The integration of robotics in identifying the sweet spot1 of padel rackets ensures consistent, data-driven precision that traditional methods often lack.

In modern padel racket production, identifying the "sweet spot" is critical for enhancing performance, ensuring durability, and delivering competitive quality. For technical product developers, R&D engineers, and quality control managers, ensuring that the sweet spot is optimized means that players enjoy improved comfort, reduced vibration, and enhanced power output. However, traditional methods for detecting the sweet spot often rely on manual inspections and subjective assessments, which may lead to inconsistencies and production inefficiencies.

Robotic systems, integrated with advanced sensor arrays2, offer a reliable solution by automating the process and generating precise measurements. These innovations are already transforming OEM production3 practices, particularly in high-end manufacturing settings associated with brands like Reebok and Hirostar.

Traditional methods have been the industry standard for decades. Yet, they come with inherent challenges that make it difficult to:

- Consistently locate the sweet spot: Human error and limited measurement techniques can result in variability.

- Optimize performance: Without precise analysis, the racket may not fully exploit the benefits of its design, especially when using materials like carbon fiber4 or advanced composites.

- Scale the production process: High-volume production is limited by the speed and accuracy of manual testing, affecting overall production efficiency.

These challenges underscore the need for a more systematic approach. Robotics in manufacturing addresses these issues by performing rapid, consistent measurements that inform R&D adjustments in near real time.

To tackle these challenges, companies are increasingly adopting robotics in manufacturing5 for automated sweet spot analysis. Below is a breakdown of the solution components:

Modern robotic systems are equipped with high-precision sensors that can detect minute variations in impact and vibration. When a padel racket is subjected to controlled strikes, the sensors capture:

- Force Distribution: Quantifying the impact across different areas of the racket.

- Vibration Patterns: Analyzing the response to ensure that energy is optimally transferred from the racket to the ball.

- Structural Integrity: Evaluating each material layer, from glass fiber to 18k carbon fiber, to confirm performance consistency.

These measurements help establish a detailed performance profile of each racket, ensuring the sweet spot is identified accurately.

