Quick Answer: weight distribution1 is a critical factor in padel racket design that directly influences performance and durability, affecting swing control, power delivery, and overall playability. Understanding how materials, design choices, and manufacturing precision interact can help procurement managers and product designers choose or customize the ideal racket to meet specific competitive and branding needs.

Padel rackets are not one‐size‐fits‐all pieces of equipment; instead, their performance is deeply rooted in technical details like weight distribution. For procurement managers and technical buyers, this factor is especially important because it plays a crucial role in both the on-court performance and the long-term durability of the equipment. In this article, we will break down the principles behind weight distribution, explore how various manufacturing techniques and materials affect it, and offer clear, actionable insights for decision-makers in the sports equipment industry.

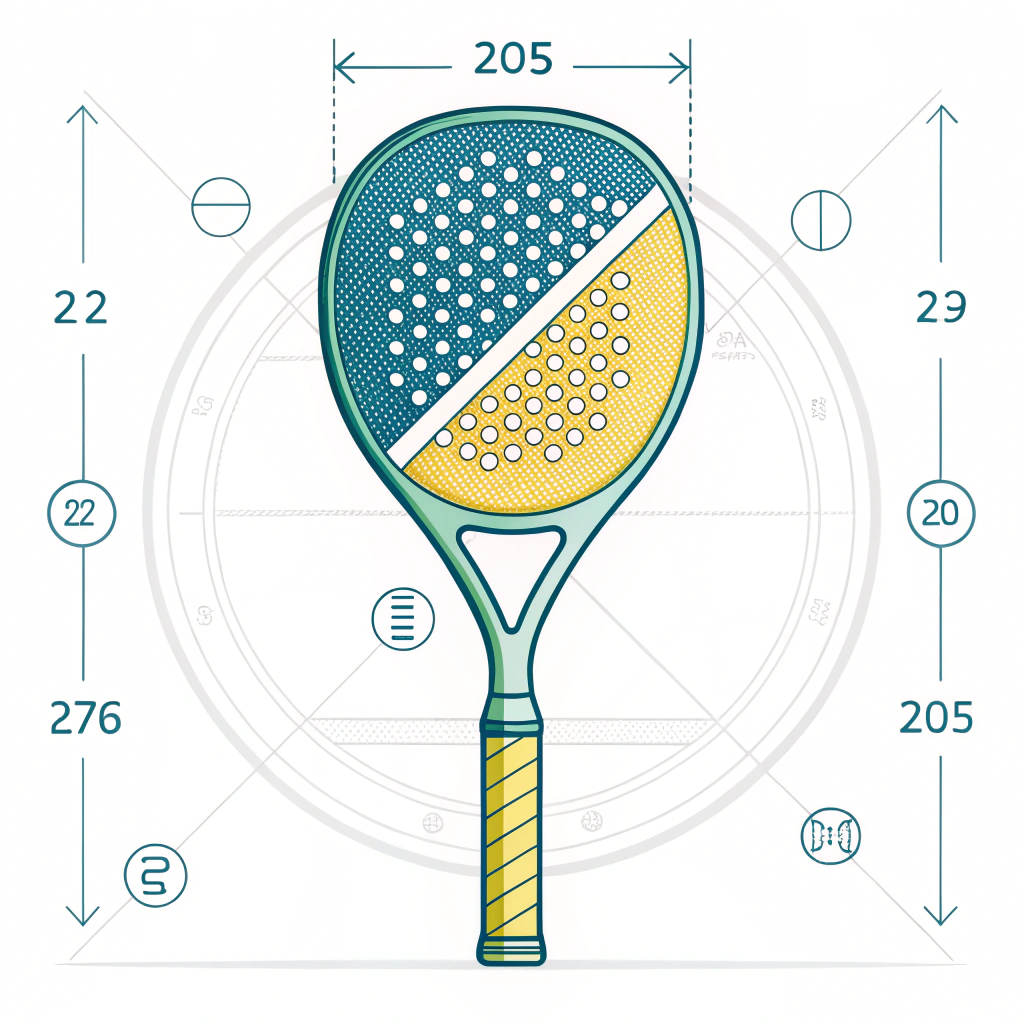

When we talk about weight distribution in padel rackets, we refer to how weight is allocated along the racket’s head, handle, and overall balance point. This distribution affects the racket's center of gravity, swinging speed, and impact power. A well-balanced racket ensures that players can enjoy both power and control, while an ill-fitted distribution may lead to increased strain and reduced performance.

