Nex Padel is a leading manufacturing partner for high-performance padel paddles, offering customized solutions through advanced production techniques, broad material selection, and fast prototyping, all designed to meet the demanding criteria of global sports equipment brands.

When sourcing padel equipment, procurement managers and product development heads require a partner who can deliver not just quality, but also innovation and reliability. Nex Padel has positioned itself as a top OEM1 for padel paddles by leveraging advanced production techniques, versatile material choices, and a robust customization process. Our manufacturing capabilities allow us to produce paddles tailored to your brand, whether you need Diamond, Round, or Teardrop shapes, alongside custom printing, logo applications on hand grips, and more.

Our factory, based in Jiaxing, Zhejiang, China, is outfitted with modern machinery and quality control systems that ensure every paddle meets the highest performance standards. We support various carbon fiber2 grades—including 3K, 12K, and 18K carbon—to provide the right balance between power, precision, comfort, and durability. Fast prototyping3 and timely delivery are key features that differentiate our service in a competitive market.

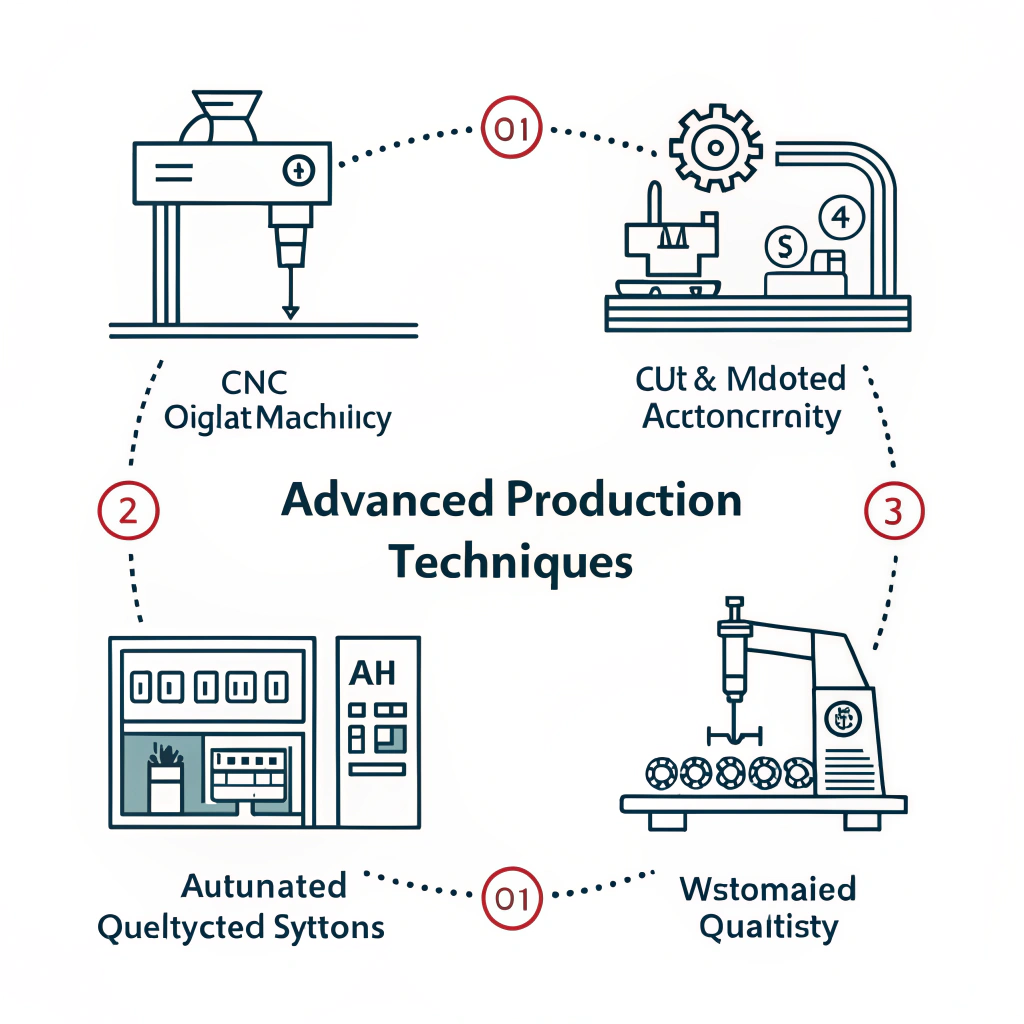

In an industry where precision is everything, our production techniques are built upon a detailed understanding of both raw materials and end-user performance requirements. Below, we outline the key components of our custom production process:

- Design Consultation: Engage with our technical team to discuss your specific design preferences (such as Diamond, Round, or Teardrop paddle shapes) and desired aesthetic elements like custom printing and color schemes.

