In today’s competitive sporting goods market, OEM1 padel racket manufacturers must balance cost control with maintaining the highest standards of quality and durability. We achieve this by leveraging advanced production techniques, meticulous supply chain management, and state-of-the-art materials. This article quickly details our approach at NEX Padel on optimizing manufacturing efficiency while controlling costs—and then explains the strategies behind it for procurement managers and business development executives.

Padel rackets are more than just sporting equipment; they represent an intricate blend of advanced materials and precision engineering. Manufacturers face multiple challenges:

- High Material Costs: Premium materials such as carbon fiber2 (available in 3k, 12k, and 18k variations) and fiberglass are essential for performance but can increase production costs.

- Complex Production Processes: Crafting a durable mold, customized shapes, and finishing touches (custom printing, handle grips) add layers of complexity.

- Supply Chain and Production Efficiency: Poorly managed supply chains lead to delays and fluctuations in cost, impacting overall profitability.

- Quality Control Requirements: Stringent quality control measures are needed to ensure every racket meets high standards even with advanced materials and custom designs.

To overcome these challenges, manufacturers must deploy strategies that optimize each production stage without compromising on the product’s end-user value.

One key strategy in balancing cost and quality is the careful selection and use of advanced materials. At NEX Padel, we utilize a range of materials:

- Fiberglass: Offers a cost-effective solution and is ideal for intermediate product lines.

- Carbon Fiber (3k, 12k, 18k): These materials offer varying degrees of stiffness, flexibility, and durability. They allow us to meet the performance demands of professional players while supporting cost efficiency when used appropriately.

- Customizable Components: Beyond the racket face and frame, elements like hand grips and handle covers can be tailored to include logos and specific design elements tailored to brand identity.

By aligning material quality with production needs, we control costs through:

- Optimized Material Sourcing: Bulk buying and long-term partnerships with suppliers lower material costs.

- Just-in-Time Manufacturing: Just-in-Time Manufacturing3 reduces inventory costs while ensuring materials are used efficiently.

- Process Automation: Incorporating automated stages in production streamlines tasks, reduces labor errors, and minimizes waste.

