High-performance padel tennis rackets can be sourced effectively by partnering with a manufacturer that leverages advanced production techniques, offers extensive customization options, and ensures strict quality control. NEX Padel exemplifies this by using a range of materials from glass fiber1 to multiple grades of carbon fiber2 (3k, 12k, 18k), versatile designs (Diamond, Round, Teardrop), and reliable OEM capabilities3 to meet diverse market needs.

Procurement and product development managers must navigate a complex sourcing landscape. The challenges include ensuring technical excellence, balancing material properties and design requirements, and verifying that the supplier can deliver consistent quality and timely production. These issues are compounded by the diversity in racket designs and customization options required by modern sports equipment brands.

- Inconsistent quality control from suppliers.

- Variations in material properties such as durability and weight.

- Limitations in customization options (e.g., shapes, colors, and logos).

- Uncertain production lead times and delivery reliability.

- Competition from other markets and regulatory compliance issues.

These challenges require a clear, solution-oriented approach to mitigate risks and optimize the supplier selection process.

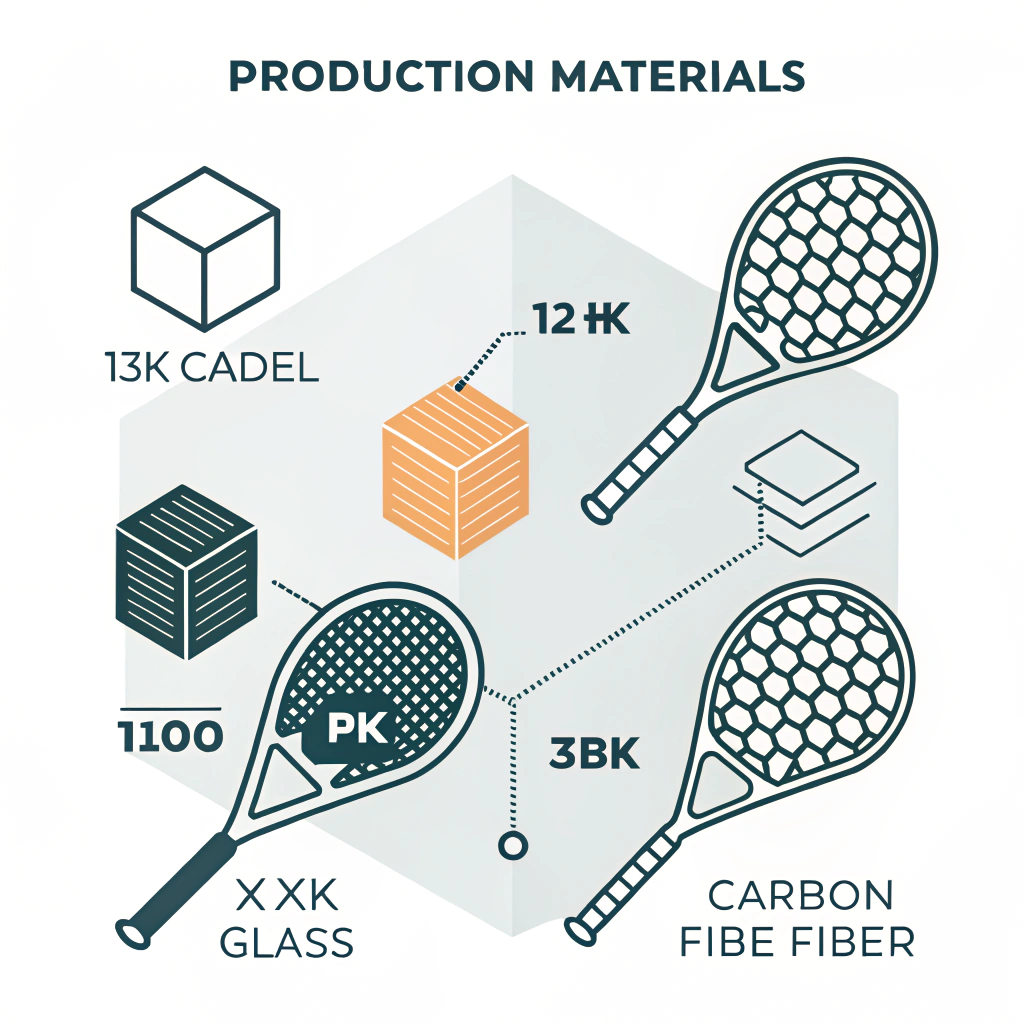

A reliable supplier for padel rackets must be proficient in a range of materials and advanced production techniques. The production of padel rackets involves multiple considerations:

Carbon Fiber Variants:

- 3k, 12k, 18k Carbon Fiber: Each grade offers a distinct balance between stiffness, durability, and weight. For instance, 3k carbon fiber creates a lighter racket, whereas 18k enhances rigidity and control.

- Graphite Composite Integration: Often combined with carbon fiber to ensure optimal performance characteristics.

Glass Fiber Material:

While carbon fiber is popular for high-end rackets, glass fiber offers a cost-effective solution for entry-level equipment without sacrificing too much performance.

To maintain high-performance standards, manufacturers deploy several advanced techniques:

- Precision Molding4: Ensures that each racket meets strict dimensional tolerances.

- Custom Printing and Color Inks: Facilitate complete customization down to hand grips and handle covers.

- Rapid Prototyping and Testing5: Shorten the design-to-production cycle while ensuring that every design meets performance metrics.

Below is a comparative table summarizing common material properties used in padel racket production:

| Material | Typical Uses | Key Benefits | Considerations |

|---|---|---|---|

| 3k Carbon Fiber | Lightweight, entry-level models | Excellent balance of weight & cost | May require reinforcement |

| 12k Carbon Fiber | Mid-range models | Enhanced stiffness & durability | Slightly heavier than 3k |

| 18k Carbon Fiber | High-performance models | Superior rigidity & control | Higher production cost |

| Glass Fiber | Budget-friendly options | Cost-effective and robust | Lower performance compared to carbon |

NEX Padel employs these materials based on the specifications required by each client, allowing them to tailor products effectively for a range of performance levels.

For sports equipment manufacturers, customization is key to meeting market demands and maintaining a competitive edge. A customizable padel racket is not just about its performance; it is also a critical element of brand identity.

- Shape Options:

- Diamond: Favored by advanced players seeking precision and enhanced power.

- Round: Offers excellent control and balance, ideal for beginners and intermediate players.

- Teardrop: Provides a versatile blend of power, control, and maneuverability.

- Print and Branding:

Manufacturers like NEX Padel support full custom printing options, enabling brands to feature unique logos, color schemes, and artwork. - Additional Custom Components:

- Hand Grip Customization: Tailor-made grips allow brands to imprint their logo and design on the handle.

- Handle Cover Options: Ensures both aesthetic consistency and enhanced functionality.

This level of customization is made possible via in-depth technical consultations and rapid sample creation. The ability to deliver fully tailored designs helps procurement managers hit the market faster and build stronger brand identities.

