Padel court construction requires a balanced mix of precise design, durable materials, and cost-effective planning. In this article, we quickly answer that building a high-quality Padel court construction1 typically costs between $24,000 and $65,000. We will walk through essential components including material selection, proper dimensions, regulatory requirements, and installation guidelines to help facility managers and sports club owners make an informed investment decision.

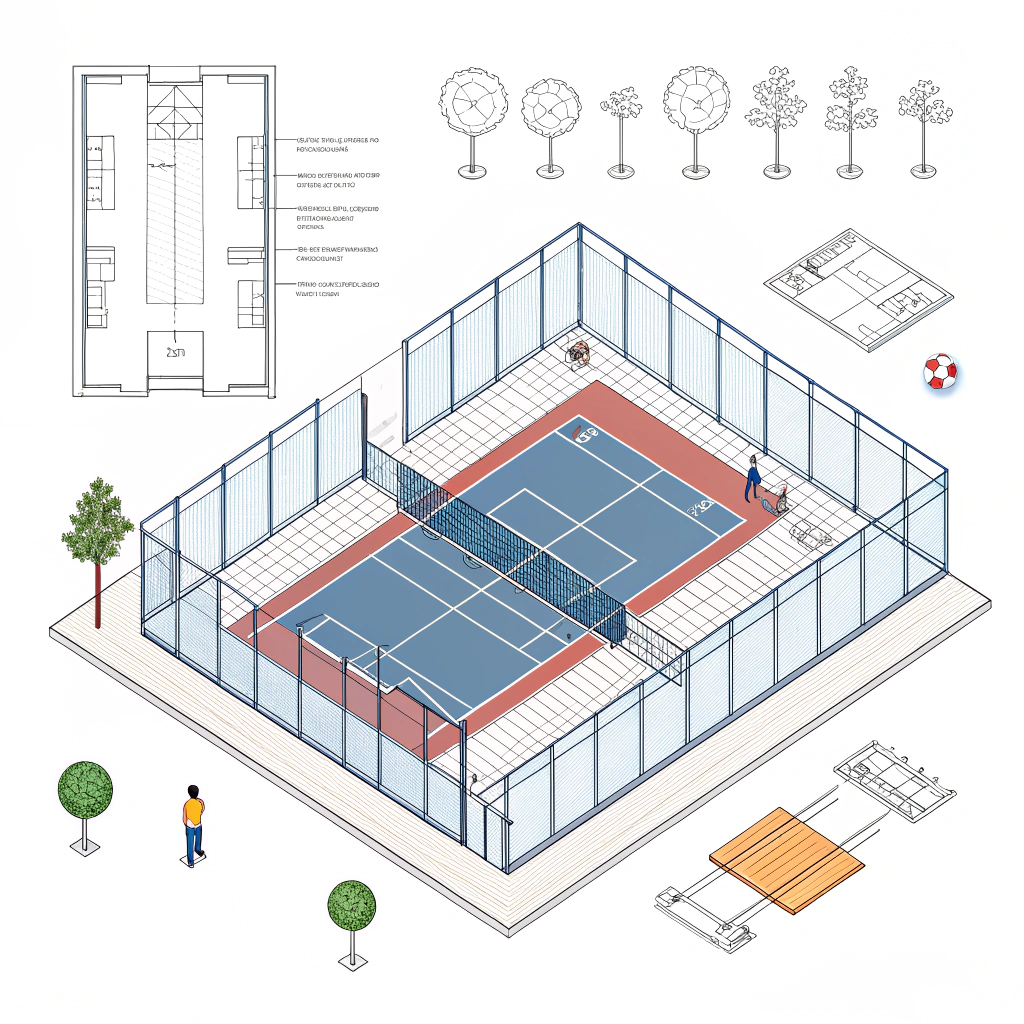

Constructing a padel court is not as simple as laying down a playing surface. It requires strategic planning, detailed technical specifications, and adherence to industry standards to ensure long-term durability and excellent playability. Padel court construction involves several important factors:

- Accurate court dimensions: Ensuring that the playing area meets international standards2.