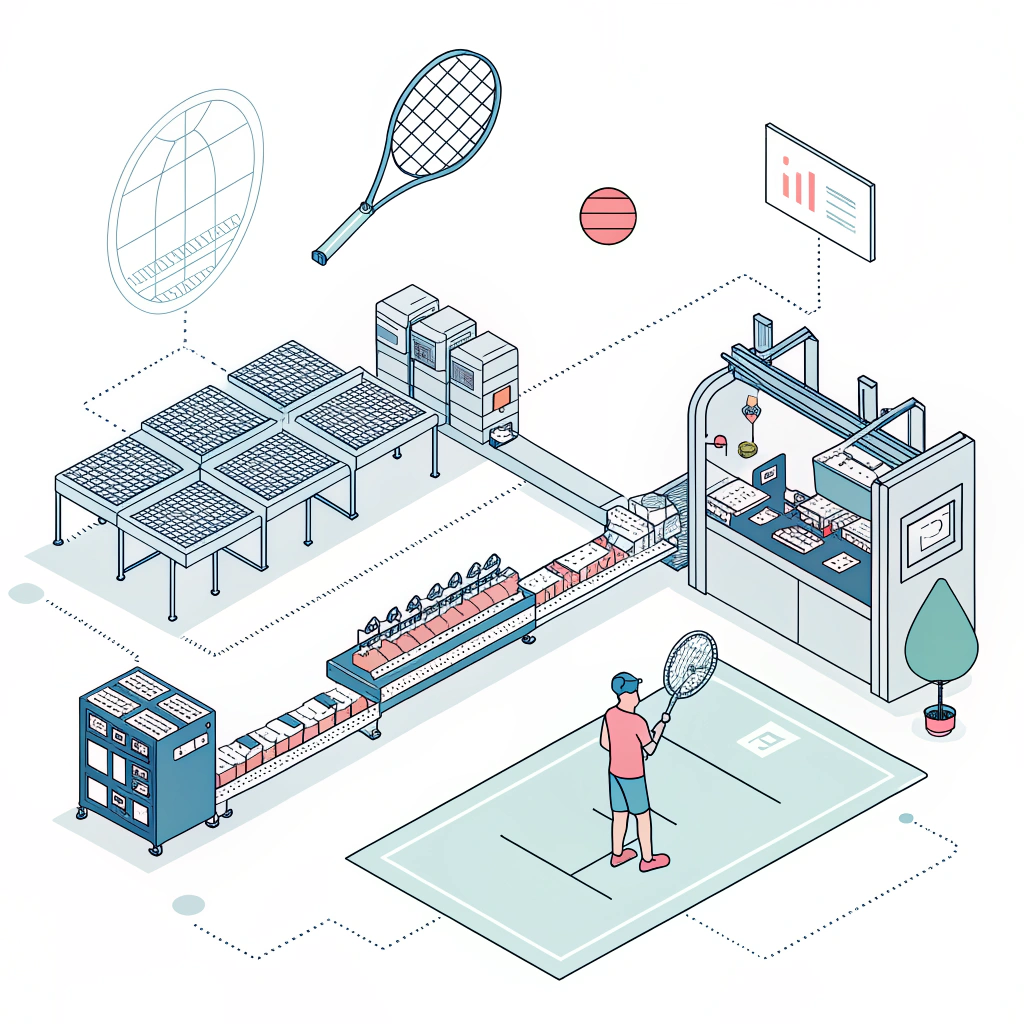

In our production process, efficiency is achieved through the intersection of advanced machinery, lean manufacturing principles, and rigorous quality control practices:

- Digital Design Tools: These allow us to create exact prototypes. Customization options for diamond, round, or teardrop shapes are designed swiftly.

- Rapid Prototyping: Our fast sampling process helps in validating design decisions before full-scale production begins.

- Cost Implication: Early prototyping helps catch design errors, reducing the risk of costly reworks.

- Precision in Mixing Composites: The preparation of composites, such as the layering of carbon fibers with resin, is controlled to optimize strength while minimizing excess use of expensive raw materials.

- Quality Grades Consideration: We select the appropriate grade (3k, 12k, or 18k) based on the product category—balancing performance needs against cost-requirements.

