmental factors during production can result in a deviation from intended specifications.

-

Quality Control Inconsistencies: Without a layered quality assurance approach, minor faults can proliferate along the production line. This is further complicated by the need for rapid sampling and quick turnaround times in a demanding market.

-

Supply Chain and Delivery Pressure: Timely delivery and rapid sampling testing are crucial. Any delays or miscommunications in the supply chain can put pressure on quality, leading to rushed processes and potential defects.

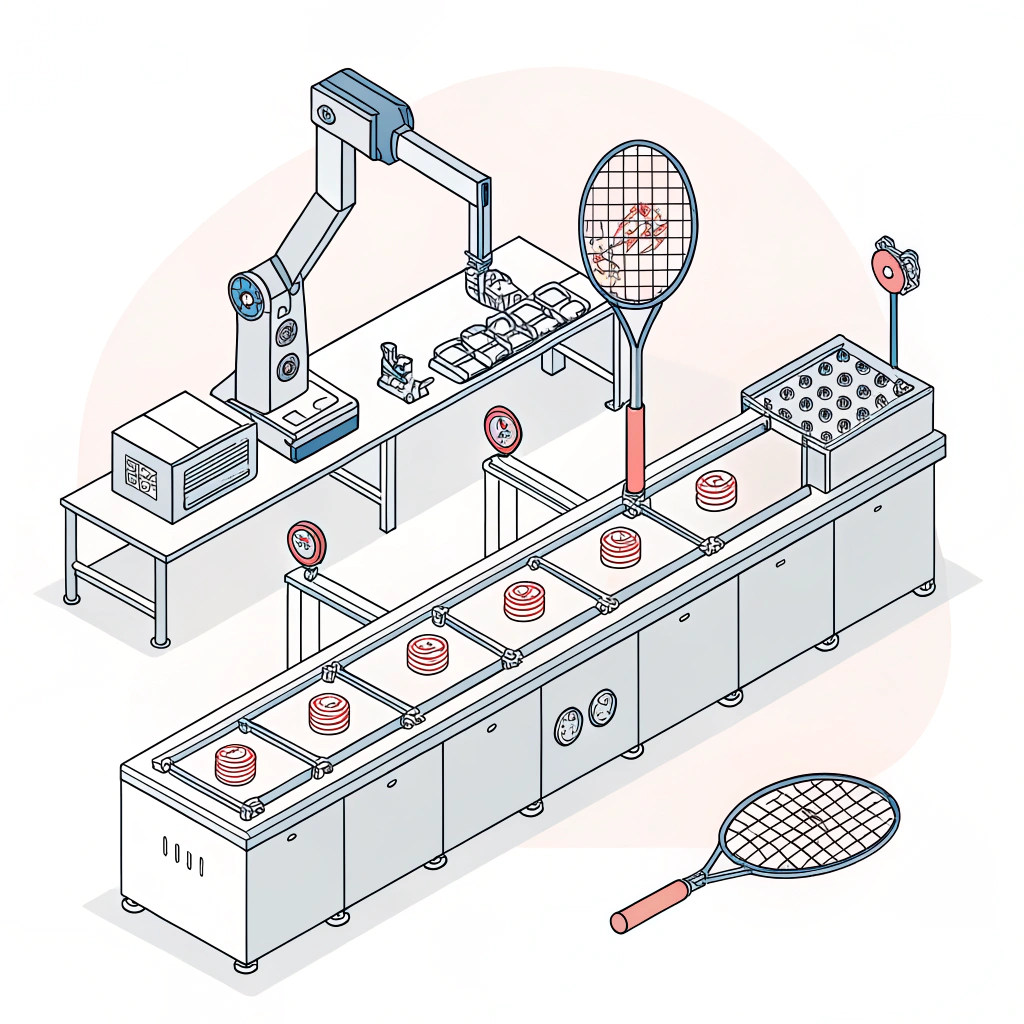

To combat these challenges, we at NEX Padel have developed a multi-step manufacturing process that emphasizes both efficiency and quality. Our process is designed to continuously monitor and control every stage of production, from raw material selection to final product inspection.