- Material selection: Choosing surfaces and structural elements that withstand wear and meet rebound performance requirements.

- Budget management and cost analysis: Balancing quality and financial feasibility.

- **Regulatory compliance3: Abiding by local construction codes and sports facility guidelines.

- Installation and maintenance guidelines: Establishing a routine for upkeep to maintain optimal performance.

For manufacturers like NEX Padel, renowned for their advanced production techniques and high-performance sports equipment, understanding these elements is critical. Our expertise in producing top-tier padel rackets parallels the precision guidelines for constructing a padel court.

When planning a padel court construction project, there are several technical and practical aspects to address. These elements are instrumental for facility managers and sports club owners:

- International Standards: Most padel courts adhere to standard dimensions, usually around 20 meters in length and 10 meters in width. Variations may occur based on specific regulatory guidelines.

- Playing Surface: Adequate space for walls and protective zones around the court is essential. This extra space ensures that out-of-bound balls do not immediately end gameplay and provides safety for players.

- Design Flexibility: Customization options such as adjustable court shapes (Diamond, Round, Teardrop) can enhance user experience. With our full customization offerings, every court can be tailored to match your facility’s needs.

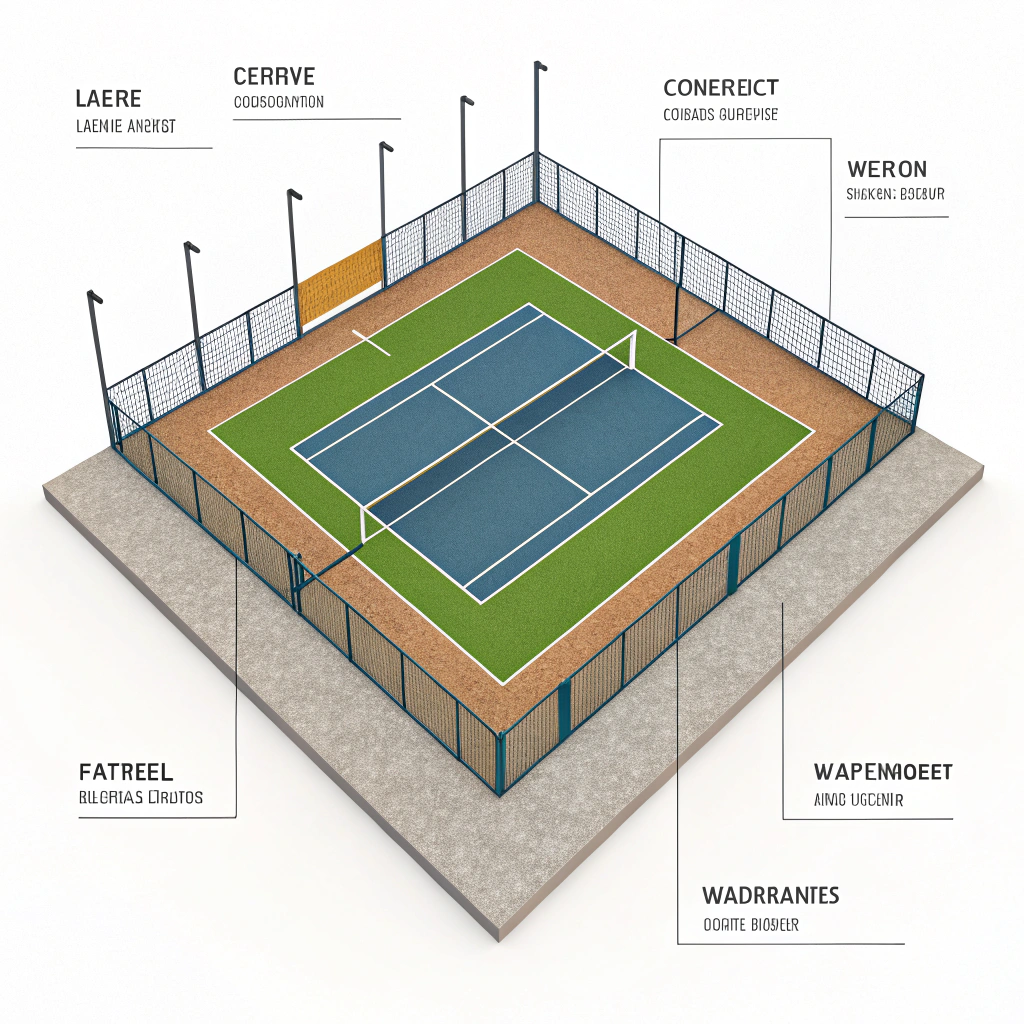

Choosing the right materials is crucial. Factors to consider include cost, durability, maintenance, and how the surface interacts with the ball.

- Surface Options: Concrete, cement, wood, Synthetic Resin4, and artificial turf are popular choices. Artificial turf, for example, has become the most effective playing surface by balancing comfort, playability, and safety.

- **Substructure Integrity5: Beyond the surface, the underlying structure such as supporting beams and sub-base layers must be robust enough to withstand weather and continuous use.

- Cost vs. Performance: Higher quality materials usually incur higher initial costs but offer reduced maintenance and longer life cycle, leading to overall cost savings.

The choice of materials directly impacts the performance and longevity of the padel court. Here are the key elements to consider:

| Material | Benefits | Considerations |

|---|---|---|

| Concrete/Cement | Durable, low maintenance, cost-effective | Hard surface, less forgiving on joints |

| Wood | Natural feel, aesthetic appeal | Requires regular maintenance, weather-sensitive |

| Synthetic Resin4 | Good rebound properties, smooth surface | May have higher installation cost |

| Artificial Turf | Excellent playability, enhanced safety, comfort | Slightly higher upfront cost, requires specific installation techniques |

