In brief, rigorous testing combined with advanced production techniques and strict quality assurance measures is essential to achieve high-performance padel rackets1 that meet international standards and exceed distributor expectations.

In today’s competitive sports equipment market, the need for high-performance padel rackets1 is more critical than ever. Distributors and retailers demand products that not only perform flawlessly on the court but also withstand the rigorous nature of competitive play. The challenge, therefore, lies in ensuring that padel rackets meet quality and durability benchmarks while incorporating advanced materials like glass fiber, 3k, 12k, and 18k carbon fiber2.

For procurement managers or technical buyers, understanding the testing and quality assurance processes behind these rackets is key to making an informed decision. Quality testing in padel rackets involves a comprehensive assessment of materials, production techniques, and manufacturing precision—ensuring that every product delivers consistent performance.

There are several reasons why thorough testing and quality assurance in padel racket production is necessary:

- Material Variability: Different materials (e.g., glass fiber vs. carbon fiber with various weaves) affect racket performance, weight distribution, and durability. Testing helps in identifying the optimal material configuration.

- Production Precision: Advanced production techniques reduce the risk of structural defects. Minimal deviations can lead to inconsistency in game performance, making rigorous quality control a non-negotiable step.

- Customization Challenges: With custom shapes, prints, and color options available, every bespoke design must be tested to ensure that its performance is not compromised.

- Handling High Stress: Padel rackets endure significant mechanical stress. Testing ensures that each racket meets the required thresholds of strength and flexibility.

- Market Expectations: Distributors rely on proven products backed by comprehensive quality testing to maintain their own reputation in the market.

By understanding these aspects, procurement managers can better appreciate the importance of selecting suppliers who invest heavily in quality assurance.

