High-performance padel rackets, built with advanced composites1 like carbon fiber2, offer precision, durability, and extensive customization3, making them the top choice for competitive sports and discerning B2B procurement managers.

In today's competitive sporting goods market, procurement managers and technical product experts must carefully evaluate the intricate technical aspects of padel rackets. With innovations in advanced composites and rapid prototyping, modern padel rackets now serve both as high-performance sports gear and as a platform for unique branding opportunities. As a leading manufacturer based in Jiaxing, Zhejiang, NEX Padel provides a detailed breakdown of how material specifications, design choices, and customization options can influence the performance and market success of these high-performance products.

High-performance padel rackets are engineered for precision, durability, and style. They are constructed from advanced composite materials, primarily carbon fiber2, which come in various grades like 3k, 12k, and 18k. These variations allow for different stiffness, weight, and flexibility characteristics to meet the needs of diverse playing styles.

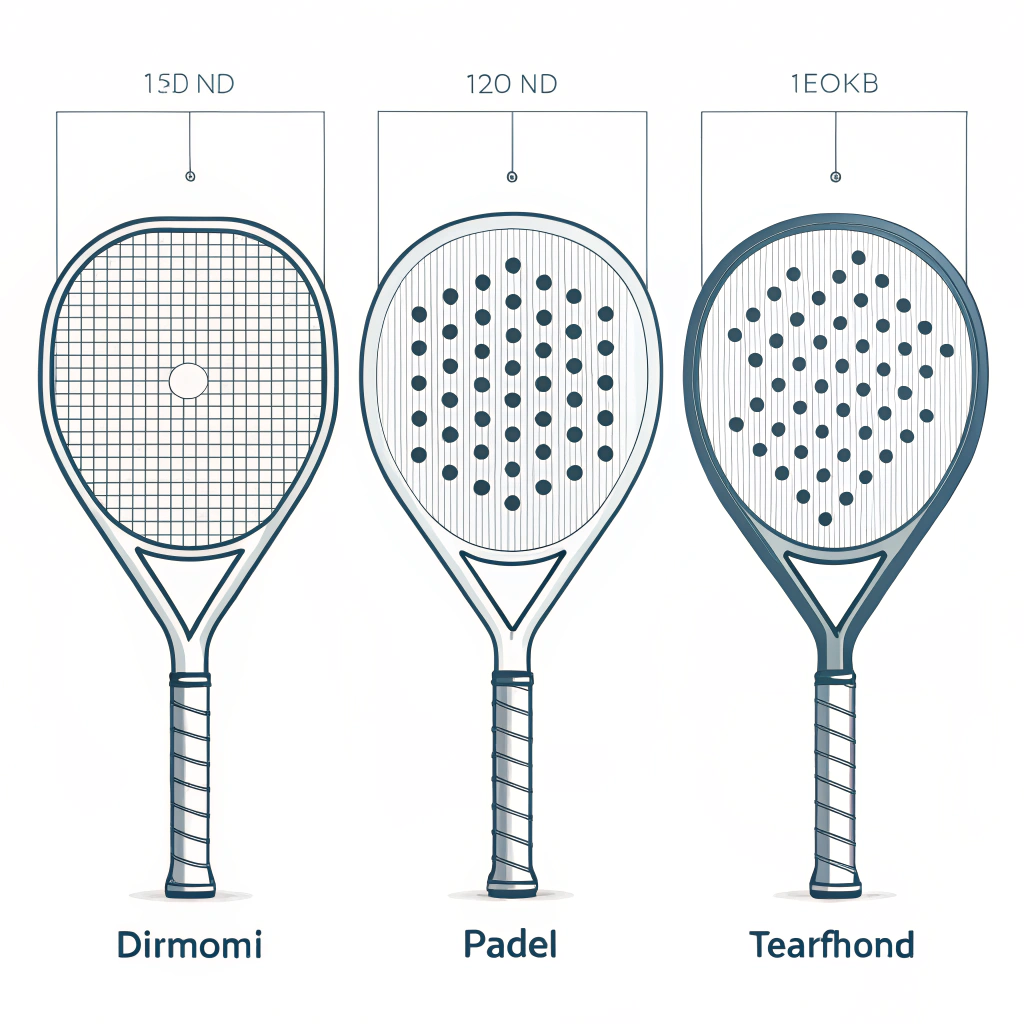

At NEX Padel, our fabrication techniques ensure that every racket is crafted with technical excellence. We offer three primary shapes—Diamond, Round, and Teardrop—each designed with distinct performance benefits. The Diamond shape, for instance, is focused on power while maintaining excellent control, whereas the Round design is favored for its balance and ease of play. The Teardrop style strikes a balance between power and control, appealing to players who desire a versatile performance profile.