Artificial turf is often favored by indoor and outdoor courts thanks to its consistent ball rebound, providing players with predictable performance. Regulatory guidelines often detail the necessary rebound specifications that these materials must meet, ensuring a uniform playing experience worldwide.

Furthermore, the sub-base and drainage systems need careful planning to handle weather changes and prevent water accumulation, preserving the playing surface's integrity over time.

For facilities looking to brand their courts or enhance user experience, customized features can be incorporated:

- Custom Prints and Colors: Logo imprinting and color schemes can be tailored, providing a unique visual identity for your sports facility.

- Enhanced Accessories: Options such as custom hand grips and handle covers add further branding possibilities, making each padel court a part of your facility’s signature experience.

For decision-makers, understanding the nuances of cost analysis is critical. A comprehensive construction budget should take into account materials, labor, customization, maintenance, and additional features that might be required.

Below is a simplified cost breakdown table which outlines potential expense categories:

| Cost Component | Estimated Range | Key Considerations |

|---|---|---|

| Surface Material | $8,000 - $30,000 | Quality and type determine cost variability |

| Base Preparation & Drainage | $4,000 - $10,000 | Ensuring long-term structural integrity |

| Structural Framework | $3,000 - $12,000 | Includes fencing, buffering, and safety nets |

| Customization & Aesthetics | $2,000 - $8,000 | Custom prints, logos, color schemes |

| Labor & Installation | $7,000 - $15,000 | Professional installation is vital |

| Maintenance Setup | $500 - $1,000 | Initial planning for upkeep and routine checks |

The total investment typically ranges from approximately $24,000 to $65,000. Choosing the right configuration and materials depends on your facility's specific needs, usage frequency, and long-term maintenance expectations.

It is helpful to balance initial expenses with projected longevity. High-quality materials, while more costly upfront, may lead to lower maintenance expenses over time and enhance the overall player experience, which is a crucial factor in the long-term success of your sports facility.

Installing a padel court goes beyond merely laying out materials; it requires meticulous planning and adherence to regulatory standards:

- Site Assessment: A thorough evaluation of the proposed site ensures it meets all foundational requirements in terms of load-bearing capacity, drainage, and environmental factors.

- Sub-base Construction: The foundation must be carefully prepared. This stage involves laying down a robust sub-base to support the surface materials.

