In short, NEX Padel offers manufacturers and distributors a complete, reliable solution for high-performance padel rackets with advanced production techniques1, customization options, and strict quality control measures2 to meet global B2B standards.

In today’s rapidly evolving sports equipment market, procurement managers face a tough challenge: finding a manufacturer that not only produces high-quality padel rackets3 but also delivers custom-designed products with competitive pricing and fast turnaround times. Many suppliers fail to meet multiple requirements simultaneously, leading to delays and product inconsistencies. The key issues include:

• Maintaining consistent quality when producing multiple types of padel rackets (Diamond, Round, Teardrop, and custom shapes).

• Ensuring that advanced materials such as 3k, 12k, and 18k carbon fiber4 and fiberglass meet both performance and durability standards.

• Balancing price pressures while offering high-end customization options such as custom printing, colors, and even personalized hand grips or handle covers.

• Managing large bulk orders with on-time delivery and quality assurance, which is crucial for purchasing managers and distributors.

Without a dependable supplier, businesses risk supply chain interruptions5, missed market opportunities, and lower customer satisfaction.

Understanding why some manufacturers struggle is crucial to identifying the best partner for your needs. Several factors typically contribute to these challenges:

-

Material Variability: Many manufacturers source materials from various vendors, which can lead to differences in quality. When these materials – especially advanced carbon fibers – are inconsistent, it negatively affects the final product.

-

Production Techniques: Conventional methods may not account for the high precision required by international standards. Precision and durability can only be achieved with advanced production techniques, including automated quality control systems.

-

Customization Complexity: The need for bespoke shapes, prints, colors, or branded accessories adds complexity to production. Without a streamlined process, customization can lead to longer production times or increased costs.

-

Supply Chain Management: Inconsistent lead times and order fulfillment issues are common when a manufacturer has limited control over its production schedule. This is especially problematic in the sports equipment industry where timing is critical.

-

Quality Assurance Measures: Without stringent quality testing at every phase of production, the end product may not meet performance standards, resulting in customer dissatisfaction.

At NEX Padel, we have developed a robust approach that addresses these root causes. Our solutions are built around advanced production techniques, strict quality control, and extensive customization, ensuring each padel racket not only meets but exceeds international quality standards. Below is our solution outline:

- High-Precision Equipment: We invest in state-of-the-art machinery designed to handle materials such as fiberglass and various grades of carbon fiber (3k, 12k, 18k) with utmost precision.

- Automated Quality Checks: Our manufacturing process integrates automated quality control checkpoints to minimize human error and ensure product consistency.

- Shape Variability: We offer three primary racket designs – Diamond, Round, and Teardrop – and fully customizable shapes to suit specific product strategies.

- Branding and Finishing: From custom printing and personalized color options to custom hand grips and handle covers with logo placements, our customization options are designed to meet unique brand identities.

- Strict Material Testing: All materials undergo rigorous inspection to ensure compliance with international standards and performance criteria.

- On-Site Quality Inspections: Regular on-site checks during production guarantee that each batch meets both our internal and external guidelines.

- Bulk Order Capabilities: Our extensive production capacity ensures that we can manage large orders without sacrificing quality or delivery times.

- Robust Communication Protocols: Real-time updates and clear communication lines ensure that purchasing managers stay informed throughout the production process.

When it comes to manufacturing high-performance padel rackets, several key production techniques ensure that our products stand out in the market. Understanding these techniques can provide insight into why choosing a reliable partner like NEX Padel is critical.

