Padel rackets are not one-size-fits-all—they come in various sizes, shapes, materials, and designs to match different playing styles and performance needs. Choosing the right configuration depends on factors such as player skill, playing style, and specific performance requirements. In this article, we break down the key aspects of padel racket selection, discuss the benefits of different designs, and explain why partnering with a quality OEM1 like NEX Padel can make all the difference in the production and customization of high-performance equipment.

Padel rackets consist of several critical elements: the size and shape of the racket, the material used in construction, and the overall design features. Each aspect affects performance, durability, and feel during play. For example, a racket’s shape determines its balance between power and control, while the materials—from fiberglass2 to various grades of carbon fiber3 (3k, 12k, 18k)—impact weight, strength, and responsiveness.

Although the face sizes of padel rackets do not vary significantly, nuances in depth, thickness, and weight can influence a player's performance. Typically, rackets have a thickness around 36mm and weigh between 320g and 355g, though these specifications can be subtly adjusted based on user preference and skill level.

Key aspects of size and weight include:

- Face Size Consistency: Most rackets maintain a similar face size, ensuring that the hitting area remains consistent for control and power.

- Weight Range: Lighter rackets are generally preferred by beginners or defensive players, whereas seasoned players might opt for slightly heavier models to leverage power while maintaining control.

- Depth and Balance: Variations in depth, combined with weight distribution, determine the racket's balance. This ultimately affects maneuverability and the ease of generating both impulsive power and precise control.

Manufacturers like NEX Padel offer a range of customization options. By understanding padel racket size nuances, procurement specialists can ensure that each product meets market expectations and player needs.

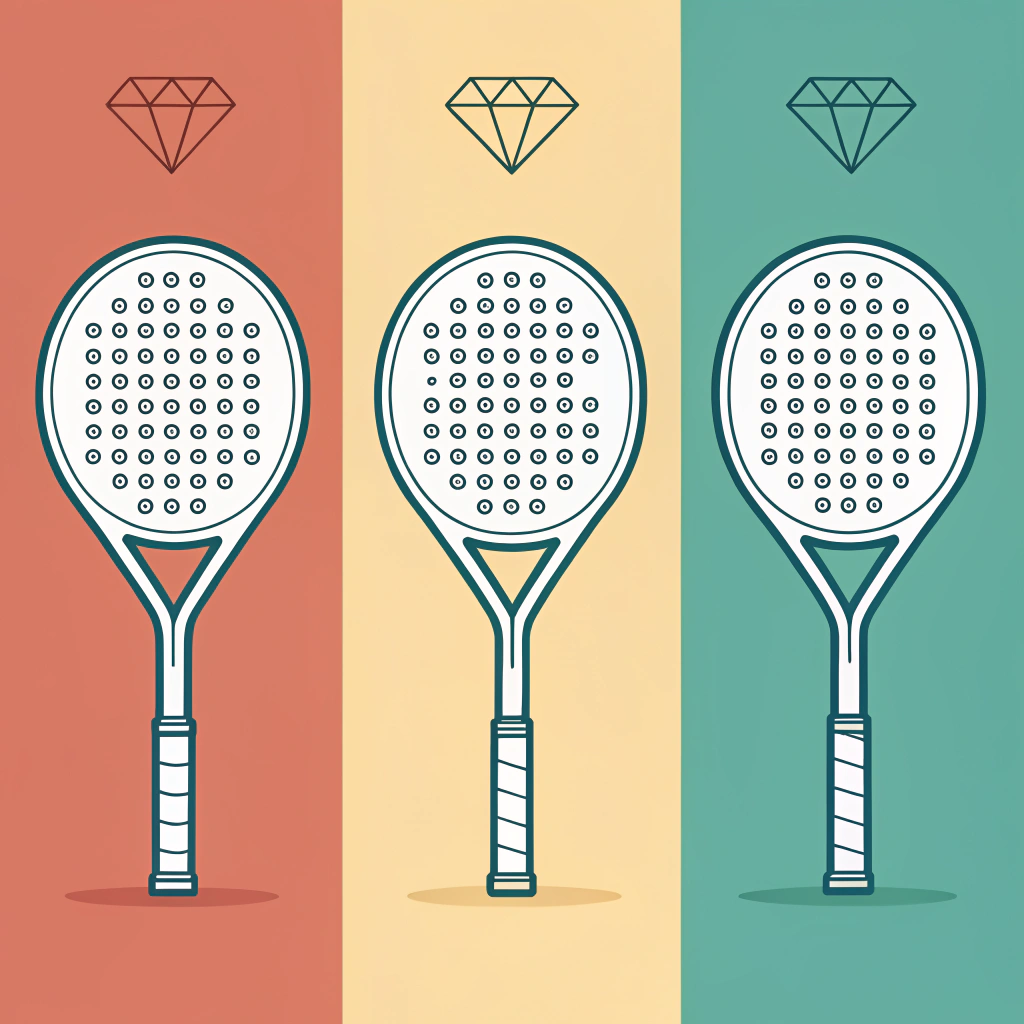

The shape of a padel racket is one of the most critical design elements affecting player performance. The three main shapes—round, diamond, and teardrop—each cater to different playing styles:

