NEX Padel stands as a trusted partner for upscale sports clubs and distributors in Dubai by offering high-performance padel rackets with advanced custom options, superior materials ranging from glass fiber1 to various grades of carbon fiber2, and a robust, timely supply chain3 designed to meet demanding B2B requirements.

In the competitive realm of sports equipment procurement, especially for high-performance padel gear, decision-makers in Dubai require a supplier who not only meets but exceeds expectations in terms of product quality, technical specifications, and delivery timelines. As global procurement managers compare suppliers, factors such as material composition, customization options, production precision, and post-production services become critical. At NEX Padel, our state-of-the-art production facilities in Jiaxing, Zhejiang, are engineered to deliver padel rackets that cater to the upper echelons of performance and durability.

This article explores the essential criteria for choosing a padel racket supplier, details our technical capabilities, and provides clear comparisons with industry benchmarks. Our focus is to empower procurement managers with reliable, data-supported insights that streamline decision-making when selecting a vendor for premium padel gear.

When procuring padel equipment, especially in a market as vibrant as Dubai, several technical and business criteria influence the final decision. The following factors stand out:

- Glass Fiber vs. Carbon Fiber: Manufacturers often choose between glass fiber, 3k, 12k, and 18k carbon fiber. These materials determine the racket’s handling, durability, and performance. High-grade carbon fiber offers superior strength-to-weight ratios, essential for professional-level equipment.

- Consistency and Durability: Uniformity in material quality ensures that every racket performs consistently under high-stress conditions.

