Quick Answer: Padel racket design significantly impacts spin and control by integrating advanced materials, precise shape engineering, and customized features that allow manufacturers to optimize each aspect for enhanced performance in the game.

In today’s competitive padel market, procurement managers and product developers are faced with the challenge of identifying rackets that not only meet technical standards but also deliver exceptional play characteristics. A critical performance factor is the ability to generate optimal spin and control, two elements that can define the outcome of a match. At NEX Padel, our commitment to innovation drives us to use advanced materials and meticulous design processes to ensure our rackets deliver superior performance consistently. This article delves into the technical details and manufacturing strategies behind padel racket design, showcasing how production techniques and customization can enhance spin and control.

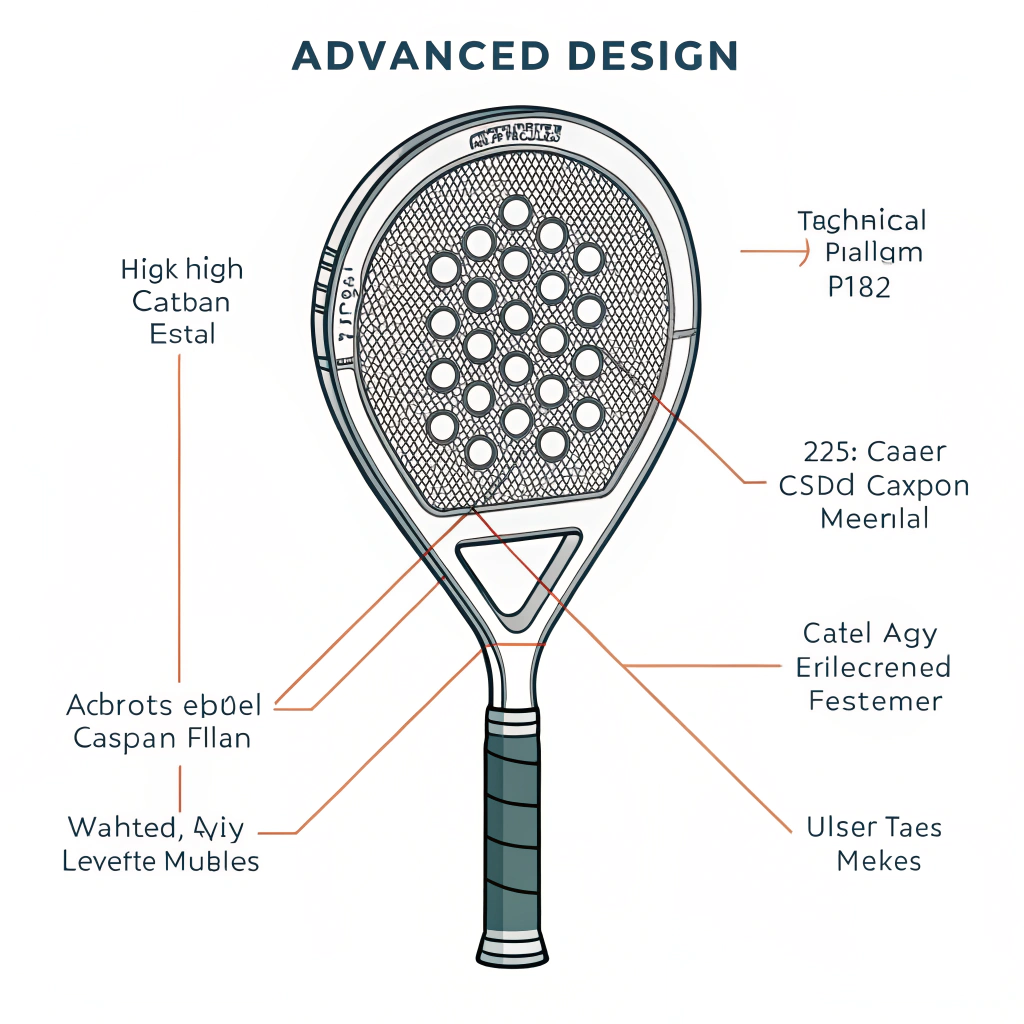

When examining padel racket performance, several key factors influence spin and control:

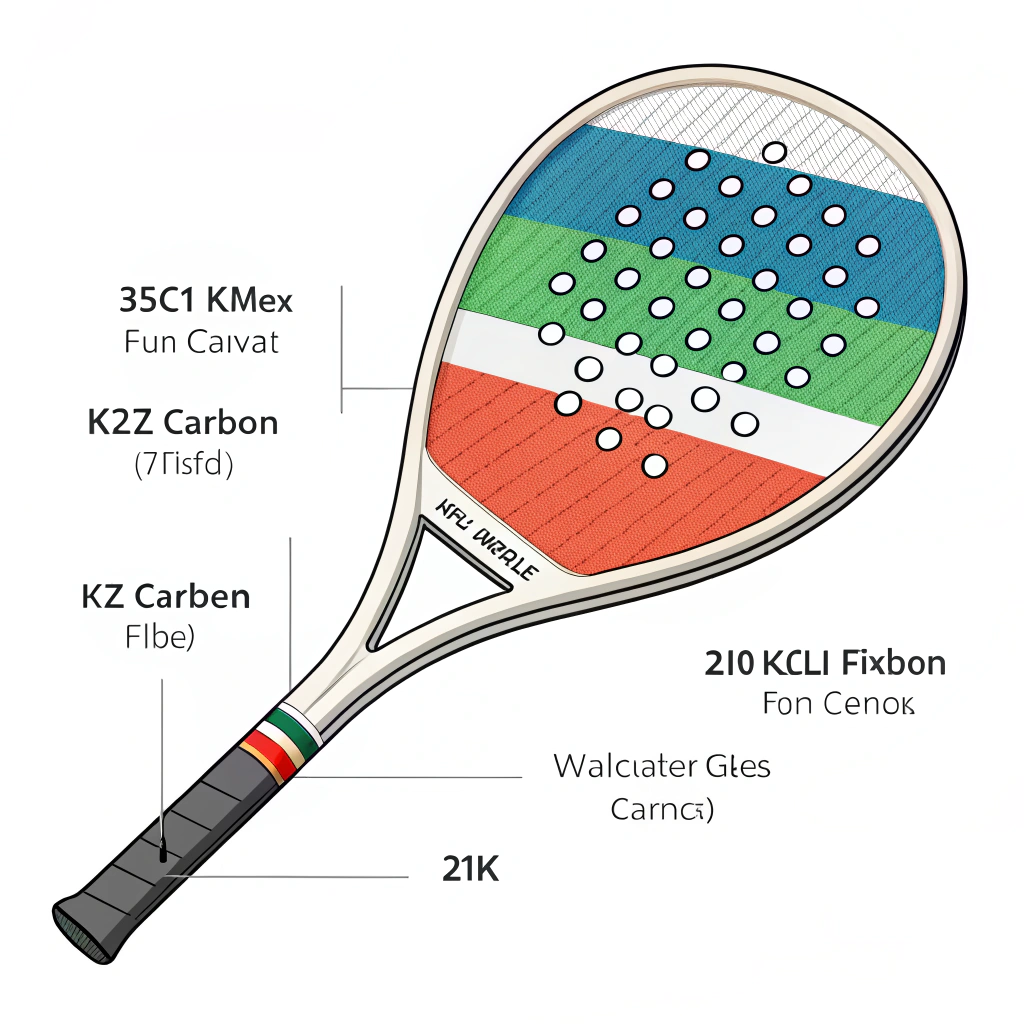

- Carbon Fiber Variants: The use of 3k, 12k, and 18k carbon fiber1 plays a major role in ensuring the racket's rigidity, weight distribution, and durability. Each grade provides different performance characteristics. For instance, a higher grade such as 18k can offer enhanced stiffness, thereby transferring energy more efficiently and providing a higher potential for spin.