-

Round Shape:

Primarily designed for maximum control and precision. This shape is preferred for beginners and defensive-oriented players who rely on technical play and accurate shot placement. A round-shaped racket provides a larger sweet spot, making it more forgiving on off-center hits. -

Diamond Shape:

Emphasizes offensive play. The diamond shape typically has a higher balance point to facilitate greater power, which can be ideal for players who are more aggressive on the court. This shape tends to have a smaller sweet spot, demanding precision and experience from the user. -

Teardrop Shape:

Strikes a balance between control and power. Suited for all-round play, the teardrop design offers versatility for a range of playing styles. It provides a mix of larger sweet spot surface and balanced weight distribution, enabling both precise control and effective power generation.

To further clarify these differences, consider the comparison table below:

| Feature | Round Shape | Diamond Shape | Teardrop Shape |

|---|---|---|---|

| Target Player | Beginners, Defensive | Offensive, Advanced | All-round players |

| Sweet Spot | Larger | Smaller | Moderate |

| Power | Moderate | High | Balanced |

| Control | High | Requires precision | Sufficient for all |

| Balance | Even & forgiving | High balance point | Optimized for versatility |

NEX Padel leverages precision manufacturing to produce each shape with consistent quality. This kind of customization ensures that every client receives a product that not only meets technical specifications but also addresses specific competitive requirements.

The choice of material in padel racket manufacturing plays a critical role in durability, performance, and user comfort. The industry primarily uses materials like fiberglass2 (already marked) and various types of carbon fiber3 (3k, 12k, and 18k) that offer differing degrees of stiffness and durability.

-

Fiberglass:

- Flexibility: Fiberglass is less rigid compared to carbon fibers, which can provide a softer feel and increased control.

- Durability: While offering more flexibility, fiberglass may not be as robust against high-impact forces over long periods.

- Cost-effectiveness: This material is often used for entry-level or intermediate rackets due to its lower cost.

-

Carbon Fiber (3k, 12k, 18k):

- Stiffness and Power: Higher-grade carbon fibers (like 12k and 18k) provide a stiffer frame, which can help generate more power and improve response times.

- Precision Manufacturing: Using advanced carbon fiber ensures that the racket maintains consistent strength and lightness. It minimizes vibrations and enhances shot accuracy.

- Customization Opportunities: Different grades enable tailored performance. For example, a beginner’s model might incorporate a blend that offers more control, whereas a high-performance racket for an advanced player would utilize a stiffer carbon fiber for power.

Manufacturers can also mix materials with design innovations such as customized hand grips and personalized handle covers. This added layer of customization not only improves the player’s comfort but also reinforces brand identity.

A simplified overview of material benefits is shown below:

| Material Type | Key Benefits | Suitability |

|---|---|---|

| Fiberglass | High control, flexible | Entry-level to intermediate players |

| 3k Carbon Fiber | Balanced rigidity | Versatile, all-round performance |

| 12k/18k Carbon Fiber | Enhanced power, stiffness | Advanced and performance-focused players |

Choosing padel equipment from a reputable OEM like NEX Padel means access to advanced production techniques and complete customization options. Our factory is equipped with state-of-the-art machinery to handle rapid prototyping, ensuring that the final product not only meets industry standards but also aligns with specific client needs.

-

Customization:

NEX Padel’s manufacturing process supports full customization of racket shapes—whether diamond, round, or teardrop. Clients can specify dimensions, materials, and even color prints. Custom logos on hand grips and handle covers further enhance the product’s appeal. -

Quality Control:

Our production facilities are monitored constantly to ensure that each component meets strict quality standards. Technological checks and production data analytics guarantee consistency across every production batch. -

Speed to Market:

With a fast sampling process and timely delivery, our OEM manufacturing service reduces lead times. In a competitive sports equipment market, this responsiveness is key to staying ahead. -

Technical Support:

Clients receive detailed technical information about material properties, weight variations, balance differences, and manufacturing techniques—empowering procurement specialists to make informed decisions.

