Our high-performance padel rackets undergo rigorous lab testing1 and quality validation to ensure they meet industry standards and exceed performance benchmarks.

In today’s competitive padel equipment market, procurement managers, technical directors, and quality control specialists require clear evidence that the products they purchase not only meet but exceed defined standards. Lab testing and performance validation2 are critical to guaranteeing the durability, precision, and overall quality of padel rackets. This guide provides a technical walkthrough into how advanced manufacturing techniques and in-depth lab tests, including material verification and structural integrity assessments, help guarantee high-performance sports equipment.

The padel racket market is expanding, and so are the demands for products that deliver ultimate performance on the court. For B2B procurement managers and technical directors, the constant challenge is to source rackets that have consistent quality and engineered durability. Several issues contribute to this challenge:

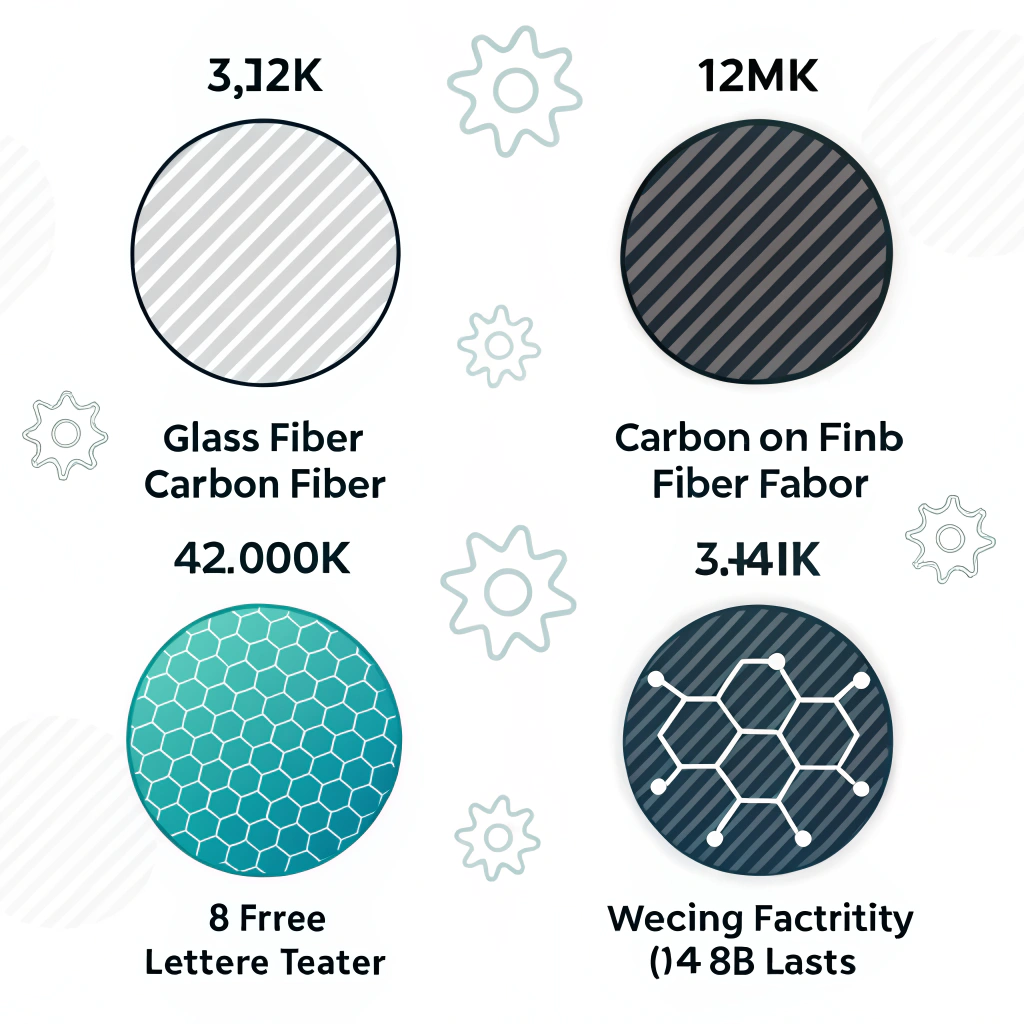

• Variability in raw materials such as glass fiber3 and various types of carbon fiber4 (3K, 12K, 18K) used in production.