-

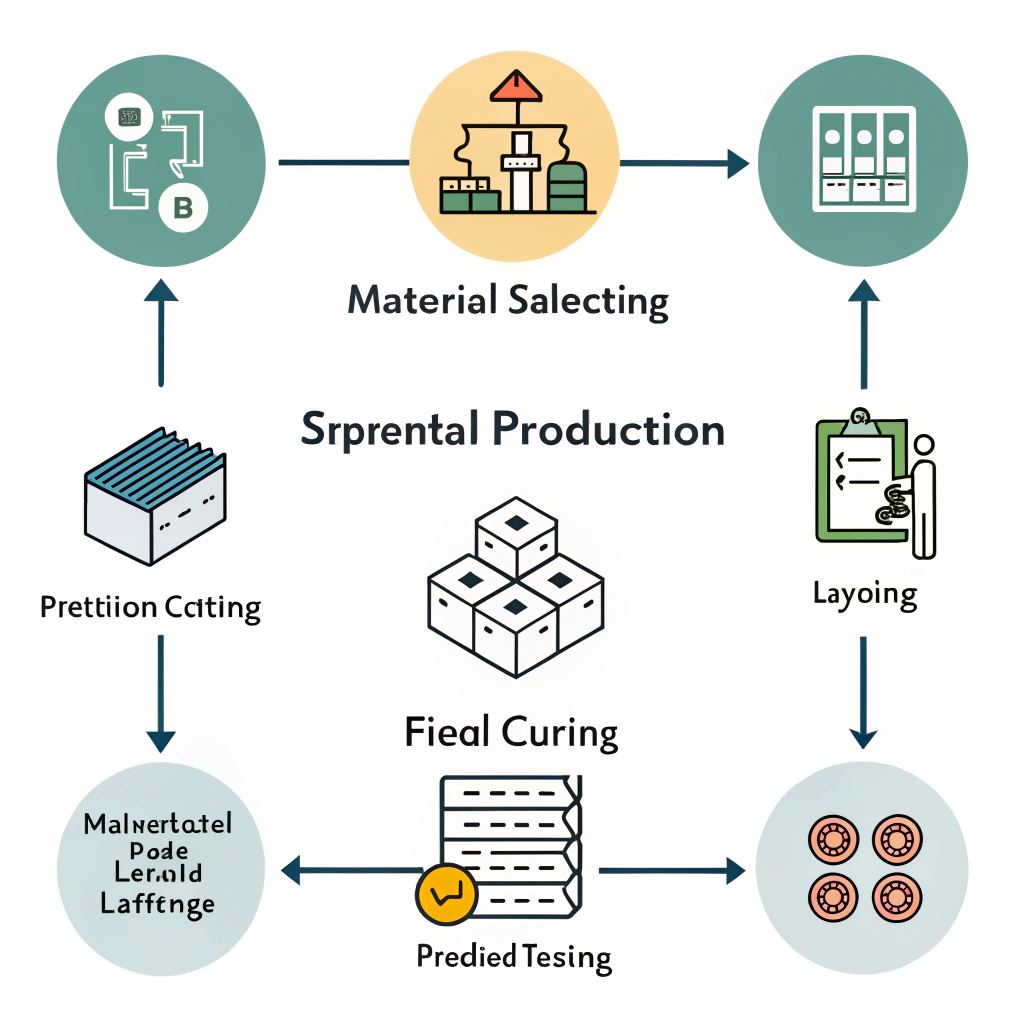

Material Selection:

- We carefully select each batch of raw materials based on stringent quality criteria. The selection includes fiberglass for lower-tier models and various grades of carbon fiber (3k, 12k, and 18k) for premium products.

- Quality indicators for these materials are measured against industry benchmarks to ensure that they meet performance and durability standards.

-

Precision Cutting and Molding:

- Advanced cutting techniques ensure that materials are uniformly sized and shaped according to the designated racket design. This step is critical for achieving the desired balance and performance.

