Padel balls are essential for competitive play, requiring precise quality control, advanced production techniques, and innovative design to ensure performance and durability. At NEX Padel, we combine traditional expertise with advanced manufacturing to deliver balls that meet the highest standards for professional clubs, distributors, and specialty retailers.

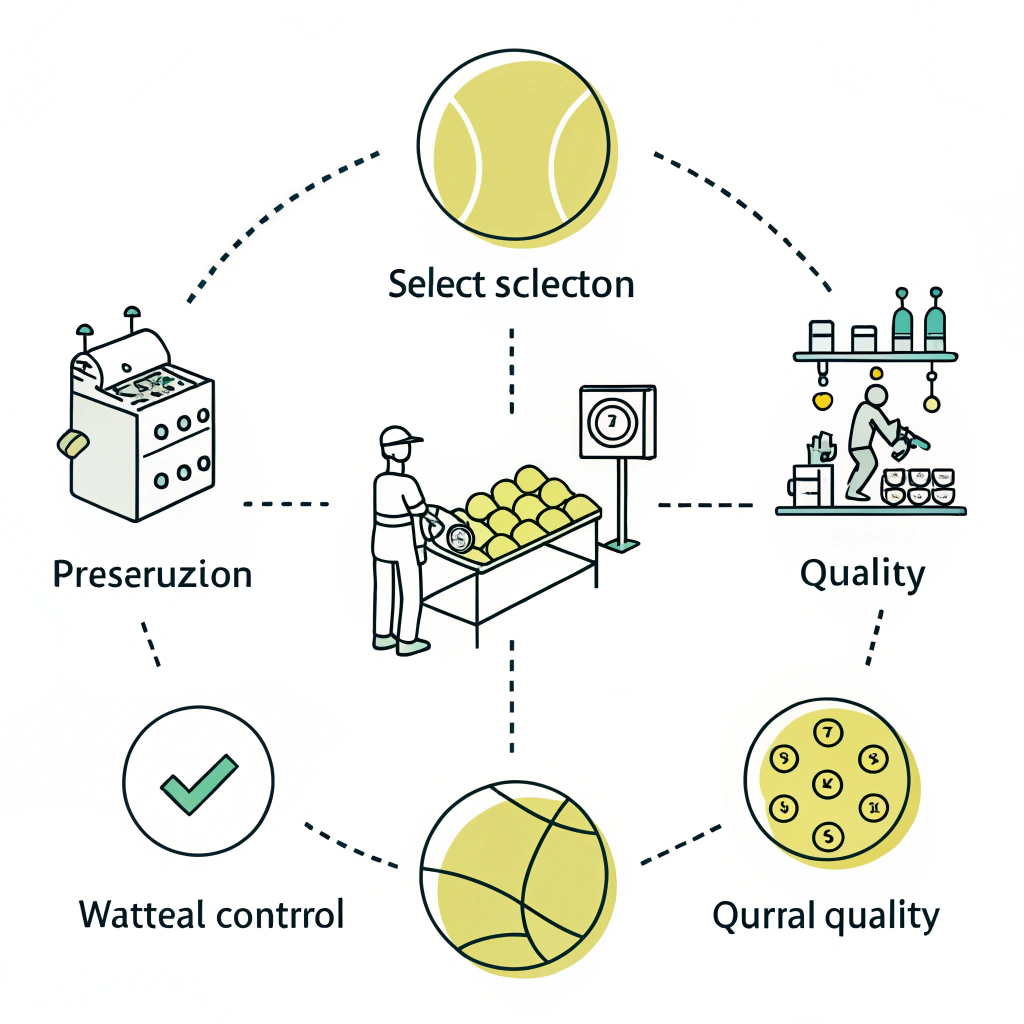

When procuring padel balls, the primary concerns include durability, pressure retention, and consistent performance on the court. High-quality balls are engineered using premium polymer materials and reinforced structures, such as the use of a pressurized tube, to maintain optimal bounce and resilience, even after several matches. Our manufacturing process focuses on factors such as:

• Material Selection – Choosing the right polymers and compounds that offer a balanced mix of elasticity and durability.