-

Materials Used:

The selection of materials such as fiberglass, carbon fiber2 variants (3k, 12k, 18k), and graphite plays a huge role. Higher grade carbon fibers often provide enhanced stiffness with less weight, resulting in improved balance without compromising durability. -

Racket Shape:

Padel rackets typically come in Diamond, Round, or Teardrop designs. Each shape offers a different center of gravity:- Diamond-shaped rackets tend to have a head-heavy balance, which increases power but demands expert handling.

- Round-shaped rackets feature an even weight distribution, making them easier to control for a broader range of players.

- Teardrop designs offer a mix between power and control, striking a balance that caters to many playstyles.

-

Manufacturing Precision:

Advanced production techniques help ensure that every racket meets strict tolerances for weight distribution. At NEX Padel, our sophisticated linage and quality controls guarantee that each racket, regardless of customization, maintains an optimal balance that meets international engineering standards. -

Customization Options:

Custom manufacturing3 isn’t just about aesthetics. Adjusting parameters like handle length, grip customization (including hand grip and overgrips with logo printing), and even the frame’s thickness can tailor the weight distribution to specific performance needs.

Performance:

A racket’s balance can dramatically influence a player's power output and maneuverability. For example, a head-heavy racket may generate more power during smashes, whereas a head-light racket tends to offer greater control and less strain on the wrist and shoulder.

Durability:

Even weight distribution ensures that the shock of ball impacts is evenly spread out, reducing the risk of fractures in high-stress areas. In manufacturing, maintaining this balance—especially when using advanced carbon fiber materials—means that the racket will endure the demands of competitive play without compromising structural integrity.

Player Experience:

From beginners to seasoned professionals, players have unique physical capabilities and styles. A lighter racket (generally between 340g and 365g) lends to easier handling and rapid response in fast-paced games, while a heavier racket (approximately 365g to 390g) is favored by experienced players who can leverage extra mass for increased power.

Below is a table summarizing some of the typical weight ranges and their impact:

| Weight Range | Characteristics | Suitable For |

|---|---|---|

| 340g - 365g | Lighter, easier to handle, promotes quick reactions | Beginners and players requiring agility |

| 365g - 390g | Heavier, offers more power and stability | Advanced players with good upper-body strength |

Errors in weight distribution typically originate during the manufacturing and design phase. The following are common causes that may lead to uneven balance:

-

Material Discrepancies:

Inconsistent material batches or variations in fiber alignment can lead to weight imbalances. When using composite materials like carbon fiber, even slight deviations can have noticeable effects on balance. -

Manufacturing Tolerances:

Lapses in quality control during curing or lamination processes may cause sections of the racket to be denser than intended. Manufacturing tolerances4 are critical for ensuring that each component meets the strict design specifications. -

Design Challenges:

When designing a custom racket, the interplay between aesthetics and functionality demands precise calculations. Over-customization without strict adherence to engineering parameters can result in a design that is visually impressive but functionally compromised.

By understanding these common pitfalls, manufacturers like NEX Padel have continuously improved production processes—such as automated quality control checks and precise material handling—to ensure optimal weight distribution.

For procurement managers and technical buyers, the next step is implementing specific solutions that guarantee both high performance and reliability. Consider the following checklist when evaluating a padel racket for your brand:

-

Material Selection:

Choose high-quality, consistent materials. For example, using advanced carbon fibers (12k or 18k) can lead to a more predictable weight distribution compared to lower-grade composites. -

Design Validation:

Implement computer-aided design (CAD simulations5) that model both dynamic play and impact forces. This simulation helps in fine-tuning the balance and ensures that the racket performs as intended under match conditions. -

Rigorous Quality Control:

Look for factories with internationally recognized quality standards. Regular testing and automated measurement processes can ensure that every produced racket meets the designated weight and balance parameters. -

Customization Flexibility:

Evaluate the manufacturer’s ability to offer tailored solutions without compromising the technical aspects. Custom shapes, grips, and colors should be offered in a way that maintains the overall design integrity. -

Feedback Loop:

Incorporate end-user feedback into the design process. Many manufacturers work closely with athletes to refine weight distribution, ensuring that the final product optimally suits various play styles.