- Our molding process utilizes cutting-edge technology that adapts to the varying curing times and resin distribution needs of different materials.

-

Layering and Curing:

- The uniform alignment of multiple layers is essential for structural strength. Each layer is applied with meticulous care under controlled environmental conditions.

- The curing process, which involves precise temperature and pressure regulation, is responsible for the final rigidity and performance of the racket.

-

Rapid Sampling and Testing:

- To maintain on-time delivery while ensuring quality, we employ rapid sampling techniques that allow us to test key product specifications at various production stages.

- Sampling data is collected in real time, and any deviation triggers immediate inspection or process adjustment.

-

Final Inspection and Customization Options:

- Once the production is complete, the rackets undergo a comprehensive quality control procedure. This includes stress testing, performance evaluation, and visual inspections.

- Custom design elements such as printing, color choices, and logo placements are added only after the fundamental quality of the racket is confirmed.

The structured approach to manufacturing not only improves production consistency but also provides a competitive edge by reducing error rates and increasing customer satisfaction.

To further illustrate our methodology, consider the following table summarizing our production techniques versus traditional processes:

| Process Stage | Traditional Manufacturing | NEX Padel’s Approach |

|---|---|---|

| Material Selection | Basic quality check | In-depth graded assessments & batch testing |

| Cutting and Molding | Standardized tooling | Precision engineering with advanced equipment |

| Layering and Curing | Uniform but less-controlled | Environment-controlled curing with adaptive methods |

| Sampling and Testing | Random sampling | Systematic, real-time quality checkpoints |

| Final Inspection | End-of-line quality check | Multi-tiered inspections with performance testing |

The above table highlights the various enhancements we have made to our production process, ensuring that every step contributes to the overall consistency and performance of our product.

Quality assurance is the backbone of our operations. At NEX Padel, every production order undergoes a detailed series of quality control measures, both automated and manual, aimed at detecting and correcting deviations as early as possible. Here are the key checkpoints in our quality assurance framework:

-

Incoming Material Inspection:

- Every shipment of fiberglass and carbon fibers undergoes rigorous quality testing. This assessment includes tensile strength, purity levels, and structural integrity tests.

- Certification and traceability are maintained for all materials to ensure compliance with international standards.

-

In-Process Quality Checks:

- Integrated sensors and automated systems continuously monitor production parameters such as temperature, pressure, and curing time.

- Operators are trained to detect any irregularities, ensuring that corrective measures can be applied in real time.

-

Final Product Testing:

- After the manufacturing process, the rackets are subjected to comprehensive performance tests. These tests simulate real gameplay conditions to confirm that every product meets the high-performance criteria expected by professional players.

- Stress tests, flexibility tests, and weight consistency checks are conducted to validate product durability.

-

Feedback Loop and Continuous Improvement:

- Data collected from each order is reviewed to identify trends or recurring issues. This feedback loop informs ongoing enhancements in both production methods and quality control protocols.

- Customer feedback and product performance insights are integrated into our planning cycle to ensure continuous process and product improvements.

One of the key requirements for our business partners is the ability to offer custom designs, be it in racket shape adjustments or branded elements like color schemes and logos. The integration of customization into production does not compromise quality when managed correctly.

-

Shape Customization:

- We provide three main shapes—Diamond, Round, and Teardrop—with the option for full customization. This allows brands to differentiate their product offerings while benefiting from our advanced production standards.

-

Branding and Design:

- Custom printing on the racket frame, hand grips, and handle caps is carefully integrated into the production process. Pre-production samples are rigorously checked for accurate color reproduction and logo clarity.

-

Rapid Sampling Protocol:

- Our rapid sampling process is designed to quickly validate new custom designs or modifications without delaying overall production. We produce prototype samples that undergo immediate testing before full-scale production begins.

- The rapid feedback loop ensures that any deviations in design or performance can be addressed quickly, minimizing production downtime.

A significant aspect of our commitment to quality is ensuring that our manufacturing process operates within a reliable and efficient supply chain. Timely delivery is essential for procurement managers and product quality specialists who need predictability and accountability from their manufacturing partners.