- Surface Installation: Specialized techniques are employed to ensure the surface material adheres precisely and uniformly to the base.

- Perimeter Setup: Installation of protective fencing and buffering zones is crucial to protect both players and the court.

- Final Inspections: Once the court is constructed, final inspections against industry standards and local regulations must be completed.

Regulatory compliance3 is a major component that facility managers must not overlook. Local building codes, international padel regulations, and safety guidelines are integral to the construction process. Failure to adhere can result in operational setbacks, legal repercussions, or even safety hazards.

Proactive planning with certified contractors and consulting architects or engineers familiar with sports facility design can help mitigate these risks. Detailed documentation is often required during and after construction, ensuring that your facility meets all statutory standards.

Many sports clubs have successfully implemented high-performance padel courts by carefully considering material and cost factors, providing a benchmark for your project. Consider the following examples:

A leading urban sports complex opted for an artificial turf padel court to attract younger, dynamic players. The facility analyzed cost versus performance and decided that although the installation was slightly above mid-range pricing, the long-term benefits in terms of player safety and comfort outweighed the initial investment. Regular maintenance schedules were implemented, and the court quickly became a signature facility attracting local tournaments.

An exclusive country club invested in custom-designed padel courts featuring high-end materials like synthetic resin for the playing surface paired with premium fencing. Extensive planning ensured that aesthetic appeal and functionality coexisted. The customization options allowed them to incorporate their brand throughout the court, creating a distinctive look that appealed to their members. Detailed cost analysis revealed that while the upfront cost was higher, the unique design significantly boosted membership satisfaction and club prestige.

These examples underline the importance of integrating precise technical detail with strategic customization to achieve a high-performing and aesthetically pleasing padel court.

In conclusion, constructing a top-notch padel court involves several intertwined factors: ensuring accurate court dimensions, selecting the right construction materials, detailed cost analysis, and meticulous installation planning. For facility managers and sports club owners, the approach should be methodical:

- Evaluate the specific needs of your facility.

- Consider various material options, balancing performance with cost.

- Ensure strict adherence to safety and regulatory standards.

- Plan for comprehensive maintenance and regular inspections post-installation.

With companies like NEX Padel, you gain not only a partner in high-performance padel equipment but also access to expertise in guiding you through the entire construction process. Taking the right steps guarantees a facility that not only meets industry standards but also enhances player experience and long-term value.

For those ready to proceed, consider reaching out for a consultation where we can discuss your needs, review the most suitable materials, and provide a detailed project guide tailored to your facility. Act now to ensure your sports club remains competitive and continues to provide a superior playing experience.

Q: How much does it cost to build a padel court?

A: Building a padel court generally costs between $24,000 and $65,000. This range depends on material quality, site preparation, labor, and customizations such as branding and specialized design features.

Q: What material is used for padel courts?

A: Padel courts use various surface materials including concrete, cement, wood, synthetic resin, and most commonly, artificial turf. The choice of material depends on the desired rebound, durability, and overall performance characteristics of the court.

Q: What is the best surface for a padel court?

A: Artificial turf is widely regarded as the best surface for padel courts due to its excellent balance of playability, safety, aesthetics, and consistent ball rebound, making it ideal for both indoor and outdoor courts.

-

Padel court construction: Click to learn about the comprehensive process of designing and building a professional padel court, from planning and material selection to execution and maintenance. ↩

-

international standards: Click to explore the global benchmarks and dimensional guidelines that ensure consistency, safety, and optimal gameplay in padel courts. ↩

-

Regulatory compliance: Click to understand the legal and safety standards required in padel court construction to ensure your facility meets all necessary codes and guidelines. ↩ ↩2

-

Synthetic Resin: Click to gain insights into the benefits and installation considerations of synthetic resin surfaces used for achieving ideal ball rebound and durability in padel court construction. ↩ ↩2

-

Substructure Integrity: Click to read more about how robust underlying structures, including support beams and sub-base layers, contribute to the longevity and performance of padel courts. ↩