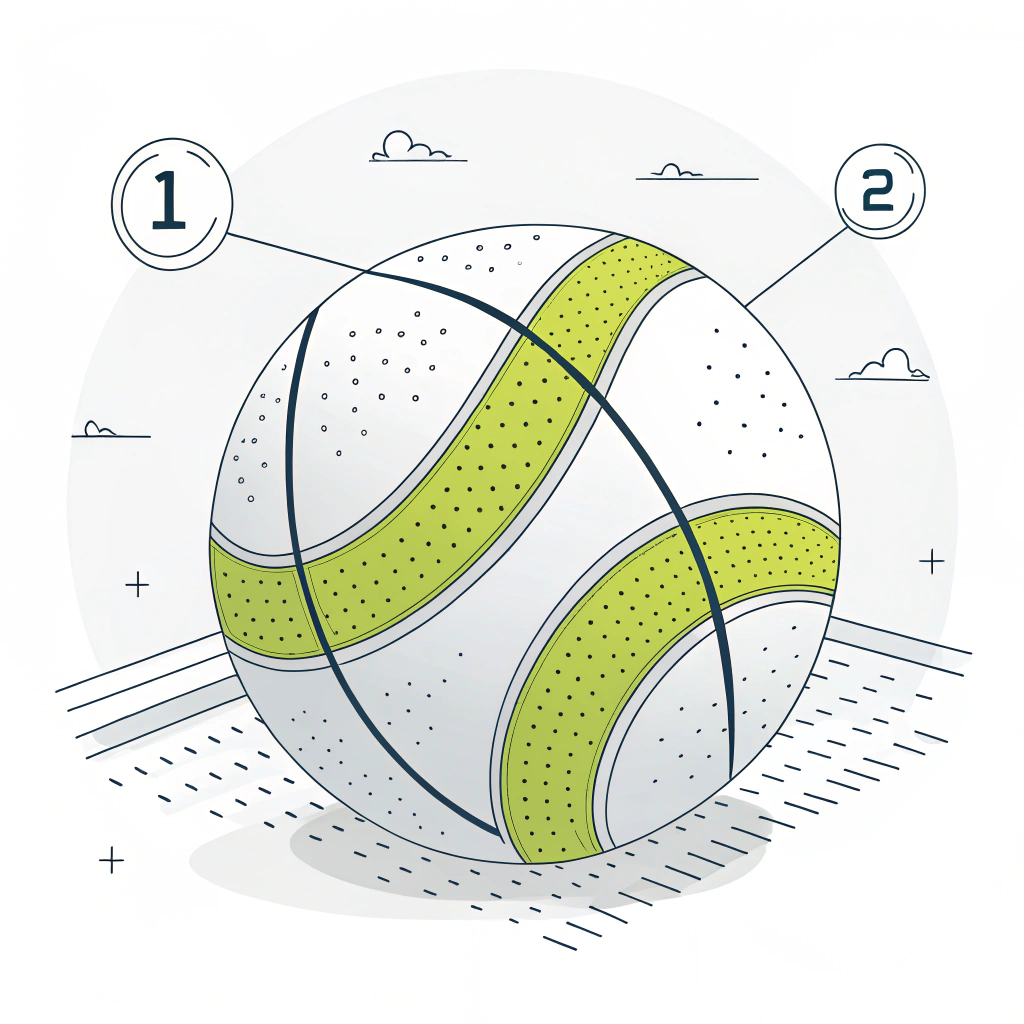

• Pressurization Technique1 – Utilizing advanced pressurization methods to enhance performance consistency.

• Manufacturing Precision2 – Ensuring uniform weight, diameter, and seam integrity for reliable play.

To help you understand these critical aspects better, consider the following table summarizing performance benchmarks:

| Factor | Description | Impact on Performance |

|---|---|---|

| Material Quality | Utilizes high-grade polymers and rubbers | Enhances durability and playability |

| Pressurization Method | Precision pressurized tube manufacturing technique | Maintains optimal bounce over time |

| Manufacturing Tolerance | Strict quality control ensuring minimal variation in weight/size | Consistency across batches |

| Customization Options3 | Options to print logos, adjust pressurization parameters | Tailored solutions for specific needs |

Ensuring that each padel ball performs consistently requires overcoming various production challenges. These include environmental factors during manufacturing, variability in raw materials, and maintaining stringent quality control standards. Below are some common challenges along with our approaches to mitigate them:

-

Temperature and Humidity Control

Production environments must be tightly controlled to avoid premature degradation of pressurized components. Our facilities monitor and regulate these variables, ensuring that each batch of balls retains pressure and elasticity over extended periods. -

Material Consistency

Sourcing raw materials with uniform quality is critical. We partner with trusted suppliers and perform rigorous quality inspections on every material batch. This ensures that polymers used in our balls offer the same performance characteristics, regardless of production volume. -

Manufacturing Precision

The manufacturing process must be optimized to reduce variation. Our state-of-the-art equipment minimizes human error by automating key production processes, resulting in padel balls that meet exacting performance specifications.

Addressing these challenges means that our padel balls are less likely to experience issues such as uneven bounce or pressure loss. This careful attention to detail is critical for clubs and professional players who depend on consistent performance during matches.