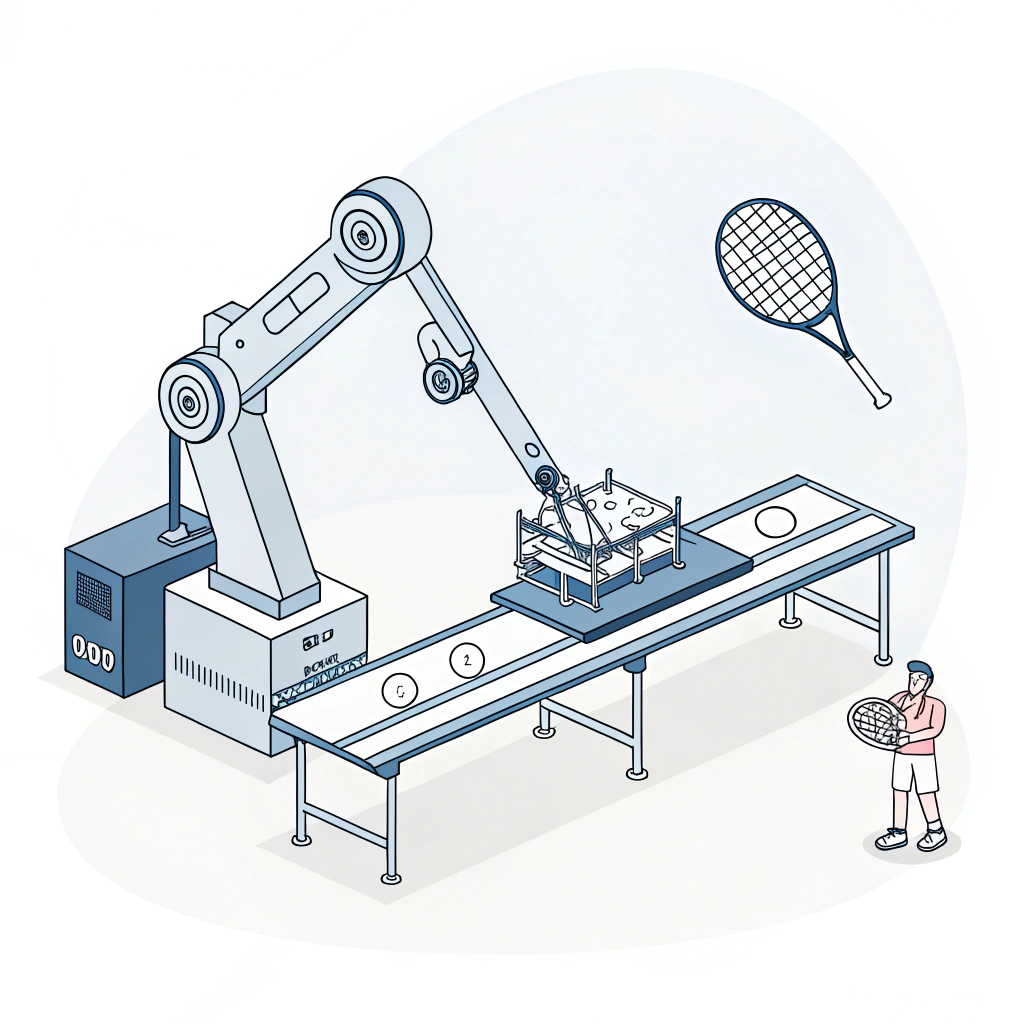

- Automated Laying Up: Some production lines incorporate robotic arms ensuring uniform resin application and fiber placement.

- Custom Molding: Tailored molding processes allow us to create unique shapes while leveraging economies of scale when producing larger batches.

- Energy Efficient Processes: Modern techniques reduce cycle times, thereby lowering energy consumption and production costs.

- Controlled Curing Processes: Precise temperature control in curing ovens ensures optimal bonding and material performance, minimizing waste from defective batches.

- Finishing Touches: Custom printings, logo applications, and hand grip configurations are completed post-curing. These elements offer another layer of customization without increasing unit cost significantly when structured efficiently.

- Rigorous Inspection: Quality assurance teams check every batch against strict metrics to ensure durability and performance.

- Cost and Efficiency Correlation: High-quality inspection reduces warranty returns and reinforces brand trust. Our pressurized tube packaging for padel balls, for example, ensures that ball pressure is maintained which is a key marker of product quality.

- Supply Chain Synchronization: Final products are then integrated into a streamlined shipping schedule, ensuring rapid delivery within budget.

This production efficiency is summarized in the following table:

| Production Stage | Key Efficiency Techniques | Cost Control Benefits | Quality Assurance Measures |

|---|---|---|---|

| Design & Customization | Rapid prototyping, digital design software | Early mistake detection, reduced rework costs | Design validation through samples |

| Material Preparation | Bulk sourcing, precise composite mixing | Reduced material waste, competitive pricing | Grade selection to match product needs |

| Laying Up & Molding | Automated laying, custom molds | Lower labor costs, energy savings | Consistent product dimensions |

| Curing & Finishing | Energy efficient curing, precise temperature control | Reduced energy costs, minimal defects | Uniform curing protocols |

| Quality Control & Packaging | Rigorous inspections, synchronized shipping | Lower returns, enhanced customer trust | Final inspection and performance tests |

While production efficiency drives down costs, managing customization without eroding margins requires additional caution:

- Layered Customization: At NEX Padel, we offer full customization in shape, print, and finish without sacrificing unit cost. This is enabled by standardizing customizable features wherever possible.

- Lean Production Principles4: Eliminating waste in both raw materials and time is crucial. We have adopted lean production methods to improve turnaround times and optimize resource deployment.

- Continuous Improvement: Frequent feedback loops from both internal teams and client partners allow for continuous refinements. Regular assessments of production cycle times and material usage help in identifying further cost-saving opportunities.

By integrating data analytics5 into production monitoring, we gain real-time insights into cost drivers. This information helps make strategic adjustments that keep costs in check while enhancing production output.

