Chinese manufacturers excel in padel racket production by combining advanced production techniques, strict quality control, high customization capabilities, and a proven track record of serving top international brands. This blend of expertise and reliability makes them the partner of choice for businesses looking to source high-performance padel equipment.

Procurement managers and directors in the sports equipment distribution industry increasingly face the challenge of sourcing high-quality padel equipment that meets the rigorous demands of competitive play. The essential requirements include durability, advanced material usage such as carbon fiber1 and glass fiber2, and customizable designs (e.g., Diamond, Round, and Teardrop shapes). Moreover, long-term partnerships hinge on reliable lead times, cost-effectiveness, and the ability to cater to specific brand demands. Companies aiming to source padel rackets must evaluate manufacturers on all these fronts.

- Manufacturing Capabilities: With evolving technologies, manufacturing processes require constant updating. Some companies still rely on outdated techniques, resulting in lower product performance.

- Material Complexity: The use of multiple materials – from 3k to 12k and 18k carbon fiber – provides versatility in racket design but demands expert handling and precise production techniques.

- Customization Demands: Brands now expect OEM manufacturers3 to offer full customization, including tailored shape designs, logo printing on hand grips, and personalized colors. This increased demand has caused many manufacturers to invest in fast prototyping and agile production methods.

- Fast Prototyping and Quick Turnaround: Time to market is crucial. Many companies are under pressure to deliver trending designs quickly, making rapid production cycles a competitive advantage.

- Cost Pressure with Quality Assurance: Procurement executives require not only high standards but also cost-effective solutions. The challenge is finding a balance between quality and price.

- Brand Reputation and Product Reliability: In a competitive marketplace, product performance impacts brand reputation. Suppliers must ensure that each manufactured padel racket can compete at the highest levels of play, which often involves meticulous quality control protocols.

Chinese padel racket manufacturers have developed a series of effective solutions to these challenges, ensuring their products meet the stringent demands of international brands.

-

Advanced Production Techniques

- Utilization of carbon fiber1 variants including 3k, 12k, and 18k ensures that rackets are both durable and lightweight.

- Implementation of state-of-the-art glass fiber2 processes also contributes to improved racket resilience.

- Adoption of automated machinery and computer-aided design (CAD) software4 to enhance consistency and precision.

-

Customizable Product Lines

- Offering three core shapes – Diamond, Round, and Teardrop – along with the option for fully customized designs.

- Customizable features extend to hand grips and handle caps, where brands can imprint their logos to maintain brand integrity.

- Ability to tailor color schemes and prints per client specifications, satisfying diverse market preferences.

-

Fast Prototyping and Short Lead Times

- Use of rapid prototyping5 techniques to quickly develop and refine new designs.

- A streamlined production process that allows for reduced turnaround times and agile order fulfillment.

- Strategic planning to ensure that large orders are processed without compromising on quality.

-

Quality Control and Reliability

- Multiple quality assurance checks throughout the production process guarantee product consistency.

- Collaboration with reputable brands such as Hirostar, Reebok, and Starvie to ensure that production meets international quality standards.

- Regular audits and performance tests to certify that low-cost production does not undermine overall product quality.