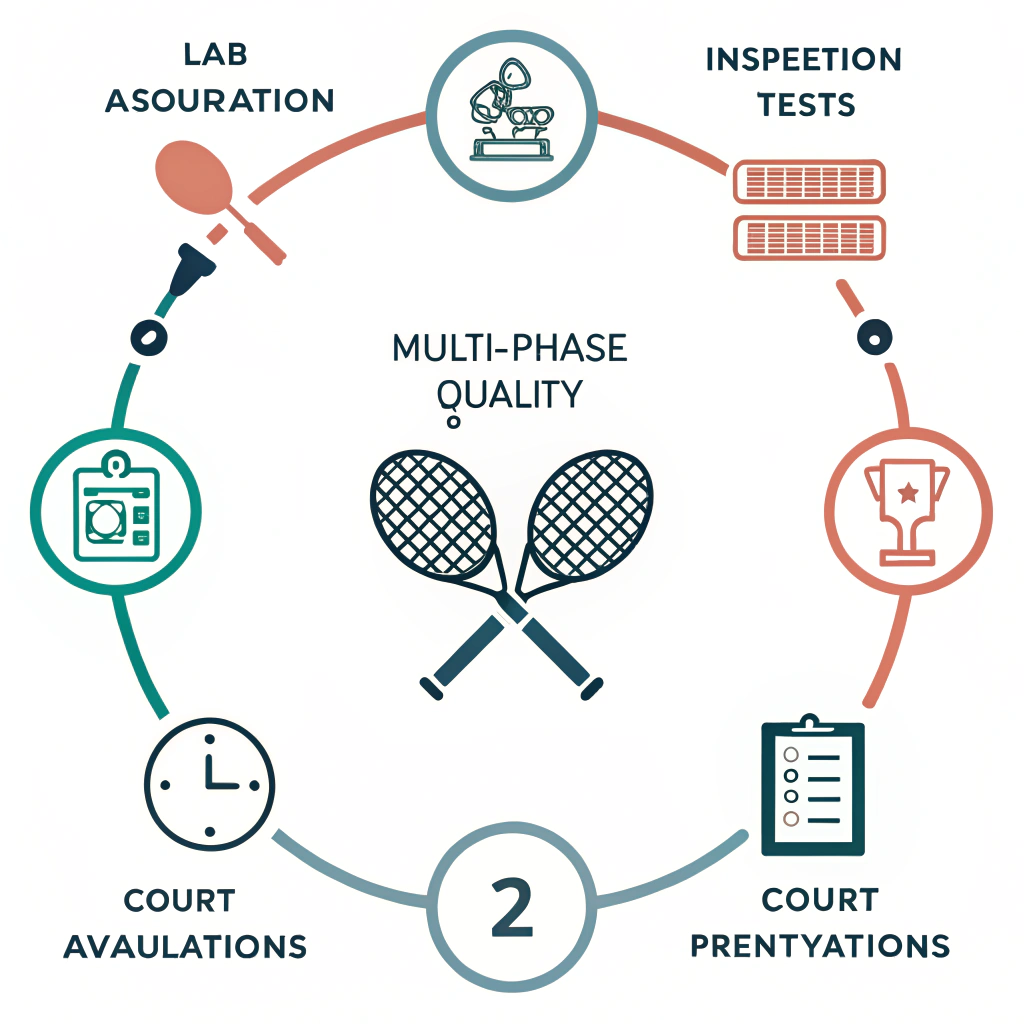

For a product that is used intensively on the court, the quality assurance process is structured into several critical phases:

- Material Inspection:

- Verification of incoming materials by checking tensile strengths, composition, and structural integrity.

- Use of advanced sensors and imaging technology to detect any microscopic defects.

- Process Validation:

- Implementing strict process protocols at every manufacturing stage.

- Monitoring production consistency, especially when using different carbon fiber weaves (3k, 12k, 18k) where each variant offers distinct performance attributes.

- Prototype Testing:

- Production of prototypes that undergo both lab-based and on-court testing.

- Evaluation under varying environmental conditions to simulate actual playing scenarios.

- Durability and Impact Testing:

- Stress tests including compression, bending, and repeated impact tests to determine lifespan.

- Ensuring that the racket withstands high impact while retaining its performance integrity.

- Customization Benchmarks:

- Every custom order, whether it’s a unique shape, print, or handle design, is individually assessed.

- Special tests are carried out to ensure that the customization process does not adversely affect the structural integrity of the racket.

Below is a table summarizing the quality control measures typically adopted in the production of high-performance padel rackets:

| Testing Phase | Key Focus | Techniques Used | Outcome Expected |

|---|---|---|---|

| Material Inspection | Incoming fibers | Microscopic analysis, tensile tests | High quality, defect-free materials |

| Process Validation | Production consistency | Sensor monitoring, process audits | Consistent manufacturing precision |

| Prototype Testing | Product performance | Lab-based stress tests, on-court trials | Validation of design and functionality |

| Durability Testing | Impact resistance | Compression, bending, cyclic tests | Long-lasting products with minimal wear |

| Customization Verification | Design integrity | Tailored tests based on customization | Assurance that quality remains unchanged |

Procurement managers can use this checklist to evaluate whether a supplier like NEX Padel adheres to industry standards and whether their testing protocols are robust enough to guarantee product reliability.

At NEX Padel, the manufacturing process is a blend of innovative technology and meticulous craftsmanship. The production of padel rackets involves several advanced techniques, ensuring that every racket performs at the highest level. Here are some key engineering insights:

The use of composite materials such as carbon fiber in various weaves (3k, 12k, and 18k) is central to our production strategy. Each weave offers distinct properties:

- 3k Carbon Fiber: Known for its flexibility and lightweight composition, ideal for players who value agility.

- 12k Carbon Fiber: Offers a balanced mix of strength and durability, suitable for versatile performance requirements.

- 18k Carbon Fiber: Provides exceptional rigidity and power, catering to advanced players who require high impact resistance.

By carefully selecting materials and blending them using composite engineering3 techniques, the final product exhibits the ideal balance of lightness, flexibility, and durability.

Precision manufacturing in padel racket production ensures minimal deviations from design specifications. Cutting-edge CNC machines and robotic arms are used during the molding and assembly phases. This high level of precision is paired with rigorous process validation, ensuring every racket adheres to the strictest quality standards.