Investing in padel racket OEM manufacturing translates to reduced risk and increased innovation. Whether updating your product lineup or launching a new brand, the ability to modify everything from padel ball packaging to racket structure is a significant competitive advantage.

For a successful product development phase, procurement teams need to balance technical nuances with market trends. Here are some key considerations:

-

Player Demographics and Usage:

The selection of racket shape and materials should be aligned with the target market. For instance, a product line aimed at beginners might lean towards round designs with fiberglass to prioritize control. An advanced player-oriented series would benefit from stiffer carbon fiber designs like the diamond or teardrop models, providing enhanced power. -

Customization Without Compromise:

Custom shapes and logos are more than aesthetic improvements. They enhance brand identity and allow for a unique user experience. Clients must keep in mind that while customization is appealing, maintaining structural integrity and consistent performance remains paramount. -

Iterative Sampling and Testing4

The OEM production process should include iterative prototype testing. Early sampling helps confirm that the selected materials and design modifications live up to performance claims. This iterative process minimizes the risk of costly production errors and ensures client satisfaction. -

Documentation and Compliance:

Detailed Technical Documentation5 is essential for B2B buyers. Specifications like weight range, thickness, balance, and material quality need to be clearly outlined. Providing comprehensive data not only instills confidence in product quality but also supports client marketing efforts. -

Market Adaptability:

As market demands evolve, manufacturers must be willing to adapt production methods. At NEX Padel, our technological infrastructure supports quick transitions in design and production, ensuring that new trends and regulatory standards are seamlessly integrated into the product development pipeline.

Based on our detailed analysis, here are practical recommendations for product development managers and procurement specialists when choosing padel rackets:

- Identify your target players' needs based on skill level and playing style.

- Compare the technical specifications of different racket shapes using detailed tables and material performance data.

- Consider collaborating with an OEM partner who can offer full customization options and robust quality control.

- Ensure that all technical details are meticulously documented to support marketing and regulatory compliance.

- Use iterative prototyping and sample testing to align final products with market demands.

By following these steps and partnering with a knowledgeable manufacturer like NEX Padel, you can optimize your padel equipment line to meet both market trends and high-performance standards.

In summary, understanding the fundamental differences in padel racket sizes, shapes, materials, and designs is essential for making informed procurement decisions. Whether you choose a round, diamond, or teardrop shape depends on the player's needs—each shape brings its distinct advantages. Similarly, material selection, from fiberglass to various grades of carbon fiber, plays a critical role in the racket’s durability and performance. Customization, quality control, and fast delivery are offered by our OEM services, ensuring that every high-performance padel racket manufactured meets rigorous industry standards.

By leveraging technical insights and production excellence, procurement specialists can reduce production risks and foster innovation in their product lines. The detailed analysis provided herein should serve as a strong foundation for your evaluation and decision-making process when sourcing padel rackets for your sports equipment portfolio.

Q: What is the best shape for a padel racket?

A: The best shape depends on the player’s style. A round racket typically offers better control and is ideal for beginners or defensive players, while a teardrop racket provides a balanced mix of power and precision suited for all-round play.

Q: Are there different sizes of padel rackets?

A: Yes, while the face sizes of padel rackets remain relatively consistent, variations in depth and weight exist. Beginners usually prefer lighter rackets around 36mm thick and weighing between 320g and 355g.

Q: What material is best for a padel racket?

A: The optimal material depends on playing preferences. Softer materials like fiberglass offer more control, while advanced options using carbon fiber (such as 3k, 12k, or 18k) provide enhanced durability and power, ensuring better performance for various playing styles.

-

OEM: Learn how partnering with an Original Equipment Manufacturer can streamline production processes, reduce costs, and offer customized solutions tailored to specific market demands. Back to OEM ↩

-

fiberglass: Discover the properties of fiberglass, including its flexibility and cost-effectiveness, which make it a popular choice in manufacturing entry-level to intermediate sporting goods. Back to fiberglass ↩ ↩2

-

carbon fiber: Explore the benefits of carbon fiber, the different grades available (3k, 12k, 18k), and how they influence the performance, weight, and durability of high-performance equipment. Back to carbon fiber ↩ ↩2

-

Iterative Sampling and Testing: Understand the importance of iterative sampling and testing in the production process to ensure that final products meet rigorous performance standards and minimize production risks. Back to Iterative Sampling and Testing ↩

-

Technical Documentation: Learn why detailed technical documentation is essential in B2B transactions for ensuring compliance, fostering trust, and supporting effective product marketing. Back to Technical Documentation ↩