Partnering with a professional padel racket manufacturer gives you consistent performance, faster time-to-market, and predictable costs—because a specialist supplier controls materials (from fiberglass1 to 3k/12k/18k carbon2), tooling, QC and logistics to turn your design into repeatable, certified product batches at scale.

Introduction — market context and why supplier choice matters

The global padel market is expanding rapidly across Europe and the Americas. For brands and private-label sellers, success now depends less on being first and more on delivering reliable product quality, consistent supply, and on-brand design. Choosing the right manufacturer is a strategic decision: it affects product performance, returns, regulatory compliance, and ultimately your brand reputation.

If you originate from e-commerce, a sporting goods brand, or are assessing OEM partners, focus on four outcomes when evaluating suppliers: repeatable quality, controllable unit cost, predictable lead times, and full support for customization and certification. A professional manufacturer reduces technical risk (wrong materials, inconsistent balance), commercial risk (unexpected MOQs3 or tooling costs), and supply risk (late shipments, poor packing).

Core benefits overview: quality, consistency, scale, and speed

A specialist padel racket factory delivers value across four core dimensions:

- Quality and performance consistency: Processes such as precision molding, controlled curing cycles, and standardized layup schedules mean each racket in a batch performs to the same spec (weight, balance, stiffness).

- Economies of scale: Larger facilities lower unit costs via bulk raw material purchasing and efficient labor allocation.

- Faster prototyping and sampling: Dedicated R&D and toolmaking shorten sample cycles from months to weeks.

- End-to-end service: From material certificates and testing to packing and export documentation—reducing your coordination overhead.

These core benefits translate into measurable business results: lower return rates, faster SKU launches, and better margin predictability.

Technical advantages: materials (fiberglass vs 3k/12k/18k carbon), shaping (Diamond/Round/Teardrop), core options, finishing

Understanding material and process differences is essential to selecting the right supplier.

Materials

- Fiberglass: Cost-effective and forgiving—good for entry-level rackets. It gives softer feel but lower stiffness and lower rebound compared to carbon.

- 3k carbon: Classic woven carbon fabric with good balance of stiffness and impact resistance—commonly used for mid-to-high performance faces.

- 12k and 18k carbon: Higher filament count, smoother surface finish and increased stiffness. 12k/18k are favored for premium models where improved stiffness and a refined look matter.

A capable OEM will offer all these materials and advise the right layup for your target player profile.

Shaping and balance

- Diamond: Head-heavy, power-oriented. Requires precise weight distribution and higher core density to avoid excessive vibration.

- Teardrop: Balanced power/control—most versatile for broad market appeal.

- Round: Control-oriented, larger sweet spot—easier for beginners.

Core and density options

- EVA foam4 densities (soft/medium/hard) alter feel and power. A pro manufacturer will keep multiple core mixes and can adjust core thickness or insert reinforcements for stiffness targets.

Finishing and surface

- Textured carbon, rubberized coatings, or anti-abrasion layers affect spin and durability. A professional factory will manage grit application, sanding, and varnish to keep surface appearance consistent across batches.

Commercial advantages: MOQ, pricing structure, tooling costs, cost per unit at scale

Commercial terms from a professional manufacturer are structured to support scalable launches.

- MOQ: Professional OEMs typically offer tiered MOQs—higher for custom mold tooling, lower for standard models. Expect to negotiate samples (1–10 units) and batch MOQs (hundreds to low thousands).

- Tooling: One-off mold costs can be a meaningful upfront. A trusted supplier will provide tooling quotes, expected mold life, and amortized cost per unit at different volumes.

- Pricing structure: Price per unit declines with volume due to material buying, production run efficiencies, and reduced quality rework.

- Transparent cost breakdown: Good suppliers will itemize raw materials, labor, tooling amortization, printing/decoration, packaging, and freight estimates.

Example cost components table (indicative):

| Cost Item | Notes |

|---|---|

| Raw materials | Fiberglass / 3k/12k/18k carbon, EVA core |

| Tooling (mold) | One-time cost, amortized over production runs |

| Labor & processing | Layup, pressing, curing, finishing |

| Printing & decals | UV printing, pad printing, matte/gloss lacquer |

| Packing | Individual bagging, carton, pallets |

| QA & testing | Sample testing, batch inspection |

| Logistics & duties | FOB/CIF, export docs, insurance |

Ask potential partners for a sample pricing table at 1k, 5k and 10k unit volumes to understand marginal cost improvements.

Customization & branding: printing, colorways, logos, grips, end caps, full-custom shapes

Full private-label capability separates professional OEMs from small workshops.

What a strong partner should offer:

- Colorways and full-surface printing with proofing cycles.

- Custom mold shapes beyond standard Diamond, Round, Teardrop—including bespoke geometries for differentiating play characteristics.

- Logo printing on head, face, and throat; custom matte/shine finishes.

- Branded grips and customizable end caps (logo embossing/foil).

