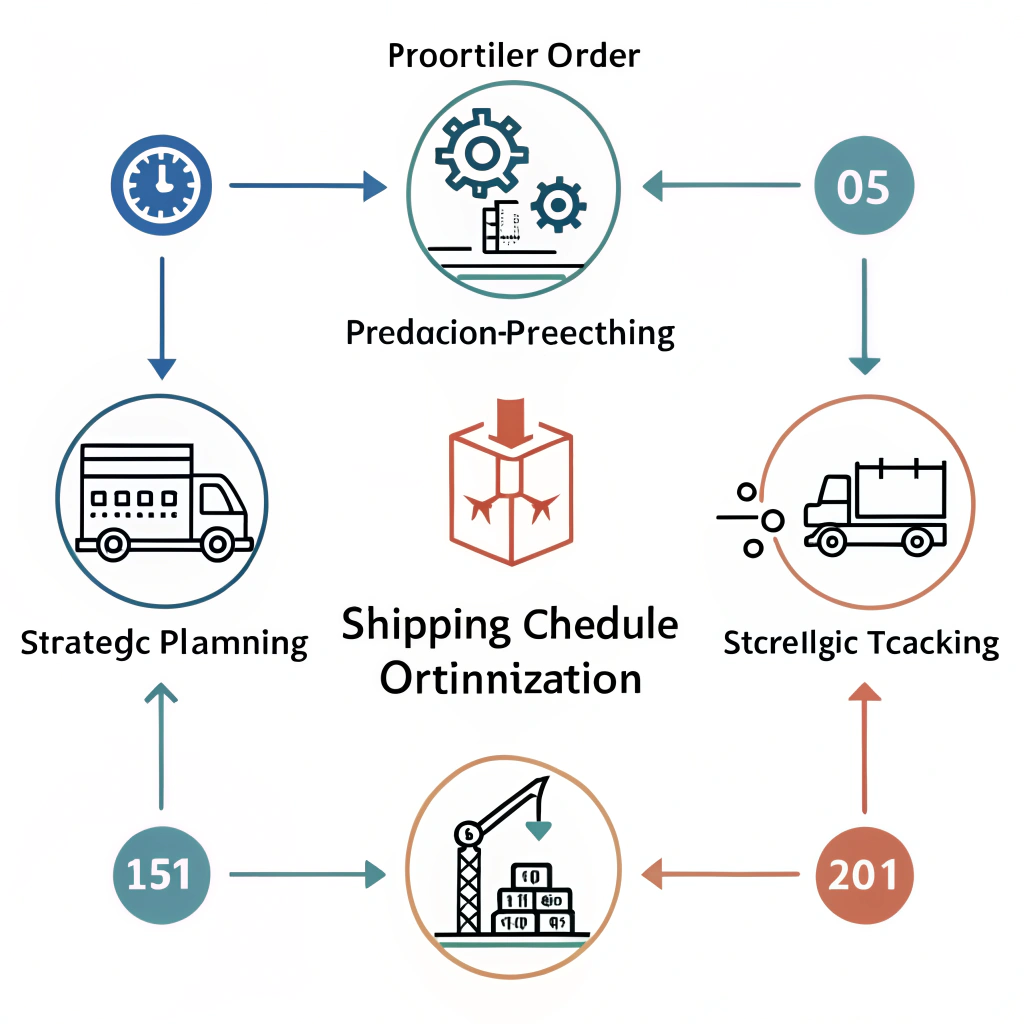

Quick Answer: Effective shipping schedule optimization for padel rackets during peak season requires a mix of proactive production planning, strategic logistics, and real-time tracking. By comparing different scheduling approaches and leveraging data-driven insights, supply chain managers can reduce delays, cut costs, and ensure timely order fulfillment.

During peak season, the demand for padel rackets and related sports equipment surges. For a seasoned supply chain manager, this spike brings about a host of challenges, including increased lead times, complex order fulfillment, and logistical bottlenecks. The critical issues include ensuring that production plans align with shipping capacities, managing inventory fluctuations, and mitigating unexpected delays. Addressing these problems head-on requires a comprehensive approach that combines planning, technology, and strategic decision-making.

