Carbon fiber technology is a game-changer for junior padel racquets. It delivers enhanced performance, lightweight design, and excellent durability that help young players improve quickly while avoiding injuries and ensuring a controlled strike.

For procurement managers1 and sports equipment distributors, selecting the right material for junior padel racquets is crucial. Young players need racquets that are not only light enough to handle easily but also strong enough to withstand growing up and increasing play intensity. While traditional materials like fiberglass have been popular due to their excellent ball output during slower hits, Carbon fiber2 is quickly gaining recognition thanks to its performance benefits.

Young athletes require gear that complements rapid movements, precise control, and the flexibility to adapt quickly during play. Therefore, the material choice directly influences the racquet’s functionality—its weight distribution, balance, durability, and overall performance. At NEX Padel, we have dedicated years to perfecting our manufacturing techniques so that every racquet meets and exceeds industry standards while offering complete customization options.

When comparing Carbon fiber2 to fiberglass, a detailed understanding of each material’s attributes is essential. Typically, fiberglass racquets are known for their inherent flexibility, which provides a high level of spring effect and ball output in slower, low-impact hits. However, for junior players advancing in skill, the superior stiffness of carbon fiber offers several benefits:

- Lightweight Efficiency: Carbon fiber's lower weight enables faster swings and improved maneuverability, which are critical for developing technique.

- Enhanced Stiffness and Stability: The stiffer structure provides precise shot control and maximum power, ensuring that each hit is both accurate and impactful.

- Durability and Longevity: The resilient nature of carbon fiber reduces the risk of minor defects and breakages over extended use, a significant consideration for equipment used in high-frequency training sessions.

Below is a comparison table that summarizes these differences to help you assess which material best aligns with your youth sporting equipment strategy:

| Feature | Carbon Fiber Racquets | Fiberglass Racquets |

|---|---|---|

| Weight | Ultra-light, enabling faster swings | Generally heavier, may slow swing speed |

| Flexibility | Lower flexion for more control | Greater flexion for extra ball output |

| Stiffness | High stiffness for precision and power | Lower stiffness, more forgiving |

| Durability | Excellent resistance against breakages | Moderate durability |

| Suitability | Best for performance-focused players | Ideal for beginner level or casual play |

This detailed comparison serves as a foundation for making an informed procurement decision. When targeting the next generation of padel players, the benefits of carbon fiber often outweigh the advantages of fiberglass for performance-driven markets.

At NEX Padel, our commitment to advanced manufacturing is at the heart of every junior padel racquet we produce. Based in Jiaxing, Zhejiang, China, we leverage sophisticated production techniques that ensure every racquet meets precise quality and performance benchmarks. Our product lineup—including Diamond, Round, and Teardrop shapes—caters to a range of player styles and preferences.

Using materials that range from fiberglass to high-grade carbon fibers such as 3k, 12k, and 18k, our production process emphasizes precision and durability. Here are some key elements of our manufacturing process that directly impact racquet performance:

- Precision Engineering3: Customized manufacturing processes ensure that every cut and layer placement achieves maximum structural integrity, allowing a tailored balance between power and control.

- Rapid Prototyping4 and Turnaround: For partners and B2B clients, our rapid prototyping service means a quick turnaround from design to production, ensuring your market keeps pace with consumer demand.

- Quality Inspection: Each racquet undergoes rigorous testing to confirm that performance standards are met before shipping.

Modern distributors and padel clubs appreciate the ability to differentiate their product lines. With our extensive customization5 capabilities, you can specify details such as:

- Racquet Shapes: Choose from our standard models—Diamond, Round, or Teardrop—or opt for a fully customized shape that fits your club’s branding strategy.

- Print and Color Customization: Custom printing and color specifications are available to enhance brand visibility and appeal to young athletes.

- Grip and Handle Options: Beyond racquet frames, we offer customization on hand grips and handle covers, including the ability to embed logos and personalized designs.

These options provide the flexibility necessary to meet unique market demands and elevate your product line to the next level. In competitive B2B scenarios, such differentiation is critical to standing out in a crowded sporting goods market.

