Quick Answer: Selecting the right padel racket for competitive performance involves assessing material quality, racket shape, weight distribution, and customization options. By understanding the benefits of different designs and materials, you can choose a padel racket that offers the ideal balance of power, control, and durability tailored to your needs.

In today’s competitive sports equipment market, making an informed decision about padel rackets is key to optimizing performance and branding for your club or retail outlet. Buyers and facility managers alike need a clear guide on how to compare racket shapes and materials, and customization options that will best suit their athletes’ distinct playing styles and market demands. In this article, we explain the major factors to consider, provide data-backed insights, and outline our solution-driven suggestions drawn from real-world industrial experiences at NEX Padel.

Problem Description

Many padel clubs and sports equipment buyers face a significant challenge when selecting the ideal padel racket. The market today is flooded with a variety of designs—from diamond to round and teardrop shapes—and materials ranging from fiberglass to advanced carbon fiber1 options like 3k, 12k, and 18k. The decision-making process becomes even more complex when considering OEM production2 and full customization needs.

Root Cause Analysis

The difficulty in selecting the right padel racket comes from several converging factors:

• Multiple Racket Shapes: Each shape offers distinct benefits—Diamond for power, Round for control, and Teardrop as a balanced option.

• Diverse Material Options: Materials like fiberglass and different grades of carbon fiber (3k, 12k, 18k) influence the racket’s weight, durability, and overall performance. Advanced composite materials may drive higher performance but also raise complexity in manufacturing.

• Customization Requirements: Clubs looking to incorporate branding with custom prints, colors, and logo placements on the racket, hand grip, or handle cover require partners with flexible production capabilities.

• Speed to Market: In the fast-paced sports equipment industry, rapid prototyping and timely delivery are essential to stay ahead of competitors and meet seasonal demand.

These factors underscore the need for a clear, criteria-based selection process that emphasizes technical quality and product customization while ensuring production efficiency.

Solution: Racket Selection Guidelines

Our solution is structured around a detailed evaluation framework that addresses the key factors influencing padel racket performance and customization. Below is a framework and a comparative table to help you make informed decisions.

-

Evaluate Racket Shape:

• Diamond Shape: Offers enhanced power and a forward center of gravity. Best for players seeking aggressive play and power strokes.

• Round Shape: Provides better control and maneuverability, ideal for beginners or players focused on precision.

• Teardrop Design: Balances power and control, making it a versatile choice for varying play styles. -

