Padel is not just a rapidly growing sport—it is a transformative trend in sports equipment manufacturing and distribution. The current surge in padel popularity is driven by market demand for innovative, high-performance, and customizable products. Advances in technology and manufacturing are reshaping how padel equipment is produced, making it a strategically viable investment for B2B partners.

Padel’s global market is experiencing robust growth. With players ranging from casual enthusiasts to professional athletes, there is a surge in demand for high-quality padel products. For distributors and brand managers, the growth of padel offers an ideal opportunity to capture new segments and expand existing portfolios.

Recent market studies indicate that padel participation is increasing steadily in Europe, Latin America, and parts of Asia. While detailed statistical data may vary by region, the overall trend points to a rising consumer interest that is expected to continue for years to come. This expansion is largely fueled by:

• Increased investments in sports infrastructure

• A growing culture of recreational sports globally

• Enhanced media exposure and promotional campaigns

By staying ahead of these trends, B2B partners can strategically position themselves to meet the rising demand for padel equipment.

There are several key factors driving the upward trajectory of padel as both a sport and a market. Evaluating these factors carefully can help distributors and brand managers make informed procurement decisions.

1. Advanced production techniques1 and Materials

Advanced production techniques1 involving materials such as fiberglass and various grades of carbon fiber2 (3k, 12k, and 18k) allow manufacturers to create rackets that offer superior durability and performance. The technological progress in composite materials translates directly into products that meet both recreational and competitive standards.

2. Customization3 and Versatility

Today’s padel rackets are not one-size-fits-all. Manufacturers now offer customization options ranging from racket shapes (Diamond, Round, and Teardrop) to bespoke logos, colors, and even hand grip designs. This flexibility is a considerable advantage for brand managers who want to differentiate their product offerings in a crowded market.

3. Quick Prototyping and Efficient supply chain4

With a focus on fast sampling and timely delivery, manufacturers like NEX Padel are well-positioned to deliver products that meet dynamic market needs. A robust supply chain4 and agile production process mean that distributors can rely on consistent stock levels and rapid order fulfillment, critical factors that support business reputation and customer satisfaction.

Working with renowned brands such as Hirostar, Reebok, and Starvie, manufacturers build credibility and reinforce product quality. These partnerships not only validate the performance of padel equipment but also provide a framework for future growth and innovation within the industry.

At the core of padel equipment manufacturing is a significant emphasis on technology and quality control. Advanced machinery, precision engineering, and data-driven manufacturing processes ensure that each product meets rigorous performance standards.

• Enhanced Material Utilization: Implementing different carbon fiber weaves enables manufacturers to fine-tune racket flexibility and stiffness. For instance, a 3k carbon fiber racket might be chosen for its lightweight properties, while 12k or 18k options provide additional strength for competitive play.

• Precision Molding Techniques5: Sophisticated molding processes ensure the perfect blend of durability and performance. It is essential that each racket not only withstands regular use but also performs optimally during high-speed play.

• Customization Options: Modern production methods allow for full customization of shapes, prints, and colors. This capability supports both large-scale orders for established brands and smaller, boutique productions that require unique visual identities.

• Quality Control Measures: Rigorous testing at every production stage guarantees that the final product meets both international standards and specific client requirements.

Below is a table summarizing some of these manufacturing innovations and their benefits:

| Innovation | Benefit | Application in Padel Rackets |

|---|---|---|

| Advanced Carbon Fiber Weaves | Improved balance between strength and weight | Customizable racket performance levels |

| Precision Molding Techniques | Consistent product quality across batches | Uniformity in design and performance |

| Customization Capabilities | Enhanced brand differentiation and market appeal | Bespoke designs tailored to customer specifications |

| Rigorous Quality Control | High durability and reliability | Assurance of long-lasting competitive equipment |

One of the most attractive aspects of the padel market is its product diversity. The innovation in racket design is particularly noteworthy, as it spans a variety of shapes and functional benefits. Here is an overview of the primary racket types and their unique characteristics:

-

Diamond Racket:

Designed for aggressive play, the Diamond racket offers enhanced power and precision. It is favored by players who prioritize offensive strategies and require explosive speed. -

Round Racket:

The Round racket is known for its forgiving playing characteristics, offering a balanced performance that suits both beginners and intermediate players. Its design helps in reducing errors and improving control. -

Teardrop Racket:

The Teardrop racket caters to an all-round playing style. It strikes a balance between power and control, making it suitable for players who switch between offensive and defensive techniques.

