Our Manufacturer Padel Racket with a monthly output of 48,000 pieces offers the capacity, reliability, and customization flexibility that procurement managers need to secure a stable supply of high-quality sporting equipment. This output, demonstrated through advanced production techniques and rigorous quality control, positions us as a top partner for large-scale orders in the competitive padel market.

In today’s rapidly evolving sports equipment market, ensuring a consistent and quality supply is paramount. For procurement professionals responsible for sourcing padel rackets, the ability to place large orders without compromising on quality or customization options is a key decision criterion. With a monthly production capacity of 48,000 pieces, our manufacturing facility is engineered to sustain high volume outputs while delivering precision, durability, and tailored solutions that meet specific market demands.

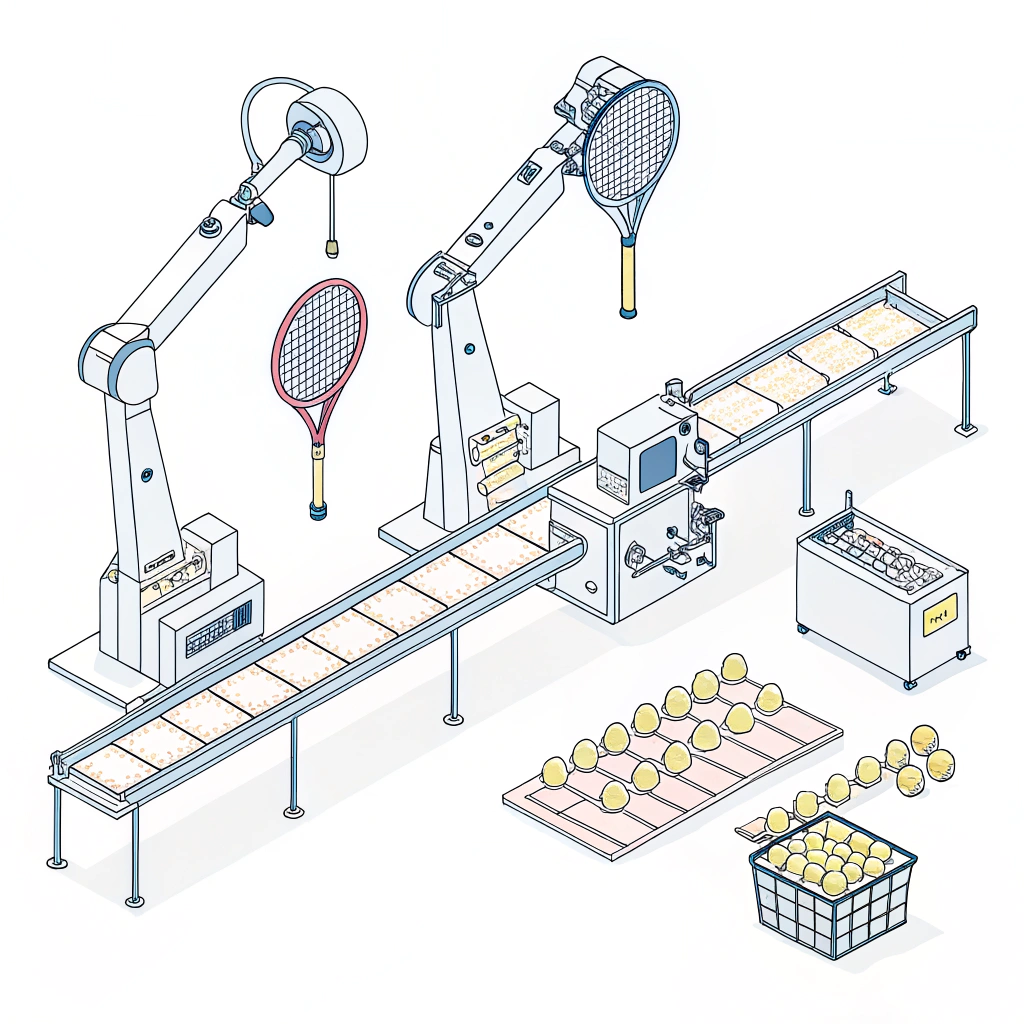

One of the core strengths of our operation is the integration of advanced manufacturing techniques1. Our state-of-the-art production lines, combined with skilled technicians, ensure that every padel racket meets exacting standards. We work with a diverse range of materials, from fiberglass to various grades of carbon fiber2 such as 3k, 12k, and 18k, to cater to different player levels—from beginners to seasoned professionals.

Our commitment to quality begins with raw material selection and extends through every step of production. Every padel racket undergoes multiple quality control checks to meet both durability and performance benchmarks. This rigorous process guarantees that even with a high production volume, each piece maintains its performance integrity.

In the competitive world of padel sports, customization is a significant advantage. We offer three main shapes—Diamond, Round, and Teardrop—as well as fully customized shapes to adhere to specific performance or aesthetic preferences. Customization goes beyond shape; we also offer options for printed designs and color variations, ensuring that each client’s brand identity is well-represented.

Additionally, our customization services extend to accessories such as hand grips and grip covers3. These components can be printed with custom logos and tailored to match specific color schemes. Such flexibility is essential for sports clubs and distribution companies that need to differentiate themselves in a crowded market.

Our manufacturing process supports a high degree of agility, meaning we can adapt quickly to market trends and specific order requirements without causing delays in the overall supply chain.