• The complexity of the manufacturing process, where every small deviation can affect the final performance.

• Increasing demand for customized designs, which, while offering market differentiation, can raise challenges in maintaining quality standards.

• Inconsistent lab testing protocols among suppliers that make it difficult for buyers to compare products.

With these challenges in mind, understanding our comprehensive testing and quality assurance process becomes the key differentiator for making informed supplier decisions.

Quality variations often stem from several factors inherent in the manufacturing and testing process. Here are some primary reasons:

• Material Choices: The type of carbon fiber used in padel rackets significantly impacts weight, stiffness, and energy transfer. For instance, 3K carbon fiber tends to offer a balanced mix of flexibility and strength, whereas 12K and 18K carbon fibers generally yield enhanced rigidity and durability. Variability in the quality of these materials can lead to inconsistent performance.

• Manufacturing Precision: Achieving the correct racket shape and design (Diamond, Round, or Teardrop) requires high precision. Small deviations in mold, temperature, or curing time can impact the overall strength and balance of the racket.

• Customization Complexity: Custom printing, color variations, and specially designed hand grips introduce additional layers of complexity. Each customization can influence factors such as weight distribution and aerodynamics.

• Lab Testing Protocols: Differences in lab testing methods, such as impact resistance, torque testing, and durability experiments, may lead to varying interpretations of a product’s performance.

Understanding these variables underlines the importance of having a standardized, data-driven approach to padel racket quality assurance.

To tackle these issues, manufacturers like NEX Padel employ a multi-stage quality assurance process that integrates advanced lab testing protocols with continuous production monitoring. Below is a detailed breakdown of our solution:

-

Material Certification:

Each batch of raw materials, whether it is glass fiber or various types of carbon fiber, is verified against industry standards. These certifications confirm that the supplied materials meet predetermined tensile strength and durability requirements. -

Production Line Monitoring:

Advanced sensors and real-time monitoring systems ensure that parameters such as temperature, pressure, and curing time remain within required tolerances. This minimizes deviations caused by raw material variability or process inconsistencies. -

Structural Integrity Testing:

Rackets undergo mechanical tests to evaluate stress resistance and energy transfer capabilities. Standardized tests include impact resistance evaluation, dynamic stiffness assessment, and shock absorption analysis. -

Customization Validation:

For customized orders, additional testing ensures that any modifications—including engraving, color matching, and logo applications—do not adversely affect performance. Hand grip and handle cover tests ensure that all components integrate seamlessly. -

Final Product Certification:

Completed rackets are subjected to a final round of performance tests that simulate real-world playing conditions. Only those that fulfil strict lab criteria for durability, balance, and performance proceed to market delivery.

Different carbon fiber types significantly affect racket performance. Below is a table that compares the key properties of the most commonly used carbon fiber grades in padel racket production:

| Material Type | Flexibility | Weight (Relative) | Durability | Usage Profile | Key Benefits |

|---|---|---|---|---|---|

| Glass Fiber | High | Medium | Moderate | Entry-level rackets | Cost-effective, good flexibility |

| 3K Carbon Fiber | Medium | Light | High | Balanced performance | Ideal for versatile play |

| 12K Carbon Fiber | Low | Lighter | Very High | Advanced players | Enhanced stiffness and control |

| 18K Carbon Fiber | Minimal | Ultra-light | Maximum | Professional level | Superior rigidity and impact strength |

Each grade has been carefully lab-tested to confirm that they meet the rigorous standards required for both performance and durability. Manufacturers can select the appropriate material based on the intended playing style and target market.

