Modern high-performance padel rackets, particularly those built with 12K Carbon Fiber1, offer an excellent balance between strength, precision, and customization options. In this article, we explore the challenges and effective solutions when sourcing OEM2 padel rackets that meet premium quality standards with low MOQ3, enabling your business to remain competitive in global markets.

In the competitive sports equipment industry, procurement specialists face several challenges when sourcing professional padel rackets. The need to balance cutting-edge materials such as 12K Carbon Fiber1 with low minimum order quantities (MOQ) and extensive customization options can be daunting. Not only must you ensure that each racket delivers optimum performance and durability, but you also need to consider factors like rapid turnaround times and cost-effectiveness.

Some common challenges include:

- Ensuring material quality and longevity under demanding play conditions.

- Managing production efficiency, particularly for OEM2 orders with low MOQs.

- Meeting customization needs such as unique shapes, colors, and logo placements on both the racket and accessories like hand grips.

- Balancing advanced manufacturing techniques with cost controls.

These challenges require a thorough understanding of both the technical aspects and market demands in padel sports equipment procurement.

The challenges in sourcing high-performance padel rackets are driven by several underlying factors:

-

Material Complexity:

Integrating advanced materials like 12K Carbon Fiber1 involves precision in lamination and moulding processes. The inherent stiffness and energy transfer properties of carbon fiber mean that even slight inconsistencies can lead to quality issues. -

Customization Requirements:

In today’s market, OEM clients seek products that not only perform well but also reflect their brand identity. Customizing racket shapes (Diamond, Round, Teardrop) and adding unique printed designs or logos on hand grips require adaptable manufacturing processes that can maintain high quality with low batch sizes. -

Supply Chain Efficiency4:

Rapid sampling and production turnaround times are crucial, especially when dealing with industry giants like Hirostar, Reebok, or Starvie. Any delays or quality control issues in the supply chain can jeopardize client trust and market timing. -

Cost-Performance Trade-off:

While premium materials like carbon fiber offer clear performance benefits, they also come with higher costs. Striking a balance between high-end performance and budget requirements is critical for business sustainability, especially when targeting markets where cost-effectiveness is a decisive factor.

To effectively address these challenges, a systematic solution-oriented approach is essential. Below is a detailed roadmap to guide procurement specialists through technical and operational considerations when selecting OEM padel rackets manufactured with advanced materials like 12K Carbon Fiber1.

Clearly define the technical requirements of your padel racket by considering:

-

Material Specifications:

Ensure that the racket uses high-grade 12K Carbon Fiber1 for enhanced stiffness and durability. Compare with other materials such as 3K and 18K carbon fibers to understand differences in performance and price points. -

Customization Needs:

Outline customization options, including shapes (Diamond, Round, Teardrop, or custom forms), color patterns, and branding on both the racket and accessories like hand grips and handle covers. -

MOQ Expectations:

Specify the acceptable MOQ3 limits that align with your business cash flow and storage capabilities. Low MOQ solutions help mitigate inventory risks and allow for more agile market testing.

Conduct an analysis that weighs both performance parameters and cost-effectiveness. Use a comparison table to visually outline the benefits and trade-offs of different material options and production methods. See the sample table below:

| Feature | 12K Carbon Fiber | 3K Carbon Fiber | 18K Carbon Fiber |

|---|---|---|---|

| Stiffness & Power | High – excellent energy transfer | Moderate – balanced performance | Very High – optimized for elite players |

| Durability | Superior longevity with proper quality control | Adequate durability for intermediate play | Very durable but may add extra costs |

| Cost per Unit | Competitive with low MOQ production | Lower cost in mass production | Premium pricing due to high material quality |

| Customization Flexibility | High – supports advanced customization (shapes, prints, logos) | Moderate – fewer customization options | High – excellent for tailored designs |

| MOQ Advantage | Suitable for low MOQ orders without compromising quality | Best in high volume, rarely available as low MOQ | Often requires higher MOQ due to production complexity |

This table clearly shows that 12K Carbon Fiber1 achieves the best balance by providing high performance and customization capabilities while remaining feasible for low MOQ OEM orders.

