When selecting a padel racket, the key to success lies in understanding how material performance, production techniques, and customization options work together to deliver exceptional durability and high performance. In this article, we detail the main challenges faced by manufacturers and buyers alike, explain the factors influencing racket longevity, and provide a clear roadmap for choosing the right supplier to meet your padel gear needs.

Procurement managers and product development leads are well aware that durability is not just an added feature—it is the backbone of competitive padel equipment. The industry demands rackets that can stand up to intense play while offering consistent performance. However, achieving this requires carefully balancing material selection, manufacturing processes, and end-user customization.

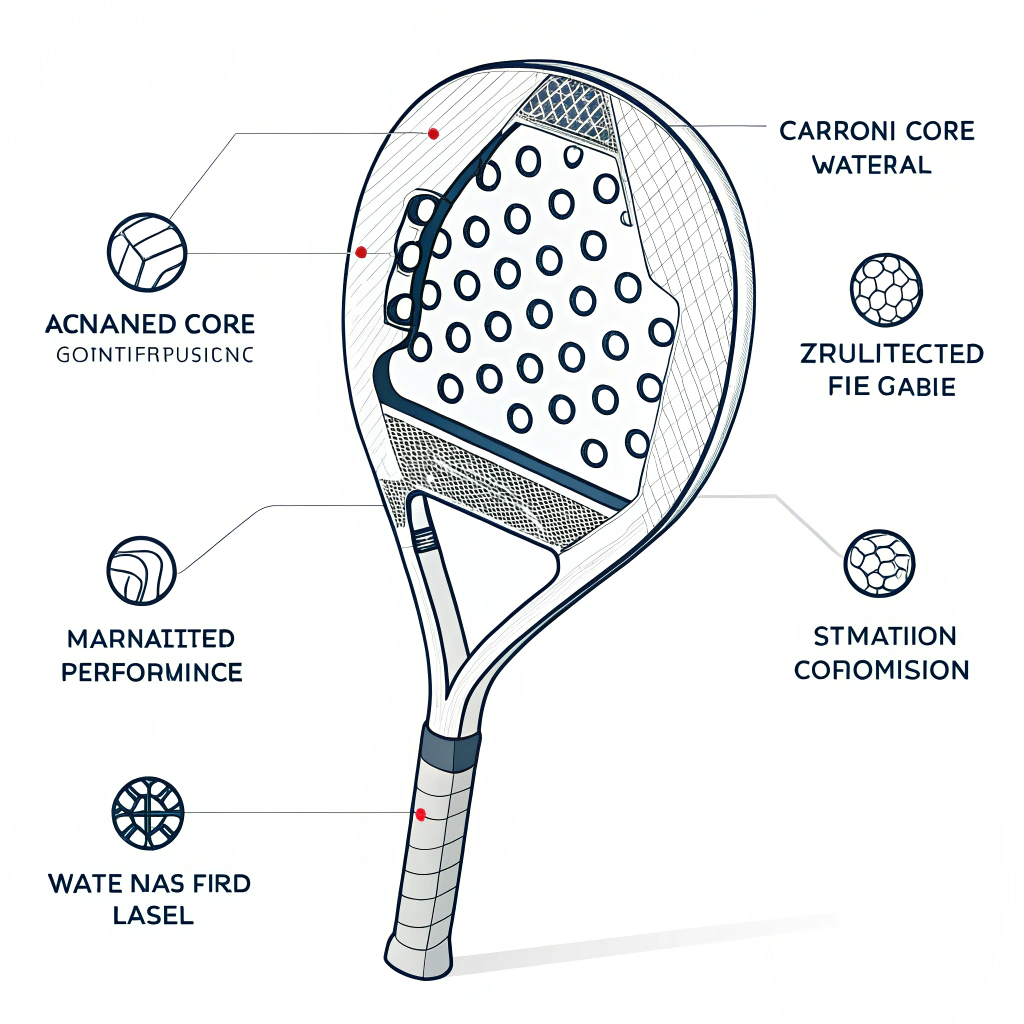

- Material Variations: Different carbon fiber grades1 (3k, 12k, 18k) offer varying levels of stiffness, weight, and durability. Each grade has its own trade-offs, impacting racket performance and lifespan.

