In essence, 18K carbon fibre1 materials produce a stiffer, more powerful rack while 12K2 offers a softer feel with enhanced vibration absorption, and 3K fibres3 strike a balanced compromise for mid-range performance. This quick answer sets the stage for understanding how these technical differences can impact your procurement decisions when sourcing high-performance padel rackets.

When selecting padel rackets for competitive athletes, it is crucial to delve into the specifics of the composite materials used. The differences between 18K, 12K, and 3K carbon fiber are not just in name—they translate into measurable impacts on racket stiffness, vibration absorption, comfort, and overall performance. In today’s technically informed marketplace, understanding these differences can lead to better B2B procurement decisions and improved product performance on the court.

Procurement managers and technical buyers often face a dilemma when choosing among padel rackets that incorporate different carbon fiber composites. The challenge is to balance cost, performance, durability, and player comfort. Specifically, decisions surrounding 18K, 12K, and 3K carbon fibers can be complex due to their distinct material properties. For a sports equipment distributor dedicated to supporting competitive athletes, understanding these nuances is essential.

Manufacturers such as NEX Padel utilize advanced production techniques4 to produce rackets that meet rigorous quality, precision, and durability standards. With different requirements in terms of flexibility and stiffness, the choice of carbon fiber type can dictate not only the feel and performance of a racket but also its longevity in high-intensity play.