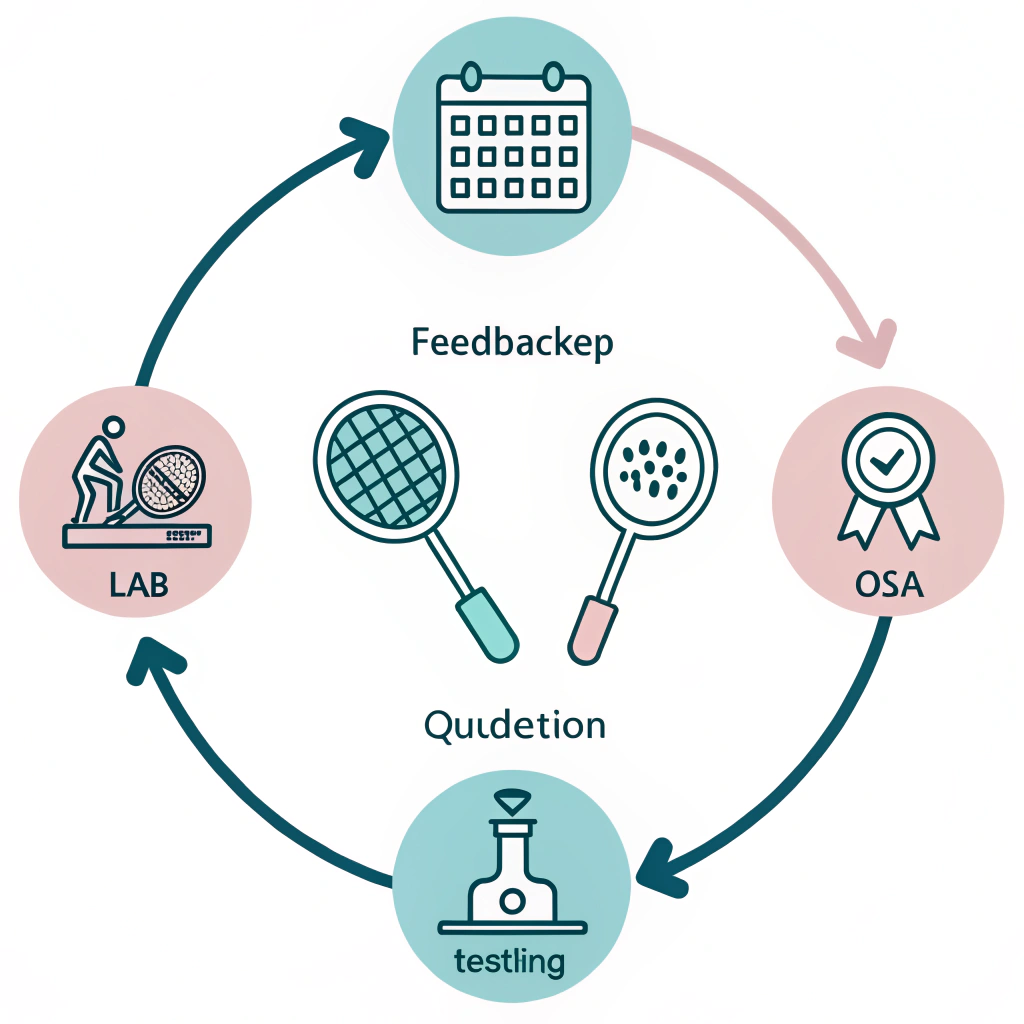

To ensure a standardized quality guarantee throughout the manufacturing cycle, NEX Padel integrates advanced lab testing technologies with state-of-the-art production techniques.

• Pre-Production Material Testing:

We perform initial screenings on all raw materials. Certifications from external labs are cross-verified with our internal testing protocols to ensure consistency with industry benchmarks.

• Real-Time Quality Monitoring:

During production, various quality control checkpoints are integrated into the assembly line. Sensors continuously monitor parameters that could affect the structural integrity of the racket.

• Post-Production Performance Trials:

Finished products are subjected to simulated usage scenarios. We use high-speed cameras and pressure sensors to capture data on racket flex and impact distribution. This data is analyzed to compare against our performance standards.