- Manufacturing Precision: Even slight deviations in production techniques can affect the structural integrity of a padel racket. High-performance padel relies on precision in areas such as resin infusion2, molding, and finishing.

- Customization Needs: With increasing demand for personalized designs and functional features (customized logos, hand grips, and handle coverings), suppliers must ensure that every customization does not compromise durability.

- External Testing and End-User Stress: Rackets face rigorous testing conditions, including impact from repeated high-force ball strikes and thermal stress, which raises the need for materials and designs that maintain performance under pressure.

Breaking down the reasons behind the frequent issues in padel racket durability helps in establishing better quality control guidelines:

-

Carbon Fiber Grades:

- 3k Carbon: Provides good flexibility and is cost-effective; however, it may not offer the highest stiffness required for competitive play.

- 12k Carbon: Strikes a balance between lightweight design and resilient performance, widely used in mid to high-level rackets.

- 18k Carbon: Offers superior performance consistency and exceptional durability, although at a higher production cost.

-

Design Differences:

Rackets typically come in three shapes—Diamond, Round, and Teardrop—each impacting weight distribution and balance differently. Optimizing the design for both control and power is critical. For instance, the teardrop shape might offer better power transmission, while a diamond shape might provide enhanced control. -

Quality Control and Industrial Standards:

Testing methods, such as the one featured in the Testfakta study3, play an essential role in qualifying a padel racket's durability. Consistent testing protocols and data-driven measures ensure that products meet rigorous standards set by the industry, especially when proven against standardized methods like simulated impact tests. -

Customization and Production Efficiency:

OEM suppliers4, especially those like NEX Padel, are adept at managing various customization orders effectively. This capability ensures that even when rackets are tailored for individual brand aesthetics or technical needs, the product quality is not compromised.

To address these challenges, we offer a comprehensive solution roadmap that procurement managers can follow to ensure they select a supplier capable of delivering the best high-performance and durable padel rackets.

A detailed comparison of carbon fiber options is crucial. Below is a simplified table summarizing the main characteristics:

| Carbon Fiber Grade | Key Characteristics | Typical Use Case | Customization Potential |

|---|---|---|---|

| 3k Carbon | Flexible, lightweight, cost-effective | Entry-level to intermediate rackets | Standard design, limited high-end finishes |

| 12k Carbon | Balanced stiffness and weight | Mid-range competitive rackets | High, supports design customizations |

| 18k Carbon | Superior stiffness and durability | High-performance/professional rackets | Maximum, ideal for premium line-ups |

This table should be used as a basis for discussions with your potential supplier to ensure their material offerings align with your product development goals.

