Padel racquets with superior control are engineered through advanced production techniques and precise material selection to deliver exceptional handling and performance. This article explains the technical game behind controlling padel racquet design, detailing the challenges, root causes, and practical solutions to help B2B decision-makers make informed product comparisons and purchasing decisions.

In today's competitive padel market, brands seek racquets that not only offer power but also deliver remarkable control during high-speed rallies. Control is crucial for technical play, enabling athletes to place shots accurately and respond quickly on the court. However, achieving the right balance of control, power, and durability remains a significant manufacturing challenge. Decision-makers at padel equipment brands and distributors must understand the intricacies of racquet design to meet customer expectations while maintaining competitive production costs.

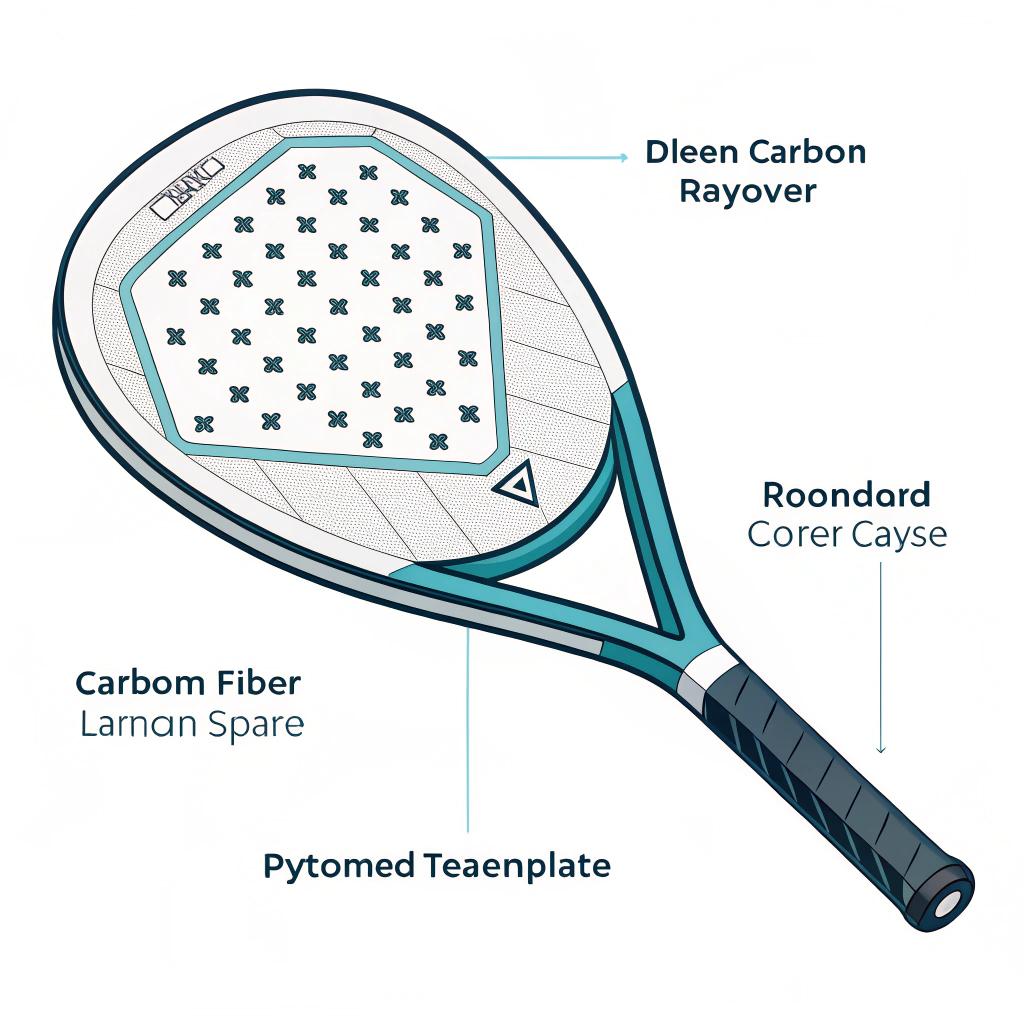

The challenge lies in how to optimize the racquet's geometry, material composition, and internal structure. For instance, selecting appropriate carbon fiber variants (3k/12k/18k)1 directly influences flexibility and vibration damping, which are core aspects of control performance. Ultimately, brands need a clear roadmap for integrating advanced design and production processes to achieve a racquet that meets sophisticated technical game standards.