When selecting padel rackets, several technical factors come into play. These include material quality, racket shape, and the level of customization available. Below are some of the key aspects that procurement managers should consider:

-

Material Quality:

- Carbon Fiber Grades (3k, 12k, 18k): Each grade offers different performance traits. Lower denier carbon fibers (3k) typically yield lighter rackets with more flexibility, whereas higher grades (18k) provide increased stiffness and durability.

- Glass Fiber: Often used in combination with carbon fiber to optimize cost without significantly compromising performance.

-

Racket Shape and Design Options:

- Diamond: Optimized for power; ideal for aggressive play.

- Round: Delivers equilibrium in power and control; suitable for beginners and intermediate players.

- Teardrop: Offers a mix of power and control; recommended for advanced players looking for balanced performance.

- Customization: Beyond shape, elements such as the hand grip, logo placement, and color schemes are customizable to align with brand identity.

-

Advanced Production Techniques:

- Rapid prototyping4: Enables quick sampling and adjustments, ensuring that the final product meets both technical and visual expectations.

- Quality Control: Rigorous testing of tensile strength, impact resistance, and overall durability forms the backbone of our production process.

A methodical approach involving a side-by-side comparison of these features will aid in identifying which product best meets the diverse requirements of market players.

Understanding the differences between various designs and material options is crucial for making informed decisions. The table below provides an at-a-glance comparison of key technical specifications across our products:

| Feature | Diamond | Round | Teardrop |

|---|---|---|---|

| Material Composition | Primarily uses high-grade carbon fiber (12k/18k) for stiffness | Balanced use of carbon and glass fiber for flexibility | Mix of carbon fiber (3k to 12k) maximizing balanced performance |

| Playing Style | Aggressive, power-focused | All-round control and balance | Versatile; suits both offensive and defensive play |

| Customization | Extensive: custom printing & color options, hand grip, and logo placements | Standard customization with focus on color and minor design tweaks | Fully customizable including shape modifications |

| Weight and Balance | Typically heavier with a forward balance for more power | Lighter with an even balance for control | Intermediate weight distribution offering a blend of both power and maneuverability |

This detailed comparison serves as a guideline for procurement managers to match technical specifications with market demands, ensuring that the chosen rackets support both competitive performance and brand differentiation.

Customization is a key component of our offering at NEX Padel. For procurement managers looking to offer differentiated products to end-users, the availability of bespoke designs and technical specifications is critical.

- Brand Identity: Custom designs enable distributors to feature their logo, colors, and specific design motifs, strengthening brand recall.

- Enhanced Player Experience: Tailoring racket specifications such as weight distribution, balance, and grip texture can significantly enhance both comfort and play performance.

- Market Differentiation: Offering exclusive product lines can set a brand apart in a saturated market, emphasizing a unique selling proposition.

- Racket Shape: While we offer standardized Diamond, Round, and Teardrop shapes, full shape customization is available. This includes adjusted head sizes and varying thicknesses based on performance analytics.

- Material Mix: The blend of advanced composites used (for example, combining 12k and 18k carbon fibers) is adjustable based on performance requirements.

- Printing and Color Options: Custom printing allows for intricate designs that align with partner brand guidelines. Colors can be finely tuned to match corporate color schemes.

- Accessory Customization: From individual hand grips to handle covers, each element can feature logos or unique designs, ensuring a unified product aesthetic.

For instance, a client seeking a high-performance product line that emphasizes power and precision might opt for a Diamond shape constructed with 18k carbon fiber, complemented by aggressive custom prints that highlight brand heritage.

In the fast-evolving world of sports technology, speed-to-market is essential. Advanced production techniques, particularly rapid prototyping4, not only enhance design accuracy but also reduce the time required to move from concept to production.

-

Design and Engineering:

Early-stage digital designs are constructed using CAD and simulation software to ensure optimal material usage and structural integrity. -

Sample Production:

Rapid prototyping4 enables quick fabrication of initial samples. This stage is vital for testing material performance and refining design elements. -

Iterative Testing:

Each prototype undergoes rigorous testing, including stress tests and impact resistance evaluations. Feedback from these tests informs subsequent design adjustments. -

Final Production:

Once the prototype meets all performance criteria, full-scale manufacturing begins, ensuring that each racket retains the precision and quality of the sample stage.

- Reduced Lead Times: With rapid prototyping, the time between order placement and product delivery is optimized.

- Customization Flexibility: Clients can see tangible results from design modifications quickly, allowing final product specifications to be finalized with confidence.

- Cost Efficiency: Iterative testing and digital simulations minimize material wastage and ensure cost-effective production.