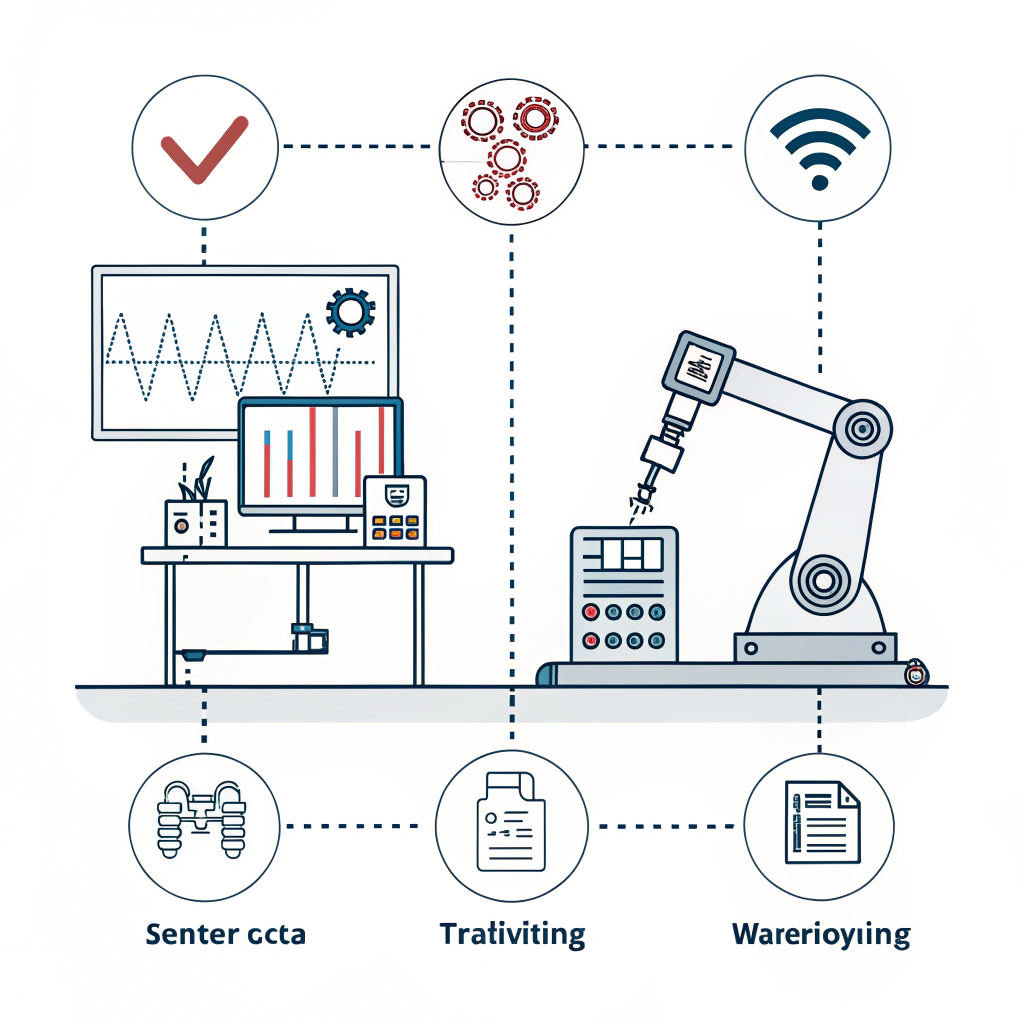

Robotic solutions integrate with advanced data analytics platforms that compile and analyze sensor data. This process involves:

- Real-time analytics: Allowing for immediate feedback during production.

- Historical data comparisons: Enabling continuous improvement by comparing current metrics with data from past production cycles.

- Automated reporting: Streamlining the quality control process with minimal human intervention.

A simplified table below illustrates a comparative analysis:

| Feature / Metric | Traditional Methods | Robotic Automated Testing |

|---|---|---|

| Precision Measurement | Variable, operator-dependent | High accuracy with sensor arrays |

| Consistency in Results | Moderate | High |

| Production Speed | Slower manual testing | Rapid and continuous |

| Data Analysis Capabilities | Limited manual insights | Robust, real-time analytics |

| Scalability for OEM Production | Challenging | Highly scalable |

The table above clearly shows the advantages robotics offer over traditional testing methods, especially for OEM production scenarios where consistency and speed are crucial.

Implementing robotics in the sweet spot analysis process involves several key steps:

Before production begins, it is essential to calibrate the robotic system. This involves:

- Configuring sensor arrays to align with the structural parameters of padel rackets.

- Establishing baseline measurements using sample rackets to fine-tune the robotic algorithms.

- Integrating the system with the central data management platform to ensure seamless data flow.

Once calibrated, the automated testing process can efficiently determine the sweet spot. The process typically includes:

- Robotic arm movement: Precisely positioning the racket and delivering calibrated impacts.

- Sensor data collection: Capturing force, vibration, and energy absorption metrics.

- Data consolidation: Aggregating the sensors’ data to pinpoint the optimal impact zone on the racket.

The continuous feedback provided by the robotic system allows R&D engineers to:

- Make real-time adjustments in production settings.

- Optimize design elements such as the distribution of carbon fiber layers or handle customization.

- Validate new prototypes quickly, thus reducing the go-to-market time for innovative racket designs.

Consistent quality control is achieved through:

- Uniform testing conditions: Robots ensure that every racket is tested under the same conditions.

- Detailed reporting: Automated reports provide comprehensive insights on any variance from the expected performance.

- Scalability: As production volumes increase, the robotic system can maintain consistent quality regardless of scale.

These improvements not only enhance production efficiency but also bolster the overall performance of padel rackets, ensuring that each product meets the high standards demanded by professional players.