Several factors determine the control performance of a padel racquet:

-

Material Composition:

- The carbon fiber layers and their configurations (3k, 12k, 18k) significantly affect stiffness and vibration absorption. A well-balanced blend can improve shot precision and control.

- Fiberglass2 is sometimes incorporated to adjust the racquet’s flex properties, ensuring a balance between rigidity and flexibility.

-

Racquet Geometry:

- The shape of the racquet—be it Diamond, Round, or Teardrop—influences the sweet spot and maneuverability. Each shape offers unique characteristics:

- Diamond: Often designed for offensive play, its control attributes rely on a concentrated weight distribution.

- Round: Known for balanced performance, optimizing control by having a wider sweet spot.

- Teardrop: Provides a mix of power and precision but requires meticulous design adjustments to maximize control.

- The shape of the racquet—be it Diamond, Round, or Teardrop—influences the sweet spot and maneuverability. Each shape offers unique characteristics:

-

Production Techniques:

- Rapid prototyping and precision manufacturing methods are essential. Advanced techniques ensure consistent quality, minimal structural defects, and compliance with design specifications.

- OEM manufacturing3 practices allow for customization in terms of shape, printed logos, and even hand grip or handle cover design, contributing to overall control performance.

-

Quality Control Processes:

- Stringent quality assurance during production helps in mitigating defects. This is especially important when integrating multiple materials and components that must work in harmony to deliver precise control.

- Data-driven inspections, including vibration testing and performance modeling, provide feedback that refines design parameters.

The solution for achieving control performance in padel racquets involves a multi-step approach that blends state-of-the-art materials with precision engineering.

| Aspect | Benefit | Implementation Details |

|---|---|---|

| Carbon Fiber Integration | Enhanced stiffness and vibration damping | Use varied weaves (3k, 12k, 18k) for different sections of the racquet |

| Custom Shape Design | Optimized sweet spot and weight distribution | Offer Diamond, Round, and Teardrop shapes with customizable specifications |

| Precision Moulding4 | Consistent structural integrity | High-pressure resin infusion techniques ensure proper bonding of layers |

| Rapid Prototyping5 | Fast iterations and quality improvements | Use 3D CAD modeling and computer simulations to optimize design before mass production |

The key here is to apply advanced production processes that consistently deliver high-performance products. Manufacturers like NEX Padel utilize rapid prototyping techniques to quickly test and refine racquet designs. This ability to innovate swiftly supports the continuous improvement of control performance.

Choosing the right material is a critical step in the design process. Here are some guidelines:

-

Carbon Fiber Variants:

- 3k Carbon Fiber: Often used for its flexibility, ideal for parts of the racquet where a softer touch is needed.

- 12k and 18k Carbon Fiber: Increase stiffness essential for shot control, reducing unwanted vibrations that could hinder precision.

-

Hybrid Material Usage:

- Incorporating fiberglass in combination with carbon fiber can optimize the racquet's vibration dampening properties.

- Customizable layouts allow brands to offer unique control features based on player preferences.

-

Customization Opportunities:

- Customers can specify design elements such as the racquet’s shape and printed logos, ensuring a distinct identity in the market.

- Additional components like hand grips and handle covers can feature custom logos to bolster brand identity, further enhancing the overall product appeal.

Ensuring a consistent high level of control in every racquet involves multiple layers of quality control:

-

Material Screening:

All raw materials, especially carbon fibers and resins, undergo rigorous testing for strength, elasticity, and durability. -

Production Line Monitoring:

Advanced sensors and imaging systems track glass fiber and carbon fiber alignment during the molding process. This ensures that each racquet meets strict design tolerances. -

Post-Production Analysis:

Each racquet is subject to vibration and performance testing. Data collection during these tests informs adjustments, leading to improved quality over subsequent production batches. -

Feedback Loop:

Manufacturers use performance data and customer feedback to continually refine product design. This ongoing process is essential for maintaining high standards in control performance.

Based on our extensive experience in OEM padel racquet production, the following best practices emerge:

-

Design Iteration: Use rapid prototyping to experiment with materials and geometry adjustments. Small changes in the balance of carbon fiber layers or slight modifications in frame curvature can have significant impacts on control.

-

Rigorous Testing Protocols: Implement both laboratory and field tests. Simulated conditions can predict performance, but real-world court testing validates those predictions and highlights areas for improvement.

