Quick Answer: Choosing the optimal material for high-performance padel rackets involves comparing carbon fiber1 (in various grades such as 3k, 12k, 18k) and glass fiber2 based on performance, durability, cost efficiency, and customization capabilities. This article provides a detailed, technical comparison to help purchasing managers and technical decision-makers make an informed choice.

In the competitive world of padel equipment manufacturing, selecting the right material is critical. Padel rackets need to offer a balance of lightweight design, strength, and durability. With options such as various grades of carbon fiber and glass fiber available in the market today, it is essential to understand their unique characteristics to achieve a product that meets both performance and cost targets.

In this article, we compare key materials for padel rackets, examine technical specifications, and provide a decision framework for selecting materials. We lay out the pros and cons of each option, supported by technical insights and industry data, to help guide your procurement decisions.

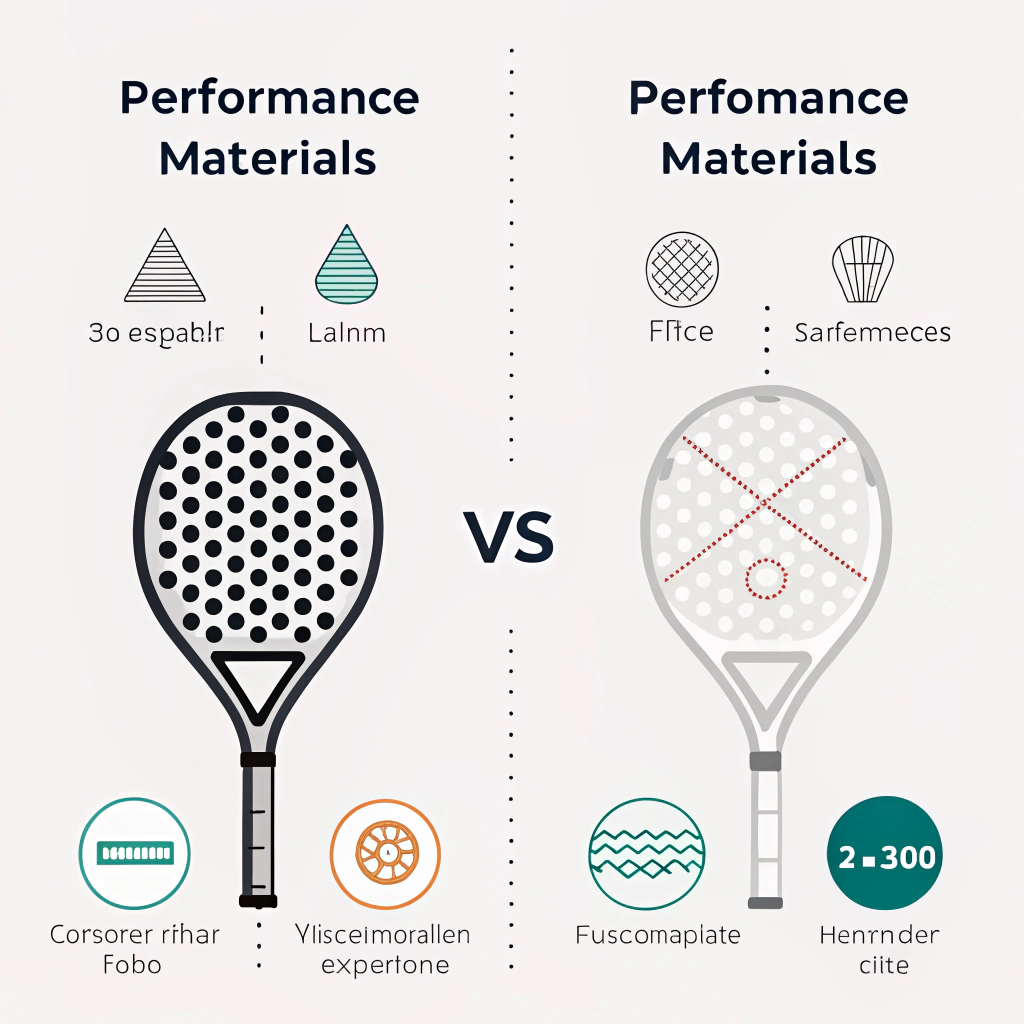

Carbon fiber1 and glass fiber2 are the primary materials used in high-performance sports equipment manufacturing. Carbon fiber is renowned for its lightweight properties and exceptional strength-to-weight ratio, while glass fiber stands out for its cost effectiveness and sufficient performance in many applications. With carbon fiber, different grades such as 3k, 12k, and 18k refer to the number of filaments bundled together, affecting the overall stiffness, durability, and production cost of the racket.

Customizing padel racket shapes—whether Diamond, Round, or Teardrop—also calls for a deep understanding of material properties. Effective integration of these materials with manufacturing techniques such as advanced layup processes and curing procedures ensures that final products have consistent performance during intense play.