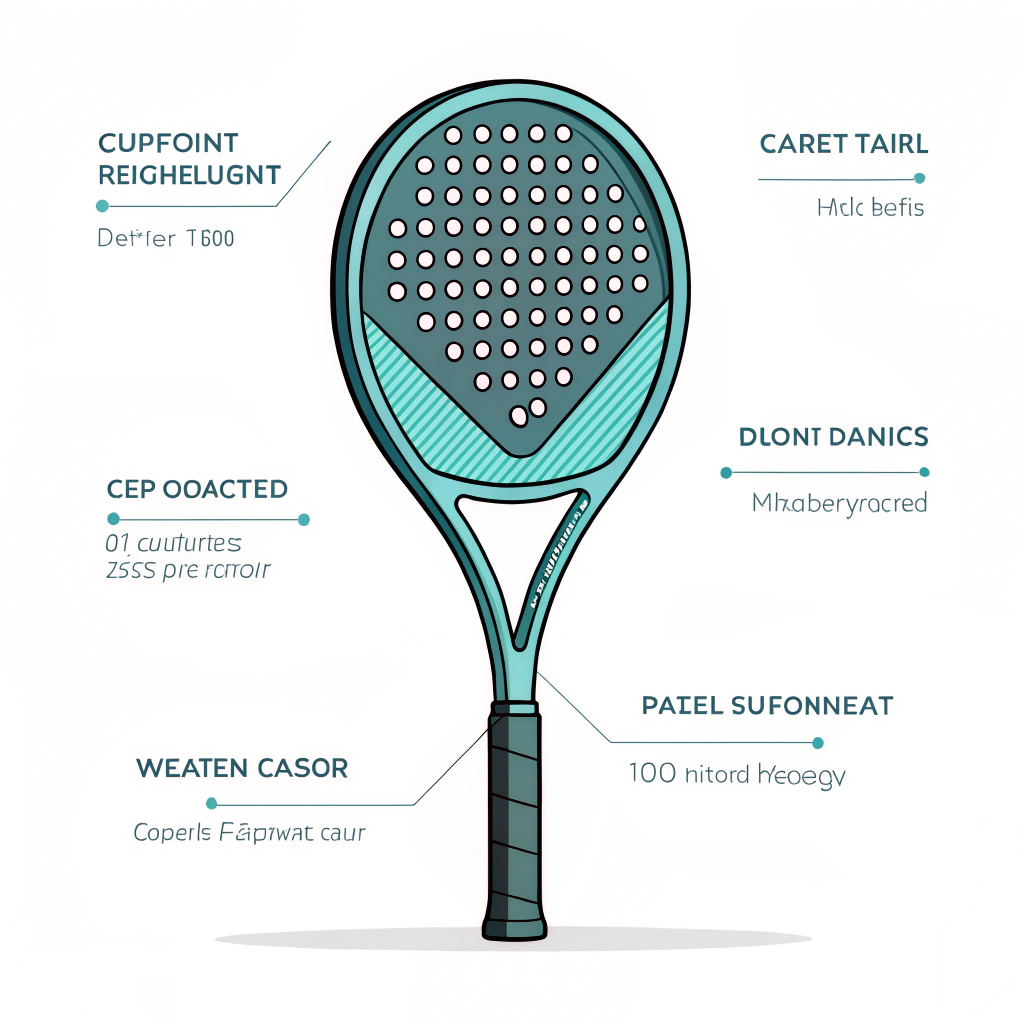

When evaluating performance, especially for the developing athlete, every aspect of racquet design plays a vital role. Carbon fiber2 contributes significantly to key performance metrics:

Junior players benefit from equipment that is easy to handle. The lightweight nature of carbon fiber reduces the risk of fatigue, supports faster reaction times, and enables young players to achieve higher swing speeds. The reduced weight works in tandem with improved control features, helping players focus on developing their skills rather than compensating for heavy, clunky equipment.

The inherent stiffness of carbon fiber means that less energy is lost through flex during a hit. This translates to more power directly transmitted to the ball, which is crucial for producing precise and effective shots. Additionally, the enhanced stability provided by carbon fiber helps in maintaining a consistent playing style even during rapid movements.

