A quick answer: foam injection1 in padel racket manufacturing2 boosts production efficiency and enhances product performance by improving material consistency, reducing production time, and increasing durability. This advanced technique optimizes quality control and lowers costs, making it a valuable asset for high-performance sporting equipment production.

In today’s competitive sports equipment market, manufacturers are continually seeking methods to improve performance, streamline production, and reduce costs. One innovative solution that has captured significant interest is foam injection. This advanced technique is transforming padel racket manufacturing2 by offering a blend of precision, efficiency, and enhanced durability that traditional methods often struggle to achieve.

Understanding the critical role of advanced production techniques, this article explains how foam injection is integrated into the manufacturing process, its cost-effectiveness, and why it is particularly suited for high-performance padel rackets. Our focus is on delivering actionable insights for R&D managers, technical procurement specialists, and engineering leads in the sports equipment manufacturing sector.

In the conventional production of padel rackets, manufacturers often encounter several challenges. These include:

- Material inconsistency3: Traditional methods produce slight variations in material distribution that can affect the overall performance of the racket.

- Increased production time: Manual processes or less sophisticated injection methods slow down production, making it hard for manufacturers to keep up with market demand.

- Quality control issues: Variability in the manufacturing process can lead to inconsistent durability and performance, impacting the final product's competitiveness in the marketplace.

Given these challenges, the need for a more reliable, efficient, and high-performance production technique has never been greater. Manufacturers are especially interested in how foam injection can help overcome these hurdles and meet the stringent demands for modern padel equipment.

-

Material Inhomogeneity: Traditional production techniques sometimes fail to distribute the core material evenly. This results in weak spots in the structure of the racket, leading to potential durability issues.

-

High Labor Costs and Time Delays: Conventional methods often rely heavily on manual processes. The labor-intensive steps not only increase the risk of human error but also prolong production cycles, making it difficult for companies to scale efficiently.

-

Limited Innovation in Material Utilization: With increasing pressure to produce lighter, stronger, and more durable rackets, manufacturers need to adopt new methods that can effectively exploit advanced composite materials4 like carbon fibers (3k, 12k, and 18k). Traditional processes may not fully leverage the potential of these materials.

Foam injection is emerging as a game-changing technique by addressing these challenges head-on. Here’s a detailed breakdown of why foam injection is valuable and how it works:

Foam injection involves injecting a specialized foam material into the mold during the production process. The foam then expands and solidifies, filling the mold uniformly. This process ensures that:

- Voids and inconsistencies are minimized.

- The distribution of the core material is uniform.

- The final product meets high standards of performance and durability.

