The latest padel racket design trends, featuring Diamond, Round, and Teardrop shapes alongside advanced carbon fiber variants like 3K, 12K, and 18K, are transforming performance and customization—providing brands with the edge to meet modern market demands.

In today’s competitive sports equipment market, choosing the right design and materials for your padel racket is both challenging and crucial. As product managers or design engineers, you face a critical decision: selecting a design innovation that not only enhances the racket’s performance but also aligns with your brand’s vision. In this article, we compare the emerging shapes—Diamond, Round, and Teardrop—and delve into the material breakthroughs with various carbon fiber options, manufacturing techniques, and Customization1 possibilities.

When sourcing and manufacturing high-performance padel rackets, two key factors dictate success: design and material. Both these elements directly influence the racket’s performance on the court, its durability, and the overall customer satisfaction. However, these decisions come with a balancing act between innovation, cost, and market trends.

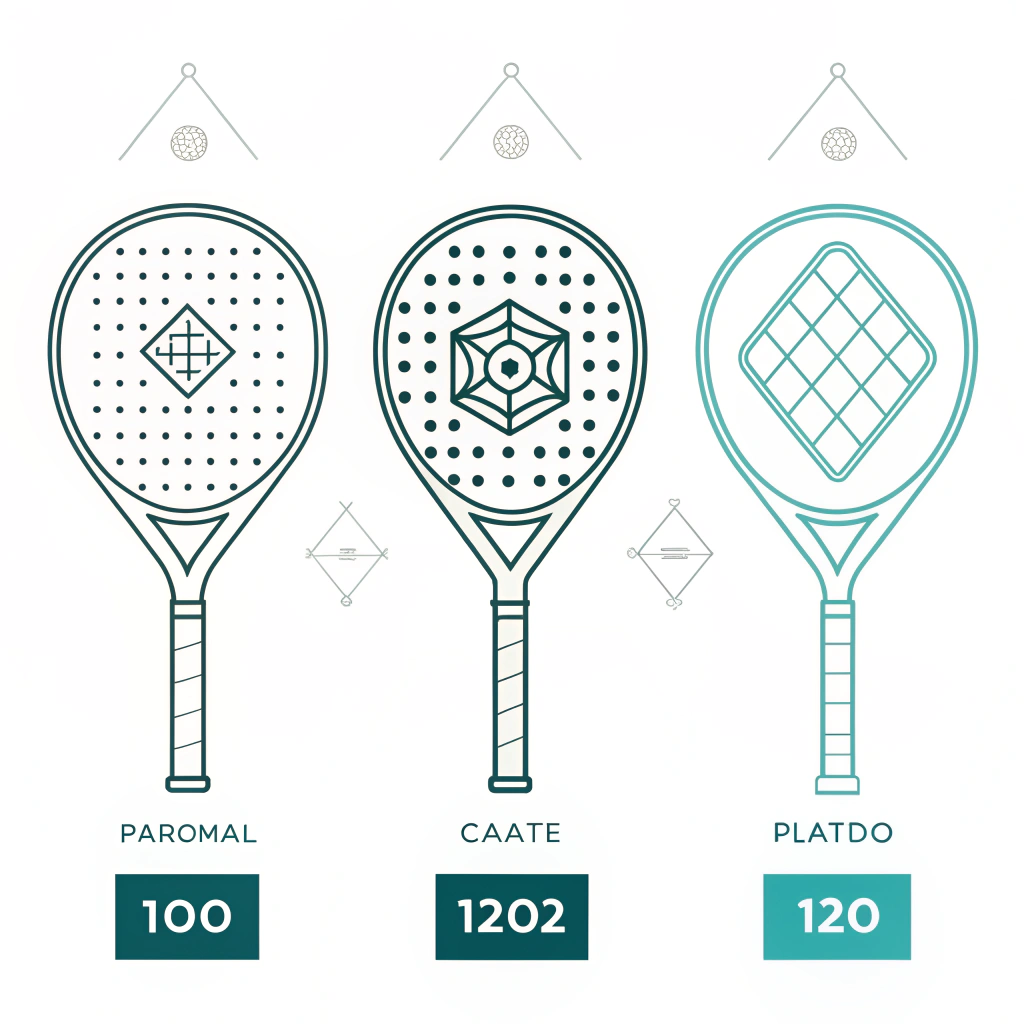

Each design type brings unique performance characteristics:

-

Diamond Shape

- Provides a larger sweet spot.