For manufacturers and distributors, the extended lifespan of carbon fiber racquets is a major selling point. Young athletes often engage in rigorous training sessions that can quickly wear down lower quality materials. With carbon fiber, the racquet maintains structural integrity and performance over time, reducing the need for frequent replacements and improving overall cost-effectiveness for sport equipment distributors.

The transition from beginner-level equipment to more performance-oriented gear is a critical phase for junior padel players. By introducing high-performance racquets early in their development, young players are better equipped to adapt to faster, more demanding competitive play. As they grow, the advanced technology of carbon fiber materials helps refine their technique, offering both power and precision essential for high-level performance.

For sports equipment distributors and padel clubs, partnering with a reliable manufacturer like NEX Padel brings several strategic advantages:

Our dedication to quality means that every racquet is produced under strict quality control measures. This consistency not only builds customer trust but also ensures that your product line stands out in a competitive market. A consistent, high-quality product reinforces your brand reputation and drives customer satisfaction.

Our full customization capabilities allow you to tailor products specifically for your target market. Whether your audience prefers a specific design or you want to consolidate your brand identity through distinctive equipment, NEX Padel provides the ability to execute your vision with precision. This level of personalization is rarely available from lower-tier competitors, giving you a competitive edge.

In today’s fast-paced sports equipment market, timely delivery is imperative. Our efficient manufacturing and logistics enable you to meet demand peaks and stay ahead of market trends. Partnering with us reduces lead times while ensuring that product quality remains uncompromised.

Investing in racquets that are built to last means long-term savings on replacements and repairs. The durability of carbon fiber racquets ensures that issues such as flex fatigue and breakage are minimized, lowering your overall maintenance and replacement costs. This cost-effectiveness, in turn, allows for scalable procurement that can adapt to market growth without sacrificing quality.

In summary, Carbon fiber2 technology for junior padel racquets not only opens the door to higher performance on the court but also provides significant strategic benefits for distributors and procurement managers. The inherent advantages—lightweight design, enhanced stiffness, durability, and superior playability—are especially relevant in the growing junior market segment where long-term development is key.

By choosing NEX Padel as your manufacturing partner, you secure access to advanced production techniques, extensive customization options, and a reliable supply chain. Our commitment to excellence ensures that whether you are expanding your product line or seeking to differentiate your brand, you can do so confidently with equipment that meets evolving market demands.

We encourage you to explore our customizable options and discuss your specific needs with our team. An informed choice today can set your business on a path to long-term market success and customer loyalty.

-

Which is better carbon or fiberglass padel racquets?

Carbon fiber racquets offer a stiffer structure that improves shot precision and power, making them ideal for performance-driven play. While fiberglass provides more flexion and a greater spring effect for slower hits, the choice depends on the player’s style and development level. -

What is a good beginner padel racket?

For beginners, a lighter racquet with a balanced design is key. Often, models designed with soft cores and head-light balance, such as certain round-shaped options, offer easier maneuverability. However, for junior players with growing skill levels, transitioning to advanced materials like carbon fiber can be advantageous. -

Are carbon fiber rackets good?

Yes, carbon fiber rackets are excellent choices, particularly for players seeking maximum performance. Their lightweight nature allows for faster swings, and their stiff structure supports powerful, precise shots without sacrificing control.

-

Procurement managers: Click here to understand the strategic role of procurement managers in selecting high-quality, performance-driven sports equipment that aligns with market demands. ↩ ↩

-

Carbon fiber: Click here to learn how carbon fiber enhances equipment performance through its lightweight yet durable properties, offering a competitive edge in sports technology. ↩ ↩ ↩2 ↩3 ↩4

-

Precision Engineering: Click here to delve into precision engineering techniques that ensure structural integrity, optimized performance, and high-quality production standards in sports manufacturing. ↩ ↩

-

Rapid Prototyping: Click here to discover how rapid prototyping accelerates product development, enabling faster market entry and agile production processes in the sports equipment industry. ↩ ↩

-

Customization: Click here to explore the benefits of product customization, including brand differentiation and tailored solutions that meet specific market requirements. ↩ ↩