- Packaging options: retail boxes, protective tubes, display-ready cartons.

- Optional full-custom runs where the supplier helps optimize layup and core to meet performance claims.

Turnaround: expect 2–4 sample iterations (prototype, pre-production sample, golden sample) before full production. Good factories will include limited revisions in their sample timelines.

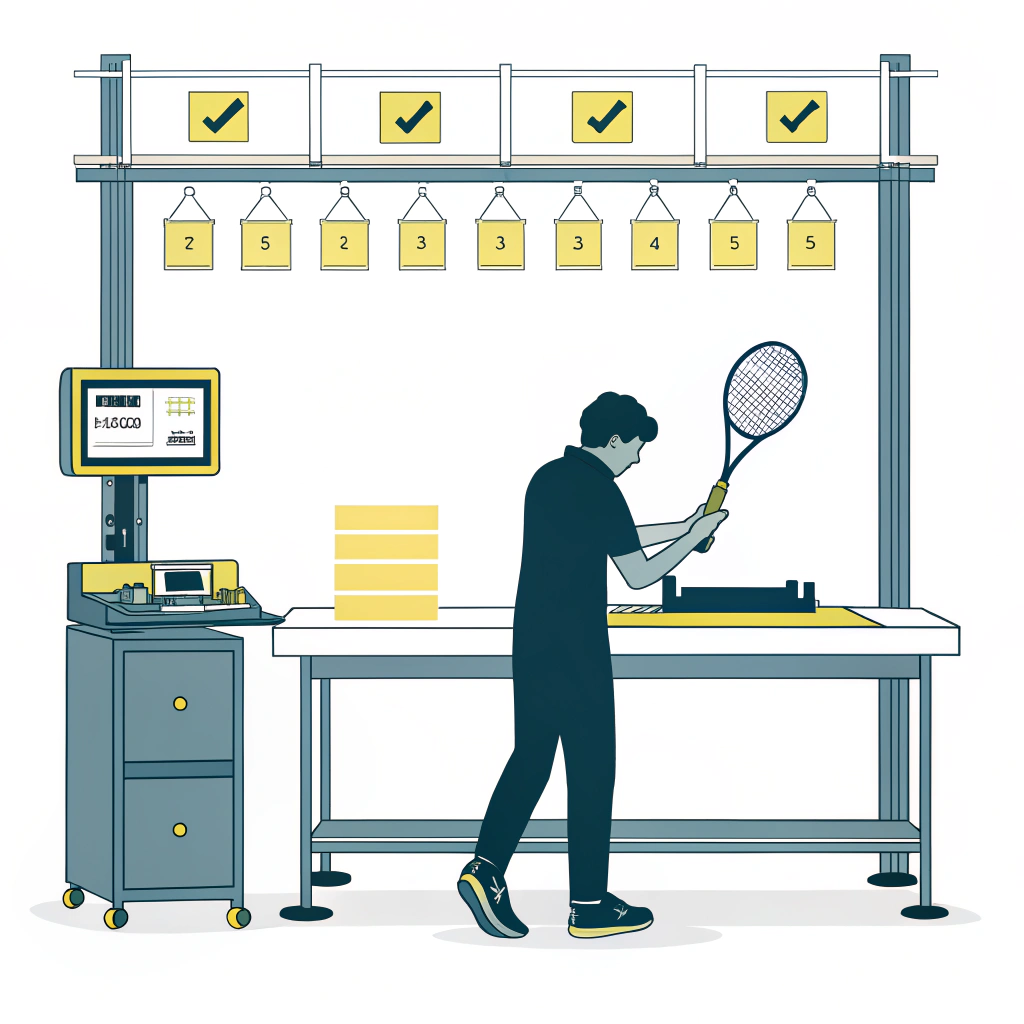

Quality assurance & compliance: QC processes, testing, certifications, sample iterations, batch traceability

Quality systems reduce returns and protect your brand.

Typical QA measures:

- Incoming material inspection (certificates for carbon fiber content, fabric weight, resin batch).

- In-line checks (weight, balance, visual defects) and statistical sampling.

- Mechanical tests: impact resistance, surface adhesion, peel tests, and vibration analysis.

- Certification: CE marking for EU market, compliance documents as required by importers.

- Batch traceability: batch codes on cartons, production logs tying units to resin/mold lot numbers.

- Pre-shipment inspection (AQL5) and independent 3rd-party testing if requested.

A mature factory will provide test reports and welcome third-party audits. They’ll track non-conformance and corrective actions, and retain sample records for golden samples.

Logistics & supply reliability: lead times, packing (pressurized tubes for balls), container scheduling, contingency planning

Predictable logistics separate reliable partners from risky ones.

- Sample lead time: 7–21 days typical for non-tooling samples; 3–8 weeks for molded prototypes depending on complexity.

- Production lead time: initial production runs commonly 30–60 days; seasonal peaks (Jan–Mar, pre-summer) can extend lead times.