- Material Selection: Choose from an extensive range of material grades. Our advanced production lines support various carbon fiber options to optimize paddle performance.

- Rapid Prototyping: Utilizing fast prototyping methods, we deliver sample paddles for on-field testing, ensuring that design choices translate seamlessly into performance.

- Strict Quality Control: Every paddle undergoes rigorous testing to ensure it meets durability, rigidity, and balance standards. Our quality control protocols are in line with international benchmarks.

- Flexible Order Quantities: Whether you require small-scale production for new models or large volumes for established lines, our systems are tailored to meet your specific requirements.

This step-by-step process ensures that every project gets the attention it deserves and meets strict quality expectations, which is crucial in decision-making for B2B buyers.

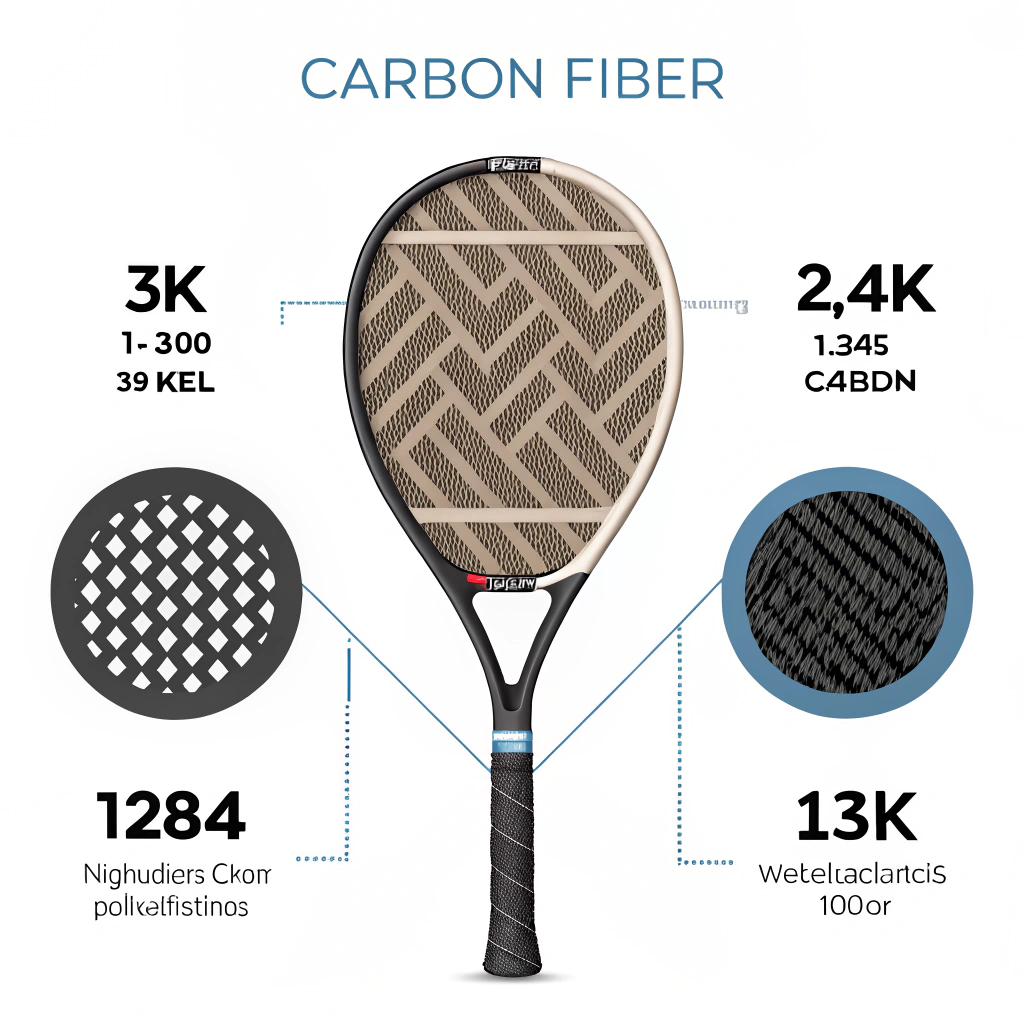

One of the critical decisions in padel paddle manufacturing is the selection of the right carbon fiber grade. At Nex Padel, we offer multiple grades such as 3K, 12K, and 18K carbon. Each type brings distinct benefits:

| Carbon Fiber Grade | Characteristics | Recommended For |

|---|---|---|

| 3K Carbon | Softer, more elastic, provides increased comfort and forgiveness | Beginners or players seeking enhanced touch and control |

| 12K Carbon | Balanced rigidity and flexibility; more precise than 3K | Intermediate players looking for a mix of power and control |

| 18K Carbon | Highest rigidity, resulting in superior power and precision for advanced techniques | Seasoned players with refined techniques requiring high impact and precision |

Our selection allows you to fine-tune the paddle’s performance characteristics based on your target market's needs. Integrating advanced materials directly influences the playability and durability of each paddle, giving your brand a competitive edge.

