High-performance padel equipment is best sourced by comparing detailed technical specifications, manufacturing processes, and customization capabilities to ensure you choose a supplier that meets your operational needs. In this article, we compare key aspects of padel rackets, including Diamond, Round, and Teardrop designs, while highlighting the quality of materials like fiberglass1 and various carbon fiber2 grades (3k, 12k, and 18k). We also discuss the importance of precision production techniques and customization options that set a supplier apart in today’s competitive market.

Choosing the right partner for your high-performance padel equipment requires a careful evaluation of several aspects. In this section, we detail the major differentiators between leading padel suppliers and outline the criteria you should consider before finalizing your procurement decision.

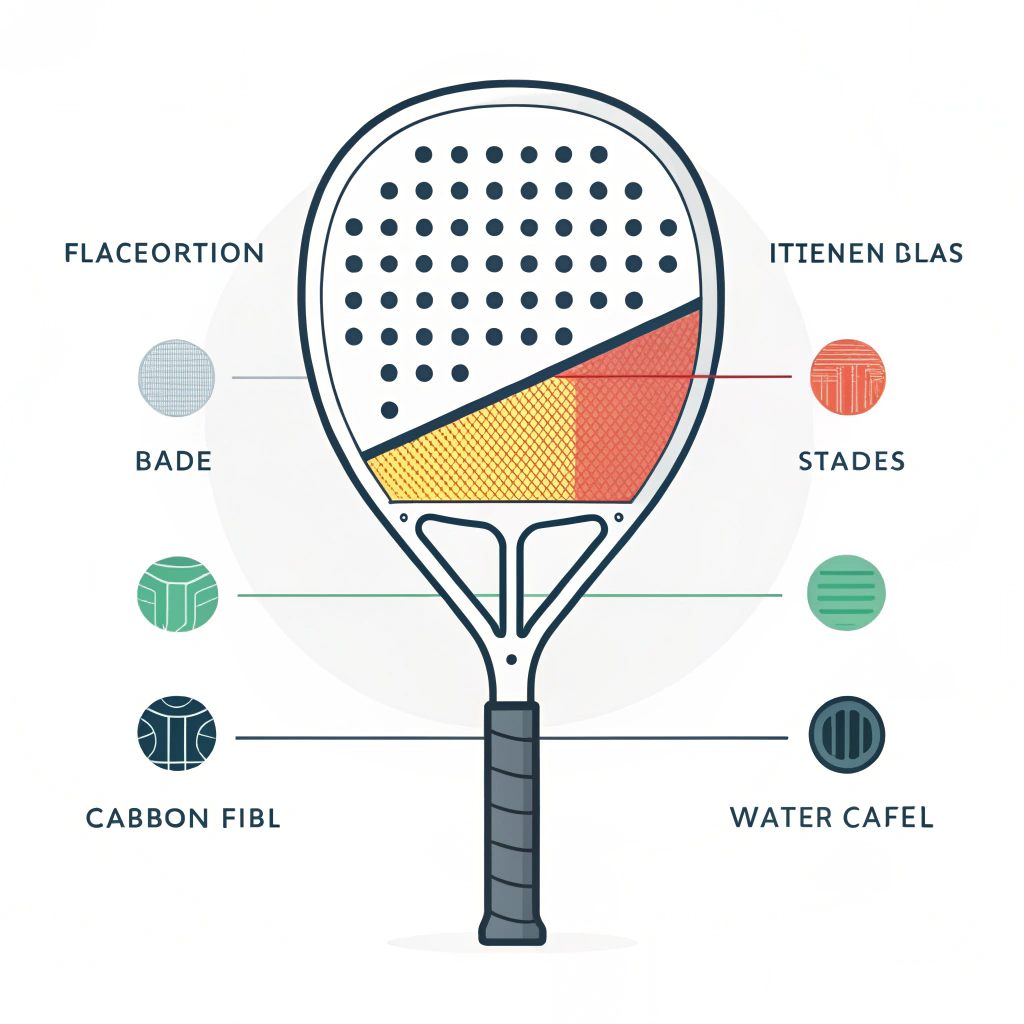

One of the main factors to consider is the quality of materials used. A highly reliable supplier uses advanced materials such as fiberglass1 and different grades of carbon fiber2. Each material has its own benefits regarding strength, weight, and durability:

- Fiberglass: Often used in entry-level to intermediate padel rackets, fiberglass provides a good balance of flexibility and durability at a competitive cost.