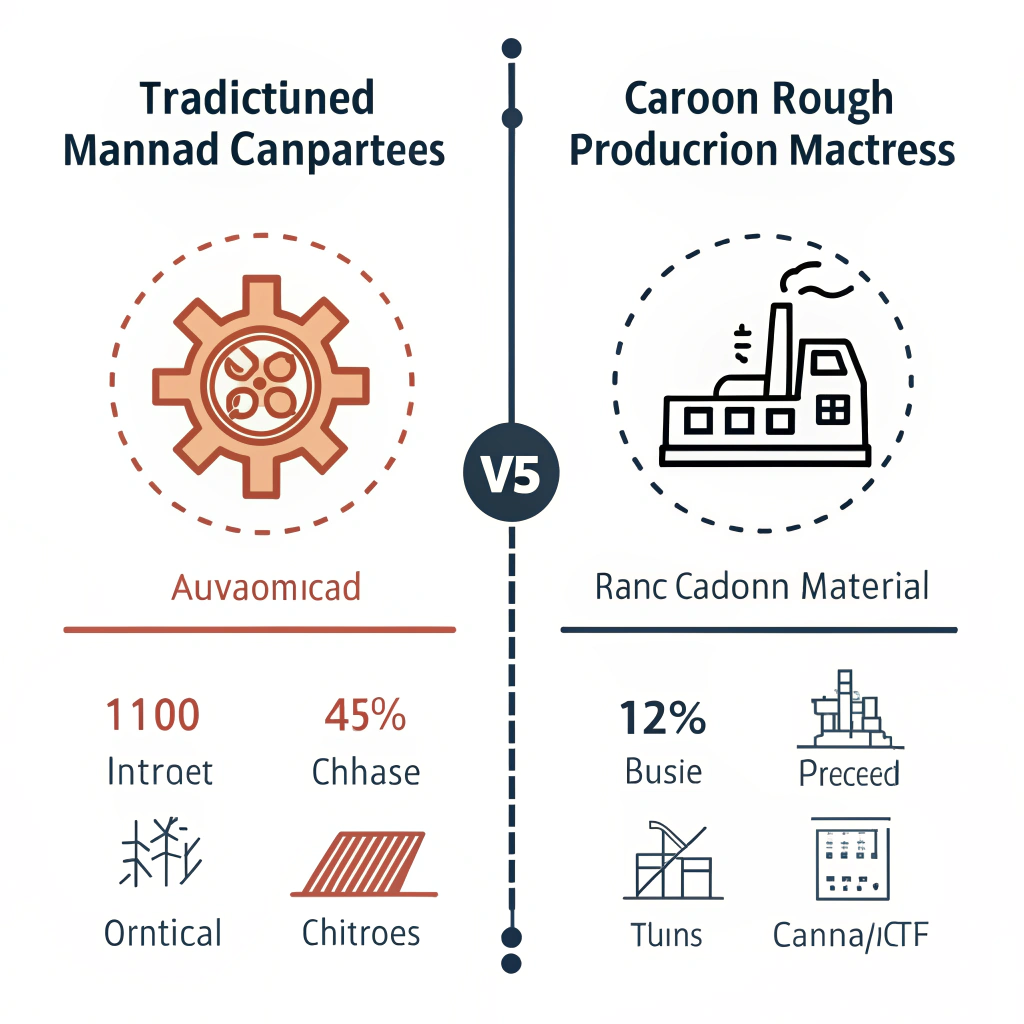

| Feature | Traditional Manufacturing | Advanced Chinese Production |

|---|---|---|

| Materials Used | Basic materials; limited fiber options | High-performance carbon fiber & glass fiber (3k, 12k, 18k) |

| Customization Options | Standard models with minimal tweaks | Fully customizable (shape, colors, logo, grips) |

| Production Speed | Longer lead times with manual processes | Fast prototyping, automated processes |

| Quality Assurance | Less frequent quality checks | Rigorous multi-stage quality control |

| Cost-efficiency | Higher cost due inefficiencies | Streamlined operations reduce costs |

| Market Adaptability | Slower to react to market trends | Agile response to market demands |

This table underscores how advanced methods employed by Chinese manufacturers offer a decisive advantage in cost-effectiveness, customizability, and timely delivery.

Given the variety of available solutions, companies can evaluate their specific needs against what Chinese manufacturers provide:

Several renowned brands have successfully leveraged these manufacturing strengths:

- Hirostar and Reebok: Both of these brands have built strong reputations partly due to their association with reliable OEM partners. Such partnerships highlight the trust that leading brands have placed in Chinese manufacturers.

- Starvie: Illustrates how high-customization and rapid turnaround are critical in meeting market trends and consumer expectations.

These case studies confirm that the strategic investment in advanced production and customized manufacturing not only meets but exceeds the industry standards required for high-performance padel rackets.

An essential part of choosing the right manufacturing partner is the ability to tailor products to market needs:

- Shape & Design Options:

- Diamond, Round, and Teardrop options allow for functional as well as aesthetic differentiation.

- Customization extends beyond the basic shape into ergonomics and user experience enhancements.

- Personalized Branding Opportunities:

- Custom printing and color options ensure that every product reflects the brand’s identity.

- Options for personalized hand grips and handle covers add an extra layer of differentiation.

- Scalable Prototyping:

- Fast prototyping means that product iterations can be immediately assessed, reducing time-to-market and enabling quick modifications based on feedback.

The ability to offer a wide range of customization ensures that brands can innovate and adapt quickly. This is especially vital in a dynamic market where small differentiators can have a significant impact on sales and brand perception.