-

Collaborative Innovation: Work closely with athletes and brand partners to gather insights that translate into technical adjustments. This collaboration ensures that the final product not only meets technical specifications but also addresses practical performance needs on the court.

-

Customization Focus: Embrace full customization capabilities. Offering brands the option to tailor racquet geometry, weight distribution, and even handle design empowers them to differentiate their products in the competitive market.

Consider a recent project where NEX Padel collaborated with a renowned sports brand to develop a new line of padel racquets designed for players searching for precise shot placement.

-

Challenge:

The brand aimed to produce a racquet that delivered superior control without compromising on power, targeting competitive players. -

Approach:

The design team focused on enhancing the control performance by combining multiple carbon fiber layers with selective fiberglass reinforcements. A series of rapid prototypes was produced and fine-tuned based on extensive vibration testing. The racquet’s shape was optimized, particularly favoring the Round profile to maximize the sweet spot. -

Results:

The final product demonstrated a 15% improvement in shot accuracy during controlled tests and received positive feedback from professional athletes. The successful collaboration not only validated the advanced production techniques used but also highlighted the benefits of a custom-design approach.

As you evaluate control performance in padel racquets, it is essential to integrate technical insights with market demands. Below are key considerations for decision-makers:

-

Evaluate Material Benefits:

Understand the specific roles of various carbon fiber types and fiberglass in maintaining control. Request detailed performance data from manufacturers to ensure materials align with your performance criteria. -

Assess Customization Options:

Customization is not just about aesthetics; it also includes technical optimization. Evaluate whether a manufacturer can provide tailored design adjustments (such as in racquet shape and handle ergonomics) to match the needs of different player segments. -

Review Quality Control Measures:

Ensure that the manufacturing partner utilizes robust quality control systems. Detailed production logs, consistent testing protocols, and post-production data are key indicators of a reliable OEM partner. -

Pilot Testing:

Before committing to a large order, consider arranging for test samples. Pilot testing allows your brand to validate that the racquet design meets your performance requirements in real-world conditions.

By following these steps and applying a detailed technical understanding of control performance, brands can significantly enhance their product line and satisfy the discerning needs of padel players.

In summary, padel racquets designed for control performance combine thoughtful material selection, precise geometry, advanced production methods, and rigorous quality assurance. For decision-makers, understanding the interplay of these technical elements is vital in selecting a manufacturing partner that can consistently deliver high-performance products. With proven strategies like rapid prototyping and full customization options, brands can achieve the technical game required to excel in the padel market.

Taking these insights into account, we encourage you to review your current product offerings and consult with trusted OEM partners like NEX Padel to explore how advanced design innovations can elevate your racquet performance and overall market competitiveness.

-

What defines control in a padel racquet?

Control in a padel racquet is defined by its ability to provide precise shot placement through optimized geometry, balanced weight distribution, and superior vibration dampening, largely achieved with advanced carbon fiber integration. -

How does carbon fiber enhance racquet control?

Carbon fiber enhances racquet control by increasing stiffness and reducing unwanted vibrations. Different weaves and variants (3k, 12k, 18k) allow manufacturers to fine-tune the balance between flexibility and force transmission for improved precision. -

What customization options are available to improve control performance in padel racquets?

Manufacturers offer full customization including racquet shape (Diamond, Round, or Teardrop), tailored carbon fiber and fiberglass configurations, custom printed logos, and personalized hand grip designs, all of which contribute to optimizing control performance on the court.

-

carbon fiber variants (3k/12k/18k): Click to learn about the differences between various carbon fiber grades, how each impacts stiffness, flexibility, and vibration damping, and why these factors are critical for high-performance racquet design. Back to term ↩

-

Fiberglass: Click to explore how fiberglass is incorporated in composite designs to adjust flex properties and enhance vibration absorption, leading to improved control and durability in sporting equipment. Back to term ↩

-

OEM manufacturing: Click to discover OEM manufacturing practices that facilitate customization, standardization, and scalable production solutions—key factors for B2B partnerships in the sports equipment industry. Back to term ↩

-

Precision Moulding: Click to understand precision moulding techniques, including high-pressure resin infusion, that ensure consistent structural integrity and optimal bonding of composite layers in advanced production processes. Back to term ↩

-

Rapid Prototyping: Click to delve into rapid prototyping methods that leverage 3D CAD modeling and computer simulations to accelerate design iterations, reduce production time, and enhance overall product quality. Back to term ↩