- Favors power over control.

- Ideal for players who prefer aggressive play style.

-

Round Shape

- Offers balanced performance in power and control.

- Generally more forgiving for beginners.

- Ensures an even weight distribution.

-

Teardrop Design

- Combines the benefits of both Diamond and Round shapes.

- Enhances maneuverability for quick shots.

- Favours a versatile play style suitable for various techniques.

These trends are not isolated; they represent a growing market demand for rackets that are not only aesthetically appealing but also precisely engineered for performance.

Choosing the right material is equally significant. Carbon Fiber2 materials, which include 3K Carbon Fiber, 12K Carbon Fiber, and 18K Carbon Fiber, are popular choices due to their unique properties:

-

3K Carbon Fiber

- Known for its durability and cost-effectiveness.

- Offers a balanced blend of stiffness and flexibility.

- Widely applied in entry-level to mid-range rackets.

-

12K Carbon Fiber

- Provides a smoother finish and improved energy transfer.

- Strikes a balance between quality and performance.

- Suitable for advanced recreational players.

-

18K Carbon Fiber

- Premium option offering maximum stiffness and minimal vibration.

- Enhances precision and control.

- Preferred in high-performance and professional-grade rackets.

The type of carbon fiber used impacts not only the playability of the racket but also the manufacturing process. Brands like NEX Padel have perfected these techniques to ensure consistent quality and performance.

Below is a table summarizing the core differences among the designs and materials, which can help shape your decision-making process:

| Aspect | Diamond Shape | Round Shape | Teardrop Shape |

|---|---|---|---|

| Performance Focus | Power-oriented; larger sweet spot | Balanced play; forgiveness | Versatile; combines control & power |

| Ideal For | Aggressive, power players | Beginners to intermediate | All-round players |

| Weight Distribution | More concentrated in the head | Even distribution | Slightly head-heavy for quick responses |

| Market Trend | Increasingly popular among pros | Consistently reliable choice | Gaining traction for its flexibility |

| Material | 3K Carbon Fiber | 12K Carbon Fiber | 18K Carbon Fiber |

|---|---|---|---|

| Cost Efficiency | High | Moderate | Lower (premium cost) |

| Performance | Balanced stiffness and flexibility | Enhanced energy transfer | Maximum stiffness and precision |

| Application | Entry- to mid-level products | Advanced recreational products | Professional sports equipment |