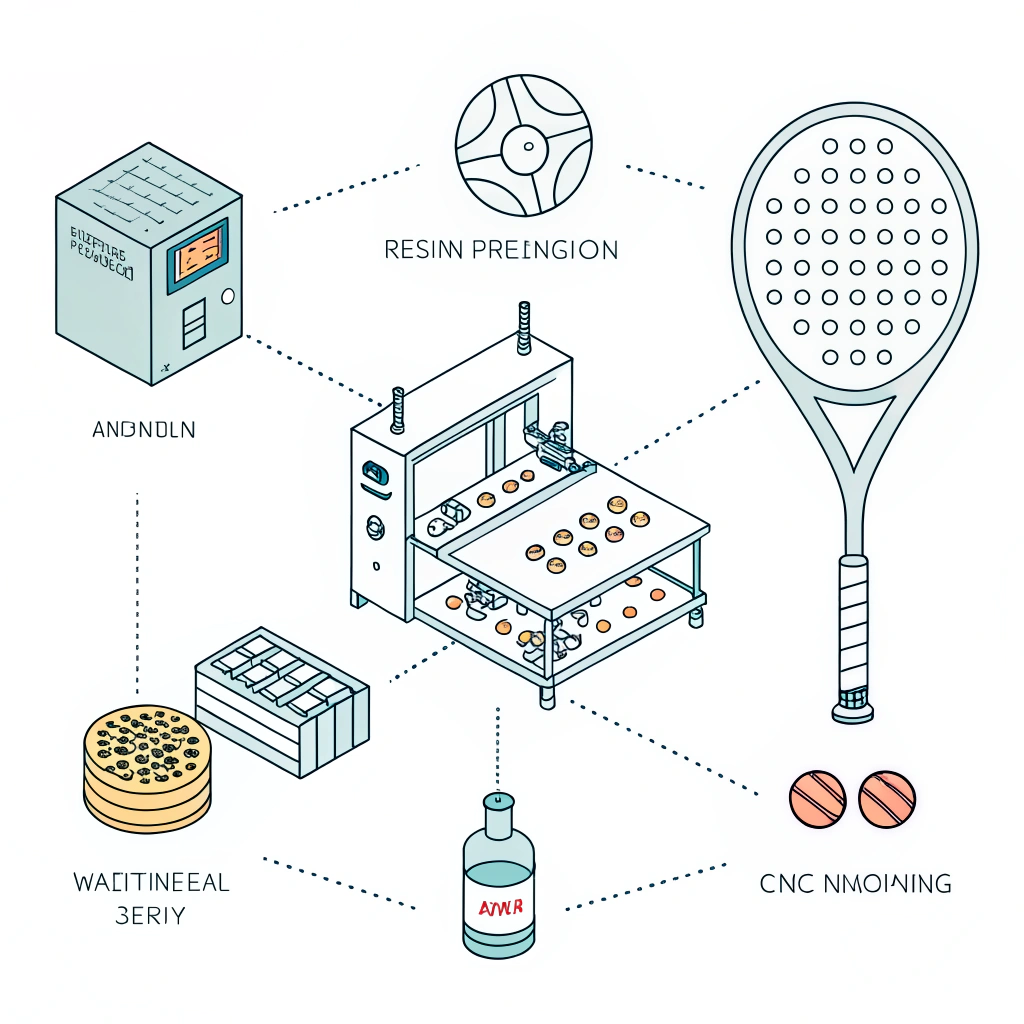

Understanding the manufacturing process will provide confidence in the supplier’s ability to meet performance requirements consistently. Consider the following essential factors:

- Production Precision: Verification of advanced techniques like resin infusion2, precision molds, and CNC machining5 helps ascertain that each racket is produced with consistency.

- Customization Flexibility: Check for the supplier’s capability to handle custom shapes (Diamond, Round, and Teardrop) and personalized prints or logos on the hand grip and handle cover.

- Test Protocols: Ask about the supplier’s quality control processes including mechanical stress tests, salt spray tests, and thermal cycling to simulate real-world usage.

Manufacturers who invest in modern machinery and skilled craftsmanship often maintain stringent quality and durability standards needed for competitive padel conditions.

One of the best ways to gauge a supplier's quality is through validated external studies. As highlighted by studies such as the Testfakta assessment, objective measurements of racket durability help underline performance differences. Although specific findings like those from the study (naming the Kuikma PR990 Hybrid Soft) may not directly correlate with our product line, they provide a benchmark for industry comparisons and set realistic performance expectations.

- Data-Driven Insights: Utilize published data to validate that the supplier's testing methods are robust. Suppliers with transparent testing data are often more reliable.

- Industry Benchmarks: Compare customer feedback with laboratory findings to understand the real-world longevity of the rackets.

The physical feel and ergonomic design of the racket directly affect its performance. Key considerations include:

- Grip Size and Handle Design: Adequate grip size ensures maximum control, whereas the design of the handle and its thickness can influence fatigue levels during prolonged use.

- Weight and Balance: The overall weight of the racket and its center of gravity determine whether it will favor a balance between power and control. Suppliers should provide detailed weight and balance statistics.

- Striking Surface and Core Structure: The composition of the racket head and the structure of its internal core are critical for both durability and performance. Advanced composites not only improve the hitting surface but also mitigate the impact shock from ball strikes.