3. Customization5 and Versatility

Customization is at the heart of modern padel equipment. NEX Padel offers various customization options including full custom shapes, unique prints, and personalized color schemes. Moreover, accessories like hand grips and handle covers can be tailored with a company’s logo without compromising the racket’s performance. Each customized order goes through extensive testing to ensure that the modification does not hinder the overall product quality.

Time-efficient production processes and well-managed logistics are crucial for meeting market demands. NEX Padel’s commitment to fast sample development and timely delivery helps build trust with partners such as Hirostar, Reebok, and Starvie, reflecting our dedication to quality throughout the supply chain.

Consider a scenario where a distributor evaluates two potential suppliers for padel rackets. Supplier A offers standard testing and quality control measures, whereas Supplier B, like NEX Padel, provides extensive testing data and detailed assurance protocols. The evaluation criteria include:

- Material performance under varying stresses

- Consistency of production quality across batches

- Customization capability without sacrificing structural integrity

- Speed and reliability of sample development and delivery

A comparative analysis between the two suppliers might show that Supplier B's rackets offer superior durability under impact tests, reduced variability in production, and additional quality checkpoints in customized orders. This data-driven approach in supplier evaluation enables procurement managers to confidently choose a partner whose products have been thoroughly validated against industry standards.

While rigorous testing and advanced production techniques considerably boost product quality, some limitations remain:

- Cost Implications: High performance and comprehensive testing can drive up production costs, which might be reflected in the final product price.

- Customization Complexity: Extensive customization requires additional testing phases, potentially lengthening the production cycle.

- Technological Dependence: Reliance on high-end machinery and sensor technologies necessitates continuous investments and upgrades to stay competitive.

Understanding these limitations allows procurement managers to weigh the benefits of enhanced quality against potential cost and delivery challenges. Importantly, the added value of superior performance and durability often justifies these considerations in the B2B market.

In summary, robust testing and quality assurance protocols in padel racket production are vital to achieving high performance and ensuring long-lasting durability. By integrating advanced composite materials with precision manufacturing and detailed customization testing, NEX Padel meets and exceeds industry standards.

For procurement managers and technical buyers, key recommendations include:

- Evaluate the supplier’s quality control checklist and testing procedures.

- Compare performance data across different material compositions such as glass fiber and various carbon fiber weaves.

- Consider the long-term benefits of investing in high-quality, rigorously tested equipment, even if the initial costs are higher.

Adopting these strategies ensures that every padel racket not only meets technical benchmarks but also provides end-users with a consistent and high-quality sporting experience. Moving forward, embracing suppliers who prioritize rigorous testing and production precision will undoubtedly drive better market results and build lasting trust in quality and reliability.

Q1: How does NEX Padel ensure quality testing for padel rackets?

A1: NEX Padel employs advanced material analysis, precision manufacturing, and comprehensive durability tests to ensure each padel racket meets strict industry standards.

Q2: What measures are taken during padel racket production to guarantee performance?

A2: Key measures include detailed material inspections, process validation, prototype testing, and specialized testing for customization—ensuring optimal balance between weight, durability, and performance.

Q3: How can customized padel rackets maintain high quality?

A3: Customized padel rackets are subjected to tailored testing protocols that evaluate structural integrity and performance, ensuring that personalized designs do not compromise overall quality.

-

High-performance padel rackets: Click to learn how performance enhancements in padel rackets are achieved through advanced design and testing protocols, ensuring superior in-game performance and durability. ↩ ↩ ↩2

-

Carbon fiber: Click to understand the different weaves and properties of carbon fiber, and how its integration affects strength, flexibility, and overall product performance. ↩ ↩

-

Composite engineering: Click to discover how composite engineering blends different materials to optimize the balance between weight, rigidity, and impact resistance in sporting goods. ↩ ↩

-

Precision Manufacturing: Click to explore the role of precision manufacturing in achieving consistent quality, including the use of CNC machines and robotic automation in sports equipment production. ↩ ↩

-

Customization: Click to learn how tailored customization options are rigorously tested to maintain product integrity while meeting unique design requirements in the sports equipment industry. ↩ ↩