• Feedback Loop and Process Optimization:

Results from the final product testing feed back into our manufacturing processes. This ensures continuous improvement and immediate addressing of any irregular performance trends.

Numerous studies and internal reviews demonstrate the success of this rigorous testing methodology. For example:

• Case Study: Enhanced Durability in Customized Rackets

One of our clients, a leading sports equipment distributor, noticed a 25% improvement in racket longevity after we introduced our enhanced customization validation protocol. Lab tests confirmed that customized hand grips maintained their structural integrity even after prolonged use.

• Performance Comparison Data:

Internal tests show that rackets using 12K carbon fiber outperform those with lower-grade carbon in terms of stiffness and energy transfer during high-intensity gameplay. These results have been validated over multiple test cycles and under varying stress conditions.

• Market Feedback:

B2B customers including global brands like Hirostar and Reebok have consistently reported higher levels of satisfaction correlating with the robust quality checks in our production process.

These data points confirm that a stringent lab testing methodology not only enhances product performance but also bolsters customer confidence in long-term performance.

While our testing methodologies provide robust quality assurance, there are important considerations and limitations to note:

• Variability in Environmental Conditions:

Lab conditions may not perfectly replicate all on-court variations. Therefore, even rigorously tested rackets may behave slightly differently under extreme climates.

• Customization Impact:

Each custom modification, whether in design or material application, introduces unique variables that require additional testing to ensure no performance degradation occurs.

• Technological Limitations:

The precision of real-time monitoring systems can be affected by calibration issues. Regular maintenance and recalibration are essential to ensure ongoing accuracy.

• Regulatory Changes:

Changes in international standards for sports equipment may require periodic updates to testing protocols. It is important for both suppliers and buyers to stay informed on these changes.

A continuous review process helps mitigate these risks, ensuring that the final product remains consistent with quality and performance benchmarks.

In conclusion, lab testing and performance validation play a pivotal role in ensuring that padel rackets deliver the high-performance required in today’s market. Through a systematic approach that involves material certification, process monitoring, rigorous structural testing, and continuous feedback, manufacturers can guarantee that each product meets strict quality and durability standards.

For B2B buyers, technical directors, and quality control specialists, understanding these testing processes is crucial for making informed procurement decisions. Consider the following actionable steps:

• Verify that your supplier’s quality assurance protocols include comprehensive lab testing and certification.

• Request comparative data on material performance, especially if you are considering customized designs or diverse material compositions.

• Ensure there is a clear feedback loop from production to quality maintenance, demonstrating a commitment to continuous improvement.

• Stay informed on regulatory changes and updated industry standards that may affect product performance or compliance.

By embracing a data-driven approach to quality assurance, you can secure padel rackets that not only meet the immediate performance criteria but also offer long-term reliability in demanding sports environments.

• What is the importance of lab testing for padel rackets?

Answer: Lab testing is essential because it confirms that each racket meets strict performance and durability standards under simulated playing conditions, ensuring safety and consistent performance.

• How do different carbon fiber variations affect padel racket performance?

Answer: Variations in carbon fiber grades, such as 3K, 12K, and 18K, directly influence the racket’s stiffness, weight balance, and durability, making material selection critical for achieving desired performance characteristics.

• What are the key measures to ensure quality control in padel racket production?

Answer: Key measures include rigorous pre-production material testing, continuous real-time monitoring during manufacturing, comprehensive post-production performance trials, and a robust feedback system for process optimization.

-

lab testing: Click to learn about the methods and standards used in laboratory testing that ensure padel rackets meet rigorous performance and durability requirements. ↩ ↩

-

performance validation: Click to explore how performance validation measures confirm that sports equipment exceeds predefined benchmarks for reliability and efficiency. ↩ ↩

-

glass fiber: Click to understand the properties of glass fiber, its role in enhancing flexibility, and why it is chosen for certain padel racket designs. ↩ ↩

-

carbon fiber: Click to read about the different grades of carbon fiber, its high strength-to-weight ratio, and its critical importance in producing high-performance sports equipment. ↩ ↩