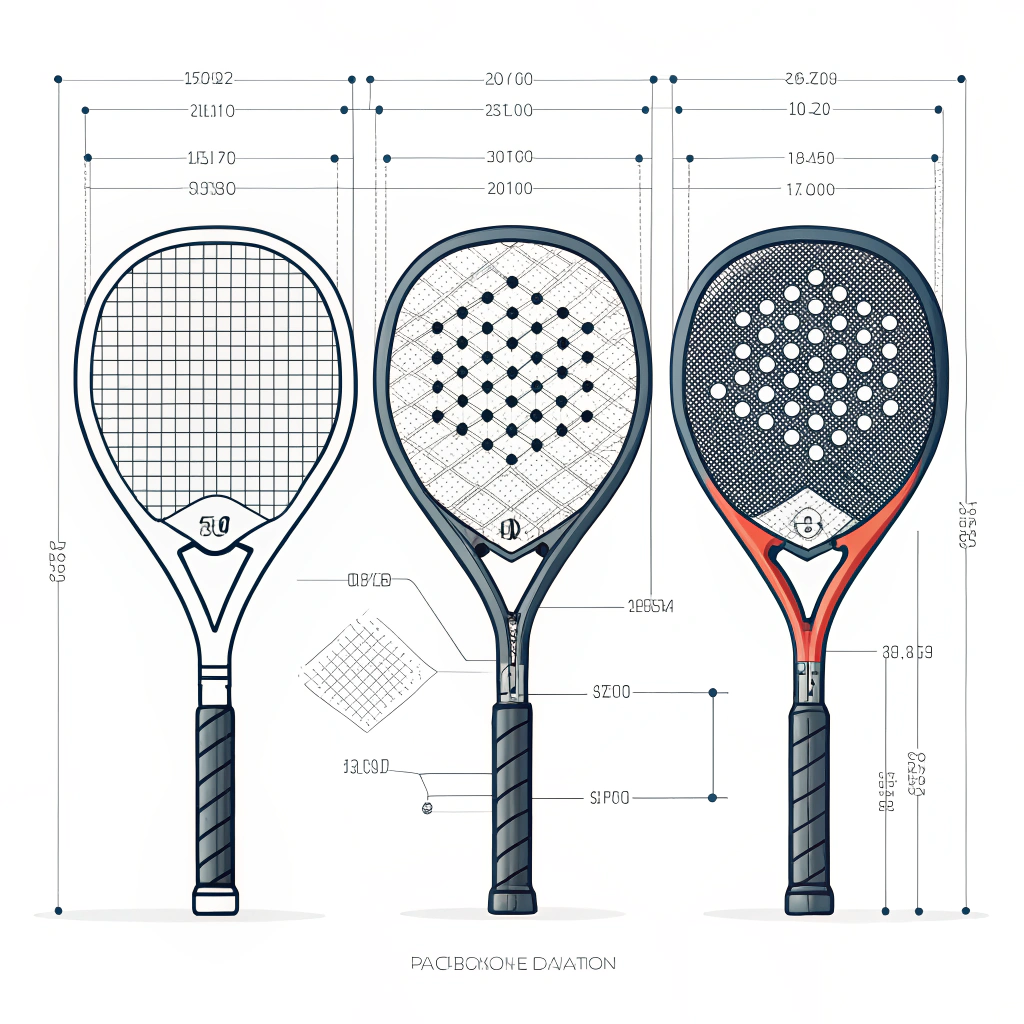

- Racket Shapes: At NEX Padel, we offer three distinct shapes—Diamond, Round, and Teardrop—each with a tailored performance profile. Custom shape options allow for a personalized balance between control, power, and maneuverability.

- Branding & Aesthetic Customization: Beyond the racket frame, our customization extends to print designs, color schemes, hand grips, and handle caps, making it easy to align the product with a club’s branding or distributor’s market positioning.

- Advanced Manufacturing Techniques: Utilizing rapid prototyping4 and precision engineering, our production lines ensure that every racket meets strict quality standards.

- Timely Delivery: Efficient production planning and logistics management ensure that our products are delivered on schedule, a crucial factor for businesses operating on tight timelines.

- Cost vs. Quality Balance: When compared to market prices, high-performance padel rackets from reliable suppliers usually range significantly in price. Our strategy focuses on offering competitive pricing without compromising product excellence, ensuring enhanced value for upscale markets.

An in-house production process that combines cutting-edge technology with detailed craftsmanship is our signature. The table below summarizes our key production capabilities and product options:

| Racket Type | Material Options | Customization Options | Key Attributes |

|---|---|---|---|

| Diamond | Glass Fiber, 3k, 12k, 18k Carbon Fiber | Custom shapes, branded print, personalized grip | Power-oriented, stability-focused |

| Round | Glass Fiber, 3k, 12k, 18k Carbon Fiber | Full customization on color and printing | Balance between power and control |

| Teardrop | Glass Fiber, 3k, 12k, 18k Carbon Fiber | Tailor-made design, ergonomic grip design | Enhanced maneuverability and comfort |

Our on-demand prototyping process allows for quick turnaround times, ensuring that customized orders move from concept to production rapidly. This is especially beneficial for procurement managers in Dubai who require agile responses to market demands or seasonal changes.

Quality padel rackets start with the selection of high-quality materials. At NEX Padel, we carefully select between glass fiber1 and multiple grades of carbon fiber2 based on the specific performance attributes required by the end-user:

- Glass Fiber offers balanced performance with enough flexibility and durability, making it an excellent choice for players transitioning to higher levels.

- 3k Carbon Fiber provides enhanced strength and excellent impact resistance while being lightweight.

- 12k and 18k Carbon Fiber options cater to advanced players demanding peak performance, toughness, and aesthetic finesse.

Using these materials, our production lines implement rigorous quality control5 checks at each stage of the manufacturing process, ensuring consistency and high performance.