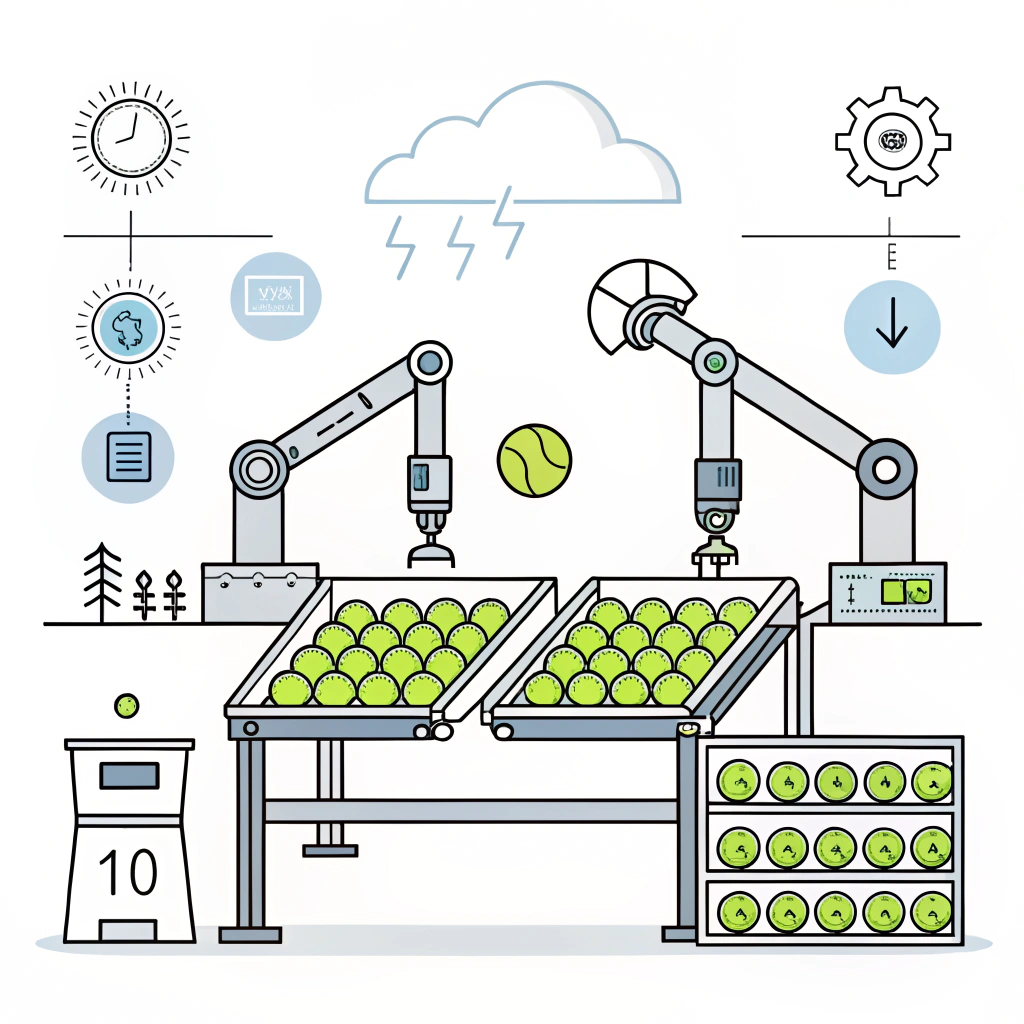

At NEX Padel, we understand that B2B customers require more than off-the-shelf products. Customization is a significant aspect of our offering, especially when it comes to padel balls. Our advanced production techniques include:

- State-of-the-Art Automation4: Utilizing robotic systems to form and pressurize each ball with unparalleled precision.

- Custom Pressure Settings: Allowing adjustments in the pressurized tube techniques to match specific court conditions or competitive requirements.

- Tailored Aesthetics: Branding options allow clubs and retailers to incorporate their logos or unique color schemes directly into the production process. This differentiation not only enhances visual appeal but also strengthens brand identity on the playing field.

For instance, some of our clients specify certain weather-related performance characteristics. In response, we adjust our manufacturing parameters to optimize performance for outdoor courts or high-humidity settings. This level of customization has made us a trusted partner for brands that require both standard excellence and bespoke production solutions.

Below is a simplified workflow diagram outlining our production process:

| Step | Description | Benefit |

|---|---|---|

| Material Inspection | Quality check of raw polymers | Ensures material uniformity |

| Automated Forming Process | Robotic molding of the ball structure | Consistency and precision |

| Pressurization Module | Controlled pressurized tube installation | Maintains bounce and durability |

| Custom Branding | Application of customized logos and color schemes | Enhances market differentiation |

| Final Quality Control5 | Comprehensive inspection before packaging | Guarantees superior product performance |

Our commitment to quality is evidenced in every stage of production. We perform multi-level quality checks from raw material sourcing to final product packaging. The key quality control measures include:

• In-Process Inspections – Continuous monitoring during the production process to catch defects early.