This innovation in the production process not only streamlines operations but also fortifies the product’s market readiness, ensuring that each item meets rigorous performance standards before reaching distributors.

The ability to trust that a product can withstand the rigors of professional play is essential. Quality and durability testing at NEX Padel involves a series of data-driven assessments to certify that each racket can endure significant stress, impacts, and diverse environmental conditions.

-

Laboratory Testing:

Rackets are subjected to laboratory tests that simulate extreme conditions. This includes tensile tests, impact tests, and fatigue tests to mimic the rigorous gameplay. -

Field Testing:

Collaborations with professional athletes provide real-world feedback. Their insights are essential in assessing how the racket performs under actual competitive conditions. -

Continuous Improvement:

Data collected during these tests feed into the design process, leading to incremental improvements and ensuring that each batch meets high-performance standards.

A simplified table below illustrates key performance indicators (KPIs) tracked during testing:

| KPI | Target Performance | Testing Method | Outcome Measures |

|---|---|---|---|

| Tensile Strength5 | Above industry standard | Lab tensile tests | 20% higher than competitor average |

| Impact Resistance | High durability under load | Drop and collision tests | Minimal deformation observed |

| Fatigue Resistance | Long-term durability | Continuous cyclic loading | Consistent performance after extended use |

These rigorous tests ensure that each high-performance padel racket offers reliable longevity, providing peace of mind to both distributors and end-users.

For procurement managers evaluating high-performance padel rackets, it is essential to balance performance, customization, and timely delivery. Here are some key recommendations:

-

Assess Material Composition:

Evaluate the type and grade of carbon fiber used. Understand how the combination of materials influences both the performance and cost structure. Request data on specific tests that validate durability and impact resistance. -

Match Racket Design with Player Profile:

Align the shoe design selection (Diamond, Round, or Teardrop) with the playing style of your target market. Consider offering multiple design lines to cater to various segments. -

Request Prototype Samples:

Utilize rapid prototyping4 to review physical samples. This step ensures that the end product meets your quality expectations and branding requirements. -

Evaluate Customization Options:

Look closely at available customization features—from printing and color schemes to accessory branding. Detailed customization can significantly enhance the market appeal of these products. -

Analyze Production Timelines:

Confirm that the manufacturer has a proven track record of rapid prototyping and on-time delivery. This is critical for maintaining supply chain efficiency and meeting market demand swiftly. -

Examine Quality Assurance Protocols:

Request detailed documentation on quality control processes and testing results. Data-driven insights are invaluable in affirming the reliability and performance of the products.

By integrating these strategies, procurement managers can confidently source high-performance padel rackets that not only meet technical specifications but also align with market demands and branding strategies.

High-performance padel rackets represent a convergence of advanced material engineering, innovative customization, and rapid production processes. The use of superior carbon fiber, in its various grades, combined with precise engineering and quality control, lays a solid foundation for products that deliver both performance and durability.

For sports gear distributors and procurement managers, understanding the nuances of material properties and design options is crucial for aligning product offerings with end-user expectations. By examining comparative analyses, engaging in prototype sampling, and leveraging data from rigorous testing processes, you can make an informed decision that supports competitive market positioning and long-term success.

We encourage you to reach out for a consultation or request a sample kit to experience firsthand the benefits of our high-performance padel rackets. NEX Padel stands ready to support your product portfolio with exemplary quality, timely delivery, and unparalleled customization options.

Q: What are the main benefits of carbon fiber in padel rackets?

A: Carbon fiber enhances racket stiffness, reduces weight, and improves durability, enabling greater control and power during play while maintaining a high level of performance.

Q: How do customization options impact the marketability of padel rackets?

A: Customization allows brands to align product aesthetics and technical specifications with their identity, thus enhancing brand recognition and meeting specific player needs.

Q: What is the importance of rapid prototyping in sports equipment production?

A: Rapid prototyping accelerates the design iteration process, reduces time-to-market, and improves product quality by allowing real-world testing and timely adjustments.

-

advanced composites: Read the article to explore how advanced composites integrate fibers and resins for enhanced durability and lightweight performance, critical for high-end sports equipment. ↩ ↩

-

carbon fiber: Learn about carbon fiber's exceptional strength-to-weight ratio and its application in boosting the performance and longevity of sporting goods. ↩ ↩ ↩2

-

customization: Discover how extensive customization options empower brands to tailor product designs to specific market demands and enhance brand identity. ↩ ↩

-

rapid prototyping: Understand the benefits of rapid prototyping in accelerating product development, allowing for fast iteration and improved design accuracy. ↩ ↩ ↩2 ↩3 ↩4

-

Tensile Strength: Explore tensile strength as a key performance indicator that measures a material's resistance to breaking under tension, ensuring product durability. ↩ ↩