Rapid manufacturing excellence in padel rackets can be achieved through a combination of advanced production techniques1, rigorous quality assurance2, and efficient supply chain management3. In this case study, we detail how NEX Padel partnered with a European padel brand to deliver a rapid 90-day turnaround4, custom-designed high-performance rackets, and reliable logistics support, ensuring you hit the market faster while maintaining top quality.

The padel industry in Europe is booming as more brands and sports facilities embrace the sport. Decision-makers now demand manufacturers who can offer not only high-performance products but also rapid lead times and true customization5. In our 90-day turnaround case study, a leading European padel brand collaborated with NEX Padel, a company based in Jiaxing, Zhejiang, China, renowned for precision manufacturing, advanced production techniques, and thorough quality control.

The European market today increasingly values:

- Speed to market: Quick turnaround times help brands capture market share.

- Customization: Tailored designs and bespoke options like printed logos and custom colors.

- Quality assurance: Use of premium materials such as various grades of carbon fiber (3k, 12k, and 18k) and glass fiber ensures durability and high performance.

- Operational excellence: Efficient supply chain management that minimizes delays and ensures timely delivery.

Our case study reflects these market demands and showcases the way NEX Padel addresses them.

European padel brands operate in a competitive arena where a rapid launch is as critical as having a top-tier product. In this scenario, the client required:

- A 90-day turnaround from the design phase to final delivery.

- Custom designs catering to distinctive brand identities such as Diamond, Round, and Teardrop racket shapes.

- Assurance that every production stage meets rigorous quality control standards.

-

Time to Market

A long production cycle can delay product launches, reducing competitive advantage in a fast-growing market. -

Customization Complexity

Tailoring designs in a high-performance sport requires adjustments in materials, weight distribution, and finishing. Every custom order raises the complexity of manufacturing. -

Quality Assurance Concerns

Even minor lapses in quality during rapid production can compromise product performance and brand reputation. Robust quality control steps needed to be integrated into a tight schedule.