This diversity can be easily compared in the table below:

| Racket Type | Key Feature | Best Suited For | Customization Options |

|---|---|---|---|

| Diamond | Power-driven design | Aggressive, competitive play | Shape, color, hand grip, logo |

| Round | Versatile and forgiving | Beginners and intermediate players | Full customization of prints and design |

| Teardrop | Balanced performance | All-round gameplay | Bespoke design, multiple material options |

The ability to customize these rackets further extends the value proposition to B2B clients. When a manufacturer like NEX Padel offers extensive customization options, it becomes easier for distributors to differentiate their product lines in competitive markets.

At NEX Padel, we have firmly established ourselves as a leading manufacturer of high-performance padel rackets and balls. Our operations in Jiaxing, Zhejiang, China, leverage the latest advancements in production techniques to deliver products that align with market demands and surpass industry standards.

• Advanced Production Techniques:

By integrating cutting-edge machinery with skilled craftsmanship, we ensure that every racket, whether it uses fiberglass or various grades of carbon fiber, is built for longevity and performance.

• Customized Solutions:

Our ability to offer fully customized products—ranging from racket shapes to bespoke printing and color options—ensures that our partners can meet the unique needs of their clientele.

• Speed to Market:

With rapid prototype development and efficient supply chain logistics, we minimize lead times without compromising on quality. This agility is critical in today’s fast-paced market, where trends can shift rapidly.

• Comprehensive Product Range:

Our portfolio includes not just rackets but also padel balls produced with precision. Using pressurized tube packaging and varying wool compositions (45% and 57%), we ensure that the balls maintain consistent pressure, improving playability and durability.

Our collaborations with companies such as Hirostar, Reebok, and Starvie underscore our commitment to quality and innovation. These partnerships provide a strong validation of our manufacturing processes and our ability to deliver at scale. As a manufacturer deeply embedded in this industry, we are constantly evaluating new trends, investing in research and development, and refining our production methods to serve the evolving needs of the padel market.