- 3k Carbon Fiber: Offers a lightweight solution ideal for players seeking speed and control in their gameplay.

- 12k and 18k Carbon Fiber: Provide higher stiffness and increased power, suitable for professional-level competition and high-intensity matches.

Understanding the production techniques is equally crucial. Advanced manufacturing processes ensure that each racket passes stringent quality control and maintains consistency in performance. At NEX Padel, for instance, the emphasis on precision manufacturing3 translates into the ability to offer fully-customized designs and a wide range of technical specifications.

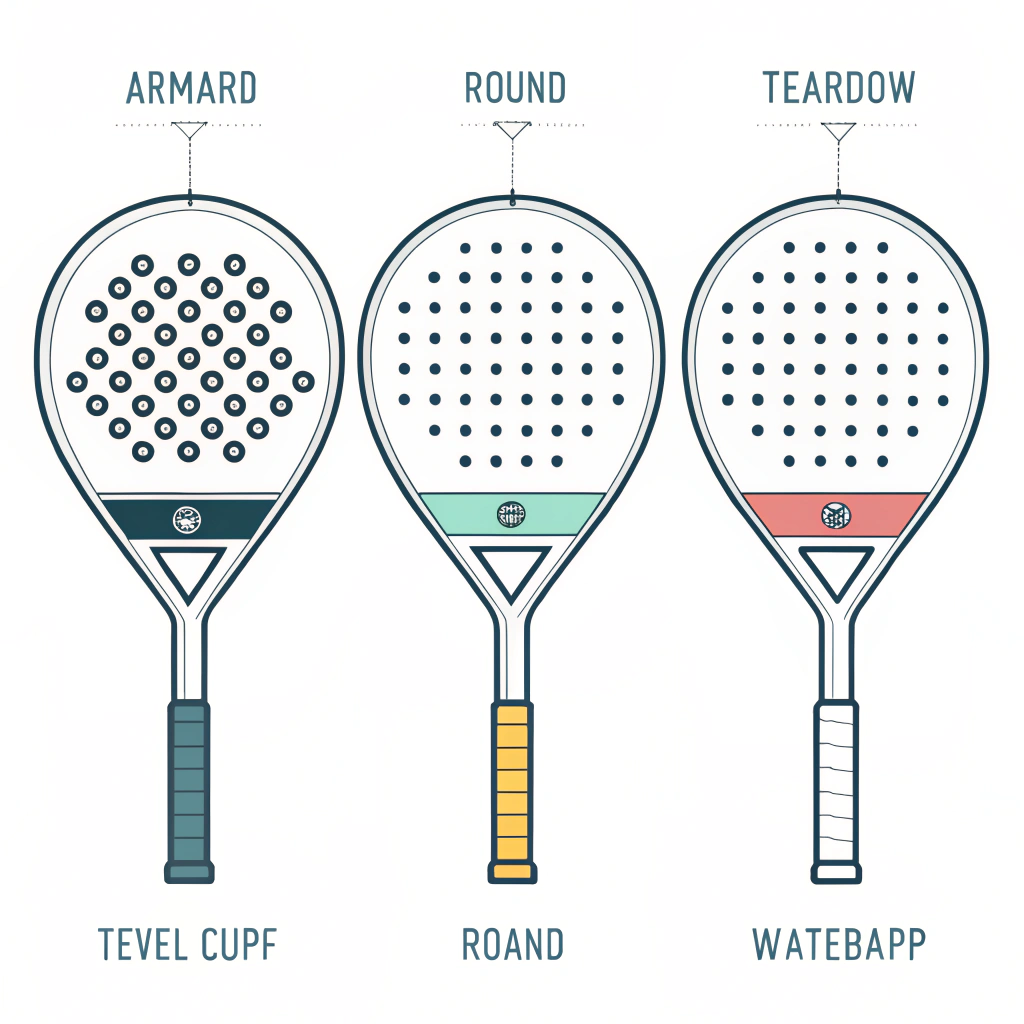

Padel rackets come in various shapes, each offering unique characteristics that cater to different play styles. The three main designs include:

- Diamond Racket: Typically offers a more aggressive play style with a focus on power. Its shape supports an optimal balance between weight distribution and impact force.

- Round Racket: Known for its enhanced control and maneuverability. It provides a larger sweet spot, making it ideal for players who prioritize precision and defensive play.

- Teardrop Racket: Acts as a middle ground between Diamond and Round rackets, blending power with control. Its design is versatile and suits a broad range of playing styles.

Below is a detailed table summarizing the key differences among these racket types:

| Feature | Diamond Racket | Round Racket | Teardrop Racket |

|---|---|---|---|

| Play Style | Aggressive, power-focused | Precision, control-oriented | Balanced mix of power & control |

| Weight Distribution | Forward-heavy for increased power | Evenly distributed for better maneuverability | Moderate distribution |

| Sweet Spot Size | Smaller, requires precision | Larger, forgiving on off-center hits | Medium size |

| User Profile | Advanced/professional players | All-level, especially beginners & intermediates | Intermediate to advanced players |

When evaluating suppliers, ensure the technical parameters of each design are clearly defined by the manufacturer.