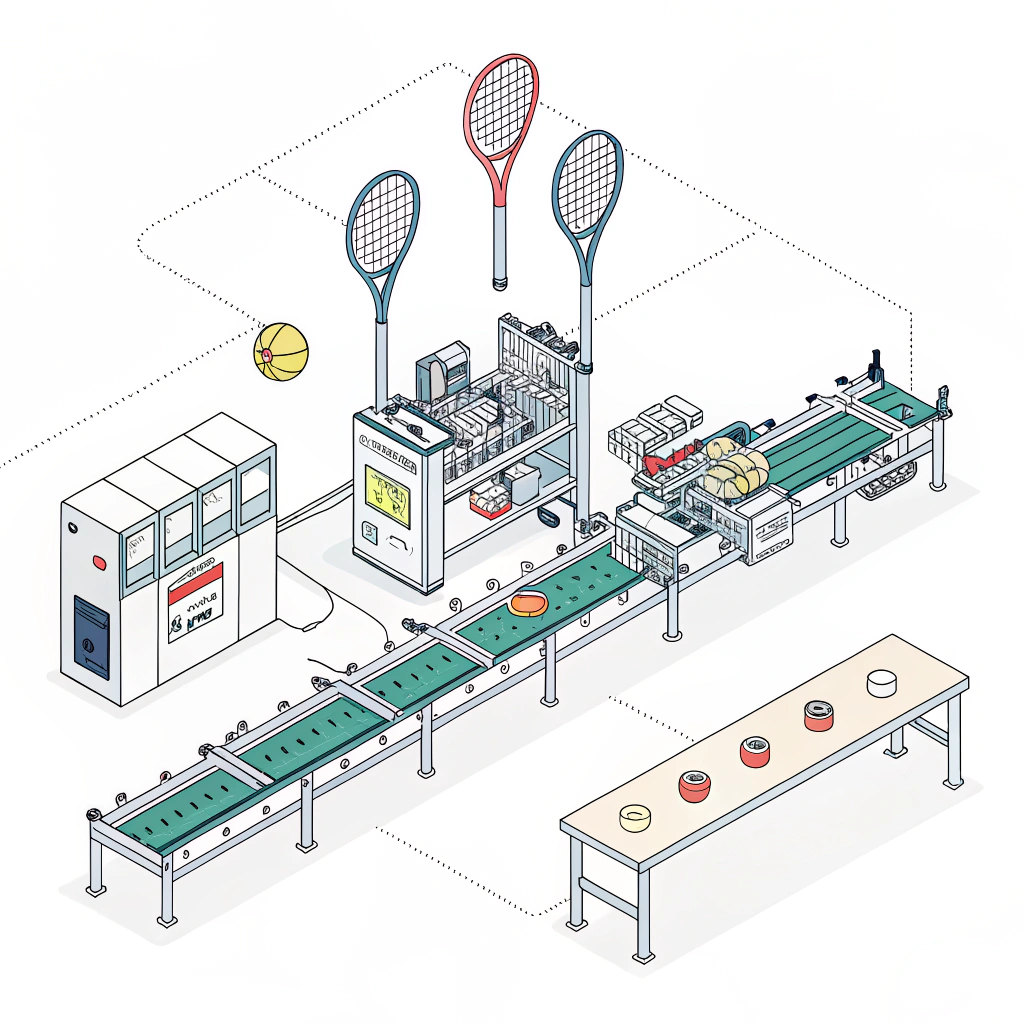

Our state-of-the-art facility incorporates the following critical production steps:

- Design and Rapid Prototyping: Engaging both digital design tools and industry expertise, each racket is conceived with precise geometrical and material standards.

- Mold Production and Layup Process: The materials are carefully mixed and layered, with automated layup processes ensuring even distribution of carbon fiber or glass fiber.

- Curing and Finishing: Innovative curing techniques guarantee that the carbon fiber takes on its maximum strength. Post-curing, each racket receives detailed finishing touches including custom branding, which enhances both aesthetic appeal and grip performance.

- Quality Inspections: A series of quality control checks, including stress testing and dimensional verification, are integral parts of our quality assurance program.

Diversification is key in today's market. Our production configuration allows:

- Full Customization of Racket Shape: The Diamond, Round, and Teardrop designs are engineered to suit different playing styles and physical dynamics.

- Brand-Specific Customization: By offering personalization options such as logo printing on hand grips or racket frames, we help our partners stand out in the competitive sports market.

- Logistics-Driven Custom Orders: With quick sampling and prototyping, we ensure that even uniquely designed models are produced within industry-standard timelines, optimizing lead times to match market demand.

For B2B procurement, one of the most critical factors is logistics. Our supply chain strategy is designed with efficiency and reliability in mind:

- Centralized Production Hub: Our facility in Jiaxing, Zhejiang, supports centralized planning, ensuring that orders are streamlined from production to shipping.