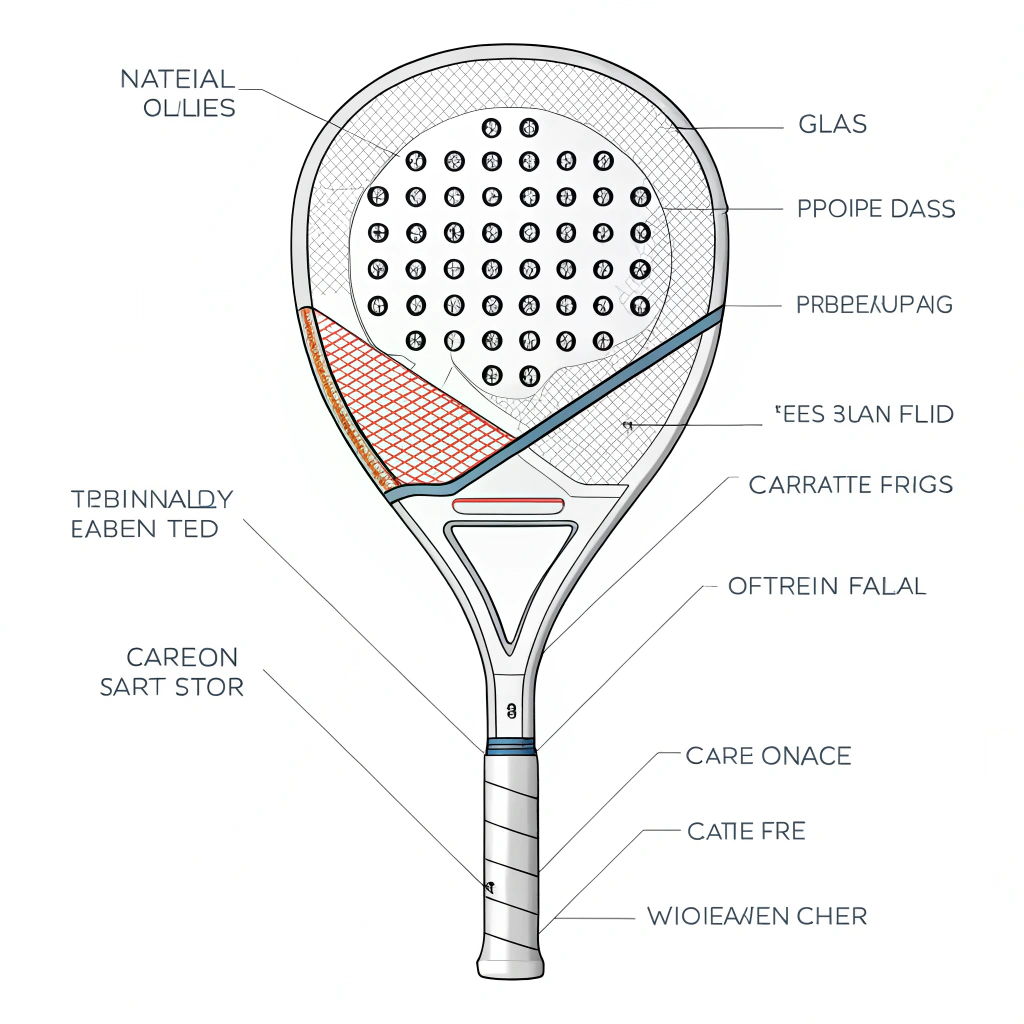

Consider Material Composition:

• Fiberglass: Suitable for entry-level to intermediate use, balancing performance with cost efficiency.

• Carbon Fiber (3k, 12k, 18k): These provide higher stiffness and strength, making them favorable for advanced players who demand enhanced durability and performance. -

Customization and OEM Production:

• Full customization, including unique shapes, printed graphics, and logo placements on hand grips or handle covers, can boost brand identity and customer loyalty.

• Quick prototyping and reliable delivery are critical. NEX Padel excels in rapid sampling and adhering to strict production schedules. -

Performance Durability and Quality Control:

• Ensure your supplier adheres to industry standards in manufacturing. Techniques such as advanced composite molding3 and surface finishing methods contribute significantly to overall product performance.

• Regular quality checks on critical attributes like balance, weight distribution, and surface texture ensure the racket meets world-class standards.

The following table compares our three primary padel racket designs along key criteria:

| Feature | Diamond Shape | Round Shape | Teardrop Design |

|---|---|---|---|

| Primary Benefit | Increased power for aggressive play | Enhanced control and precision | Balanced performance |

| Material Options | Carbon fiber (3k/12k/18k), Fiberglass | Fiberglass, Carbon fiber customizable | Mix of advanced carbon fiber and fiberglass |

| Customization | Full customization available | Standard to customizable options | Highly customizable |

| Player Suitability | Advanced, power-focused players | Beginners to intermediate players | Versatile players looking for balance |

| Stock / OEM Capability | Quick prototyping, tailored designs | Established product line with customization | Flexible production and rapid delivery |

Technical Details on Materials and Manufacturing

At NEX Padel, our manufacturing processes and material selection are based on rigorous technical standards. The choice between fiberglass and varying carbon fiber grades (3k, 12k, 18k) depends on your target market and expected usage patterns. For example:

• Fiberglass: Although it may have lower stiffness compared to carbon fiber, it is highly reliable for entry-level and mid-range products. Its lower cost can be a strong competitive advantage for clubs seeking quality without excessive financial expenditure.

• Carbon Fiber (3k/12k/18k): Each grade offers incremental benefits in terms of durability and weight. For instance, 18k carbon fiber delivers superior strength and minimal flex, ideal for athletes who generate high swing speeds. Choosing the right carbon fiber variant can significantly impact the power-to-control ratio, making it essential to match the material choice with the intended user profile.

Our advanced machinery and precision tooling ensure that every racket produced undergoes stringent quality control tests. Custom shapes, precise balance, and perfect weight distribution are verified before the product reaches you. This attention to detail is what sets NEX Padel apart in a competitive landscape.