Several high-performance manufacturers have integrated robotic systems into their production lines with impressive results. Consider a scenario where a leading OEM decided to upgrade its quality control process:

- Before Robotics: Manual inspections resulted in a 15% variability in sweet spot identification, leading to inconsistent racket performance and increased production costs.

- After Robotics Implementation: Variability dropped to less than 3%, with production speed increasing by 25%. The precise measurement capabilities enabled targeted optimizations, particularly for Diamond and Teardrop shaped rackets, where the sweet spot location greatly influences playing dynamics.

These results clearly indicate that robotics-driven sweet spot analysis can significantly improve both product reliability and production efficiency.

While robotics offers immense benefits, there are practical factors to consider:

- Initial Investment and Training: Advanced robotics systems require significant upfront costs and specific training for technical personnel to manage and maintain them.

- Integration Challenges: Existing production lines may need adjustments to accommodate robotic systems, requiring careful planning and possibly temporary production disruptions.

- Customization Complexities: For companies offering high levels of customization—such as shape, color, and handle/hand grip design—robots must be recalibrated to account for varying specifications.

A small table summarizing the limitations:

| Consideration | Impact on Implementation | Mitigation Strategy |

|---|---|---|

| Initial Investment | High upfront cost | Long-term ROI analysis and financing options |

| Technical Training | Learning curve for staff | Comprehensive training programs |

| Integration Efforts | Potential production disruption | Phased integration and pilot testing |

| Customization Variability | Need for recalibration | Flexible robotics with adaptive algorithms |

Addressing these limitations effectively requires a well-planned strategy, ensuring that the benefits ultimately outweigh the initial hurdles, leading to enhanced manufacturing automation and product performance.

Robotic systems have redefined sweet spot identification in the padel racket manufacturing process. Their ability to deliver precise, automated, and consistent results surpasses traditional manual methods—an advantage that is especially significant in high-growth OEM environments.

Key takeaways and recommendations include:

- Embrace Robotics for Precision: The adoption of robotics ensures that each racket is tested with a high degree of accuracy. This is crucial for maintaining consistent performance, especially in high-stakes sporting gear production.

- Invest in Data-Driven Processes: Continuous data collection and analytics provide insights that fuel further product optimizations and innovations. Establish feedback loops to integrate testing data into the design phase.

- Plan for Seamless Integration: Be mindful of the initial challenges, including investment and training. Implement a phased approach to integrate robotics into existing production lines.

- Customize with Confidence: With robotic flexibility, manufacturers can offer a range of customization options without compromising on performance, making it easier to meet diverse customer needs.

- Monitor and Optimize: Leverage automated reports and real-time analytics to refine the sweet spot identification process continuously.

By integrating these advanced testing methods, companies like NEX Padel can enhance the performance and reliability of padel rackets, creating a competitive edge in the global market. The synergy between robotics and traditional manufacturing techniques paves the way for innovative product development and efficient OEM partnerships.

Which padel racket has the best sweet spot?

For round-shaped rackets, the sweet spot is typically centered. In contrast, for diamond-shaped rackets, the optimal impact area is usually closer to the top. Robotics can help pinpoint these areas with precision, ensuring each design meets performance standards.

What is the sweet spot in padel?

The sweet spot in a padel racket is the optimal area for impact, typically located near the center but adjusted based on racket design. This zone requires less energy to generate maximum performance, and robotic testing helps confirm its ideal placement for each specific design.

-

sweet spot: Click to learn about the optimal impact zone on sporting equipment, which maximizes power output and minimizes energy loss during use. ^Return ↩

-

advanced sensor arrays: Click to discover how advanced sensor arrays enable high-precision measurements and quality control in modern manufacturing processes. ^Return ↩

-

OEM production: Click to read about Original Equipment Manufacturer (OEM) production models and strategies for scaling quality and efficiency. ^Return ↩

-

carbon fiber: Click to explore the properties and benefits of carbon fiber in enhancing product performance and durability in manufacturing. ^Return ↩

-

robotics in manufacturing: Click to understand how integrating robotics in manufacturing improves production consistency, safety, and efficiency. ^Return ↩