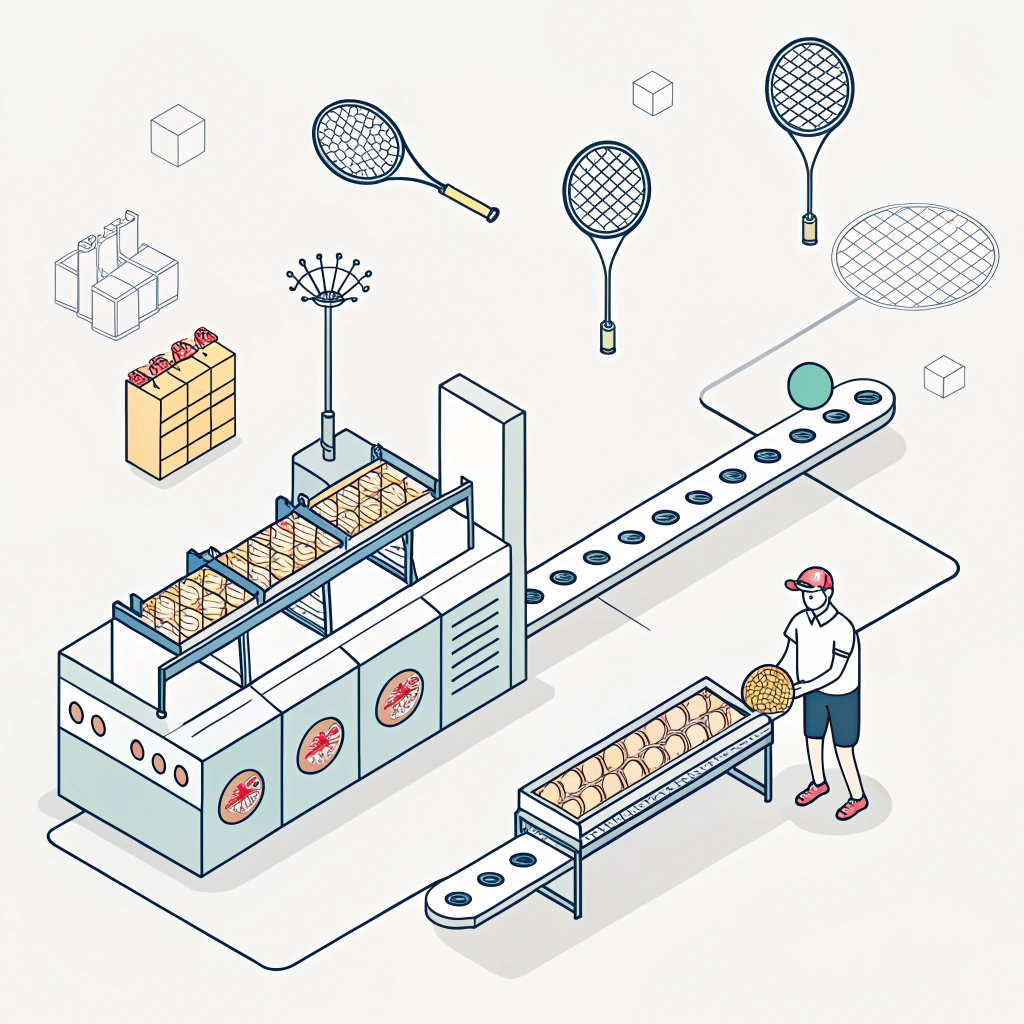

Developing a clear process flow for foam injection can be visualized as follows:

| Production Stage | Traditional Method | Foam Injection Method |

|---|---|---|

| Material Preparation | Manual cutting and distribution | Automated, precise foam mixing |

| Injection | Manual placement and curing | Automated foam injection ensures uniform filling |

| Curing Process | Prolonged, less controlled curing | Controlled heating and curing cycles |

| Quality Control | Visual and manual inspection | Enhanced digital quality control systems5 |

| Production Time | Longer cycle due to manual steps | Faster turnaround with automation |

This table highlights the key differences between traditional and foam injection methods in padel racket manufacturing.

Implementing foam injection comes with several technical and economic benefits, making it an attractive option for leading manufacturers:

-

Improved Material Consistency:

- Foam injection ensures a uniform distribution of materials like foam and composite reinforcements, reducing the risk of weak spots that could compromise racket performance.

- Enhanced accuracy during the production process means each racket meets precise quality standards.

-

Increased Production Efficiency:

- Automation in the foam injection process significantly cuts down production time.

- Reduced dependency on manual labor minimizes human error and delays, allowing for rapid scaling of production to meet increasing demand.

-

Enhanced Durability and Performance:

- The process results in a padel racket structure that is more robust and less prone to issues like chipping or cracking.

- Consistent application of foam ensures that the racket withstands high impact forces during play, enhancing both longevity and performance.

-

Cost-Effectiveness:

- Though the setup for foam injection may require initial investment, the long-term savings from reduced labor costs, lower scrap rates, and fewer quality control issues are significant.

- Manufacturers report lower overall production costs and improved return on investment when switching to foam injection techniques.

-

Quality Control Improvements:

- Automated foam injection processes integrate seamlessly with digital quality control systems5, thus ensuring each product is subjected to rigorous inspections.

- Real-time monitoring allows for immediate adjustments, further boosting the consistency and quality of each unit produced.

While foam injection offers clear benefits, it is also important to acknowledge some practical considerations:

- Initial Investment: Upgrading equipment and training personnel for foam injection processes can require significant upfront costs. However, the long-term benefits often outweigh these initial expenses.

- Process Calibration: Manufacturers must invest time in fine-tuning the foam injection process parameters to tailor them specifically to padel racket production. Factors like foam viscosity, pressure, and curing times require detailed experimentation.

- Material Compatibility: Ensuring that the foam material is compatible with advanced composite materials (such as 3k, 12k, and 18k carbon fiber) is crucial. Extensive testing is needed to guarantee that the foam does not adversely affect the performance of these premium materials.

- Customization Capabilities: For companies like NEX Padel that offer full customization—including racket shape, color, and even custom prints or logos on hand grips and covers—the foam injection process must be versatile enough to accommodate these variations without compromising production efficiency.