• Performance Testing – Subjecting padel balls to accelerated usage tests that simulate multiple matches to verify durability and pressure retention.

• Final Batch Testing – Randomized testing of finished products to ensure they meet industry standards.

These processes not only help in identifying any potential issues but also allow us to fine-tune our production methods, ensuring that even under high-performance conditions, our padel balls maintain their integrity and offer consistent performance.

A couple of statistical insights from our in-house studies include:

- Over 95% of our padel balls pass the final batch testing without any pressure drop beyond acceptable limits.

- Durability tests indicate that our balls sustain optimal performance for an average of 3 to 5 matches under standard conditions, which is a benchmark in the industry.

This rigorous approach to quality control ensures that our products remain reliable even in competitive, real-world environments.

Consider a scenario where a prominent club required padel balls tailored for both indoor and outdoor play. The club faced issues with standard padel balls losing pressure too quickly during extended play. They approached us seeking a durable solution with specific branding elements.

We addressed the club’s requirements by:

- Custom Material Selection: We fine-tuned the polymer blends to enhance durability while maintaining performance across different environmental conditions.

- Optimized Pressurization: Adjusted our pressurized tube process to improve pressure retention, even under harsh outdoor conditions.

- Branded Customization: Implemented custom printing options to incorporate the club's logo and color scheme.

By adapting our production process to meet these needs, the club experienced a significant improvement in ball performance, including fewer interruptions during matches due to equipment failure. This case study clearly demonstrates our capability to tailor manufacturing processes for varied market requirements, ensuring that every client receives a product that meets or exceeds their performance expectations.

When evaluating suppliers for padel balls, procurement managers must consider several practical aspects:

• Product Consistency – It is essential that the supplier demonstrates rigorous quality control protocols to ensure that every batch of balls performs consistently.

• Customization Capabilities – The ability to personalize products with specific performance tweaks, visual branding, and custom packaging is paramount in today's competitive market.

• Timely Delivery – Manufacturing partners with proven lead times and rapid prototyping capabilities can enable clubs and retailers to keep up with market demand without interruption.

Additionally, engaging with a supplier who has extensive industry experience and a commitment to innovation can result in long-term benefits. Not only do you get a superior product, but you also gain a partner who understands the evolving demands of modern padel sports equipment.

In our experience, combining technical manufacturing expertise with flexible custom solutions allows procurement teams to meet both the operational and branding needs of their organizations. Whether you are a club looking to provide your players with reliable equipment or a distributor aiming to enhance your market offering with high-performance padel balls, aligning with a knowledgeable and responsive manufacturer is critical.

In summary, when considering padel ball suppliers, assess their production capabilities, quality control processes, and customization options carefully. A thorough evaluation will ensure that the products you procure perform reliably under the demands of competitive play and enhance the overall playing experience.

At NEX Padel, we pride ourselves on our comprehensive approach to padel ball manufacturing. Our blend of advanced production techniques, strict quality control, and customization flexibility makes us a reliable partner for B2B clients looking for excellence in sports equipment. We invite procurement managers and sports equipment buyers to explore our production capabilities further and to experience the benefits of partnering with a manufacturer who not only meets industry standards but sets them.

For further inquiries into our production methods, pricing models, or custom solutions, please contact our dedicated B2B support team at NEX Padel. We are committed to helping you make informed decisions that drive your competitive edge on the court.

People Also Ask

Q: What are the best padel balls to buy?

A: The best padel balls are those that combine excellent durability, consistent pressure retention, and superior performance. Leading brands like Bullpadel, Head, Babolat, and Wilson are well-regarded for their quality. However, a reliable supplier like NEX Padel offers advanced production techniques and customization options, ensuring you get high-performance balls tailored to your needs.

Q: How often should you replace padel balls?

A: Under normal conditions, padel balls can typically last between 3 to 5 matches. For regular play or when used on abrasive court surfaces, balls may need replacement sooner, as continuous play can lead to quicker degradation of performance.

-

Pressurization Technique: Click to read an article that explains how advanced pressurization methods enhance ball performance by maintaining optimal pressure and bounce characteristics. ↩ ↩

-

Manufacturing Precision: Click to learn about the importance of precise manufacturing processes in ensuring product consistency and reliability for competitive play. ↩ ↩

-

Customization Options: Click to explore how tailored production solutions, including logo printing and performance adjustments, can help you meet specific market needs. ↩ ↩

-

State-of-the-Art Automation: Click to discover how robotic systems and automation reduce human error and improve production efficiency in modern manufacturing facilities. ↩ ↩

-

Final Quality Control: Click to read about rigorous quality control measures that ensure every product meets industry standards and performs reliably. ↩ ↩