Padel rackets with original designs and high-performance materials are essential for competitive play, and NEX Padel delivers precision-engineered1, customizable solutions to meet these demands. Our advanced manufacturing processes and extensive material options ensure that every padel racket—from glass fiber2 to various carbon fiber3 grades (3k, 12k, 18k)—is designed to consistently deliver performance and durability.

Procurement managers face numerous challenges when sourcing padel rackets that need to satisfy high-performance standards while remaining fully customizable. Often, companies must balance:

• Technical specifications such as weight, balance, and stiffness

• Material choices including glass fiber and various grades of carbon fiber

• Specific OEM4 requirements like original design geometry, handle customization, and racket aesthetics

In many cases, the conventional suppliers either lack the precision manufacturing capability or fail to offer the diverse customization options that modern players and brands demand. This creates a dilemma for decision-makers who must compare multiple suppliers, weighing their material quality, production speed, and overall OEM service levels.

Modern padel rackets require a mix of advanced materials to perform at the highest levels. The differences in carbon fiber types (3k, 12k, and 18k) directly affect the racket's weight distribution and vibration absorption. Glass fiber, on the other hand, offers a balance between flexibility and durability. Each material type contributes uniquely to racket performance, and an in-depth understanding of these materials is crucial when selecting a supplier.

A key differentiator in the market is the ability to provide original designs tailored to brand and player specifications. Whether opting for Diamond, Round, or Teardrop shapes, it’s vital that the design not only aligns with the aesthetics but also meets performance benchmarks. Moreover, customizable elements such as hand grip design, logo printing, and color variations further complicate the supply process and require a partner with state-of-the-art technology and flexible production lines.

Meeting the strict standards demanded by high-performance equipment requires precision engineering. Advanced production techniques, including rapid prototyping and stringent quality control measures, ensure that every batch of rackets meets both industry standards and customer expectations. The challenge lies in consistently delivering precision across a wide range of customization options.

Innovation in accessory options, like customizable hand grip coverage and unique racket handle designs, plays a crucial role in setting brands apart. However, procuring innovative products must not compromise reliability. Decision makers need suppliers who can innovate without sacrificing production speed or quality, ensuring that new designs are as durable and high-performing as traditional ones.

NEX Padel leverages years of expertise and a commitment to quality to address these challenges. Our comprehensive solution is structured into distinct areas:

We offer a wide array of material options allowing our partners to specify exactly what is needed for optimal performance. A quick comparison:

| Material | Features | Application Focus |

|---|---|---|

| Glass Fiber | High flexibility and cost-efficiency | Entry-level to intermediate performance |

| 3k Carbon | Light weight with moderate stiffness | Balanced performance across levels |

| 12k Carbon | Increased stiffness and precision | Advanced performance, enhanced control |

| 18k Carbon | Ultimate strength and durability | Premium level, competitive play |

This table illustrates our ability to provide tailored material choices, ensuring that each racket meets the specific performance and durability requirements demanded by professional standards.