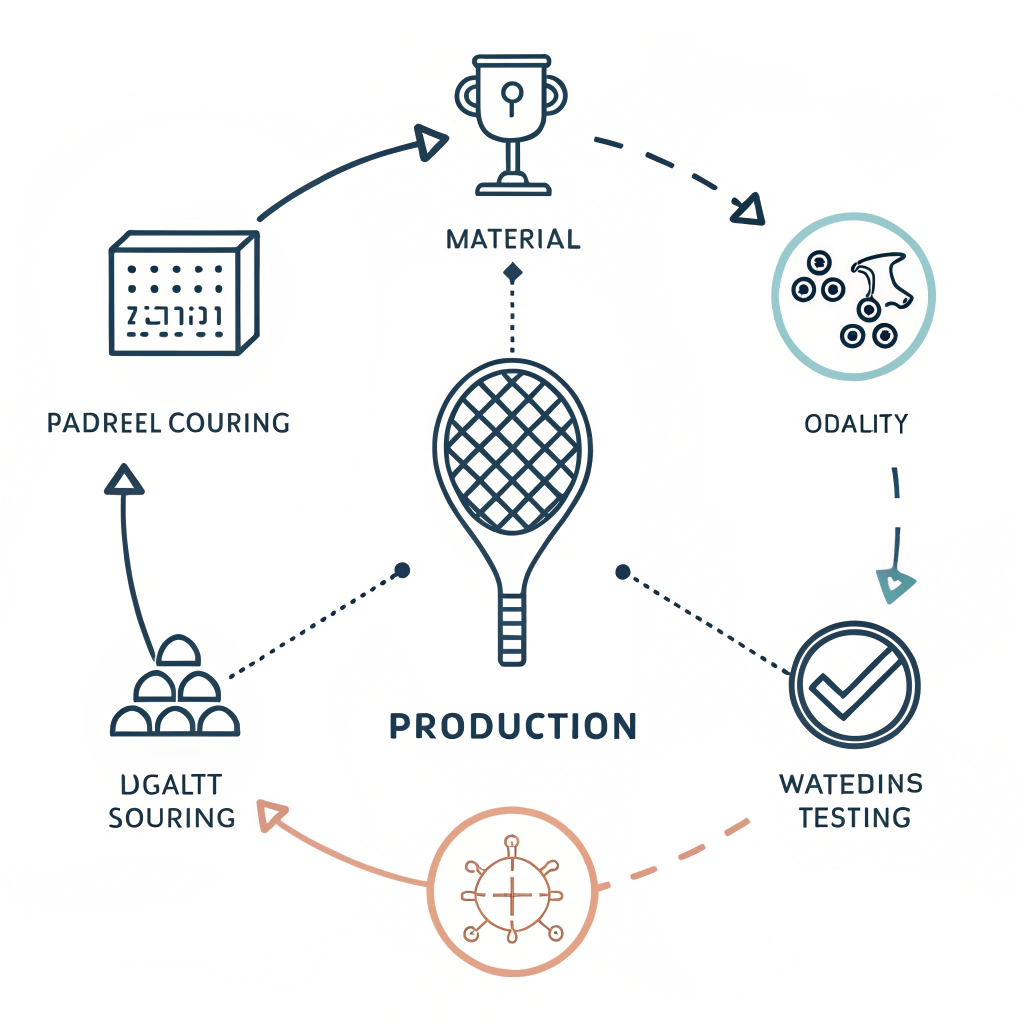

Maintaining quality is essential to upholding the performance standards expected from high-end padel rackets. A robust quality control framework covers every stage of production—from raw material inspection to the final product verification.

- Incoming Material Inspection:

Materials such as various grades of carbon fiber and glass fiber undergo rigorous inspection for compliance with international standards. - In-Process Monitoring:

Continuous monitoring during the molding and curing processes ensures that every racket meets predefined quality benchmarks. - Final Product Testing:

Rackets are put through performance tests that simulate real-world conditions to verify their durability and playability.

Additionally, a streamlined production process minimizes lead times. NEX Padel is well-regarded for rapid prototyping and quick turnaround times, which is crucial for meeting market demands and seasonal production cycles.

A simplified flow of the production process is illustrated below:

| Stage | Key Activities | Importance |

|---|---|---|

| Material Sourcing | Quality verification and batch testing | Ensures material consistency |

| Pre-Production Design | Customization and rapid prototyping | Reduces design-to-market timelines |

| Molding and Curing | Precision production and quality monitoring | Guarantees product performance |

| Post-Production Testing | Performance and durability assessment | Ensures end-user satisfaction |

NEX Padel has built a solid reputation through strategic partnerships with well-known brands like Hirostar, Reebok, and Starvie. These collaborations demonstrate the practical benefits of their manufacturing processes:

A leading sports equipment brand collaborated with NEX Padel for the production of a new line of padel rackets. Faced with the challenge of balancing performance with design flexibility, the brand required:

- Customizable printing and color options for their distinct brand identity.