For procurement managers, these physical parameters should be documented in technical datasheets provided by the supplier.

A systematic supplier evaluation checklist can help ensure that no key aspect is overlooked. Here is an example of a simplified checklist:

| Evaluation Criteria | Key Questions | Rating (1-5) |

|---|---|---|

| Material Quality | Are carbon fiber grades (3k, 12k, 18k) clearly defined? | |

| Manufacturing Processes | Does the supplier use advanced precision production methods? | |

| Customization Capability | Can they accommodate design, logo, and grip customizations? | |

| Quality Control and Testing | What standardized tests are used to ensure durability? | |

| Production Efficiency | What are the production lead times for custom orders? | |

| Customer Feedback & Case Studies | Are there documented case studies or testimonials from reputable brands? |

Using such a checklist assists procurement managers in making data-driven decisions, ensuring that the selected supplier meets all performance and quality thresholds required for competitive padel equipment.

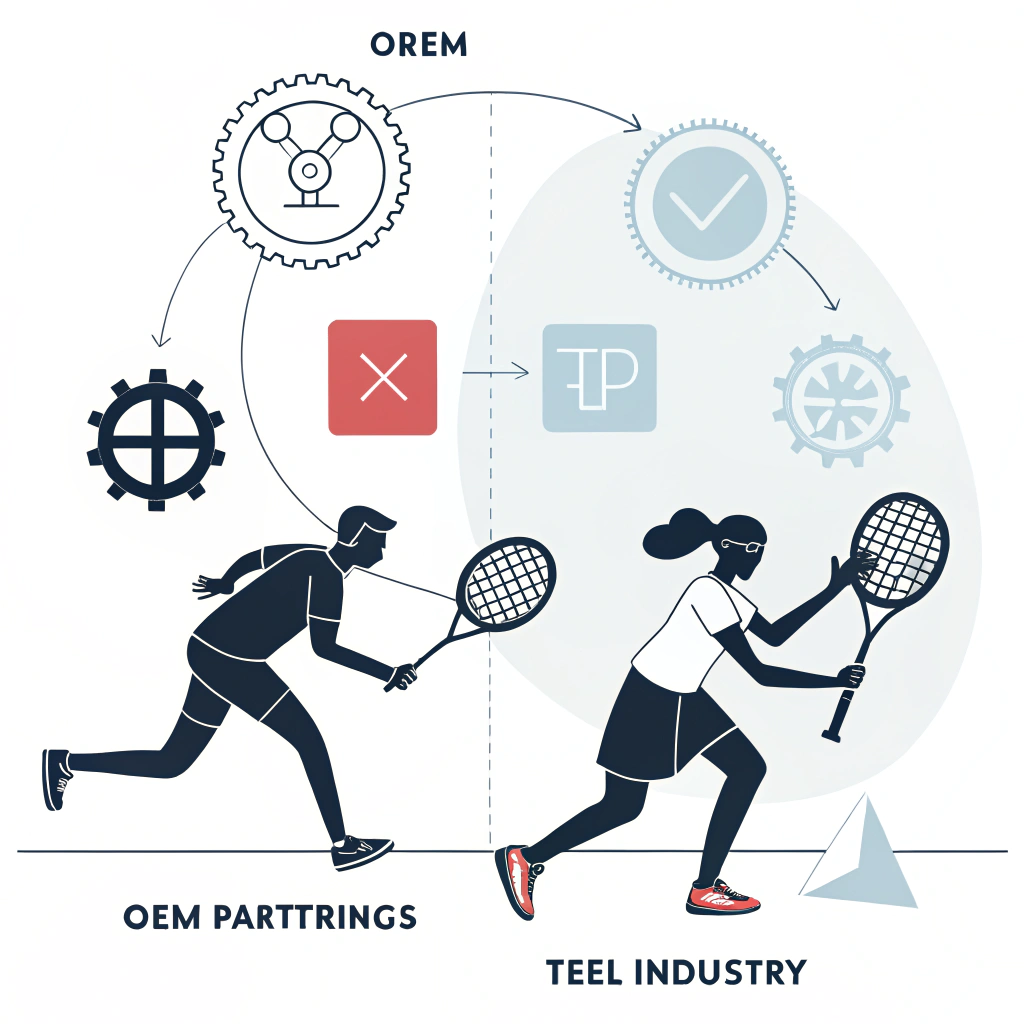

Engaging with a supplier experienced in high-performance sports equipment manufacturing can provide tangible benefits:

- Accelerated Prototyping and Customization: Companies like NEX Padel demonstrate fast sample production and on-time delivery—a key factor for product development cycles.

- OEM Partnerships: Collaborating with established brands such as Hirostar, Reebok, and Starvie means that the supplier has a proven track record in overseeing quality production while meeting customized design needs.

- After-Sales Support: Robust post-production support, including detailed technical datasheets and feedback loops with end-users, significantly enhances the trustworthiness and renewal rate in business-to-business transactions.

The combination of detailed data and flexible manufacturing processes enables suppliers like NEX Padel to deliver high-performance, durable padel rackets that meet the rigorous demands of competitive play while offering extensive customization.

In summary, ensuring racket durability and high-performance is a multi-step process that hinges on carefully comparing material specifications, manufacturing precision, and customization capabilities. Procurement managers should rigorously evaluate suppliers using technical datasheets, independent testing data, and industry benchmarks.

Our approach includes:

- Evaluating different carbon fiber grades and understanding their technical trade-offs.

- Analyzing manufacturing practices that ensure precision and consistency.

- Comparing suppliers using a detailed evaluation checklist to guarantee that specifications meet high-performance standards.

- Supporting decisions with data-driven insights and proven industry performance studies.

As you decide on a supplier, ensure that your partner can deliver not only on paper but also in reproducible, real-world performance. Reach out for detailed technical documentation, request samples where possible, and consider trial orders to experience firsthand the level of precision and quality offered.

Making an informed supplier choice now will guarantee that your padel products stand out in the market and meet the rigorous demands of competitive play. For procurement managers and product developers seeking lasting performance and advanced product differentiation, aligning with a technologically proficient manufacturer is the first step towards achieving superior market competitiveness.

People Also Ask

Q: What is the most durable padel racket?

A: Based on extensive testing and standardized impact studies, the most durable padel rackets are those that consistently employ high-grade carbon fibers, like 18k carbon, alongside precision manufacturing processes. Studies such as the Testfakta assessment have shown that certain models, when rigorously tested, demonstrate superior longevity under continuous play conditions.

Q: How long should a padel racket last?

A: On average, a high-quality padel racket, used between 3 to 7 times a week, can last from 2 to 8 months. For players engaging in intensive play, it is advisable to evaluate the racket's performance periodically to ensure it still meets required standards.

Q: What to look for in a good padel racket?

A: A good padel racket should exhibit excellent physical attributes such as proper grip size, optimal weight distribution, and balanced control versus power. Key elements include a well-designed handle, a robust head, and a quality core to ensure stability and durability during high-impact play.

-

Carbon Fiber Grades: Click to read an article detailing the differences between various carbon fiber grades (3k, 12k, 18k) and how each affects durability, stiffness, and overall performance in high-end sporting equipment. ↩ ↩

-

Resin Infusion: Click to explore the resin infusion process, its role in bonding composite materials, and why it is critical for achieving structural integrity in high-performance padel rackets. ↩ ↩ ↩2

-

Testfakta Study: Click to read about the Testfakta study, a benchmark assessment that measures product durability through standardized impact and stress tests, providing valuable insights for quality control. ↩ ↩

-

OEM Suppliers: Click to understand the concept of OEM suppliers, how they operate in the manufacturing ecosystem, and their importance in delivering customized, brand-specific sports equipment. ↩ ↩

-

CNC Machining: Click to learn about CNC machining and its impact on precision manufacturing, ensuring consistent quality and performance in complex product designs. ↩ ↩