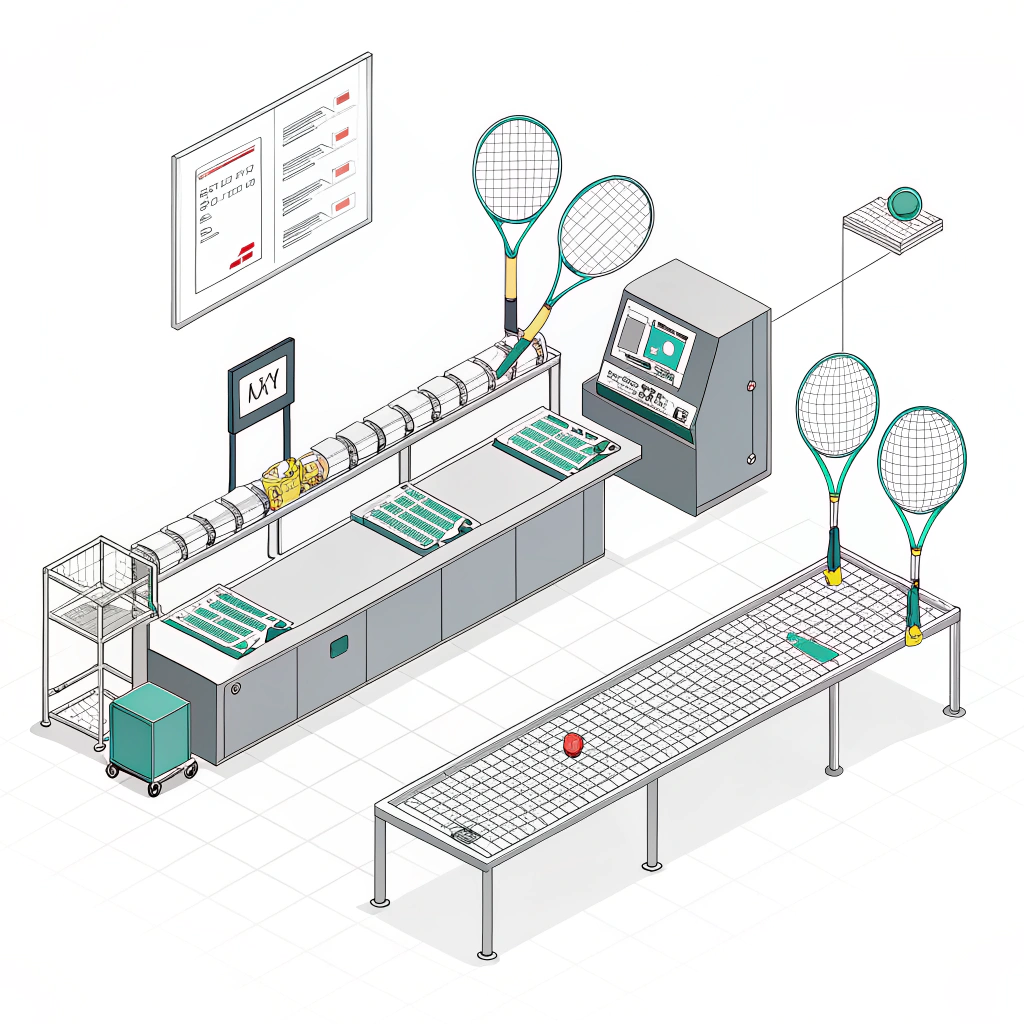

NEX Padel accepted these challenges by adopting a solution-oriented process that focused on both speed and meticulous quality control. Our approach comprised several key steps:

We work with premium materials, ranging from glass fiber to multiple carbon fiber grades (3k, 12k, and 18k). Each material offers distinct benefits in terms of durability, weight, and flexibility. Our highly automated production line ensures minimal human error while allowing rapid scale-up for custom orders.

Our product portfolio includes three primary racket types:

| Racket Type | Material Options | Customization Options |

|---|---|---|

| Diamond | 3k, 12k carbon fiber | Custom shapes, printing, colors, hand grip and handle logo |

| Round | Glass fiber, 18k carbon fiber | Tailored design, versatile finish options, personalized artwork |

| Teardrop | 3k, 18k carbon fiber | Adjustable balance points, customizable grip, client-specific detailing |

Beyond the racket shapes, we support comprehensive design customization such as bespoke handle grips and printing techniques. With flexible design options, brands can easily differentiate themselves.