For many B2B buyers, the ability to customize paddle rackets is a key differentiator. A reliable supplier should offer custom shapes, printing options, and colors to align with your brand’s identity and market demands. At NEX Padel, complete customization is available not only for the racket body but also for essential components like the hand grip4 and handle covers. This allows your products to stand out and cater to niche market requirements.

Another essential aspect is production speed. Quick sample production and timely deliveries are critical in the fast-paced sporting goods market. NEX Padel is known for its rapid prototyping5 and efficient production cycle, ensuring that any bulk orders or special projects are completed on time.

Before making a procurement decision, understanding the supplier’s quality assurance process is fundamental. High-performance padel equipment must adhere to strict quality standards to satisfy both professional athletes and recreational players. Consider the following factors when evaluating quality:

- Quality Control Checks: Detailed inspections at each stage of production to ensure consistency and durability.

- Material Traceability: Ability to trace the origin of materials such as carbon fiber grades and fiberglass.

- Performance Testing: Implementation of rigorous testing protocols to ensure every product meets performance expectations.

Using state-of-the-art quality assurance techniques, manufacturers like NEX Padel guarantee that every batch of rackets meets high-performance standards. The company's partnerships with prominent brands such as Hirostar, Reebok, and Starvie serve as a testament to their reliability and commitment to excellence.

While high-performance padel equipment may come at a higher initial cost, the long-term value provided often outweighs these expenses. The design durability, superior production techniques, and customization options result in equipment that has a longer lifespan and provides consistent performance.

A detailed cost-benefit analysis should consider:

- Initial Production Costs: Raw materials and manufacturing processes.

- Longevity and Durability: Cost per play or match considering wear and tear.

- Customization Premium: Added value from custom branding and design.

By choosing a supplier with proven long-term reliability and production capabilities, you not only reduce the risk of frequent replacements but also enhance your brand’s reputation in the market.