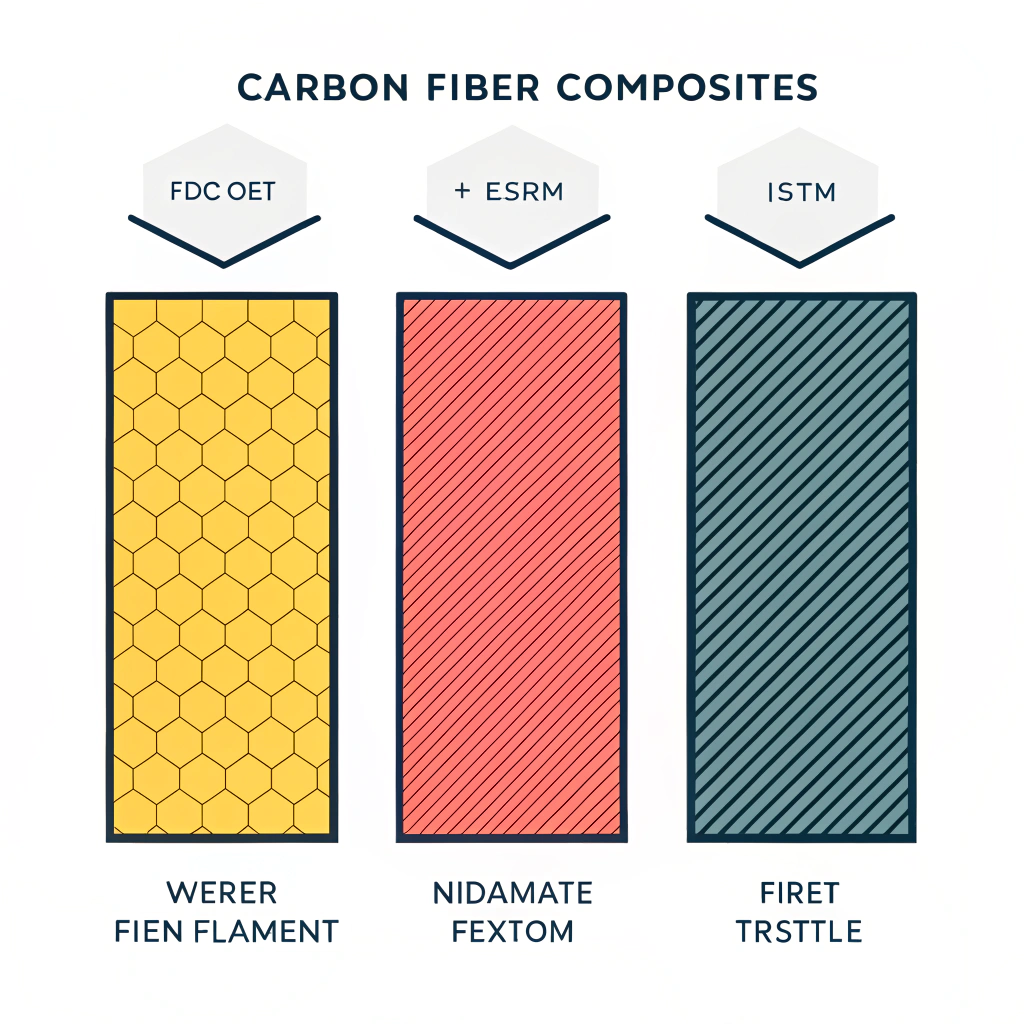

The differences in carbon fiber types come down to the filament count5 and arrangement within the composite material:

-

3K Carbon Fiber: Consists of approximately 3000 filaments per tow. This composition generally offers a balanced performance, making it a versatile option suitable for rackets that require moderate stiffness and responsive handling. It typically provides a mix of performance traits that may be ideal for players looking for an all-around option.

-

12K Carbon Fiber: With a higher filament count, 12K carbon fiber tends to be more flexible. This translates into a softer feel, which enhances comfort and offers better vibration absorption. Such characteristics are particularly beneficial for players who prioritize control and reduced arm fatigue during extended play sessions.

-

18K Carbon Fiber: Often used for the top-end competitive rackets, 18K carbon fiber yields a stiffer structure. This material-driven stiffness results in a more powerful and precise response. Players who demand aggressive play and rapid energy transfer from their equipment will appreciate the attributes of 18K composites.

The variations in these materials stem from decisions made during the manufacturing process. Factors like filament twisting, resin content, and production technique all play a part in ensuring that the final product meets specific performance goals.

To better visualize these differences, consider the table below which outlines key performance attributes for each type of carbon fiber used in padel rackets:

| Material | Filament Count | Stiffness | Comfort & Vibration Absorption | Performance Attributes | Ideal For |

|---|---|---|---|---|---|

| 3K | ~3000 | Balanced | Provides moderate vibration dampening | Versatile; balanced power & feel | All-around performance |

| 12K | ~12000 | More flexible | Superior vibration absorption; softer feel | Enhanced control & reduced fatigue | Players preferring comfort and control |

| 18K | ~18000 | High stiffness | Minimal vibration absorption | Greater power and precision | Aggressive, power-oriented play |

This table simplifies the complex makeup of padel rackets and clearly illustrates that each material has its own merits. Ensuring that the procurement process includes a detailed technical assessment of these characteristics is key to meeting the diverse needs of athletes and distributors alike.