Best Practices for Racket Selection

-

Define Your Target Demographic: Understand whether your players prioritize power, control, or a balanced approach to game play. This clarity will guide the decision between diamond, round, or teardrop designs.

-

Assess Material Benefits: Analyze whether investing in a higher grade of carbon fiber offers a tangible performance benefit for your user base. Remember, while premium materials increase performance, they also impact pricing.

-

Customization Capabilities: Embrace customization to strengthen brand identity. Custom logos, colors, and even personalized handle grip drawings not only improve aesthetics but can also promote brand loyalty among users.

-

OEM Production Efficiency: Leverage suppliers like NEX Padel who offer rapid prototyping4 and reliable production schedules. Quick sampling enables you to see a proof of concept before a full-scale order, reducing risk and ensuring alignment with your specifications.

-

Rely on Data and Case Studies: Baseline your decision on industry data, customer reviews, and performance benchmarks. For instance, collaborations with well-known brands like Hirostar, Reebok, and Starvie have helped refine our product designs over time through iterative feedback and market performance analysis.

Industry-standard tests such as balance measurements and impact durability testing are essential. Make use of sample products to perform your in-house tests before scaling orders. This practice ensures that your chosen products not only meet but exceed performance expectations in real-world settings.

Case Study: Improving Club Performance through Optimized Equipment

One of our major padel club partners was experiencing a decline in player satisfaction due to outdated equipment. By switching to our teardrop designed rackets manufactured with advanced carbon fiber materials, the club reported a measurable improvement in match performance and player confidence. Our rapid prototyping feature allowed for swift customization that matched the club’s brand colors and logo designs. This case underscores the value of integrating technical expertise with customization to achieve superior outcomes.

Here are the key benefits the club experienced:

• Enhanced balance and swing power leading to increased match wins.

• Custom designs that elevated the club’s brand identity and market appeal.

• Quick turnaround on new product orders, minimizing downtime.

This example demonstrates how advanced material choices and tailored designs can directly influence on-court performance and off-court customer satisfaction.

Summary and Next Steps

Selecting the ideal padel racket is a complex process that blends technical specifications, material performance, and customization options. By understanding the nuances between racket shapes—diamond, round, and teardrop—and weighing the pros and cons of materials such as fiberglass and various carbon fiber grades, you can confidently choose a product that meets your club’s specific needs.

At NEX Padel, our commitment to quality, rapid prototyping, and OEM customization means you benefit from:

• A detailed product selection framework that aligns with modern performance requirements.

• The latest production techniques and materials to ensure product durability.

• Proven track records demonstrated through successful collaborations with leading global brands.

We invite you to explore our extensive range of padel rackets and experience the blend of technology, customization, and precision manufacturing that defines the future of padel sports equipment. Contact us today to learn how our tailored solutions can elevate your sports facility’s performance and brand identity.

People Also Ask

• Are expensive padel rackets worth it?

While high-end padel rackets may offer advanced materials and cutting-edge design features, they are not always necessary to improve gameplay. For many players, upgrading after a year of use in a lower-cost model can be more beneficial than starting with the most expensive option.

• What is the best padel racket for aggressive players?

Aggressive players often prefer rackets with a forward center of gravity and enhanced power. While specific models may vary, rackets with a diamond shape and advanced carbon fiber construction are designed to provide the necessary power output and stability.

• How to tell a good padel racket?

A high-quality padel racket will have an optimal shape, appropriate weight distribution, and a balanced handle size. Additionally, the choice of materials—for example, the difference between fiberglass and carbon fiber—affects both performance and durability. Rackets used by top athletes typically demonstrate superior control, impact resistance, and surface texture for enhanced spin.

-

Carbon fiber: Click to discover the benefits and technical specifications of carbon fiber, including its grading (3k, 12k, 18k) and impact on performance and durability in high-end rackets. ↩ ↩

-

OEM production: Click to learn how original equipment manufacturer production processes streamline custom manufacturing, ensuring quality control and efficient scale-up for sports equipment providers. ↩ ↩

-

Advanced composite molding: Click to understand advanced composite molding techniques that enhance structural integrity and performance in modern padel rackets. ↩ ↩

-

Rapid prototyping: Click to explore how rapid prototyping enables quick design iterations and faster time-to-market, essential for competitive sports equipment industries. ↩ ↩