Optimization starts with an accurate understanding of your shipping schedule. This involves:

-

Proactive Order Forecasting and Production Planning

Forecasting demand accurately is essential. With advancements in data analytics, companies can predict order volumes based on historical data, market trends, and seasonal fluctuations. When forecasts are accurate, production schedules can be adjusted to meet the demand efficiently. This is particularly crucial for padel rackets, where variety in materials (ranging from fiberglass to different grades of carbon fiber) demands precise production coordination. -

Strategic Logistics and Transportation Planning

Shipping schedules need to incorporate factors such as transportation modes, expedited shipping options, and carrier reliability. For peak season orders, selecting the right mix of carriers and shipping routes is critical. This process may involve negotiating capacity with transportation partners ahead of time and leveraging expedited shipping where necessary to mitigate delays. -

Real-time tracking1 and Data Analytics

Utilizing real-time tracking systems helps mitigate and manage unexpected delays. Data analytics serve a dual purpose by both providing operational insights and allowing for dynamic adjustments to shipping schedules. An efficient tracking system can alert managers about potential bottlenecks and enable quick decisions to reroute shipments if needed.

To manage the complexities of peak season shipping, it is helpful to compare different approaches to determine the best fit for a given supply chain. Below is a table that outlines the pros and cons of two key scheduling strategies:

| Strategy | Pros | Cons | Ideal For |

|---|---|---|---|

| Proactive Scheduling2 | Predictable lead times; easier planning; better carrier negotiations | Requires accurate forecasting; higher initial planning effort | Stable environments with recurring seasonal spikes |

| Reactive Scheduling3 | Flexibility to handle unforeseen demand; lower initial commitment | Increased risk of delays; higher costs during emergency shipping | Markets with high unpredictability and last-minute orders |

By comparing these strategies, supply chain managers can select an approach that aligns with their operational needs and market dynamics. For instance, if your production is closely linked with peak seasonal trends, a proactive schedule might be more effective despite its upfront challenges.

For successful logistics optimization during peak season, several key factors must be considered:

Reducing lead times is critical for meeting tight delivery windows. This isn't just about faster shipping—it’s about synchronizing production outputs with shipping capacities. Effective lead time management can be achieved by:

- Setting realistic production times.

- Coordinating with transportation partners in advance.

- Incorporating buffer times for unexpected delays.

Expedited shipping might reduce delays but often at a higher cost. Balancing cost with speed is a constant challenge. Tools like cost analysis tables can help determine the optimal spend that supports timely delivery without eroding profit margins.

At companies like NEX Padel, flexibility is key. Whether dealing with a range of materials like 3k, 12k, and 18k carbon fiber, or customizing shapes and brands, the ability to adjust production and shipping according to customer needs is a significant advantage. Custom shipping solutions often require a dedicated logistics plan that leverages both in-house expertise and external partnerships effectively.

Unpredictable variables such as weather, labor strikes, or carrier issues create risks that must be anticipated. Implementing backup plans such as alternative routes, reserves with secondary carriers, or even insurance can cushion the impact of unforeseen disruptions.

For supply chain managers tasked with balancing high order volumes and cost control during peak season, consider the following best practices:

- Forecasting and Inventory Analysis: Use historical data and present market trends to forecast demand. This data drives production planning and minimizes stock-outs.

- Carrier Negotiations: Secure logistics contracts during off-peak seasons to lock in favorable rates and guaranteed capacity.

- Technology Integration: Invest in Enterprise Resource Planning (ERP) systems5 that integrate production, inventory, and logistics data for real-time decision-making.

- Dynamic Adjustments: Use real-time data to identify disruptions and reassign shipments swiftly.

- Communication Channels: Establish clear communication lines between production teams, shipping carriers, and logistics coordinators to ensure quick response times.

- Contingency Plans: Have backup carriers and alternative shipping routes ready to deploy.

- Performance Analysis: Review shipping performance data at the end of the season to identify bottlenecks and areas for improvement.

- Cost Analysis: Compare actual shipping costs against estimates to understand variances and refine future forecasts.

- Customer Feedback: Gather insights from customers regarding delivery timelines and service quality to adjust strategies accordingly.