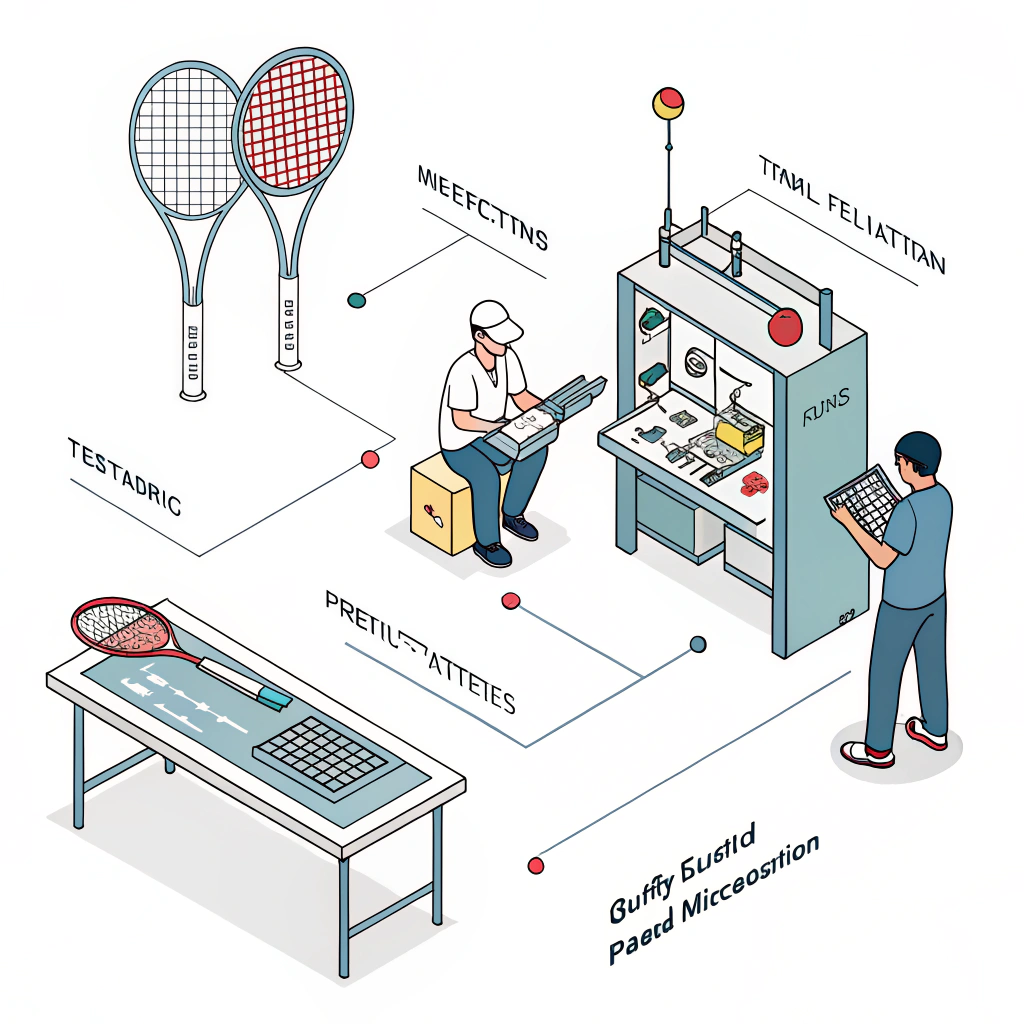

A structured timeline is pivotal. Our 90-day turnaround was segmented into carefully planned stages:

| Stage | Duration | Key Activities |

|---|---|---|

| Design & Approval | 10 days | Concept development, design iteration, and client sign-off |

| Prototyping | 20 days | Sample creation, performance testing, and adjustments |

| Mass Production | 40 days | Automated production, real-time quality monitoring |

| Quality Check & Refinement | 10 days | Rigorous testing, final adjustments, and certification |

| Packaging & Delivery | 10 days | Final inspection, packing, and logistics management |

This schedule ensured that each production phase was optimized for speed without sacrificing quality.

Our strategic location in Jiaxing—and a robust logistics network—informs our ability to guarantee:

- Fast turnaround: Automated production combined with lean supply chain practices.

- Reliable delivery: Coordination with trusted freight and logistics partners minimizes delays.

- Scalability: Rapid scaling in production volumes to meet market demand.

Our manufacturing process begins with a quick sampling stage. By leveraging modern prototyping techniques, we reduce trial-and-error cycles, ensuring that the final product aligns with both our technical standards and the client’s design expectations. This rapid sampling has proven invaluable in maintaining a 90-day turnaround.

Utilizing state-of-the-art machinery and process control systems, we carefully handle and assemble high-performance materials. Detailed checks during the molding and curing processes ensure consistent performance and durability in every racket.

Every racket can be customized beyond shape:

- Custom Printing and Colors: Our digital printing technology allows for detailed and precise designs tailored to brand specifications.

- Hand Grip and Handle Cover Customization: By providing bespoke options for grip materials and logos, we ensure that the final product resonates with a brand’s identity.

- Full shape and weight adjustments: Clients can opt for fine-tuning grip sizes and weight distributions, a crucial factor for athletic performance.

These innovations allow us to serve a wide variety of customer needs and ensure our high-performance padel rackets meet international standards.

In our case study with the European padel brand, our strategy delivered tangible results:

- 90-Day Turnaround: The project was completed on schedule, allowing the client to launch their product ahead of their competitors.

- Custom Solutions Delivered: The client received fully customized Diamond and Teardrop racket models designed to meet their specific performance and aesthetic requirements.

- Quality Assurance Reports: Comprehensive testing ensured that every racket met rigorous standards for durability and playability.