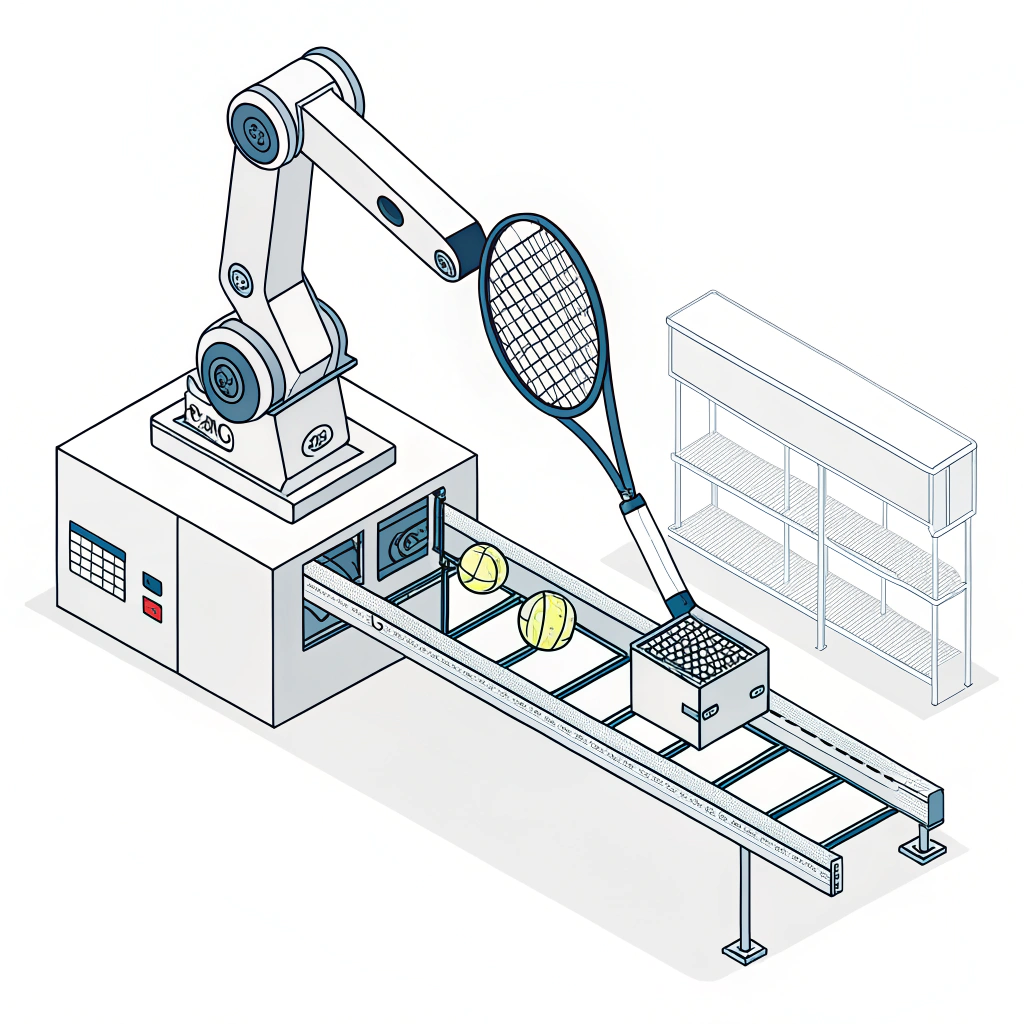

Our production process is defined by Rapid Prototyping5, stringent quality controls, and the latest manufacturing techniques. Some key benefits include:

• Rapid Prototyping: Speed up the design iteration process, ensuring faster time-to-market.

• Precise Customization: Tailor every aspect of the racket—from its shape (Diamond, Round, Teardrop) to detailed elements like logo placement and hand grip customization.

• Quality Assurance: Each step in the production process is monitored and controlled, ensuring consistency and durability.