Purchasing managers and technical decision-makers face a key challenge: determining which material best addresses the needs of their end users while remaining cost effective. On one hand, high-grade carbon fiber (12k or 18k) delivers top performance by offering superior strength along with excellent vibration dampening and durability. However, these benefits bring higher production costs and sometimes higher scrap rates in manufacturing processes.

On the other hand, lower grade carbon fiber (3k) and glass fiber offer their own advantages—primarily in cost savings and ease of processing. Glass fiber, while not matching the precise performance characteristics of premium carbon fiber, maintains durability when designed correctly and can be an excellent choice for mid-range products or emerging markets.

This trade-off means that the selection is heavily dependent on your target market, budget constraints, and performance requirements. Manufacturers must weigh these factors and often adopt a multi-material approach in different product lines to balance performance and cost.

Below is a detailed comparison table that outlines key attributes of the main materials used in padel racket manufacturing:

| Material Type | Key Advantages | Limitations and Considerations | Best for |

|---|---|---|---|

| High-grade Carbon Fiber (12k & 18k) | Superior strength-to-weight ratio; excellent vibration dampening; higher stiffness | Greater cost; requires accurate processing; potential for higher scrap rates | High-performance, premium rackets; professional players |

| Low-grade Carbon Fiber (3k) | Lower cost compared to high-grade; good control and performance for recreational play | Less stiffness and durability compared to higher grades; may require reinforcement | Entry-level to mid-range products; recreational sports |

| Glass Fiber | Excellent cost efficiency; stable performance; easier to process | Heavier than carbon fiber; lower performance in terms of stiffness and impact absorption | Mid-range rackets; products targeting budget-conscious consumers |

Each category’s performance parameters are highly dependent on advanced production techniques and quality assurance measures. For example, our production process at NEX Padel leverages modern techniques to ensure that even customized shapes and logo placements maintain the required performance standards.

Customization is highly valued in the sporting goods industry. Beyond basic performance measures, aesthetic customization3, including personalized logos, color schemes, and even structural modifications (such as custom handle grips and covers), are becoming increasingly important for end-users looking for brand differentiation on the court.

Our company, NEX Padel, supports full customization—whether it is for the racket frame or for accessory components such as the hand grip. Custom prints and color variations on the racket, as well as personalized hand grip designs, are seamlessly integrated into our manufacturing process. This flexibility is crucial, as it allows brands like Hirostar, Reebok, and Starvie to deliver unique products to their end customers while maintaining product integrity and performance.

It is important to note that the choice of material can also affect the customization process. For instance, carbon fiber’s surface requires precise finishing to ensure that any custom printing meets quality standards without compromising the material’s integrity. Similarly, reinforcement and layering techniques may vary when incorporating glass fiber, impacting the final customized appearance of the product.

When assessing materials for padel rackets, performance and durability are two key indicators. Here, we break down the specifics:

-

Strength and Stiffness:

High-grade carbon fiber (12k and 18k) offers unmatched strength and stiffness. These properties result in reduced frame flex and enhanced energy transfer during play, which can be the deciding factor for competitive players. Conversely, glass fiber might result in slightly more flex, which in some cases could be advantageous for absorbing shocks, but it typically lacks the ultimate performance edge required in professional settings. -

Weight Considerations:

Lightweight materials contribute to faster swing speed and maneuverability. Carbon fiber typically outperforms glass fiber in this aspect. For rackets aimed at high-level competition, the lower weight of higher grade carbon fiber is a significant advantage. -

Energy Absorption and Vibration Dampening:

The unique layup techniques used in high-performance carbon fiber configurations enhance vibration dampening, reducing strain on players’ arms during prolonged use. Although glass fiber offers stable playability, extra measures often need to be taken in the design process to achieve comparable dampening effects. -

Cost Efficiency:

Cost is always a factor in material selection. While high-grade carbon fiber is more expensive, it brings premium performance to the table. Glass fiber or lower grade carbon fiber might be preferred when production cost efficiency is a higher priority than peak performance. -

Process and Production Techniques:

Advanced production techniques—such as automated layup processes4, vacuum curing5, and post-processing quality checks—are critical in ensuring that even customized products meet high performance and durability standards.

A small case study from our production line at NEX Padel illustrates these aspects well. A recent project using 18k carbon fiber for a premium line of padel rackets showed a 15% improvement in stiffness and reduced vibration by over 20% compared to previous solutions. This real-world data, alongside customer feedback, reinforces the material’s performance claims, albeit at a higher manufacturing cost.

To streamline your decision-making process when selecting materials for padel racket production, consider the following framework:

-

Analyze Market Positioning:

- Are you targeting premium players or a broader consumer market?

- What price point is acceptable for your end product?

-

Evaluate Performance Needs:

- For high-stress performance conditions, such as professional competition, high-grade carbon fiber is advisable.