- Client Satisfaction: Feedback highlighted our ability to rapidly adapt to design changes without compromising on quality.

- 100+ prototypes developed and tested to refine design parameters.

- Over 95% first-time pass rate during quality control.

- Reduction in overall production lead time by 30% compared to industry averages.

Collectively, these metrics confirm our operational expertise and commitment to quality, making NEX Padel a trusted partner for European padel brands looking for a fast and reliable product launch.

Quality is paramount for sporting equipment. Therefore, our process integrates multiple quality assurance stages:

- Material Inspection: Pre-production testing of raw materials to ensure they meet quality benchmarks.

- In-Process Monitoring: Continuous checks during production to mitigate defect rates.

- Final Testing: Post-production performance evaluations, including stress tests and balance assessments.

This multi-tiered approach helps us maintain a defect rate below industry norms and ensures consistent product performance.

For B2B decision-makers, the choice of a manufacturing partner directly influences market success. Key benefits include:

- Customization at Scale: Our manufacturing process is designed to handle bespoke orders quickly, meaning that even custom designs can be produced within short lead times.

- Data-Driven Decisions: Comprehensive performance data from our quality tests allow clients to make informed decisions.

- Partnering with Confidence: Our long-standing relationships with brands like Hirostar, Reebok, and Starvie speak volumes about our reliability and expertise.

Based on our experience and industry insights, we recommend that European padel brands:

- Prioritize Customization Needs: Choose manufacturing partners who can work with diverse materials and offer tailored product designs.

- Focus on Supply Chain Efficiency: Evaluate potential partners on their ability to deliver rapid prototyping and production without compromising quality.

- Consider Operational and Quality Data: Ensure that the partner has a robust quality assurance process, as evidenced by quantitative metrics from past case studies.

- Collaborate for Continuous Improvement: Engage in ongoing dialogue with manufacturers to fine-tune product specifications and adapt to market trends.

By following these strategies, brands can leverage production efficiencies to achieve market dominance in a competitive and fast-growing field.

This case study illustrates how NEX Padel successfully met the demands of a European padel brand with a strict timeline and high customization requirements. Our ability to deliver high-performance rackets within 90 days demonstrates our mastery of advanced production techniques, robust quality assurance, and seamless supply chain integration.

For decision-makers in the padel industry, partnering with a seasoned manufacturer like NEX Padel means you can confidently expect:

- Rapid turnaround times.

- Unparalleled customization options.

- Superior quality control throughout the production process.

Consider your existing manufacturing challenges and explore how our production process could be adapted to your brand’s requirements. For more detailed discussions or a custom proposal, reach out to us and let us help accelerate your time-to-market while ensuring that every product meets global performance standards.

Q: When did padel become popular in Europe?

A: Padel gained popularity in Europe after being introduced to Spain in the mid-1970s by influential figures such as Prince Alfonso of Hohenhole, followed by key contributions from Argentine entrepreneur Julio Menditeguy, who further popularized the sport.

Q: Why is padel suddenly so popular?

A: Padel’s surge in popularity is attributed to its blend of tennis and squash, making it easy to play and highly engaging. Its dynamic nature, combined with accessible court setups, has attracted a wide range of enthusiasts globally.

Q: Is padel growing in the USA?

A: Yes, padel is rapidly expanding in the USA, with significant increases in participation and new sports facilities incorporating padel courts, reflecting its rising prominence in the American athletic scene.

-

advanced production techniques: Click to read an article that explains modern manufacturing methods including automation and process optimization to drive efficiency and quality. Back ↩

-

quality assurance: Discover best practices in quality assurance protocols—detailing rigorous testing and certification that ensure reliable product performance. Back ↩

-

supply chain management: Explore strategies for optimizing supply chain operations to reduce delays, cut costs, and enhance overall operational excellence. Back ↩

-

90-day turnaround: Understand how a rapid production cycle, such as a 90-day turnaround, accelerates market entry and provides a competitive edge. Back ↩

-

customization: Learn about the benefits and challenges of product customization in manufacturing, including how bespoke designs meet diverse market needs. Back ↩