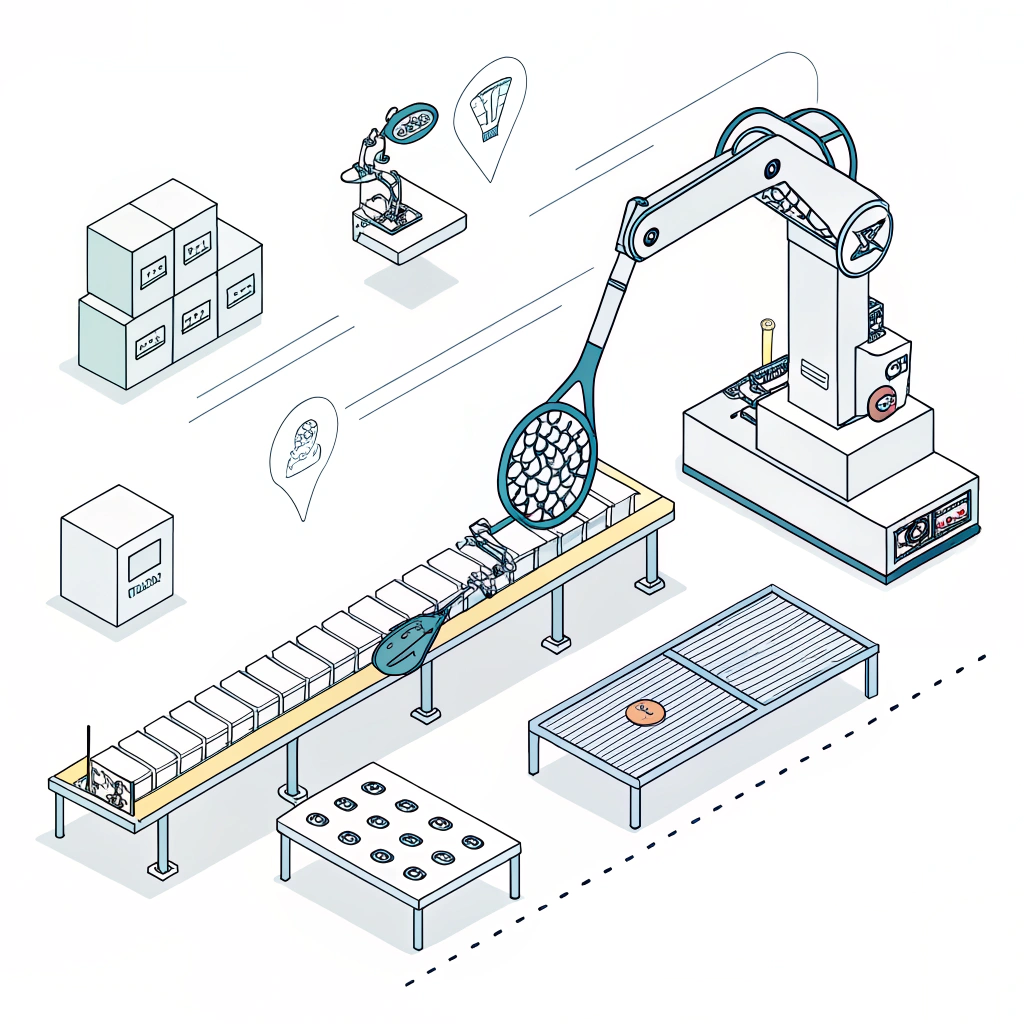

We position ourselves as more than just a manufacturer; we are your OEM partner. Our role is to bring innovations from the drawing board to reality. Through direct collaboration, we make it easy for procurement managers to tweak original designs or even create new designs that align perfectly with brand identity. Key aspects include:

- Customization: Full custom design capabilities that include shape, material, and color.

- Speed: Fast sampling and on-time delivery that ensures production targets are met.

- Expertise: A deep understanding of industry standards helps us guide partners through the design evolution process.

We support our claims with data gathered from rigorous testing. For instance, by using advanced carbon fiber variants, our rackets maintain a consistent frame stiffness while absorbing impact, leading to prolonged durability and reduced player fatigue. Such performance benchmarks are often shared with our OEM partners to ensure transparency and confidence in our production capabilities.

Some best practices that help us stand out in a competitive market include:

• Establishing clear and direct communication channels, ensuring that design modifications are implemented swiftly.

• Leveraging state-of-the-art machinery which minimizes manual error and maximizes precision.

• Incorporating customer feedback loops that allow us to continuously improve material performance and design accuracy.

When partnering with a supplier for customizable, high-performance padel rackets, consider the following action points:

-

Evaluate Material Options: Understand the performance characteristics of various grades of carbon fiber and glass fiber. Ensure that the supplier has robust testing and quality control regimes in place.

-

Review Customization Capabilities: Assess whether the supplier can handle unique design molds such as Diamond, Round, and Teardrop shapes along with other custom elements like grip design and logo printing.

-

Assess Manufacturing Speed and Prototyping: Rapid Prototyping5 is not merely a luxury; it is a necessity when adapting to market trends. Confirm that the supplier can produce samples quickly without compromising quality.