Below is a checklist table that summarizes these critical solutions:

| Critical Factor | Recommended Action | Impact on Performance/Durability |

|---|---|---|

| Material Quality | Use high-grade carbon fiber and standardized composites | Consistent weight, improved durability |

| Design Simulation | Apply CAD and dynamic modeling tools | Optimized balance and performance |

| Quality Control | Implement automated inspection and standardized tolerances | Reduced risk of manufacturing variances |

| Customization Process | Maintain engineering controls during customization | Personalized design without balance loss |

| User Feedback | Collect performance data from athletes | Enhances product evolution and refinement |

For B2B professionals sourcing padel rackets, it is essential to work with a partner who is familiar with these technical nuances. NEX Padel’s advanced production techniques — rooted in decades of research and refined through partnerships with leading international brands — serve as a benchmark for quality and performance in this industry.

-

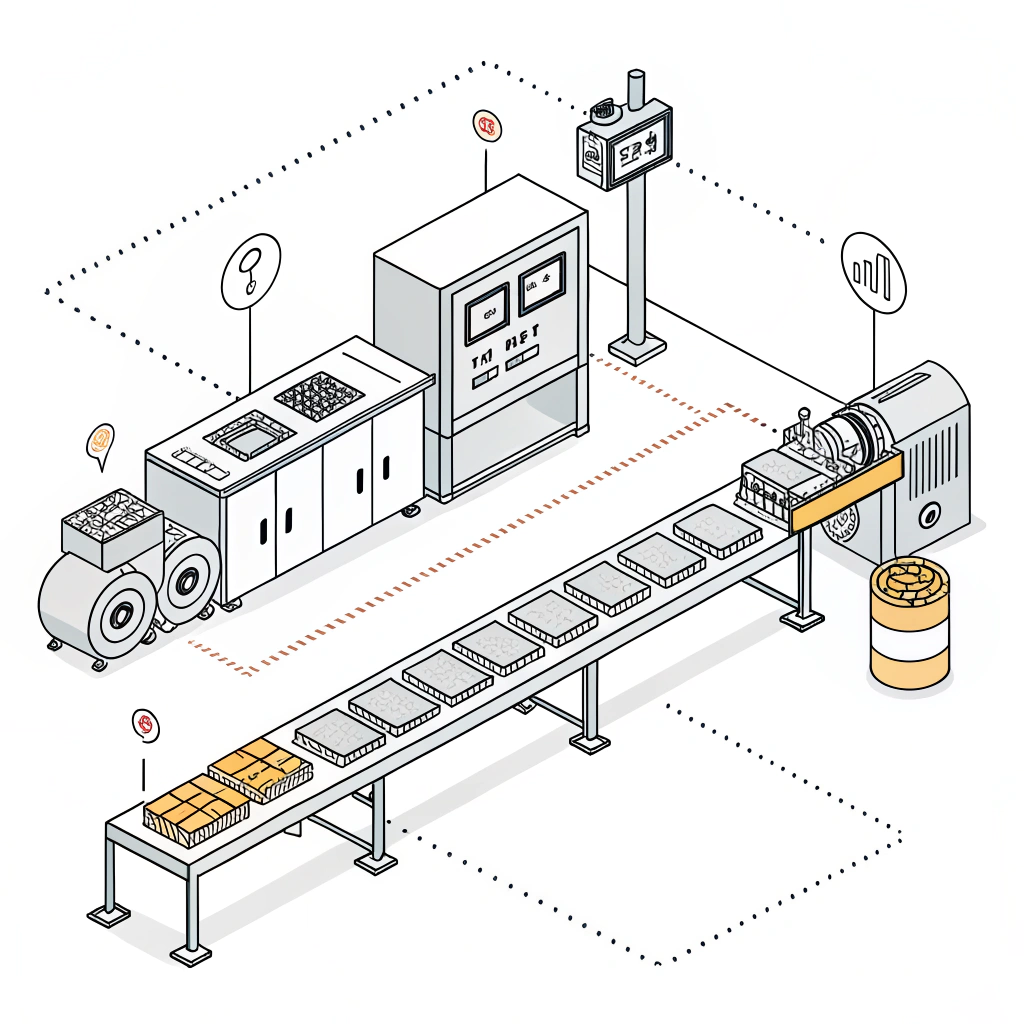

Controlled Lamination:

During the layering process, uniform pressure and temperature control are maintained to ensure that the fibers are evenly distributed. This results in a more consistent weight distribution across the racket. -

Precision Curing:

Modern ovens and curing machines offer high precision in temperature control, ensuring that the racket’s resin cures evenly across all areas. This mitigates the risk of localized weight discrepancies. -

Comprehensive Testing:

Each prototype undergoes a series of tests, including drop tests, vibration analysis, and dynamic simulation under load. These tests simulate real-play conditions to validate that the racket meets performance goals before entering mass production. -

Customization Protocols:

Custom solutions, whether for an adjusted shape or personalized printing, follow stringent protocols that do not compromise the underlying balance. Each modification is cross-checked with design and engineering teams to ensure technical feasibility.