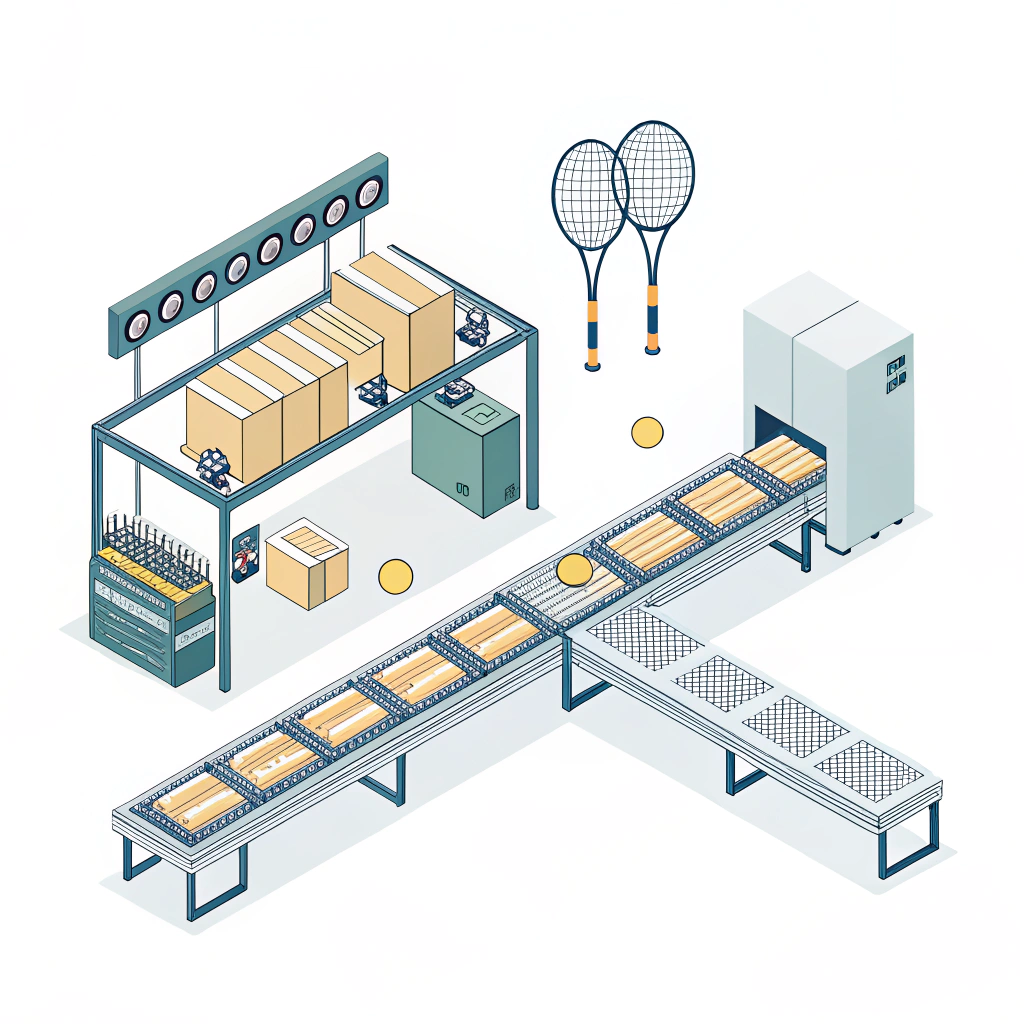

At NEX Padel, our advanced production techniques and strict quality control processes allow us to offer a range of options made from different carbon fibers. Here are a few insights based on our manufacturing experience:

-

Customization and Flexibility:

Our production lines support custom designs, whether using Diamond, Round, or Teardrop shapes. When coupled with the material properties of 12K carbon fiber, for example, the softer feel can be enhanced through custom printing and hand grip customization. This level of flexibility not only meets market demand but also gives end-users the ability to choose a racket that fits their play style perfectly. -

Production Efficiency:

Implementing rapid prototyping processes helps reduce the turnaround time on new designs. When evaluating carbon fiber types, production teams optimize the mix of resin and carbon fiber layers to ensure each racket meets the expected performance standards while balancing cost and material efficiency. -

Quality Control:

Each batch of rackets is tested intensively to guarantee that the technical parameters align with the design specifications. This involves rigorous performance testing under simulated match conditions to verify that the chosen composite material, whether 3K, 12K, or 18K, delivers on the promise of durability, power, and comfort. -

Real-World Data Support:

Our collaboration with internationally recognized brands like Hirostar, Reebok, and Starvie provides data-driven insights. By analyzing feedback from these partnerships, we refine our production techniques and material choices. The result is a padel racket that consistently performs across varying levels of play intensity.