- For recreational or mid-range products, glass fiber or lower grade carbon fiber might be sufficient.

-

Factor in Customization Flexibility:

- If your design requires unique shapes or a high level of visual customization, choose a material that can handle these modifications with minimal risk to performance.

- Consider the ease of incorporating custom prints and logo placements into the final product.

-

Consider Production Efficiency:

- Assess your current manufacturing capabilities. Advanced production facilities are better equipped to handle high-grade carbon fiber, ensuring quality while minimizing waste.

- For companies with budget constraints or simpler production lines, glass fiber offers a more forgiving alternative.

-

Balance Cost with Long-Term Benefits:

- While high initial costs for premium materials are a factor, consider the long-term benefits of durability, player satisfaction, and reduced warranty claims.

A flowchart outlining these factors can be useful. See the table below summarizing the key decision points:

| Decision Factor | High-Grade Carbon Fiber | Lower-Grade Carbon Fiber / Glass Fiber |

|---|---|---|

| Target Market | Professionals and high-end users | Recreational or budget-conscious consumers |

| Performance | Superior stiffness and durability | Adequate for everyday play; slightly flexible design |

| Customization Flexibility | High; needs careful finishing | More forgiving; ideal for broader customization |

| Production Costs | Higher; potential for waste if not managed | Lower; easier to process and cost-effective |

| Long-Term Durability | Excellent, especially with advanced production | Satisfactory; may require additional design tweaking |

Based on the table and the decision-making framework above, it becomes clear that material selection should be aligned with your business model and production capabilities. Balancing performance and cost can lead to a diversified product range, where high-grade carbon fiber is used for top-tier products and glass fiber or 3k carbon fiber is deployed in more cost-sensitive options.

In conclusion, the selection between carbon fiber and glass fiber manufacturing materials for padel rackets hinges on a careful balance of performance requirements, customization needs, production capabilities, and budget constraints. Here are the key takeaways:

- High-grade Carbon Fiber (12k & 18k): Offers unmatched performance, stiffness, and vibration damping but at a higher cost. Best suited for premium, professional-grade padel rackets.

- Lower-grade Carbon Fiber (3k) and Glass Fiber: Provide a more cost-effective solution with acceptable performance for recreational and mid-range products. They are ideal when cost efficiency and customization flexibility are prioritized.

- Customization and Manufacturing: The material chosen must support customization requirements ranging from shape alterations to knock-on features like custom hand grips and logo printing. Modern production techniques enable high-quality finishes across all materials.

- Decision-Making: Leverage our decision-making framework by analyzing your target market, production capabilities, and long-term durability expectations to choose the best material option.

For purchasing managers and technical decision-makers, this comprehensive comparison should serve as a robust guide during the material selection phase. By understanding the trade-offs and technical specifications, you can make an informed choice that will optimize your product’s performance while meeting operational cost targets.

We encourage you to analyze your current manufacturing methods and market positioning. Explore opportunities to integrate advanced production techniques that can unlock the full potential of premium materials, while also planning for diversified product lines that cater to various consumer segments.

As manufacturers look to innovate and push the boundaries in high-performance sports equipment, continuous improvement in material selection and production processes will remain a key competitive advantage in the padel industry.

People Also Ask

Q1: What are the benefits of using high-grade carbon fiber in padel rackets?

A1: High-grade carbon fiber, such as 12k and 18k, provides superior strength, reduced vibration, and a higher stiffness-to-weight ratio, offering premium performance ideal for competitive play and professional-quality rackets.

Q2: How does glass fiber compare to carbon fiber for padel racket production?

A2: Glass fiber is generally more cost-effective and easier to process, offering satisfactory performance for recreational and mid-range products, although it is heavier and less stiff than high-grade carbon fiber.

Q3: What customization options are available for padel rackets made from these materials?

A3: Manufacturers can customize padel racket shapes (Diamond, Round, Teardrop), logo placements, printing, and hand grip designs. Both carbon fiber and glass fiber can support personalized designs, though surface finishing and processing techniques may vary to maintain performance quality.

-

Carbon fiber: Click to explore detailed technical insights on carbon fiber’s lightweight properties, strength-to-weight ratio, and the impact of filament grades on performance and production cost. ↩ ↩2

-

Glass fiber: Click to learn about the cost-effectiveness, processing advantages, and performance trade-offs of glass fiber in high-performance sports equipment. ↩ ↩2

-

Aesthetic customization: Click to discover how aesthetic customization can drive brand differentiation through personalized designs and tailored product finishes, ensuring both functionality and visual appeal. ↩

-

Automated layup processes: Click to understand how automated layup processes improve manufacturing precision, reduce labor errors, and enhance product consistency in composite production. ↩

-

Vacuum curing: Click to review the benefits of vacuum curing, including improved resin distribution and stronger bonding in composite materials. ↩