By following these best practices, manufacturers can consistently produce padel rackets that deliver on the promise of high performance while ensuring longevity and reduced risk of injury.

For B2B sports equipment distributors, selecting a padel racket with optimal weight distribution translates into tangible business benefits. A well-balanced racket can enhance a player’s confidence on-court, reducing the rate of returns and enhancing brand reputation. Furthermore, when designing custom rackets or rebranding existing products, technical precision becomes a unique selling proposition.

-

Market Differentiation:

By offering a product that has been finely tuned for both performance and durability, brands can distinguish themselves in highly competitive markets. The technical advantages of balanced rackets can be highlighted in marketing campaigns, trade shows, and customer presentations. -

Cost Efficiency:

Improved durability directly correlates with reduced warranty claims and fewer replacements, resulting in long-term cost savings. A product that maintains its structural integrity over time reinforces customer trust and supports a brand’s sustainability messaging. -

Enhanced Customer Experience:

Players who use rackets with excellent weight distribution report better on-court performance, which reinforces brand loyalty. Satisfied customers are more likely to recommend products, creating a positive cycle that benefits both distributors and manufacturers.

Below is a comparative analysis table highlighting the competitive advantages associated with optimized weight distribution:

| Advantage | Description | Business Impact |

|---|---|---|

| Improved Performance | Even weight distribution ensures better swing control and reduced player fatigue | Enhanced customer satisfaction |

| Increased Durability | Reduced stress concentration extends the product’s lifespan | Fewer warranty claims and cost savings |

| Market Differentiation | Technical superiority is a strong point in branding and competitive comparisons | Higher market share and brand loyalty |

| Customization Excellence | Ability to tailor designs without sacrificing performance standards | Meets diverse buyer requirements |

In summary, the weight distribution in padel rackets is not just a technical specification—it is a cornerstone of performance, durability, and customer satisfaction. By understanding the key factors such as materials, design, manufacturing precision, and customization flexibility, procurement managers can make informed choices that align with their brand strategies.

For companies seeking to elevate their product offerings, partnering with a manufacturer like NEX Padel, with our proven expertise and precise production capabilities, can offer a significant competitive advantage. Whether you are looking for stock products or bespoke customizations, our advanced processes ensure that every racket meets the highest standards in both performance and longevity.

Your next step should involve evaluating current supplier capabilities and aligning them with industry best practices. Consider integrating regular feedback loops, investing in cutting-edge testing technology, and ensuring that all material sources are verified for consistency. These initiatives not only improve product quality but also strengthen your brand’s reputation in an increasingly competitive market.

-

How to choose padel racket weight?

For optimal performance, consider lighter rackets (340g - 365g) for easy handling and quick reactions, whereas heavier rackets (365g - 390g) provide more power and stability for experienced players. The ideal choice depends on the player’s strength and play style. -

What to consider when buying a padel racket?

Key considerations include racket shape for proper fit, weight balance to match your power and maneuverability needs, handle size for comfort, and materials used in construction which affect durability and performance. -

Is it better to have a lighter or heavier padel racket?

Lighter rackets are generally easier on the arm and allow for rapid swings, making them a smart choice for conserving energy and improving agility. However, players with natural strength may benefit from heavier rackets, which can enhance power output during play.

-

weight distribution: Click to read about how proper weight allocation improves a racket's balance, impacting swing control and overall playability, which is essential for optimizing performance and durability. ↩ ↩

-

carbon fiber: Click to explore the benefits and properties of high-grade carbon fibers used in sports equipment, highlighting how they enhance structural strength while reducing weight. ↩ ↩

-

custom manufacturing: Click to discover how custom manufacturing enables tailored designs that meet specific performance requirements, blending aesthetics with engineering precision. ↩ ↩

-

manufacturing tolerances: Click to understand the critical role of precise manufacturing tolerances in ensuring product consistency and performance, which minimizes variances in weight distribution. ↩ ↩

-

CAD simulations: Click to learn how computer-aided design simulations contribute to design validation by modeling dynamic forces and ensuring optimal racket balance. ↩ ↩