Quick Answer: Reducing lead times in padel racket manufacturing relies on optimizing production scheduling1, enhancing supply chain collaboration, and adopting rapid prototyping2 techniques that ensure quality while cutting delays.

In the competitive sports equipment industry, production delays can significantly impact lead times and order turnaround. For padel racket manufacturers, such as NEX Padel, optimizing production scheduling is crucial. Lead time reduction3 is not merely about accelerating processes; it involves refining each step from material procurement to final assembly while ensuring that quality is not compromised. Production managers and supply chain specialists often face challenges such as inconsistent material flows, misaligned vendor schedules, and downtime in production. These challenges can lead to increased costs, unhappy customers, and operational inefficiencies.

Several factors contribute to elongated production schedules. Understanding these root causes is essential:

-

Inconsistent Material Supply: Delays in raw material delivery, such as the various carbon fiber grades (3k, 12k, 18k) and fiberglass, can create bottlenecks that disrupt the entire production cycle.

-

Inefficient Production Scheduling: Without a well-organized schedule, production lines may experience idle time, overlapping tasks, or resource underutilization. This mismanagement affects overall efficiency.

-

Suboptimal Vendor Collaboration: Multiple parties, including suppliers of padel balls and customized components like hand grips or logos, are involved. Poor communication or misaligned production timelines with these partners can result in delays.

-

Rapid Prototyping Complexity: Although rapid prototyping2 is one of the industry's major advancements, the challenge lies in balancing speed with thorough quality control. If initially unrefined, prototypes might need several iterations, further delaying mass production.

-

Quality Assurance Procedures: While critical to deliver a high-performance product, excessive or redundant quality control measures without integration in the production flow can slow down the process.