A summary table of these practices is presented below:

| Phase | Key Actions | Expected Outcomes |

|---|---|---|

| Pre-Season | Forecast orders, negotiate contracts, integrate technologies | Improved planning and cost-effective shipping |

| During Peak Season | Monitor, adjust dynamically, maintain clear communications | Reduced delays and efficient order fulfillment |

| Post-Season | Analyze performance, assess cost effectiveness, incorporate feedback | Better preparedness for future peak seasons |

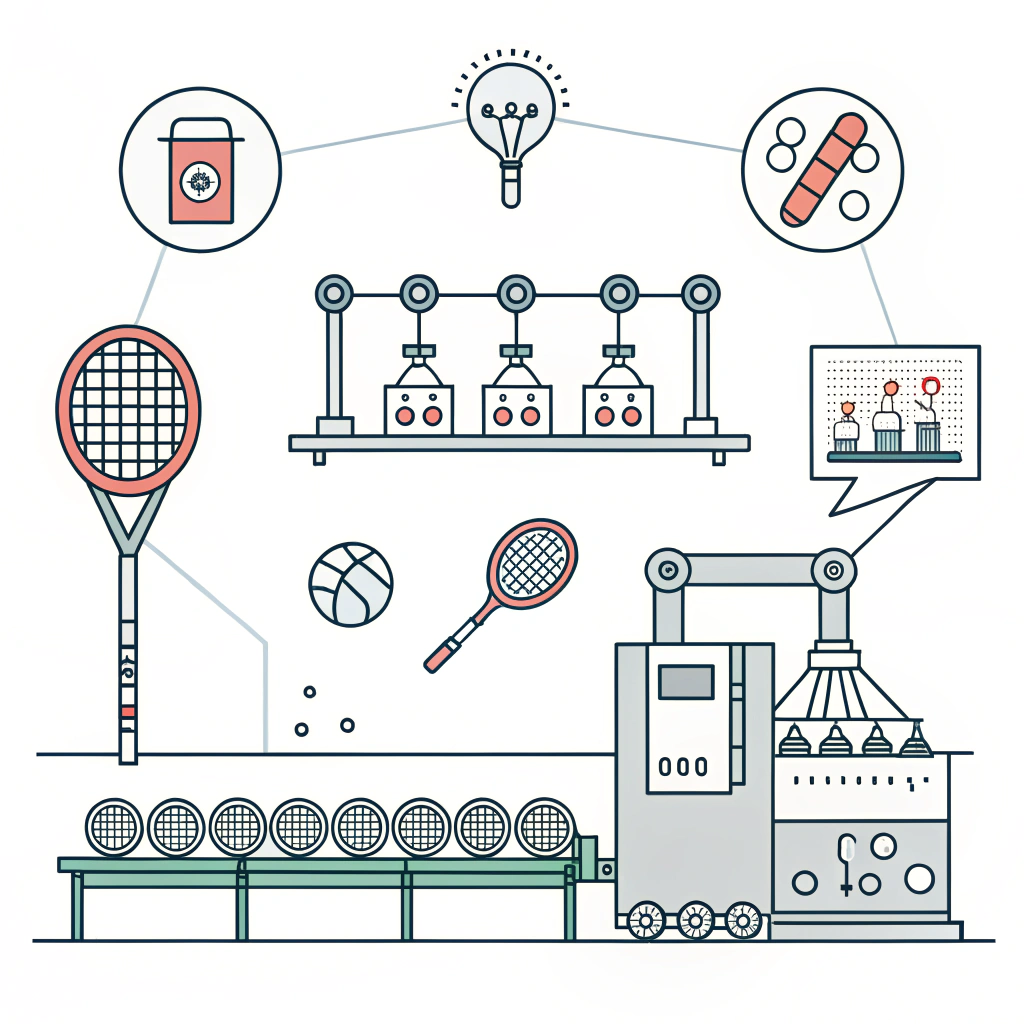

At NEX Padel, a leading manufacturer known for high-performance padel rackets, we face the peak season with a robust, data-driven strategy. Our process includes:

- Advanced Production Planning: By employing modern production techniques for different racket materials (e.g., fiberglass, 3k/12k/18k carbon fiber), we ensure production speeds align with market volatility.