- A range of material choices to cater to different player skill levels.

Outcome:

NEX Padel's rapid prototyping and extensive technical expertise allowed the brand to:

- Launch three distinct models targeting various customer segments (Diamond for advanced players, Round for intermediate players, and Teardrop for versatile play).

- Maintain high quality and performance benchmarks while ensuring fast delivery, which was crucial for a seasonal product launch.

Such success stories underscore the importance of partnering with a manufacturer that not only understands the technical nuances of padel racket production but also values the strategic needs of its partners.

For procurement and product development managers looking to source top-quality padel rackets, careful consideration of supplier capabilities is key. Here are actionable steps to ensure your manufacturer meets your specific needs:

- Assess Material Expertise:

Verify that the supplier can work across varied materials like 3k, 12k, and 18k carbon fiber and glass fiber, ensuring a full range of performance options. - Evaluate Customization Capabilities:

Ensure that you can obtain full customization—from racket shape (Diamond, Round, Teardrop) to branding on hand grips and covers. - Inspect Quality Assurance Protocols:

Confirm that the manufacturer has a robust in-house quality control framework, with rigorous testing at every production stage. - Confirm Production Lead Time:

A supplier like NEX Padel provides rapid prototyping and competitive lead times, reducing market entry delays. - Review Past Partnerships:

Look at case studies and existing brand collaborations to gauge the manufacturer’s track record and reliability.

Each of these steps plays a critical role in selecting a supplier that not only meets but exceeds your product quality and customization requirements. NEX Padel’s proven expertise in producing high-performance padel rackets makes them a strong partner for brands focused on innovation and quality.

Sourcing high-performance, customizable padel rackets requires a careful evaluation of technical capabilities, material expertise, production efficiency, and quality control measures. With advanced manufacturing techniques and a tailored approach to customization, manufacturers like NEX Padel stand out as leaders in the industry. Their ability to work with diverse materials—ranging from various grades of carbon fiber to sophisticated glass fiber composites—enables them to deliver products that are both innovative and reliable. For procurement managers, partnering with such a supplier means more than just acquiring a product; it means investing in a relationship that fosters quality, performance, and market success.

By following structured steps to assess material expertise, customize design options, enforce quality controls, and ensure rapid delivery, companies can confidently choose a supplier that aligns with their strategic goals.

-

Which brand makes the best padel rackets?

Highly regarded manufacturers produce top padel rackets through the collaboration of engineering excellence and quality control. Leading brands often rely on expert OEMs—such as NEX Padel—who use advanced materials and customization techniques to create rackets that excel in both performance and user-specific requirements. -

Are any tennis rackets not made in China?

Yes, some tennis racket manufacturers produce their products outside of China. For example, Yonex manufactures its tennis rackets in Japan, which helps them maintain very tight manufacturing tolerances and quality control. However, many high-performance padel and tennis rackets are successfully produced by Chinese OEMs that meet stringent international standards. -

Who makes the best tennis rackets in the world?

Determining the best tennis racket depends on individual performance needs and playing style. Several established brands deliver top-quality tennis rackets through collaborations with experienced manufacturers. It is essential to compare technical specifications, production methods, and quality assurance measures before making a purchasing decision.

-

glass fiber: Click to learn about the properties, cost benefits, and typical applications of glass fiber in sports equipment manufacturing. ↩ ↩

-

carbon fiber: Click to explore the different grades of carbon fiber, their performance characteristics, and how they are utilized in high-end racket production. ↩ ↩

-

OEM capabilities: Click to understand what Original Equipment Manufacturer (OEM) capabilities entail, including the benefits of partnering with OEMs for customized production. ↩ ↩

-

Precision Molding: Click to read more about precision molding techniques and how they ensure dimensional accuracy and product quality in manufacturing. ↩ ↩

-

Rapid Prototyping and Testing: Click to find out how rapid prototyping accelerates product development and improves time-to-market while maintaining quality standards. ↩ ↩