Ensuring consistent product quality is non-negotiable when you’re engaged in high-performance padel racket manufacturing. Here’s how Chinese manufacturers excel:

- Raw Material Inspection

- Rigorous material testing for all carbon fiber and glass fiber components to ensure they meet international standards.

- In-Process Quality Checks

- Continuous monitoring during production to catch and correct defects early.

- Utilization of precision instruments and software to monitor tolerances and structural integrity.

- Final Product Testing

- Comprehensive testing regimes that simulate actual game conditions.

- Certification processes that are in line with global benchmarks.

Manufacturers often rely on key performance indicators (KPIs) such as defect rates, production time variances, and post-production durability tests. These metrics are shared with clients to build trust and prove the reliability of the production process.

Table: Key Quality Control Metrics

| Quality Metric | Standard Benchmark | Achieved Value (Example) |

|---|---|---|

| Defect Rate | <1% | 0.5% |

| Production Consistency | 95-98% | 97% |

| Durability Score | >90% | 92% |

| Lead Time Compliance | 100% on-time | 100% |

This focus on quality ensures that both cost and performance expectations are met, making Chinese manufacturing an attractive option for high-performance padel equipment.

For B2B procurement managers evaluating potential manufacturing partners, a structured approach is essential. Here are key recommendations:

-

Assess Facility Capabilities

- Ensure the manufacturer can handle advanced materials like different types of carbon fiber and glass fiber.

- Verify the presence of fast prototyping and agile production methods capable of meeting current market demands.

-

Evaluate Customization Options

- Confirm the range of customization available, from racket shapes (Diamond, Round, Teardrop) to aesthetic details such as color and logo placement.

- Consider the manufacturer’s ability to offer end-to-end OEM solutions, including complementary products like padel balls and accessories.

-

Examine Quality Control Procedures

- Request detailed quality assurance processes and recent performance metrics.

- Consider third-party quality audits and client testimonials as additional proof of reliability.

-

Consider Cost-Effectiveness

- Obtain transparent pricing models that reflect the balance between cost and high-quality production.

- Look for evidence of efficient production processes that reduce overhead without compromising on quality.

-

Review Past Partnerships and Case Studies

- A track record of successful partnerships with internationally recognized brands provides a level of confidence in the manufacturer’s capabilities.

- Ask for case studies or references that explain how challenges were addressed through innovative production techniques.

In summary, Chinese manufacturers, such as those at NEX Padel, excel due to their:

- Adoption of advanced production techniques

- Superior quality control measures

- High level of customization

- Proven track record with top global brands

Procurement managers should conduct thorough evaluations based on facility capabilities, customization options, and quality assurance processes. By doing so, they can secure a partner who not only meets technical requirements but also contributes to long-term business growth and competitive advantage.

Moving forward, consider engaging in a detailed consultation with manufacturing experts to explore how tailored solutions can further elevate your product offerings. This proactive approach ensures that you are partnering with a supplier who is committed to quality, innovation, and timely deliverables.

Q1: What makes Chinese manufacturers reliable for padel racket production?

A1: Chinese manufacturers utilize advanced production techniques, strict quality control processes, and offer extensive customization options that cater to high-performance specifications demanded in international markets.

Q2: How do customization options in Chinese padel racket manufacturing benefit brands?

A2: Customization options, such as choice of racket shapes (Diamond, Round, Teardrop), color schemes, and personalized branding on hand grips, allow brands to differentiate their products in competitive markets and meet specific customer requirements.

Q3: What quality control measures are employed in Chinese padel racket manufacturing?

A3: Quality control measures include thorough raw material inspections, continuous in-process quality checks, rigorous final product testing, and adherence to global standards through multi-stage audits and performance metrics.

-

carbon fiber: Click to learn how carbon fiber materials enhance racket durability and performance through superior strength and lightweight properties. ↩ ↩2

-

glass fiber: Click to understand how glass fiber is used in manufacturing to improve product resilience and impact resistance. ↩ ↩2

-

OEM manufacturers: Click to explore the role of OEM manufacturers in providing customized and efficient production solutions within B2B supply chains. ↩

-

computer-aided design (CAD) software: Click to learn how CAD software is used to ensure precision and innovation in modern manufacturing processes. ↩

-

rapid prototyping: Click to discover how rapid prototyping accelerates product development and shortens lead times in manufacturing cycles. ↩