Paddle shape is a key consideration in achieving the desired balance between power and maneuverability. At Nex Padel, we offer three primary designs:

- Diamond Paddle: Known for its forward balance, the Diamond paddle is designed to maximize power during offensive play. It is suitable for aggressive players who rely on strong, forceful strokes.

- Round Paddle: With a center of gravity that supports excellent control and precision, the Round paddle is ideal for players focusing on balanced performance with a softer touch.

- Teardrop Paddle: Combining elements of both Diamond and Round designs, the Teardrop paddle provides a blend of power and control, making it a versatile option for a variety of playing styles.

A key benefit of our OEM production is the flexibility to offer full customization. Whether you need unique color schemes, bespoke printing, or personalized hand grip designs, our production line accommodates your brand's individual requirements without compromising on performance.

High-performance products require precision engineering and stringent quality checks. At Nex Padel, our production framework includes:

- State-of-the-Art Machinery: We use the latest production tools and CNC equipment4 to ensure every paddle is constructed with exacting precision.

- Automated Quality Inspection: Digital Inspection5 systems monitor every stage of production, ensuring that variations in production do not lead to inconsistencies in the final product.

- Data-Backed Production Metrics: Our production metrics are aligned with industry standards. We continuously improve our techniques based on data analytics and feedback from field tests.

- Sustainability Practices: In addition to performance, we focus on sustainable manufacturing practices. Energy-efficient production processes and responsible waste management are core components of our operations.

Our fast prototyping capability means that design iterations can be quickly evaluated and refined, reducing time to market and allowing procurement managers to swiftly respond to market trends.

Several well-known brands already benefit from our OEM expertise. For example, companies like Hirostar, Reebok, and Starvie have relied on our advanced production techniques and customization options to create padel paddles that stand out in the market. These collaborations highlight a few key outcomes:

- Reduced Production Time: Our streamlined processes have enabled partners to dramatically cut the time between design conceptualization and market release.

- Enhanced Product Quality: With rigorous quality control and material testing, our paddles feature consistent performance, leading to higher customer satisfaction.

- Increased Customization: By offering various carbon fiber options and paddle shapes, our partners have been able to target diverse market segments with tailored products.

These case studies underscore the fact that a production partnership with Nex Padel not only provides state-of-the-art manufacturing but also supports the continuous evolution of product design to match dynamic market demands.

Procurement managers and industry decision-makers are constantly looking for manufacturers that can combine innovation, customization, and rapid delivery with unbeatable quality. Nex Padel meets these criteria by:

- Offering full customizability in paddle shape, design, and material composition.

- Utilizing advanced production techniques to ensure precision and consistency.

- Providing flexible production with fast prototyping, ensuring that each order meets market demands and technical requirements.

If you seek a reliable OEM partner who not only understands the technicalities of padel paddle manufacturing but also adapts to your brand’s vision for high-performance sporting products, consider Nex Padel. We invite you to reach out for further discussion, sample evaluation, or a detailed consultation regarding your upcoming padel equipment projects.

Take the next step towards superior product performance by partnering with Nex Padel—the leader in innovation and quality in padel paddle manufacturing.

Q: Who manufactures padel rackets?

A: Leading manufacturers like Nex Padel, as well as renowned brands such as QUAD, are known for their commitment to innovation, quality production, and performance in the padel racket market.

Q: Which brand is best for padel rackets?

A: The best brand for padel rackets can vary based on specific player needs and market focus. While many top brands are known for their excellent product lines, it is crucial to evaluate each manufacturer's production capabilities, customization options, and quality control processes to determine the right fit for your business needs.

Q: Which is better, 3K or 12K carbon?

A: The choice between 3K and 12K carbon depends on the desired performance; 3K carbon is generally softer and offers more elasticity for comfort, while 12K carbon provides greater rigidity, thereby delivering enhanced power and precision for skilled players.

-

OEM: Click to learn more about the Original Equipment Manufacturer model, which explains how OEM partnerships streamline production and enhance product customization for businesses. ↩ ↩

-

Carbon fiber: Click to explore in-depth information on carbon fiber, including its different grades and how each contributes to product performance and durability. ↩ ↩

-

Fast Prototyping: Click to understand fast prototyping processes that accelerate product development cycles, enabling quicker market entry and iterative design improvements. ↩ ↩

-

CNC equipment: Click to review the role of Computer Numerical Control (CNC) equipment in precision manufacturing, highlighting its impact on product quality and consistency. ↩ ↩

-

Digital Inspection: Click to discover how digital inspection systems enhance quality control through real-time monitoring and data-driven analysis during production. ↩ ↩