- Timely Dispatch: Adhering to rigorous manufacturing timelines, our logistic solutions allow for timely deliveries—especially vital for procurement managers coordinating with high-end sports clubs and retail channels in Dubai.

- Real-Time Order Tracking: Implementing modern tracking tools, we provide transparency in order status which builds trust with our partners.

A recent contract required delivery of custom-designed padel rackets for a series of sports events in Dubai. Despite the exceptionally tight timeline, our agile production processes—notably the rapid prototyping and quality verification steps—ensured that the order was completed and delivered on schedule, without compromising quality. This case highlights our commitment to meeting even the most pressing delivery requirements.

When evaluating suppliers, procurement managers must adopt a comprehensive view that goes beyond the technical specifications. Consider the following decision-making points:

- Industry Experience: With years of dedicated experience in padel racket manufacturing, NEX Padel delivers quality products consistently.

- Client Portfolio: Serving globally recognized sports brands like Hirostar, Reebok, and Starvie reinforces our credibility in the industry.

- Tailored Solutions: Offering full customizations in shapes, color, prints, and even grip personalization, our offerings are designed to meet bespoke requirements ensuring market differentiation.

- Speed & Responsiveness: Our rapid sampling and prototyping decrease the time between design finalization and production, allowing partners to respond swiftly to market trends.

- Cost Efficiency: While premium materials and advanced production techniques naturally command a price premium, our competitive pricing model ensures that businesses obtain high value for their investments.

- Value Proposition: A combination of high-quality materials, expert manufacturing, and reliable logistics translates into lower long-term costs related to product returns or failures.

Deciding on the right padel racket supplier is a critical step for procurement managers aiming to bolster their product offerings with reliable, high-quality, and customizable solutions. With a focus on cutting-edge technology, refined materials, and robust supply chain management, NEX Padel is perfectly positioned to meet the needs of upscale sports clubs and distributors in Dubai.

Key takeaways include:

- A deep understanding of material properties and their impact on racket performance is essential for evaluating product quality.

- The ability to customize design elements and incorporate branding offers a strategic edge in the competitive sports market.

- Efficient production processes and strict quality control, combined with reliable logistics and timely delivery, create a strong value proposition.

For procurement managers ready to upgrade their padel equipment offerings, aligning with a supplier who prioritizes precision, durability, and innovation is fundamental. Explore our facility, review our custom solutions, and consider partnering with NEX Padel to experience a seamless transition towards high-performance, custom-designed padel rackets tailored for the upscale Dubai market.

We invite you to reach out for a consultation or request a sample order to experience firsthand the quality and efficiency that set NEX Padel apart in the competitive sports equipment landscape.

Q: How much should a padel racket cost?

A: The cost of a padel racket typically ranges from approximately £50 to well over £400 for high-end models. Trusted brands offer rackets within the £50 to £300 range, while specialized or custom models with advanced materials can command higher prices.

Q: How much is paddle in Dubai?

A: Pricing for padel court sessions in Dubai generally starts at AED 300 per hour for court doubles. Extended play times, such as 1.5 hours or 2 hours, may cost around AED 450 to AED 600 per court.

Q: What is the best padel racket to buy?

A: The best padel racket varies based on personal playing style and performance requirements. Top models include those known for their technical advancements and design, with many professionals favoring high-performance options that offer robust materials, excellent balance, and customization features.

-

glass fiber – Read this article to understand the properties, applications, and benefits of glass fiber in high-performance sporting equipment. ↩ ↩ ↩2

-

carbon fiber – Learn about the advanced manufacturing techniques and material properties that make carbon fiber an ideal choice for enhancing product durability and performance. ↩ ↩ ↩2

-

supply chain – Explore insights on modern supply chain strategies, logistics innovations, and their role in ensuring timely delivery and quality management in B2B operations. ↩ ↩

-

rapid prototyping – Discover how rapid prototyping accelerates product development, enabling swift iterative design and fabrication tailored for competitive market demands. ↩ ↩

-

quality control – Understand the critical processes and methodologies behind quality control, ensuring consistent product excellence and reducing defects in manufacturing. ↩ ↩