-

Supplier Relationships:

- We maintain strong, long-standing relationships with our raw material suppliers. These relationships are built on trust, quality, and consistent performance.

- Regular audits and collaborative planning help ensure that our suppliers meet the same high standards that we set for our own production.

-

Efficient Logistical Coordination:

- Our production planning integrates real-time tracking of orders and shipments. This coordination helps to preempt potential delays and allows for rapid response to any supply chain disruptions.

-

Scalability:

- Our manufacturing process is designed to be scalable. Whether handling small custom orders or large-scale production runs, our system reliably maintains production quality and consistency.

-

Risk Management:

- We employ risk management strategies that include inventory buffers, diversified supplier bases, and contingency protocols. These strategies ensure that even in the face of unforeseen challenges, our quality standards remain uncompromised.

Real-world success stories and data-driven insights provide additional proof of the effectiveness of our quality control and production processes. Over the years, NEX Padel has partnered with renowned brands such as Hirostar, Reebok, and Starvie, ensuring that our products meet the rigorous demands of professional players.

A leading sports brand recently transitioned its production needs to NEX Padel. The client required a high-volume order of customized padel rackets with specific performance parameters and branding elements. Through our integrated quality control processes and rapid sampling protocol, we were able to:

- Deliver prototypes in less than two weeks, which underwent intensive performance testing under simulated match conditions.

- Implement custom shape and branding validations that met the client's exact specifications without compromising on performance.

- Achieve a 100% on-time delivery record for the complete order, ensuring that the client could confidently meet market launch deadlines.

The data from this project indicated a significant reduction in quality-related returns and an increase in customer satisfaction. This success story underscores the importance of combining advanced production techniques with industry-leading quality assurance practices.

At NEX Padel, our commitment to excellence is evident in every aspect of our manufacturing and quality control processes. By addressing common challenges in padel racket production through advanced material selection, precision manufacturing, and multi-layered quality checks, we ensure that every order meets the high standards expected by our B2B partners.

For procurement managers and product quality specialists evaluating manufacturers, the key takeaways include:

- The importance of using advanced production techniques and material testing to maintain consistency.

- The benefit of a comprehensive quality control system that includes both in-process checks and final performance testing.

- The value of rapid sampling and adaptable customization processes that retain high product standards while meeting market demands.

- The advantage of partnering with a manufacturer that has proven supply chain reliability and an established track record with major industry brands.

We encourage decision-makers to closely evaluate these aspects when selecting a manufacturing partner. By aligning with a partner like NEX Padel, you can be confident of receiving high-quality, consistently performing padel rackets that adhere to strict production and quality standards.

Q1: How does NEX Padel ensure manufacturing consistency?

A1: NEX Padel ensures manufacturing consistency by employing rigorous material selection, precision cutting, controlled layering and curing processes, and a robust rapid sampling and testing protocol at every production stage.

Q2: What quality control measures are in place for padel racket production?

A2: Our quality control measures span multiple stages, including incoming material inspections, in-process monitoring of temperature and pressure, final performance and stress testing, and continuous feedback loops to drive process improvements.

Q3: How does NEX Padel customize padel racket design without compromising quality?

A3: Customization at NEX Padel is integrated into our production workflow through pre-validated design protocols, rapid sampling for prototype approval, and additional final inspections to ensure that custom elements—such as unique shapes, prints, and logos—meet our strict quality standards before full-scale production.

-

advanced production techniques: Click to explore detailed insights on how the latest manufacturing innovations boost efficiency and product consistency. ↩ ↩

-

quality control measures: Click to read about comprehensive methods for monitoring and ensuring product quality at every stage of production. ↩ ↩

-

material selection processes: Click to understand the critical steps in choosing and testing raw materials to meet industry performance standards. ↩ ↩

-

supply chain reliability: Click to discover strategies that secure a stable and efficient supply chain, ensuring timely production and delivery. ↩ ↩

-

rapid sampling: Click to learn how this technique accelerates prototyping and ensures quality in real-time production environments. ↩ ↩