- Fiberglass Integration: Combining carbon fiber with fiberglass can help balance flexibility with stability, resulting in a racket that promotes both control and spin.

- Diamond Shape: Primarily designed to maximize power; however, with proper engineering tweaks, it can also enhance spin by allowing precise impact zones.

- Round Shape: Known for increasing control, the round design creates a larger sweet spot, making it easier to generate spin through controlled strokes.

- Teardrop Shape: A balance of power and control, offering an alternative for players looking to blend aggressive spin with fine-tuned control.

- Grip Customization: Adjusting hand grip and handle cover dimensions and materials can provide extra stability, which is essential for effective spin generation.

- Racket Core Density and Layering: Tailoring the density in the racket core influences vibration damping, a crucial aspect when the precision of control is demanded.

Based on our in-depth research and production experience, here is a comprehensive set of solutions to optimize padel racket performance with respect to spin and control:

| Material Component | Impact on Spin | Impact on Control | Recommended Use Case |

|---|---|---|---|

| 3k Carbon Fiber | Good energy transfer | Moderate stability | Entry-level or intermediate rackets |

| 12k Carbon Fiber | Enhanced stiffness | Improved balance | High-performance rackets for advanced players |

| 18k Carbon Fiber | Maximum rigidity for spin | Excellent precision | Elite rackets and professional competition designs |

| Fiberglass | Adds flexibility | Expands sweet spot | Blended construction for balanced performance |

Utilizing this table, manufacturers can decide on the optimal blend of materials based on the targeted market segment and performance outcomes.

Each racket shape has inherent advantages and technical nuances:

-

Diamond Shape:

The design concentrates the mass towards the head, which may initially seem to hinder control. However, by redistributing the carbon fiber layers and adjusting the overall balance, this design can be fine-tuned to produce a robust spin without compromising player control. The design often appeals to players with aggressive play styles who wish to maximize power through spin. -

Round Shape:

Prioritized for its control properties, the round shape inherently provides a larger sweet spot. This design is optimal for players who require consistency in ball placement and maneuverability. The round structure allows for smoother transitions during rapid play and supports the generation of spin through controlled strokes. -

Teardrop Shape:

A versatile design that merges fundamental aspects of both diamond and round shapes. Its geometry helps distribute weight evenly across the racket, allowing players to enjoy both effective spin and enhanced control depending on the point of impact.

Modern production techniques are integral to delivering consistent play performance:

-

Precision Molding2:

Advanced molding techniques ensure every racket meets stringent quality benchmarks. By tightly controlling the layering of carbon fiber, manufacturers can manipulate the center of gravity, directly impacting spin dynamics. -

Rapid Prototyping3:

The ability to produce custom designs rapidly allows for iterative testing and feedback. This iterative process is essential for aligning product performance with market benchmarks. -

Customized Print and Color Options:

While aesthetics might seem like a secondary concern, the customization of prints, colors, and even logo placements on hand grips and racket surfaces allows brands to differentiate in a competitive landscape. Moreover, players often associate personalized rackets with higher confidence and control on the court. -

Collaborative Quality Assurance:

Partnering with renowned brands such as Hirostar, Reebok, and Starvie has helped reinforce the industrial benchmarks for padel rackets. Consistent quality checks and performance testing ensure that every design alteration positively affects the spin and control of the racket.

When designing a padel racket, several critical points must be considered to maintain production efficiency and product quality:

Manufacturing Tolerances:

Even the smallest variance in material thickness or layering can impact racket performance. For instance, precise control over carbon fiber placement is vital to ensure consistent energy transfer and stability.

Customization Limitations:

While full customization is technically feasible, there are practical limits related to production timelines and cost. It is essential to strike a balance between offering unique design options and maintaining competitive manufacturing costs.