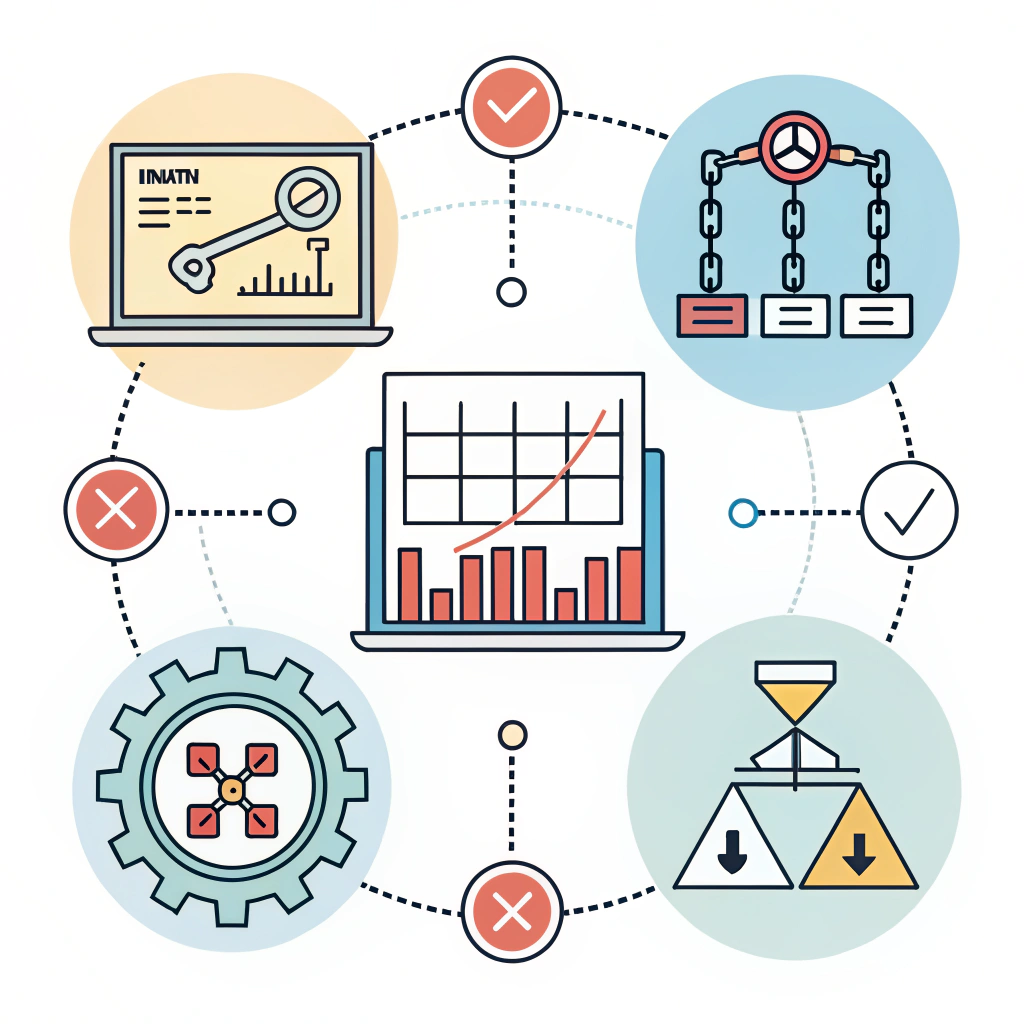

To manage and mitigate the delays caused by these challenges, a well-structured approach is required. The following table outlines key areas for improvement, common challenges, and proposed solutions.

| Key Area | Common Challenges | Proposed Solutions |

|---|---|---|

| Material Procurement | Unreliable supplier schedules | Develop long-term supplier partnerships and automated ordering systems |

| Production Scheduling | Overlapping tasks, resource mismanagement | Implement advanced scheduling software and lean manufacturing4 principles |

| Vendor Collaboration | Miscommunication and misaligned timelines | Set clear SLAs, engage in regular cross-functional meetings |

| Rapid Prototyping & Quality Control | Multiple iterations causing delays; redundant testing | Integrate rapid prototyping with quality checkpoints and feedback loops |

| Inventory Management | Excess inventory or shortage due to forecasting issues | Use data-driven demand forecasting and real-time inventory tracking systems |

Why It Matters: A streamlined supply chain ensures that the production process receives a consistent flow of high-quality raw materials.

How to Improve:

- Long-Term Partnerships: Foster relationships with key suppliers to secure priority in material delivery.

- Automated Reordering: Implement electronic data interchange (EDI)5 systems to trigger automatic orders when inventory reaches a predefined threshold.

- Quality Assurance Integrated with Supply: Conduct routine supplier assessments to ensure materials meet quality standards on the first delivery.

Why It Matters: Efficient scheduling minimizes downtime and syncs various production stages seamlessly.

How to Improve:

- Integrative Scheduling Software: Invest in software solutions that incorporate machine learning to predict and adjust production bottlenecks.

- Lean Manufacturing Principles: Apply lean methodologies to reduce waste and improve production flow. This involves techniques like Just-In-Time (JIT) production, where every component is available exactly when needed.

- Cross-functional Coordination: Ensure that production, procurement, and quality control teams have synchronized schedules with regular status updates and forecast reviews.

Why It Matters: In a process that involves multiple suppliers and contract manufacturers, clear communication is indispensable.

How to Improve:

- Regular Meetings: Schedule periodic union meetings with vendors to review performance metrics, discuss potential delays, and plan for upcoming production cycles.

- Shared Data Platforms: Utilize shared databases where both parties can track orders, quality tests, and production progress in real-time.

- Clear Contractual SLAs: Define Service Level Agreements (SLAs) with detailed timelines and penalties for delays, ensuring accountability across the board.

Why It Matters: Rapid prototyping enables faster product innovation but must be balanced with quality checks to avoid repeated iterations.

How to Improve:

- Iterative Feedback Loops: Shorten the cycle by integrating immediate feedback from each prototype stage, allowing for quick adjustments.

- Digital Simulation Tools: Use simulation software to minimize physical trials. This can help predict potential issues before a physical prototype is built.

- Consolidate Quality Checks: Rather than multiple standalone quality control sessions, embed quality checkpoints directly into the prototype and production process.

Why It Matters: Efficient inventory management prevents both overstocking and shortages, which can be detrimental to production timelines.

How to Improve:

- Data-Driven Forecasting: Utilize analytics to predict demand trends, especially during peak seasons or special order surges.