Consider NEX Padel, a leading manufacturer known for advanced production techniques and partnerships with top brands such as Hirostar, Reebok, and Starvie. By integrating foam injection into its manufacturing process, NEX Padel was able to achieve:

- A 30% reduction in production cycle time compared to traditional methods.

- Notable improvements in product consistency and structural integrity.

- A significant drop in material wastage, leading to improved cost savings.

The success of these initiatives demonstrates how foam injection not only supports efficient production but also aligns with the high-performance demands of modern padel rackets.

For organizations considering the adoption of foam injection in padel racket manufacturing, the following roadmap and best practices provide a clear pathway to successful implementation:

-

Assessment Phase:

- Conduct a detailed cost-benefit analysis comparing traditional methods with foam injection.

- Evaluate current production capabilities and identify areas where foam injection can offer the most significant improvements.

-

Pilot Project:

- Implement a pilot phase to test foam injection on a limited production line.

- Monitor key performance indicators (KPIs) such as production time, material usage, and product durability.

-

Technical Calibration:

- Fine-tune process parameters such as foam viscosity, injection pressure, and curing times.

- Collaborate with material scientists to ensure the foam’s compatibility with various composite materials.

-

Scale-Up Phase:

- Gradually scale up the production process based on pilot project outcomes.

- Invest in automation equipment and integrate digital quality control systems to maintain consistency.

-

Continuous Improvement:

- Establish periodic reviews to identify further optimization opportunities.

- Encourage feedback from R&D teams and technical staff to refine the process continually.

-

Training and Development:

- Provide extensive training for operators and supervisors on the foam injection process.

- Develop detailed documentation and standard operating procedures (SOPs) to ensure consistent execution across shifts.

Foam injection in padel racket manufacturing represents a strategic advancement that addresses key production challenges while offering improved durability, efficiency, and cost-effectiveness. By investing in this advanced method, manufacturers can achieve consistency in product quality, reduce production time, and ultimately deliver high-performance sporting equipment that meets the rigorous standards of today’s competitive market.

Companies such as NEX Padel have demonstrated the effective application of foam injection, showcasing reduced production cycles and enhanced overall performance of rackets. For R&D managers, technical procurement specialists, and engineering leads, evaluating foam injection as a means to streamline production and boost product quality is a step toward future-proofing your manufacturing operation.

As you consider implementing foam injection technologies, we highly recommend:

- Starting with a small scale pilot project to gauge benefits.

- Collaborating with experts in material science to optimize process parameters.

- Leveraging automation and quality control systems to ensure consistent production outcomes.

Taking these steps will not only enhance your production efficiency but also position your company as a leader in innovation within the sports equipment manufacturing sector.

People Also Ask

Q: Who makes foam core pickleball paddles?

A: Brands like Selkirk and CRBN are known for their foam core pickleball paddles. Their use of foam core technology has paved the way for innovative designs and improved playability, positioning them as trendsetters in paddle sports.

Q: What is the best core for pickleball paddles?

A: Among the various core options, polymer has emerged as a superior choice in pickleball paddle manufacturing. Its consistent performance and durability make it ideal for high-end paddles, though some unique designs may also blend other materials effectively.

Q: Are thermoformed paddles less durable?

A: Thermoformed paddles are generally more durable than their cold-pressed counterparts. The controlled heating and molding processes used in thermoforming reinforce the paddle’s structure, reducing risks of chipping, cracking, or surface delamination while ensuring long-term performance.

-

foam injection: Read more about this innovative method to understand how injecting foam can enhance the uniformity and durability of sporting equipment by reducing production time and improving quality control. ↩

-

padel racket manufacturing: Learn how the specialized manufacturing process for padel rackets integrates advanced techniques to meet high-performance standards in competitive sports markets. ↩ ↩2

-

Material inconsistency: Understand how variability in material distribution can impact product performance and how advanced manufacturing techniques help achieve uniformity and quality. ↩

-

advanced composite materials: Explore articles explaining the role and benefits of advanced composite materials, such as carbon fibers, in enhancing product strength while reducing weight in high-performance equipment. ↩

-

digital quality control systems: Discover the benefits of integrating digital quality control systems in manufacturing processes to ensure consistent, accurate, and scalable production outcomes. ↩ ↩2