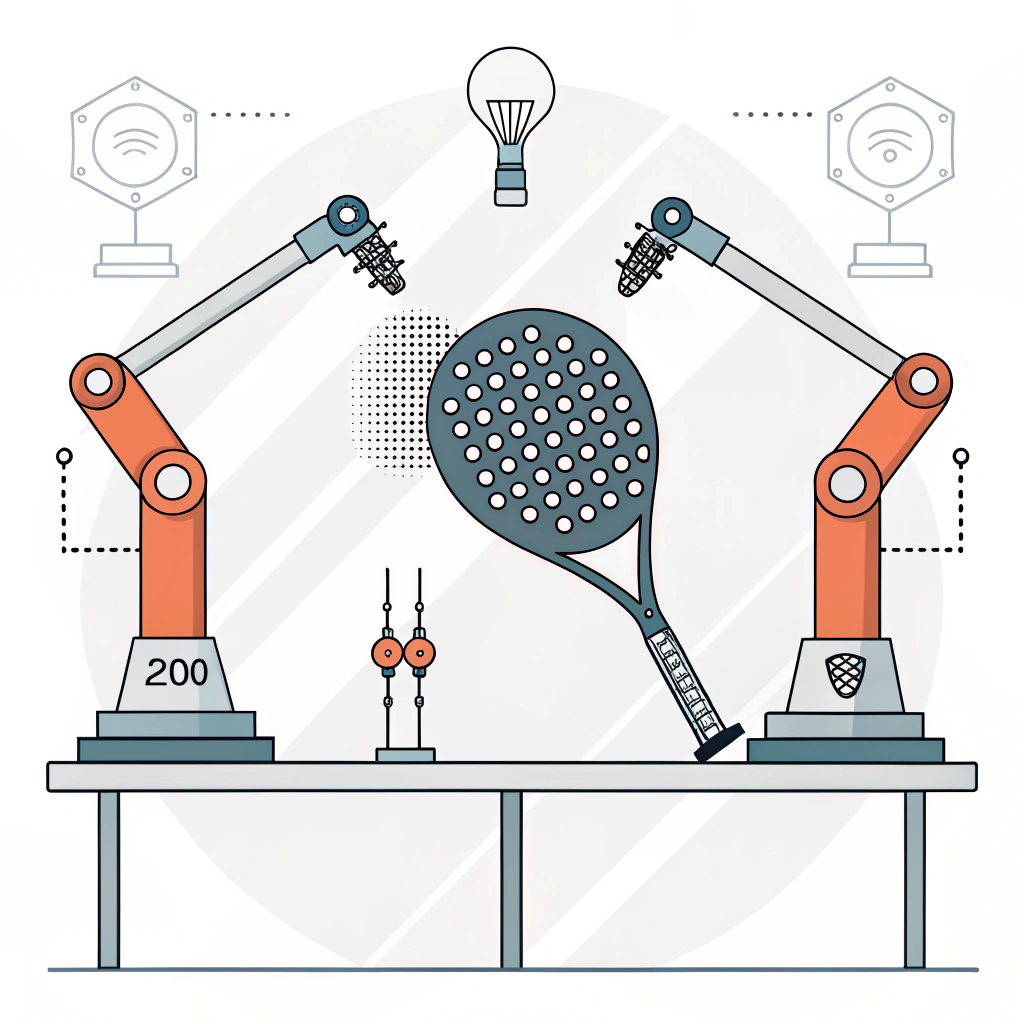

Looking forward, the padel market is poised for even more significant growth. With increasing investments in digital technologies and data analytics, manufacturers and distributors alike will have better tools to predict consumer trends and adjust production strategies accordingly. The continued integration of advanced robotics, AI-powered quality control, and smart logistic systems will further enhance product quality and operational efficiency.

Businesses that choose to invest in padel products today are not just capitalizing on a fleeting trend—they are positioning themselves at the forefront of a sustainable growth market. By partnering with dependable manufacturers like NEX Padel, brands can offer innovative, high-quality products that meet the rigorous demands of competitive contact sports while also appealing to broader recreational audiences.

The surge in padel popularity is backed by several key factors: technological advancements, innovative manufacturing techniques, heightened customization capabilities, and robust global market trends. For B2B distributors and brand managers, understanding these dynamics is crucial when making informed procurement decisions.

To summarize:

• Padel is rapidly transforming from a niche sport into a mainstream phenomenon driven by global trends.

• Advances in materials like carbon fiber and fiberglass, coupled with precision production, are reshaping product performance.

• Customization is key—offerings that can be tailored to specific markets and consumer demands create a competitive edge.

• Strategic partnerships with manufacturers like NEX Padel provide a reliable foundation for long-term business growth.

If you are considering expanding your product portfolio or entering the padel market, now is the time to invest in solutions that align with these emerging trends. Collaborate with industry leaders who understand both the technology and the market dynamics to ensure you can meet consumer expectations with high-performance, customizable products.

By leveraging these insights and forging strong partnerships, B2B players can not only keep up with industry trends but also shape the future of the padel market.

-

What are the key trends in padel equipment manufacturing?

Answer: The main trends include the adoption of advanced materials like various grades of carbon fiber, precision molding techniques, and extensive customization options. These trends help manufacturers improve performance, durability, and product differentiation. -

How do advanced technologies like carbon fiber influence padel racket performance?

Answer: Advanced carbon fiber techniques enable manufacturers to fine-tune the balance between light weight and strength, leading to rackets that offer enhanced speed, durability, and control. This technological advancement is crucial for both recreational and competitive players. -

What customization options are available for padel rackets?

Answer: Customization can include shape modifications (such as Diamond, Round, or Teardrop designs), bespoke printing, color choices, and even personalized hand grip designs. This allows brands to create unique products that cater to specific market needs and consumer preferences.

-

Advanced production techniques: Click to learn how modern manufacturing methods, including automation and integration of new materials, drive efficiency and innovation in production. ↩ ↩2

-

carbon fiber: Click to explore the properties of carbon fiber, its various grades (3k, 12k, 18k), and its role in enhancing product performance in sporting goods. ↩

-

Customization: Click to read about strategies for leveraging product customization to meet niche market demands and differentiate brand offerings. ↩

-

supply chain: Click to delve into effective supply chain management practices that improve production agility, reduce lead times, and boost overall operational efficiency. ↩ ↩2

-

Precision Molding Techniques: Click to understand the molding processes that ensure product consistency, durability, and high performance in competitive markets. ↩