- Parallel Logistics Coordination: Partnering with reliable shipping carriers who understand the seasonal demands allows us to maintain a balance between cost and expedited shipping needs.

- Integrated Technology: Our ERP system links manufacturing data with logistics tracking, ensuring real-time monitoring and maintaining an agile response to sudden changes in demand.

These operational highlights are supported by demonstrates from our partnerships with top brands such as Hirostar, Reebok, and Starvie, proving that our strategies not only meet, but exceed, industry standards.

For supply chain managers aiming to implement similar strategies, here are some operational tips distilled from our experiences and industry insights:

- Adopt a Phased Implementation: If transitioning to a new shipping schedule strategy, do so in phases. Pilot with a subset of orders to gauge effectiveness before scaling up.

- Invest in Technology: Tools that provide real-time visibility into shipping operations can be game changers. They allow quick decision-making and adjustment under pressure.

- Regular Communication: Maintain daily touchpoints with logistics teams during peak seasons. This minimizes surprises and maintains alignment across all departments.

- Leverage Data Analytics: Use analytics not just for forecasting but also to measure the performance of each shipping phase. Constantly refine your approach based on data trends.

- Consider Customization: Tailor shipping strategies to your specific product line. For instance, high-end customized padel rackets might justify premium logistics services compared to standard models.

In summary, effective shipping schedule optimization during peak season is not a one-size-fits-all solution. For B2B procurement managers in the sports equipment distribution industry, the key lies in comparing proactive and reactive scheduling approaches while integrating them into a dynamic, data-driven logistics framework. Here’s a recap of the essential elements:

- Proactive vs. Reactive Scheduling: Evaluate your operational environment and choose the strategy that best mitigates risk while ensuring timely delivery.

- Real-time Data Tracking: Adopt integrated ERP systems and real-time monitoring tools to manage shipping adjustments on the fly.

- Cost Management vs. Efficiency: Balance expedited shipping with cost control, customizing your approach based on order volumes and market demands.

- Preparedness: Develop comprehensive contingency plans that cover potential disruptions, ensuring uninterrupted order fulfillment even in volatile peak seasons.

For companies like NEX Padel, continuous improvement in production planning and shipping coordination remains a cornerstone of our strategy. We encourage logistics managers to examine current shipping schedules, adopt technology enhancements, and prepare strategically for peak season challenges.

As you plan your next peak season shipping strategy, consider these insights as practical guidelines to enhance your logistics operations. Continuous evaluation, scenario planning, and proactive measures will pave the way for smoother, more efficient order fulfillment.

Q: How can I reduce lead times during peak season?

A: Reducing lead times during peak season requires accurate forecasting, proactive production planning, and real-time tracking. Coordination with reliable carriers and incorporating buffer times for unexpected delays can help maintain smoother logistics operations.

Q: What is the difference between proactive and reactive shipping scheduling?

A: Proactive shipping scheduling involves planning ahead using demand forecasts and established carrier agreements, while reactive scheduling adapts in real-time to changes in order volume and unexpected disruptions. Each approach has its trade-offs in cost, flexibility, and risk management.

Q: How do real-time tracking systems improve shipping schedules?

A: Real-time tracking systems provide immediate visibility into shipment status, enabling quick response to delays and bottlenecks. This allows managers to adjust routes and shipping strategies dynamically, ultimately reducing delays and streamlining order fulfillment.

-

Real-time tracking: Click to access insights on how real-time tracking systems improve operational visibility, enabling prompt responses to shipping delays and dynamic route adjustments. ↩ ↩

-

Proactive Scheduling: Click to learn how proactive scheduling uses demand forecasts and pre-planned logistics strategies to streamline shipping and reduce delays. ↩ ↩

-

Reactive Scheduling: Click to explore reactive scheduling techniques that allow businesses to respond flexibly to unforeseen order spikes and disruptions. ↩ ↩

-

Lead Time Management: Click to discover strategies for managing lead times effectively, ensuring production output synchronizes optimally with shipping capabilities. ↩ ↩

-

Enterprise Resource Planning (ERP) systems: Click to understand how ERP systems integrate multiple business functions—production, inventory, and logistics—for enhanced real-time decision-making. ↩ ↩