When comparing suppliers, technical comparisons based on data are invaluable. Below is an example of how a detailed technical comparison might look:

| Parameter | Supplier A (NEX Padel) | Supplier B | Supplier C |

|---|---|---|---|

| Material Options | Fiberglass, 3k, 12k, 18k Carbon Fiber | Limited carbon fiber options | Fiberglass only |

| Production Techniques | Advanced precision manufacturing | Standard molding techniques | Mixed methods |

| Customization Level | Full custom options (shape, color, printing, logos) | Limited to color customization | No customization |

| Lead Time | Rapid prototyping and timely delivery | Longer production cycles | Varies significantly |

| Quality Assurance | Stringent QC, material traceability | Basic QC methods | Inconsistent quality |

The data above clearly indicates why NEX Padel has positioned itself as a leader in the market. Decision-makers must weigh these parameters and align them with their operational requirements and market demands.

Apart from the major factors already discussed, several other aspects should be considered during supplier evaluation:

- After-Sales Support: The availability of customer service and technical support post-purchase. This can include warranty services, maintenance, and further customization.

- Industry Reputation: Testimonials from industry leaders and successful collaborations with well-known brands add credibility.

- Sustainability and Innovation: Evaluation of the supplier’s commitment to sustainable practices and ongoing innovation in product design.

Consider the case of a regional padel club looking to upgrade its equipment line. Faced with multiple suppliers, the procurement manager focused on three primary criteria: quality of materials, customization capability, and after-sales support. The decision ultimately weighed in favor of NEX Padel due to their superior production techniques and extensive customization options. Here are some of the actions taken:

- A detailed comparison of racket designs was made using technical data provided by each supplier.

- NEX Padel’s rapid prototyping allowed the club to test sample rackets extensively.

- The club benefited from a flexible lead time that aligned with their seasonal market cycle.

This case emphasizes that a strategic supplier like NEX Padel not only meets technical specifications but also supports business objectives through adaptive and innovative production practices.

In summary, choosing the right supplier for high-performance padel equipment involves a comprehensive comparison of production materials, design options, customization capabilities, quality assurance, and overall cost-effectiveness. NEX Padel demonstrates leadership through its advanced use of fiberglass1 and carbon fiber2, coupled with precision manufacturing and efficient production cycles.

For procurement managers and padel club operators, it is essential to perform a detailed supplier assessment. Consider creating a checklist that includes the production process, quality control mechanisms, and customization options offered. A side-by-side comparison table, as provided above, can be a powerful tool in making a well-informed decision.

Your next step is to reach out to suppliers with a detailed set of requirements, ask for relevant data, and conduct sample tests to ensure that the products meet your high standards. A strategic partnership with a supplier like NEX Padel can significantly enhance your product offerings, ensuring that your padel equipment meets both market demands and performance expectations.

Q: What equipment do I need to play padel?

A: To play padel, you primarily need a high-quality racquet designed for the sport, such as a Diamond, Round, or Teardrop padel racket. The racquet is the main tool, and selecting one that meets your performance and customization needs is essential.

Q: Why is padel not popular in USA?

A: Padel’s limited popularity in the USA is partially due to cultural preferences and a different sports market dynamic. While it offers a fun, socially engaging experience and a tactically rich doubles game, it has not yet gained as much traction as other popular racquet sports.

Q: Is padel harder than pickleball?

A: Padel generally demands more physical effort than pickleball due to its larger court size and dynamic gameplay. The inclusion of walls and rapid changes in direction further increase its physical intensity and complexity.

-

fiberglass: Reading this article will provide insights into the properties, applications, and benefits of fiberglass as a composite material in sporting equipment. ↩ ↩ ↩2 ↩3

-

carbon fiber: Discover how carbon fiber, including its various grades, enhances durability, strength, and performance in high-performance sporting equipment. ↩ ↩ ↩2 ↩3

-

precision manufacturing: Explore advanced manufacturing processes that ensure product consistency and high quality in competitive markets. ↩ ↩

-

hand grip: Understand the design features and material considerations for hand grips that enhance user comfort and performance in sports equipment. ↩ ↩

-

rapid prototyping: Learn about rapid prototyping techniques that accelerate product development and streamline production cycles. ↩ ↩