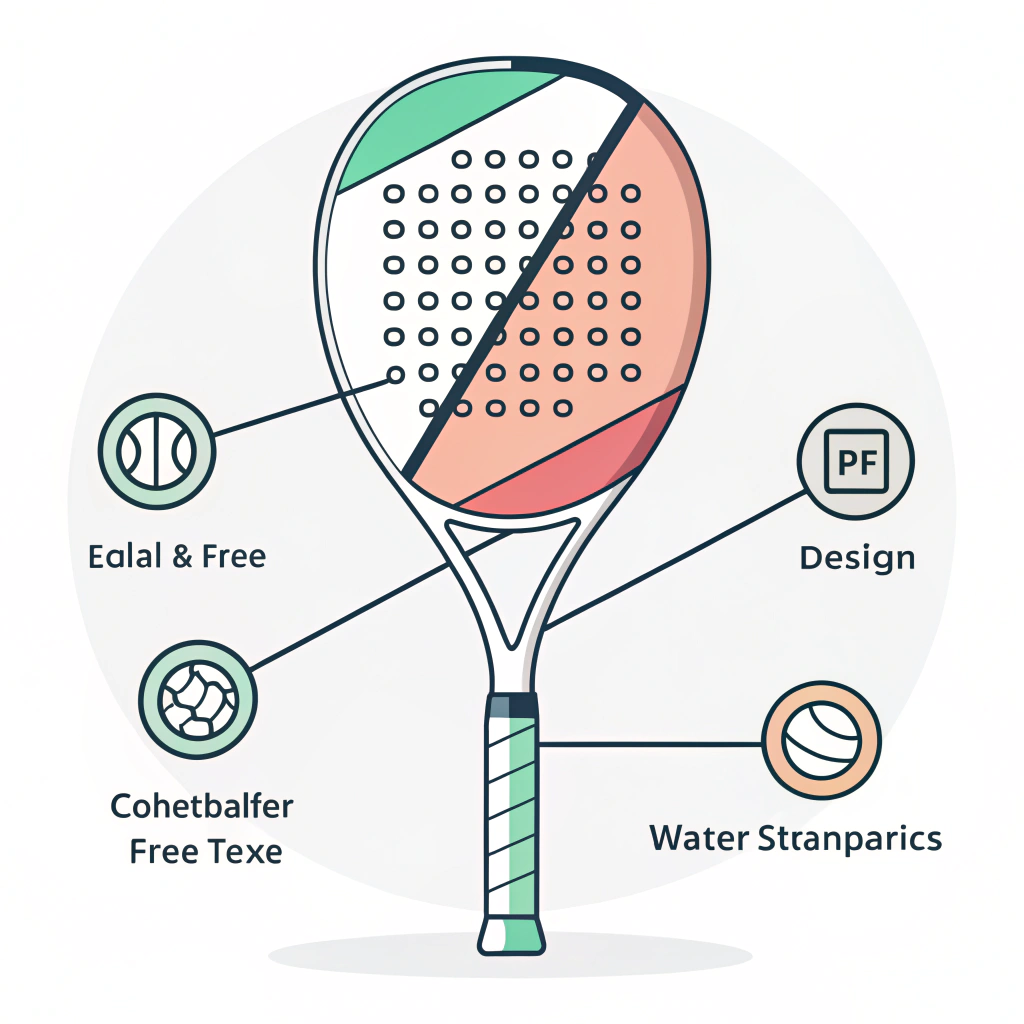

In the current landscape, customization is no longer a luxury—it’s a necessity. Leading manufacturers, like NEX Padel, offer various customization options including tailored shapes, unique printing, and personalized colors. A customizable padel racket can significantly bolster brand identity and market differentiation.

-

Shape Customization:

Not limited to Diamond, Round, or Teardrop, manufacturers can also produce bespoke designs to meet specific performance requirements. For instance, adjusting the racket’s balance or head size can cater to niche player segments. -

Material and Technology Integration:

Advanced technologies allow manufacturers to integrate different carbon fiber types into a single racket design, achieving the desired combination of power, control, and durability. This hybrid approach can provide a competitive edge. -

Graphics and Branding:

Custom printing on the racket’s surface, hand grip (hand gel), and handle cover can reinforce brand identity. Creating a recognizable look is crucial for customer loyalty in the highly competitive sports equipment market.

Investing in these customization strategies not only meets consumer demands but also opens avenues for premium pricing and enhanced market positioning.

From concept to market, efficient production processes are vital. Manufacturers face challenges in meeting quality standards while optimizing turn-around times. NEX Padel’s factory experience provides a roadmap on how to manage these challenges.

-

Rapid Prototyping & Iterative Design3:

Quick sample iterations allow for swift adjustments. By experimenting with different carbon fiber variants and racket shapes, manufacturers can immediately identify performance improvements or design flaws. -

Quality Control4 and Material Monitoring:

Using rigorous testing procedures ensures that each racket meets high-performance standards. Advanced production techniques coupled with strict quality control produce consistent results. -

Efficient Customization Process:

Integrating customization options into the production line through Digital Printing5 and automated assembly ensures high efficiency and reduced lead times. This has proven essential for brands that need to adapt to rapidly changing market trends. -

Supplier and Factory Collaboration:

Close partnerships with material suppliers—especially for premium carbon fibers—and specialized equipment suppliers ensure a steady production flow. Collaborative efforts lead to innovation, with shared insights on how to push the envelope further in design and performance.