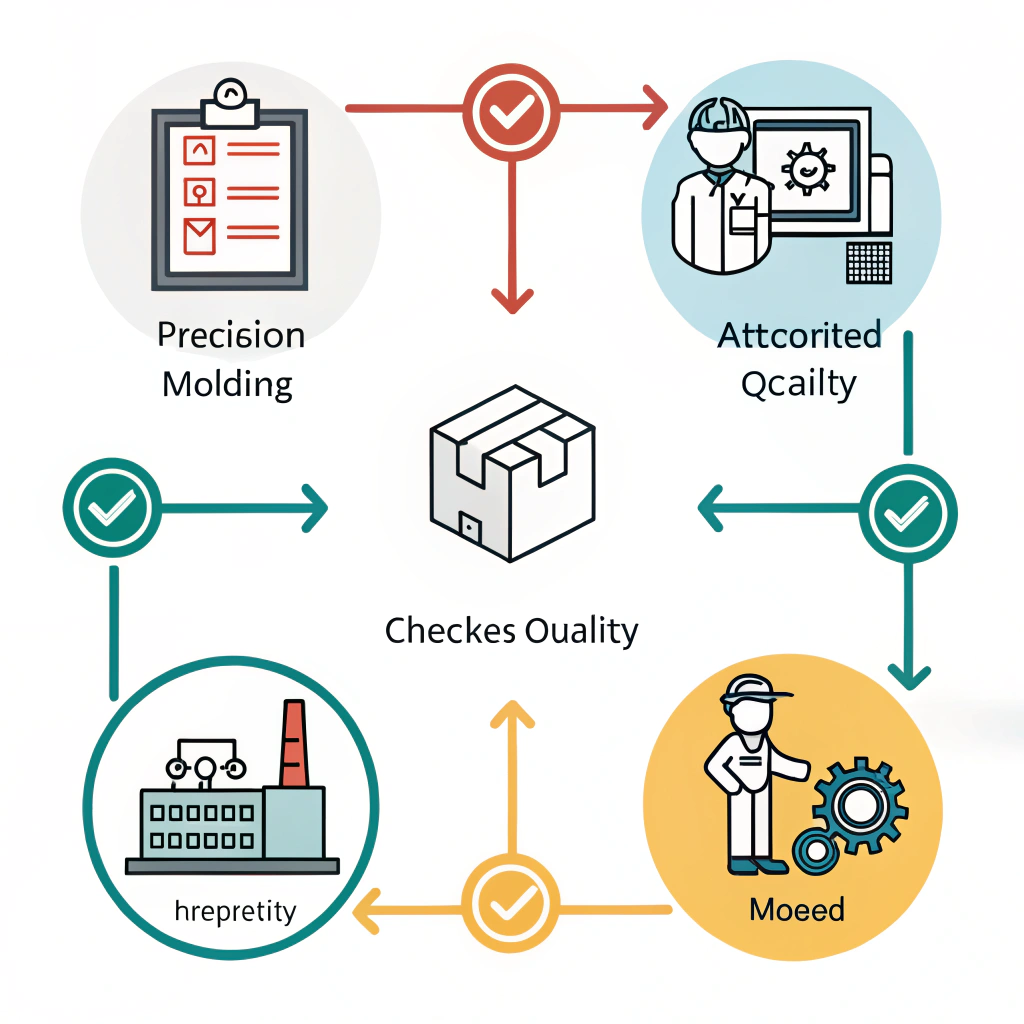

Our process includes the following steps:

-

Material Selection and Sourcing:

We carefully select high-quality materials from trusted suppliers. For example, our carbon fiber grades (3k, 12k, 18k) are meticulously inspected to guarantee performance consistency. -

Pre-Production Testing:

Before full-scale production begins, prototypes are developed and tested under various conditions. This phase allows us to identify any potential issues early in the process. -

Precision Molding and Forming:

Using advanced molding techniques, each racket is formed to exact specifications. Even slight deviations can affect balance and performance, so precision is essential. -

Customization:

Once the base product is created, customization elements are added. Our technological setup enables seamless integration of custom prints, colors, and branding details. -

Post-Production Quality Control:

Each unit undergoes final inspections. Automated testing and human oversight ensure that every racket meets quality standards. -

Packaging and Delivery:

Finally, products are packaged securely – with specialized materials (including Pressurized tube packaging for padel balls) to avoid any pressure loss – before being dispatched for on-time delivery.

| Production Stage | Traditional Methods | NEX Padel Advanced Techniques |

|---|---|---|

| Material Sourcing | Varied suppliers, non-uniform | Centralized sourcing with strict QC |

| Precision Molding | Manual intervention | Automated, precision-controlled process |

| Quality Control | Random sampling | Continuous automated inspection |

| Customization | Limited options | Extensive customization, including full OEM designs |

| Delivery & Packaging | Standard packaging | Customized, pressure-maintaining packages for padel balls |

While our solutions address the most common challenges, there are key points that purchasing managers and distributors should consider when selecting a padel racket manufacturer:

-

Customization Flexibility:

Ensure that the supplier truly offers flexibility. With NEX Padel, you can opt for custom shapes, prints, and even technical components such as hand grips. -

Material Quality:

Confirm that the manufacturing process adheres to international standards by using high-grade materials consistently. Our rigorous testing protocols ensure you receive top-quality components. -

Production Capacity:

Depending on your market needs, verify that the supplier can handle high-volume production. Our production capacity is designed for both small batches and bulk orders. -

Lead Time Transparency:

A reliable partner provides clear communication on production schedules and delivery timelines. NEX Padel maintains open lines of communication to keep you informed every step of the way. -

Cost Efficiency:

Balancing competitive pricing with quality assurance is essential. Our focus on efficiency ensures that while we maintain high standards, we also provide cost-effective solutions for bulk padel racket production.

Our approach is backed by numerous case studies and performance data. For instance, our partnerships with major brands like Hirostar, Reebok, and Starvie have consistently met performance benchmarks and delivery deadlines.

A leading European distributor sought a high-performance, custom-designed Diamond padel racket that incorporated branding and advanced materials. Our process involved:

• Collaborating on custom design specifications.

• Prototyping and testing using our automated quality control systems.

• Successfully delivering over 10,000 units within the agreed timeline.

• Achieving a 98% customer satisfaction rate based on post-delivery surveys.

This case demonstrates our capability to meet complex, customization-heavy orders while maintaining efficiency and quality.

If you are a purchasing manager or distributor evaluating suppliers for padel rackets, consider the following steps to ensure you partner with a reliable manufacturer:

-

Evaluate Material Standards:

Inspect your supplier’s material sourcing and quality assurance protocols. Ask for certifications and sample test reports. -

Visit the Manufacturing Facility:

If possible, schedule a visit to see firsthand the production techniques and quality control systems in action. -

Request Customization Demonstrations:

Ensure that your supplier can meet your specific customization needs. This includes testing prototype designs for balance, durability, and aesthetic appeal. -

Review Case Studies or Client References:

Ask for detailed case studies like the one mentioned above to understand the supplier’s track record in managing bulk orders and custom designs. -

Negotiate Clear Contract Terms:

Ensure that your contract includes defined quality standards, lead times, and communication protocols to avoid misunderstandings during production.

In summary, NEX Padel stands out as a leader in the padel racket manufacturing industry by offering a solution-oriented approach that integrates advanced production techniques, rigorous quality assurance, and extensive customization options. We turn the challenges of material variability, production precision, and customization complexity into competitive advantages for your business.

For organizations seeking a dependable, cost-effective, and technologically advanced supplier, our transparent processes and proven track record provide the assurance needed to meet both immediate and strategic procurement goals. We invite you to partner with us, leverage our expertise, and together drive success in a competitive market environment.

Take the next step: evaluate your current supplier requirements, reach out for a detailed consultation, and explore how NEX Padel’s high-performance, customizable solutions can transform your supply chain.

• What factors determine the quality of a padel racket?

Answer: The quality depends on material selection, precision in molding techniques, stringent quality control, and the ability to customize based on performance needs.

• How do manufacturers ensure consistent performance in bulk orders?

Answer: Consistency is achieved through centralized sourcing, automated quality inspections, and a robust production process that includes pre- and post-production testing.

• Can padel racket manufacturers handle high customization requests?

Answer: Yes, leading manufacturers use advanced production techniques that allow for extensive customization, including personalized shapes, prints, and accessory branding.

-

advanced production techniques: Click here to dive into the latest manufacturing innovations that improve efficiency, precision, and product consistency in sports equipment production. ↩ ↩

-

quality control measures: Read more to discover the rigorous testing and inspection processes that ensure every product meets international quality standards. ↩ ↩

-

high-quality padel rackets: Read the article to understand the defining characteristics that distinguish high-quality padel rackets, including design, durability, and performance benefits for your business. ↩ ↩

-

3k, 12k, and 18k carbon fiber: Read the article to explore the differences between these carbon fiber grades and learn how each impacts racket performance and longevity. ↩ ↩

-

supply chain interruptions: Learn about how disruptions in your supply chain can affect your business operations and what strategies can mitigate these risks. ↩ ↩