Quality control is not an afterthought—it is embedded at every production stage. Our quality management system is designed to:

- Guarantee Durability and Performance: Every racket is tested to ensure it meets rigorous performance criteria. This includes stress tests, impact tests, and real-world usage simulations.

- Align with Global Standards: By adhering to international quality guidelines, we ensure that our products not only compete on price but also on performance and reliability.

- Enhancing OEM Relationships: High levels of quality control build confidence in our OEM1 partnerships. Brands like Hirostar, Reebok, and Starvie trust us for our consistency and dedication to quality.

Quality assurance is also bolstered by our supply chain management. Close supplier relationships ensure a steady flow of high-quality materials, allowing us to control costs without compromising quality. This closed-loop system supports a transparent production process where every step is documented and continuously improved.

For procurement managers, selecting an OEM partner is as much about production efficiency as it is about trust and collaboration. Our strategic approach includes:

- Transparent Cost Structures: Detailed breakdowns of material costs, labor, and process overheads provide clarity. This transparency enables clients to understand how pricing is structured and where savings are realized.

- Robust Supply Chain Integration: Reliable and agile supply chain management minimizes delays and optimizes inventory levels. This synergy ensures that production remains on schedule and costs remain predictable.

- Mutually Beneficial Partnerships: We work closely with our partners to customize solutions that meet their exact needs. From fully customized racket shapes to tailored branding options, our capabilities ensure that every client’s unique vision is brought to life without sacrificing efficiency.

This alignment between production efficiency, cost management, and quality assurance creates not only great products but also long-lasting, value-driven relationships with our clients.

To summarize, the strategies for achieving a balance between cost control and product excellence in padel racket manufacturing are multi-faceted:

- Careful material selection and strategic sourcing allow us to use cost-effective yet high-performing materials.

- Advanced production techniques—from digital design and automated processes to precise curing methods—drive efficiency.

- Lean Production Principles4 and continuous process improvement help manage costs.

- Robust quality assurance protocols build trust and ensure every product meets international standards.

- Transparent cost structures and a robust supply chain foster strong OEM partnerships.

These practices not only reduce operational costs but also enable rapid prototyping and customization capabilities that meet the dynamic demands of the sports equipment market. By partnering with an experienced OEM like NEX Padel, procurement managers and business development executives can be confident in the efficiency, reliability, and uniqueness of every product delivered—maintaining competitive pricing without sacrificing performance.

Taking action means understanding that cost efficiency and quality are not mutually exclusive. With the right strategies in place, both can be achieved simultaneously, ensuring that every padel racket produced is a perfect blend of affordability, precision, and durability.

People Also Ask

Q1: What production techniques are used in OEM padel racket manufacturing?

Advanced production techniques include automated composite laying, digital design for rapid prototyping, specialized curing processes, and integrated quality control measures that ensure precise material application and optimal performance.

Q2: How can manufacturing efficiency be improved without compromising padel racket quality?

Efficiency improvements rely on lean production principles4, continuous process refinement, and robust supply chain integration. Using state-of-the-art machinery and precise quality control helps maintain high product standards while reducing wastage and costs.

Q3: How does NEX Padel manage cost control while offering custom design options?

NEX Padel balances cost control and customization by standardizing customizable features, employing data analytics5 for production improvement, bulk sourcing high-quality materials, and maintaining transparent cost structures that ensure both efficiency and tailor-made design options.

-

OEM: Read the article to understand the role and benefits of Original Equipment Manufacturers in establishing efficient production partnerships and ensuring product quality. ↩ ↩2

-

Carbon Fiber: Discover how carbon fiber's unique properties contribute to enhanced performance and durability in high-end sports equipment manufacturing. ↩

-

Just-in-Time Manufacturing: Learn about the principles of just-in-time production and how it minimizes inventory costs while improving material efficiency. ↩

-

Lean Production Principles: Explore the methodologies of lean production that focus on waste reduction, process optimization, and continuous improvement in manufacturing. ↩ ↩2 ↩3

-

Data Analytics: Understand how data analytics drives operational insights, allowing businesses to optimize production processes and identify cost-saving opportunities. ↩ ↩2