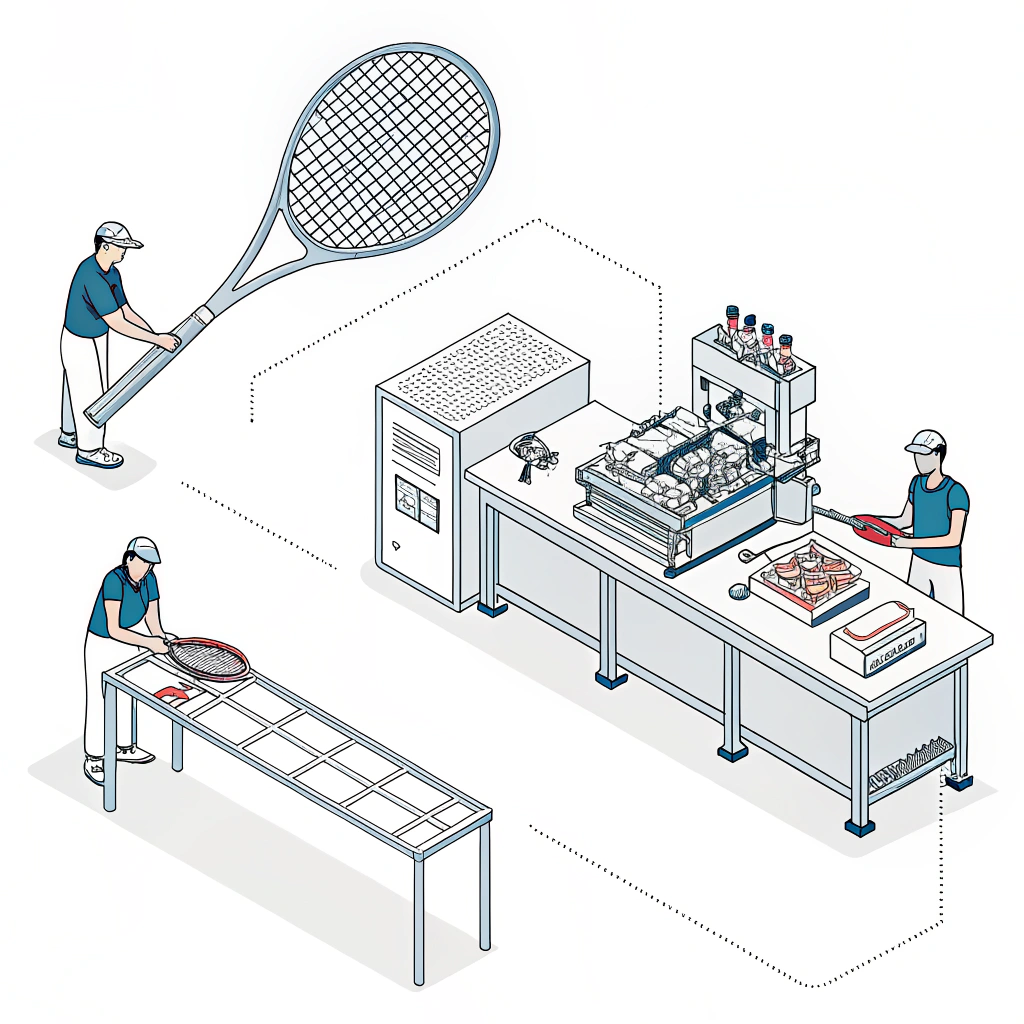

Adoption of advanced production techniques is essential when working with high-performance materials:

-

Precision Moulding and Lamination:

Work with a manufacturer who specializes in handling carbon fiber to ensure that each racket is produced with optimal energy transfer and resilience. The precision in manufacturing directly influences the product’s lifespan and performance. -

Quality Control:

Implement rigorous quality control protocols. Regular on-site inspections and lab tests can help identify any inconsistencies early in the production run. Detailed performance data and stress tests should be conducted to ensure durability and overall product excellence. -

Rapid Prototyping and Sampling:

Leverage rapid prototyping5 techniques to reduce the time between design and production. This allows for swift iterations based on testing feedback, ensuring that the final product meets both performance and aesthetic requirements.