Procurement managers evaluating large-scale manufacturing partners must consider several factors to ensure a reliable supply chain. Below is a comparative table summarizing key production metrics:

| Production Metric | Our Manufacturer | Industry Standard |

|---|---|---|

| Monthly Output | 48,000 pieces | 20,000-35,000 pieces |

| Quality Control | Multi-level QC checks at various stages | Basic final product inspection |

| Variety of Materials | Fiberglass, 3k, 12k, 18k carbon fiber2 | Typically limited to one or two material grades |

| Customization Options | Full customization on shape, printing, grips | Partial or standard options only |

| Lead Time4 | Rapid sample production and timely delivery | Longer lead times under high-demand conditions |

| Production Technology | Advanced production line with precision robotics | Traditional assembly with manual oversight |

This detailed comparison illustrates our dedication to not only meeting but exceeding industry standards in every aspect of production, ensuring that our partners can confidently rely on us for every order.

In the realm of high-volume manufacturing, flexibility is as crucial as capacity. Our production lines are designed to handle sudden surges or unexpected changes in order volume without compromising product quality. This scalability is particularly beneficial when catering to major sports events or establishing long-term supply relationships.

Flexibility in production is supported by our use of modular manufacturing techniques. This modern approach allows us to swiftly shift between different product specifications—whether switching from a Diamond-shaped to a Teardrop racket or adapting color schemes based on seasonal trends. Such adaptability ensures that our clients can always meet market demands and capitalize on emerging opportunities.

A high monthly production output might raise concerns about potential sacrifices on quality. However, our production process is built on a layered quality assurance framework that includes:

- Raw Material Inspection: Every batch of imported or locally sourced material is tested to ensure it meets the required specifications.

- In-Process Testing: Automated sensors and manual checks work in tandem to monitor the production process continuously.

- Final Product Testing: Completed rackets undergo thorough testing for durability, balance, and overall performance before they are approved for shipment.

- Custom Quality Reviews: For orders with specialized customization, additional QC steps are performed to confirm that each specification matches the client's demands.

These measures collectively guarantee that our padel rackets are not only robust and aesthetically pleasing but also engineered to deliver superior performance on the court.

In the B2B sports equipment sector, having reliable partners is indispensable. Our high-output manufacturing capability has enabled us to serve leading brands such as Hirostar, Reebok, and Starvie, underlining the trust placed in our production and customization prowess. By consistently aligning our production strategies with market needs and technological advancements, we have carved a niche that appeals to procurement professionals seeking both quality and dependability.

Furthermore, our production philosophy emphasizes quick response times. High-order volumes do not hinder our ability to offer rapid sample production and timely deliveries—two critical factors when participating in fast-paced sporting markets or major international tournaments.

For procurement managers considering a manufacturing partner for padel rackets, the following strategies can help optimize your sourcing decisions:

- Assess Production Capacity: Look beyond basic output numbers and evaluate the technology used and the quality control framework. Our capacity of 48,000 pieces per month is a testament to both our technological investment and production agility.

- Prioritize Customization Needs: Ensure your manufacturing partner can offer the level of customization that aligns with your branding requirements. With options across racket shapes, color, and accessory customization, our offerings stand out in a competitive market.

- Investigate Lead Time4 and Sample Production: Rapid sample production and reliable lead times are vital during peak season or when launching new product lines. Our proven record of expedited sample turnaround and on-time deliveries makes us an ideal partner.

- Compare Quality Control Standards: A detailed look at quality control measures can reveal important insights into production consistency. Our multi-tier quality check process is designed to guarantee that every piece leaving the production line meets premium performance standards.

By focusing on these areas, procurement professionals can ensure that they are not only meeting current market demands but are also poised for future growth. The combination of high production volume, robust quality control, and extensive customization possibilities makes our manufacturing approach a strategic investment for those looking to secure a competitive edge in the market.

In conclusion, our manufacturing capabilities, which include a consistent output of 48,000 padel rackets per month, advanced production techniques, and a comprehensive quality control framework, offer a compelling solution for businesses in the sports equipment sector. This blend of high volume production, flexibility in customization, and unwavering commitment to quality ensures that our partners can always supply the market with premium, tailor-made padel rackets. For procurement managers, choosing a partner with these capabilities means aligning with a manufacturer who not only meets but exceeds industry expectations, paving the way for long-term success and market growth.

People Also Ask

Q: What is the best brand for padel rackets?

A: The best brand for padel rackets varies by player preference and market trends. Top brands like Babolat, NOX, and HEAD are widely recognized, with each offering unique features tailored to different play styles. Our focus is on high-quality production allowing for customized solutions that meet diverse market needs.

Q: What is the best budget padel racket?

A: The best budget padel racket ultimately depends on a buyer's specific requirements. While several brands offer affordable models with good performance, our manufacturing process supports a range of cost-effective customization options that ensure both quality and value, meeting the needs of various budgets without sacrificing performance.

Q: Do expensive padel rackets make a difference?

A: Expensive padel rackets often feature enhanced materials and refined production techniques that may benefit experienced players by offering improved durability and performance nuances. However, for beginners or intermediate players, the higher cost does not always translate into better performance. It is essential to balance price with personal skill level and playing style to determine the most suitable option.

-

advanced manufacturing techniques: Click to read an article detailing modern production methods that enhance precision and efficiency in manufacturing processes. Back to term ↩

-

carbon fiber: Click to learn about different grades of carbon fiber, their properties, and how they are used to achieve optimal performance and durability in sporting equipment. Back to term ↩ ↩2

-

hand grips and grip covers: Click to discover how custom hand grips and grip covers can enhance user comfort and brand identity, along with insights into material choices and design trends. Back to term ↩

-

Lead Time: Click to explore the concept of lead time in manufacturing, its impact on production scheduling, and strategies to minimize delays for timely delivery. Back to term ↩ ↩2