Understanding industry trends and consumer preferences is a significant part of decision-making. Several industry reports indicate that the demand for high-performance rackets with customizable features is on the rise. Brands that adapt to these trends by leveraging advanced materials and innovative designs are more likely to capture a larger market share.

-

Consumer Behavior:

Studies have shown that players are increasingly looking for rackets that offer a blend of power and control. The balanced performance of Round and Teardrop designs addresses these needs effectively. -

Material Performance:

Recent field tests indicate that higher carbon fiber counts, such as 18K, significantly improve the racket's performance by offering enhanced stiffness and durability. These materials are particularly favored among professional athletes. -

Customization Trends:

Customized sports equipment is becoming a norm rather than an exception. Brands that offer personalized options see higher customer retention and a stronger brand presence in the market.

By grounding your sourcing and manufacturing decisions in data, you can align your product line with consumer expectations and market opportunities.

Given the detailed comparisons and market insights, here are practical steps to help you in your next product development cycle:

-

Assess Your Target Market:

Understand whether your audience prefers performance focused on power (Diamond) or balanced play (Round/Teardrop). Matching the racket design with user expectations is key. -

Select the Appropriate Material:

Evaluate the performance characteristics of 3K, 12K, and 18K carbon fibers. Factor in aspects such as cost, weight, stiffness, and durability when selecting your material mix. -

Integrate Customization Early On:

Customize not only aesthetics but also functional elements such as grip and balance. Early integration of these elements in the design phase can reduce post-production modifications and costs. -

Collaborate with Experienced Manufacturers:

Partner with manufacturers like NEX Padel who have deep expertise in advanced production techniques. Their experience in dual or hybrid material applications can be a game-changer. -

Leverage Data and Continuous Feedback:

Use market data and user feedback as continuous inputs for product improvement. Regular reviews and testing sessions can help refine the design and material combination for the best performance. -

Plan for Future Trends:

Stay informed on emerging trends in padel techniques and performance demands. Investing in research and development today can position your brand as a leader in sports equipment innovation tomorrow.

The decision-making process in selecting the right padel racket design and material is multifaceted. By comparing the nuances of Diamond, Round, and Teardrop shapes, along with understanding the distinct benefits offered by various carbon fiber variants, you can better align your product offerings with market trends and customer needs. Manufacturers and sourcing managers should not only focus on the immediate performance benefits but also invest in customization and efficient production techniques to drive long-term success.

Implementing a data-driven, customization-focused strategy will ensure that your next padel racket line is both innovative and competitive. Embrace these emerging trends, collaborate with experienced partners, and make informed decisions based on precise performance metrics to secure a strong foothold in the evolving sports equipment market.

People Also Ask

Q: What are the benefits of using carbon fiber in padel rackets?

A: Carbon fiber provides high strength with low weight, improves racket stiffness, enhances durability, and allows for precise control over performance parameters, which is why advanced types like 3K, 12K, and 18K are integral in high-performance designs.

Q: How does the shape of a padel racket affect performance?

A: The shape of a padel racket—whether Diamond, Round, or Teardrop—impacts the sweet spot size, weight distribution, and overall balance, directly influencing the power, control, and maneuverability on the court.

Q: What customization options are available for padel rackets?

A: Customization options include altering the racket shape, personalized printing and color schemes, as well as custom hand grip and handle cover designs, which can be tailored to enhance both aesthetic appeal and functional performance.

-

Customization: Click here to read about the strategic advantages of product customization in meeting market demands and enhancing brand differentiation. ↩ ↩

-

Carbon Fiber: Click here to learn about the properties, manufacturing processes, and performance benefits of carbon fiber, which make it a popular choice in high-performance sports equipment. ↩ ↩

-

Rapid Prototyping & Iterative Design: Click here for insights into rapid prototyping methods that accelerate product development and allow for swift design improvements. ↩ ↩

-

Quality Control: Click here to explore best practices in quality control and testing procedures that ensure product consistency and reliability. ↩ ↩

-

Digital Printing: Click here to understand how digital printing technology enhances customization capabilities in manufacturing, offering efficiency and design flexibility. ↩ ↩