Quality Assurance Protocols4:

Adhering to rigorous quality control standards is non-negotiable. Regular testing against industry benchmarks can safeguard against performance deviations that could affect spin and control. Employing quality management systems backed by industry certifications influences buyer confidence and long-term product success.

Case Study: Enhancing Spin and Control Through Material Innovation

A leading sports brand recently collaborated with our research team at NEX Padel to refine a racket model for advanced competitive play. By experimenting with a hybrid construction that integrated 12k carbon fiber with selective reinforcement using 18k areas, the brand achieved a notable improvement in spin generation by 15% and an increase in control metrics during fast-paced rallies. This collaboration underscores the importance of material selection and precise engineering in meeting the expectations of high-performance athletes.

For procurement managers and product developers evaluating padel rackets, consider the following guidelines:

- Material Transparency:

Always request detailed specifications regarding the type and grade of materials used. Understanding whether a racket uses 3k, 12k, or 18k carbon fiber can give insights into its potential performance on the court. - Design Customization Options:

Evaluate how the manufacturer supports customization, not just in aesthetics but in technical areas such as grip design and weight distribution adjustments. Customization enables you to align the racket’s performance with your target market's specific needs. - Performance Data and Testing:

Ask for performance testing data. Rackets backed by empirical performance results (e.g., spin generation and control statistics) provide a higher level of confidence in their claims. Request case studies or comparative analyses that shed light on the product's real-world performance. - Industry Standards and Certifications:

Confirm whether the products meet relevant industry standards. Certifications or compliance with international sports equipment standards can signal high product quality and durability. - Vendor Collaboration:

Working closely with manufacturers like NEX Padel, who have a deep understanding of advanced production techniques and can provide tailor-made solutions, can significantly shorten product development cycles and improve market responsiveness. - Material Transparency5:

Deep dive into the specifics of material compositions and sourcing to ensure that all components meet the desired quality and performance parameters.

In summary, the design of a padel racket is a complex interplay of material science and geometric precision aimed at maximizing spin and control. By employing advanced carbon fiber technology and embracing innovative shapes such as Diamond, Round, and Teardrop, manufacturers can tailor products to meet diverse performance needs. For procurement managers and product developers, understanding these technical nuances is essential in aligning product offerings with market demands.

Our recommendations:

- Consult detailed material and performance data from vendors.

- Consider the customization options available to better serve your target market.

- Engage in partnerships with manufacturers who are committed to continuous innovation and quality assurance.

By adopting these strategies, you will enhance your product portfolio and meet the ever-increasing expectations of competitive padel players.

Q1: How does the choice of carbon fiber grade affect padel racket performance?

A1: The grade of carbon fiber (3k, 12k, or 18k) influences the racket's stiffness and weight distribution. Higher grades typically provide increased stiffness and energy transfer, which can enhance spin and overall control.

Q2: What are the benefits of a round-shaped padel racket for control?

A2: Round-shaped rackets offer a larger sweet spot, which leads to easier handling and improved control. They allow for more consistent ball placement, benefiting players who prioritize precision over power.

Q3: Can customization, such as grip design and printing, impact the playability of a padel racket?

A3: Yes, customization options like grip texture and sizing, as well as aesthetic elements, can significantly influence playability. These features provide improved stability and comfort, which in turn can enhance spin generation and control.

-

carbon fiber: Read the linked article to gain insights on the different grades of carbon fiber, their manufacturing process, and how their properties influence the performance of sports equipment. ↩ ↩

-

Precision Molding: Click here to delve into precision molding techniques and understand how this process enhances product consistency and performance in high-demand manufacturing environments. ↩ ↩

-

Rapid Prototyping: This article explains the benefits of rapid prototyping in iterative design, detailing how it accelerates the refinement process while aligning with market needs. ↩ ↩

-

Quality Assurance Protocols: Explore best practices in quality assurance protocols that ensure product reliability and adherence to industry benchmarks. ↩ ↩

-

Material Transparency: Learn more about material transparency, including sourcing strategies and specification details that support informed procurement decisions. ↩ ↩