- Inventory Automation: Implement automated tracking systems that update inventory levels in real-time for quick decision-making.

- Flexible Storage Solutions: Adopt modular inventory systems that allow for quick pivots when production needs change.

NEX Padel faced challenges with increasing lead times due to irregular deliveries and inconsistent production schedules. By integrating an advanced scheduling system and forming tighter vendor alliances, the company experienced a 20% decrease in lead time over six months.

Key steps implemented included:

- Automating order triggers for raw materials.

- Setting up weekly cross-department meetings to review production schedules and address bottlenecks.

- Introducing simulation software to refine rapid prototyping processes.

This case study underlines that even minor adjustments in scheduling and supplier management have significant impacts on operational efficiency. It reinforces that reducing the lead time is achievable through systematic process improvements and technology integration.

While implementing the above solutions, it is crucial to watch out for:

-

Integration Complexity: Introducing new systems like advanced scheduling software may require a time investment and initial training. Ensure staff are well-trained to adapt to these systems.

-

Supplier Dependency: Over-reliance on a single supplier can create vulnerabilities. Diversify suppliers to avoid risks associated with supply chain disruptions.

-

Quality vs. Speed Trade-Off: Balance rapid prototyping with quality checks. Rushing the prototyping phase could lead to more iterations and negate the time saved.

-

Cost Implications: Initial investments in technology and training can be high. Conduct a cost-benefit analysis to ensure that the long-term gains justify the expense.

For production managers and supply chain specialists aiming to reduce lead times in padel racket manufacturing, consider these actionable steps:

- Conduct a Detailed Audit: Start with a comprehensive review of your current production schedules and supply chain efficiency. Identify key areas where delays occur.

- Invest in Technology: Prioritize software tools that align with your production needs, particularly those that provide real-time tracking and predictive scheduling.

- Foster Vendor Relationships: Build stronger collaborations with all vendors involved, ensuring consistent communication and synchronization across the board.

- Embrace Lean Methods: Incorporate lean manufacturing practices to minimize waste and streamline production flow.

- Review and Adapt Regularly: Production processes should be dynamic. Regularly review schedules, supplier performance, and inventory levels to adapt quickly to changing demands.

By following these recommendations, businesses can not only reduce their lead times but also improve overall quality control and operational efficiency. These improvements directly contribute to better customer satisfaction and enhanced competitiveness in the market.

Q1: What production scheduling techniques help reduce lead times in padel racket manufacturing?

A1: Effective production scheduling techniques, such as software-driven scheduling and lean manufacturing principles like Just-In-Time (JIT), align production tasks and optimize resource allocation. Regular cross-functional meetings further ensure that supplier deliveries and production timelines remain synchronized.

Q2: How can supply chain collaboration improve order turnaround in sports equipment manufacturing?

A2: Strong supply chain collaboration enhances order turnaround by establishing clear service level agreements, regular status meetings, and shared platforms for tracking production progress. This alignment minimizes delays and ensures that all parties are aware of timing and quality requirements.

Q3: What role does rapid prototyping play in reducing production delays?

A3: Rapid prototyping accelerates the product development cycle by allowing manufacturers to quickly test and refine new designs. When integrated with iterative feedback and digital simulation tools, rapid prototyping minimizes the time spent on multiple physical iterations, thereby reducing overall production delays.

-

production scheduling: Click to understand how optimized production scheduling can streamline operations, reduce downtime, and improve overall process efficiency. ↩ ↩

-

rapid prototyping: Click to explore the benefits and challenges of rapid prototyping techniques in accelerating product development and reducing iteration cycles. ↩ ↩ ↩2

-

Lead time reduction: Click to learn more about strategies and best practices for minimizing the time between order initiation and product delivery in a manufacturing environment. ↩ ↩

-

lean manufacturing: Click to discover lean manufacturing methodologies that minimize waste and enhance production efficiency through techniques like Just-In-Time (JIT). ↩ ↩

-

electronic data interchange (EDI): Click to read about how electronic data interchange systems automate procurement processes and improve supply chain coordination. ↩ ↩