Based on the detailed analysis above, here is a clear checklist to guide procurement managers in making informed decisions:

-

Define Performance Needs:

Identify whether the focus is on power, precision, or comfort. For aggressive play with high power output, 18K carbon fiber may be ideal. Conversely, for players prioritizing comfort and control, 12K carbon fiber would be more appropriate. For a balanced performance, 3K carbon fiber could be the go-to option. -

Evaluate Customization Options:

Consider the advantages of customizing elements like the racket shape, printing, hand grips, and handle covers. Customization can significantly enhance the product’s market appeal and cater to niche segments. -

Review Manufacturing Capabilities:

Match the selected material’s production requirements with the manufacturer’s expertise. NEX Padel’s state-of-the-art production techniques ensure that the particular properties of each carbon fiber type are fully optimized. -

Compare Cost vs. Performance:

Assess the overall cost implications by comparing material cost, production time, and quality assurance processes. A detailed ROI analysis should be conducted to balance the upfront investment with the long-term benefits of improved racket performance and durability. -

Seek Expert Consultations:

Engage with technical experts to discuss the optimal material for your specific requirements. Direct consultation with manufacturers like NEX Padel can provide additional insights and help tailor the product specifications accordingly.

Below is a suggested decision matrix that can help guide your B2B procurement process:

| Decision Factor | 3K Carbon Fiber | 12K Carbon Fiber | 18K Carbon Fiber |

|---|---|---|---|

| Target Player Profile | Versatile, all-round players | Players seeking comfort & control | Power-oriented, aggressive players |

| Material Flexibility | Balanced | High | Low |

| Vibration Absorption | Moderate | Excellent | Limited |

| Production & Customization Ease | High | Moderate | Requires precision |

| Cost Implications | Moderate | Competitive | Premium |

Implementing this matrix into your procurement strategy may improve outcome clarity and help align your product offerings with market expectations.

-

Material Selection Impacts Performance:

Understanding the precise differences between 18K, 12K, and 3K carbon fiber is critical to meeting both player expectations and distributor quality standards. -

Customization Elevates Product Value:

Options to customize racket shapes, logos, and handle materials ensure that the final product can be tailored specifically to market needs, ultimately enhancing athlete satisfaction and brand reputation. -

Advanced Manufacturing Matters:

Leveraging production techniques that optimize the properties of each carbon fiber type not only improves performance outcomes but also minimizes defects, ensuring durability and longevity in high-performance play.

For procurement managers seeking to optimize their sports equipment portfolio, aligning material characteristics with performance goals is key. Our experience at NEX Padel, supported by industry-leading data and feedback from established brands, can guide you towards a solution that elevates your product offering while providing a competitive edge.

Is 3K carbon better than 12K padel?

While 3K carbon fiber offers a balanced performance, 12K carbon fiber provides a slightly softer feel that enhances comfort and vibration absorption. This difference can be significant for players looking for greater control and reduced arm fatigue.

Which is better 12K or 18K padel racquets?

The choice depends on performance goals. 12K racquets are designed for a more flexible, comfortable hit with excellent control, making them ideal for players who value sensitivity and feel. In contrast, 18K racquets offer a stiffer structure that translates to more power and precision, suitable for aggressive playing styles.

What material is best for padel rackets?

High-quality padel rackets typically leverage advanced carbon/graphite composites for durability and a harder feel. While fibreglass rackets are lighter and cheaper, they offer a softer feel compared to the superior performance characteristics of carbon composites used in top-tier rackets.

-

18K carbon fibre: Click to learn how high filament count in 18K carbon fibre leads to a stiffer, more powerful structure that benefits aggressive play and rapid energy transfer. ↩

-

12K: Click to discover how 12K carbon fibre’s increased filament count enhances flexibility, resulting in a softer feel with superior vibration absorption and improved player comfort. ↩

-

3K fibres: Click to explore how 3K carbon fibre balances stiffness and responsiveness, making it ideal for versatile, all-around performance in padel rackets. ↩

-

Advanced production techniques: Click to delve into modern production methods that optimize carbon fibre properties, ensuring high precision, quality control, and performance consistency in sports equipment. ↩

-

Filament count: Click to understand the importance of filament count in carbon fibre composites and how it directly influences material stiffness, vibration absorption, and overall durability. ↩