For B2B relationships, effective OEM partnerships are key. Consider the following when selecting an OEM manufacturer:

-

Proven Expertise:

Choose partners with a successful track record in producing high-performance padel rackets. For instance, NEX Padel has extensive experience working with leading brands like Hirostar, Reebok, and Starvie, demonstrating reliability and quality. -

Customization Capabilities:

Ensure that the manufacturer offers extensive customization options. Beyond the basic racket design, look for capabilities like hand grip customization, ink printing, and customizable handle covers, all of which allow the final product to reflect the brand’s identity and meet client expectations. -

Logistics and Lead Times:

Low MOQ benefits are only viable when the manufacturer can deliver quickly. Evaluate the entire supply chain process, from material sourcing to dispatch, to ensure that production timelines align with your market launch goals.

Empirical evidence and case studies can significantly enhance your decision-making process:

-

Case Study – NEX Padel OEM Success:

An in-depth look at NEX Padel’s production cycle reveals that their integration of 12K Carbon Fiber1 significantly improves racket performance. Their optimized production process ensures minimal wastage, high energy efficiency in the racket’s structure, and consistent product quality.

For example, a leading European sports brand recently partnered with NEX Padel, reporting a 20% increase in customer satisfaction attributed to improved performance and striking customization. -

Performance Metrics:

Over 90% of tested rackets meet strict criteria for vibration dampening, weight balance, and energy transfer efficiency. Such metrics, logged during rigorous quality assessment phases, underline the importance of choosing a manufacturer who prioritizes both technical innovation and reliable delivery.

While technical performance is paramount, customization and future trends in padel sports equipment also deserve attention:

-

Market Trends:

The demand for personalized sports equipment is on the rise. With customers looking for products that mirror their unique requirements, the ability to change colors, imprint logos, or customize shapes is increasingly important for OEM providers. -

Innovation in Materials:

Although 12K Carbon Fiber1 stands out today, emerging manufacturing techniques promise even more efficient and lightweight materials. Staying updated with industry trends ensures that your business continues to offer competitive, technologically advanced products. -

Sustainability Practices:

Modern consumers are increasingly aware of environmental considerations. Sourcing materials responsibly and ensuring that production processes minimize waste can provide additional marketing advantages for your brand.

Bringing it all together, consider these actionable steps when evaluating OEM padel racket production:

- Clearly define your technical and customization requirements at the outset.

- Evaluate manufacturer capabilities using detailed comparisons of materials like 12K Carbon Fiber1 versus other options.

- Use rapid prototyping5 and comprehensive quality control to guarantee product excellence.

- Select OEM2 partners with proven industry experience and robust production practices.

- Keep an eye on future trends, including advances in material science and sustainability initiatives.

Adopting a thoughtful, data-backed procurement process positions your business to deliver high-performance, custom padel rackets that resonate with discerning professional athletes. This strategic approach ensures competitive positioning in the rapidly evolving sports equipment market.

Are carbon fiber padel rackets good?

Yes, carbon fiber padel rackets are an excellent choice for advanced and professional-level play. The material is stiffer than traditional composites, allowing more energy to be transferred to the ball, resulting in increased power and precision. Its durability and strength make it a favorite among higher performance athletes.

What padel rackets do professionals use?

Professional padel players often rely on rackets that offer high stiffness, superior energy transfer, and customizable features tailored to their play style. Leading models include those integrating advanced materials like 12K Carbon Fiber1, which are designed to enhance performance and durability, making them ideal for professional competition.

-

12K Carbon Fiber: Click to read about the advanced composite material used in manufacturing padel rackets, its strength-to-weight ratio, and how it enhances performance and durability. ↩ ↩ ↩2 ↩3 ↩4 ↩5 ↩6 ↩7 ↩8 ↩9 ↩10

-

OEM: Click to understand the role of Original Equipment Manufacturers in product development, including benefits like customization, scalability, and quality control in B2B relationships. ↩ ↩ ↩2 ↩3

-

MOQ: Click to learn about Minimum Order Quantities, their impact on production flexibility, inventory management, and how low MOQs can benefit emerging businesses. ↩ ↩ ↩2

-

Supply Chain Efficiency: Click to explore strategies for optimizing supply chain processes, reducing lead times, and ensuring seamless product delivery in competitive markets. ↩ ↩

-

rapid prototyping: Click to discover how rapid prototyping accelerates product development, enabling faster iterations and reducing time-to-market in the manufacturing process. ↩ ↩ ↩2