- Packing: Padel balls should be shipped in pressurized tubes (we work with tubes and 45%/57% wool mixes) to protect performance; rackets require protective wrapping, cartons, and palletization to prevent edge damage.

- Container planning: professional factories manage full container loads (FCL) and less-than-container (LCL) options and provide ETAs. They also offer air freight for urgent small shipments.

- Contingency: inquire about backup production capacity, alternate shifts, and buffer stock policies.

Clear communication and agreed production schedules with penalties or earnest money help align expectations.

How to evaluate a manufacturer: checklist (factory visits, samples, references, material certificates, lead times, IP protection)

Use this practical checklist during selection:

| Evaluation Item | What to ask / inspect |

|---|---|

| Factory capability | Number of presses, autoclaves, ovens, mold workshops |

| Materials portfolio | Availability of 3k/12k/18k carbon, fiberglass, EVA core types |

| Sample process | Lead time, revisions allowed, cost per iteration |

| MOQ & pricing tiers | Unit price at 1k/5k/10k and tooling amortization |

| QC & testing | In-house labs, test reports, AQL levels |

| Certifications | ISO, CE compliance, any sport-specific test reports |

| References | Clients, especially known brands (ask for contactable refs) |

| IP & NDA | Written NDA, mold ownership terms, tooling custody |

| Logistics track record | Shipping timelines, export docs, customs support |

| After-sales support | Warranty policy, spare parts, repair guidance |

Factory visit tips: observe cleanliness, workflow logic, mold storage, and ask to see sample batches and QC logs. Request materials certificates and photos/videos if an in-person visit isn’t possible.

Case study / social proof: NEX Padel capabilities and partner outcomes

NEX Padel, based in Jiaxing, Zhejiang, China, specializes in high-performance padel racket OEM. We provide rapid prototyping, flexible layups (from fiberglass to 18k carbon), and support for Diamond, Round, and Teardrop shapes. Our private-label clients include recognized brands like Hirostar, Reebok and Starvie, reflecting our ability to meet strict brand specs and compliance needs.

What partners report:

- Faster sample iterations: typical sample cycles reduced to 10–21 days.

- Lower rework: standardized QC reduced returns by measurable percentages in co-developed SKUs.

- On-brand customization: full-color printing and grip/end-cap customization enabled higher retail conversion for private-label launches.

If you prioritize quick R&D cycles, predictable costs, and consistent product performance, a partner like NEX Padel is positioned to deliver.

Call to action: next steps for B2B readers (request sample, ask for MOQ/pricing, R&D collaboration)

Next steps to move from evaluation to decision:

- Request a product specification sheet for demo models in Diamond, Round, and Teardrop.

- Ask for a sample quote including tooling, unit price at 1k/5k/10k, and sample lead times.

- Submit your logo and basic colorway brief for a quick mockup and lead-time estimate.

- Schedule a short technical call to review materials (3k/12k/18k carbon vs fiberglass) and performance targets (weight, balance, core hardness).

- Request references from existing brand clients and any available test reports.

If you want, contact NEX Padel to request a sample pack and a complete commercial proposal including tooling amortization and lead-time commitments.

People Also Ask

Do expensive padel rackets make a difference?

Expensive padel rackets often use higher-grade materials and more precise manufacturing, which can improve durability, stiffness, and balance. However, price alone does not guarantee better gameplay for every player—improvement depends on player level and fit between racket characteristics (weight, balance, core) and the player’s style. For many players, upgrading from an entry-level fiberglass racket to a mid-range carbon model yields the most noticeable difference.

What are the best padel rackets made of?

Top-performing rackets commonly use carbon fiber for the face and frame because it balances lightness, strength, and stiffness. Different weaves (3k, 12k, 18k) offer trade-offs between surface finish, stiffness, and cost. Manufacturers typically pair carbon faces with EVA cores at varying densities for targeted feel and power. Fiberglass remains a valid choice for beginner-level models due to cost and a softer touch.

-

fiberglass: Read the linked article to understand fiberglass material properties, manufacturing implications, and the trade-offs between cost, feel, and durability for entry-level vs. performance rackets. ↩︎ ↩

-

3k/12k/18k carbon: Reading this resource explains weave counts and filament differences, how they affect surface finish, stiffness, impact resistance, and cost—helpful for choosing the right carbon layup for mid vs. premium models. ↩︎ ↩

-

MOQs: Learn how minimum order quantities are structured (tiered MOQs, samples vs. batch sizes), negotiation levers, and the impact on unit cost, inventory, and launch planning. ↩︎ ↩

-

EVA foam: This link clarifies EVA core formulations and density options, showing how core choice affects feel, power, durability, and manufacturing adjustments suppliers can make to meet performance targets. ↩︎ ↩

-

AQL: Review Acceptable Quality Limit (AQL) sampling plans and defect thresholds to understand how inspection standards affect batch acceptance, return risk, and warranty exposure. ↩︎ ↩