-

Examine Quality Control Measures: Inquire about the quality assurance process. Reliable data and performance metrics should back every claim of efficiency and durability.

-

Plan for Long-Term Partnership: Select a supplier who can serve not only as a manufacturer but as a strategic partner, facilitating ongoing research and development to continually innovate your product offerings.

A sample checklist you can use during supplier evaluation:

| Evaluation Criterion | Key Questions | Status |

|---|---|---|

| Material Quality | Are detailed material test results available? | To be verified |

| Customization Range | Can the supplier fully customize shape, print, and grip? | Yes/No |

| Prototyping Speed | What is the average turnaround time for prototypes? | Measured in days |

| Quality Control | Is there a comprehensive quality assurance process? | To be detailed |

| OEM Collaboration | How does the supplier handle design iterations? | To be discussed |

Taking a systematic approach, such as this checklist, ensures that your selection process is thorough and aligned with your performance requirements.

Consider a global sports brand that recently partnered with us for the production of a new line of padel rackets. The project involved:

• Evaluating multiple material options to meet distinct performance goals

• Designing a unique racket shape that diverged from the typical market offerings

• Customizing the hand grip and handle cover with brand-specific logos

• Implementing a rapid prototyping strategy that shortened the product development cycle

By adopting our comprehensive production approach, the brand saw a 20% reduction in the product development cycle and an improvement in overall performance metrics. Data from independent testing confirmed that the newly designed rackets provided improved balance, reduced vibration, and increased durability, ultimately translating into better on-court performance. This success story reinforces the importance of partnering with a manufacturer capable of delivering both innovation and consistency.

For procurement managers and OEM partners, the search for a high-performance, customizable padel racket supplier can be complex. However, by focusing on material excellence, advanced production techniques, and close OEM collaboration, NEX Padel provides a comprehensive solution that bridges the gap between design innovation and production precision.

If you are looking for a reliable partner who can offer:

• Advanced material options such as 3k, 12k, and 18k carbon fiber and glass fiber

• Full-scale customization, including racket shape, hand grip design, and OEM branding

• Rapid prototyping and rigorous quality control processes

... then it’s time to consider how enhancing your product portfolio can be achieved swiftly and cost-effectively. We invite you to discuss your requirements with us so that we can tailor a manufacturing process that meets your specific performance benchmarks and market expectations.

Together, we can build the next generation of high-performance padel rackets that set a new industry standard in both design and durability.

Q: What makes NEX Padel’s padel rackets different from other suppliers?

A: NEX Padel offers advanced material options like 3k, 12k, and 18k carbon fiber alongside glass fiber, ensuring precision-engineered performance and customization options that cater specifically to OEM needs and high industry standards.

Q: How does NEX Padel ensure the durability and performance of its rackets?

A: We implement rigorous quality control measures throughout our advanced production process—including rapid prototyping and detailed testing—to maintain consistent performance and durability across all customization levels.

Q: Can NEX Padel support full OEM customization for padel rackets?

A: Yes, our comprehensive OEM services enable full customization from racket shape (Diamond, Round, Teardrop) to hand grip design, logo printing, and color options, ensuring every product meets unique brand and performance requirements.

-

precision-engineered: Click to learn how precision engineering integrates advanced techniques and meticulous quality control to deliver superior product performance and durability. ↩ ↩

-

glass fiber: Click to understand the benefits of glass fiber, including its flexibility, cost-efficiency, and role in balancing durability with performance in sporting goods. ↩ ↩

-

carbon fiber: Click to explore the various carbon fiber grades (3k, 12k, 18k) and their unique contributions to weight distribution and vibration absorption in high-performance sports equipment. ↩ ↩

-

OEM: Click to dive into the concept of Original Equipment Manufacturer (OEM) partnerships and how they enhance product customization, quality, and innovation. ↩ ↩

-

Rapid Prototyping: Click to learn about rapid prototyping techniques that accelerate design iterations, reduce time-to-market, and allow for faster product development cycles in manufacturing. ↩ ↩ ↩2