Quick Answer: When selecting padel racket materials, understanding the differences between fiberglass1 and various carbon fiber2 weaves (3k, 12k, 18k) is key. Fiberglass offers cost efficiency and consistent performance, while carbon fiber variants deliver increased durability and performance precision—each with unique production and customization considerations essential for OEM manufacturing3.

The padel racket market demands constant innovation in materials and production techniques to meet competitive performance benchmarks. For product procurement managers and technical buyers, selecting the right material is fundamental. Whether you opt for fiberglass or one of the carbon fiber weaves, the trade-offs in performance, durability, cost, and manufacturability will directly influence your brand’s product competitiveness. In this article, we provide a detailed comparative analysis of padel racket materials, discussing material properties, production techniques4, and customization5 options to help you make a confident procurement decision.

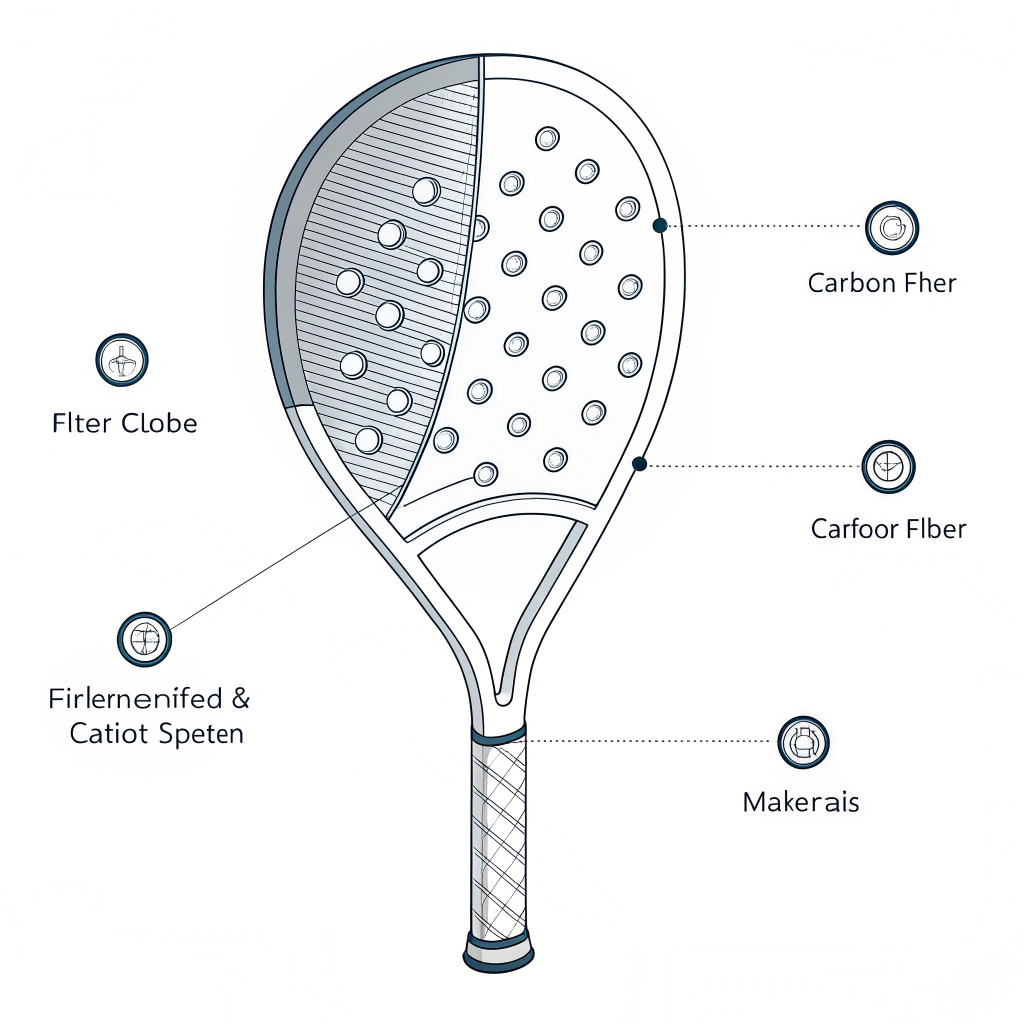

Choosing the optimal material depends on understanding its underlying properties and how these translate into on-court performance and long-term durability. Below, we outline the features of the two primary materials used in high-performance padel rackets.

Fiberglass is a well-established material in racket manufacturing due to its:

- Cost Efficiency: Lower raw material cost benefits large-scale OEM production.

- Flexibility: Offers a forgiving balance between rigidity and flex, adaptable to various play styles.

- Ease of Production: Well-known production techniques reduce the risk of material inconsistencies.

Pros:

- Economical for mass production.

- Consistent performance across batches.

- Lighter weight compared to some materials.

Cons:

- May not achieve the extreme stiffness available with higher-end carbon fibers.

- Slightly reduced durability when high impacts are a frequent occurrence.

Carbon Fiber introduces higher performance thresholds compared to fiberglass. The common weaves available are:

-

3k Carbon Fiber:

- Structure: Utilizes 3000 filaments per tow.

- Properties: Offers an excellent balance between stiffness and lightweight performance.

- Usage: Preferred for mid-range rackets that require a balance of durability and cost-effectiveness.

-

12k Carbon Fiber:

- Structure: Incorporates 12,000 filaments per tow.

- Properties: Enhances stiffness and impact resistance while maintaining a relatively low weight.

- Usage: Ideal for high-performance rackets with greater power and precision.

-

18k Carbon Fiber:

- Structure: Comprises 18,000 filaments per tow.

- Properties: Maximizes energy transfer and provides high durability for aggressive play.

- Usage: Best suited for professional-level equipment where performance is paramount.

Pros:

- Higher stiffness leading to superior power transmission.

- Improved durability under repeated high-impact conditions.

- Enhanced customization potential with structure-specific properties.

Cons:

- Higher material and production costs.

- Requires precision in layering and curing processes to avoid defects.

Below is a comparative table illustrating the key attributes of these materials:

| Material | Fiber Count | Stiffness | Durability | Weight | Cost Level | Ideal Application |

|---|---|---|---|---|---|---|

| Fiberglass | N/A | Moderate | Moderate | Light | Low | Entry to mid-level rackets |

| 3k Carbon Fiber | 3000 | High | High | Very Light | Moderate | Mid-range to high-performance |

| 12k Carbon Fiber | 12000 | Very High | Very High | Light | High | Professional & advanced play |

| 18k Carbon Fiber | 18000 | Maximum | Maximum | Light | Premium | Top-tier, high-impact game |

As a leading manufacturer, NEX Padel leverages state-of-the-art production techniques to ensure that every padel racket meets rigorous performance standards. For OEM buyers, it is critical to understand the production nuances that influence a material’s behavior during use.

Our production process involves:

- Layering Precision: For carbon fibers, achieving the optimal balance between rigidity and flexibility requires precise layering.

- Curing Processes: Controlled curing is essential to lock in the material properties, especially for high filament count carbon fibers where curing anomalies can affect performance.

- Quality Control: Continuous monitoring during production minimizes defects, ensuring each batch meets stringent durability specifications.

We also support full customization including racket shape (Diamond, Round, Teardrop), grip customization, and even personalized printing. This flexibility is essential for OEM brands wanting to imprint their identity while ensuring product performance.

For OEM partners, the decision is layered with considerations:

- Material Productivity: Fiberglass provides rapid production cycles with cost benefits, while carbon fiber variants, particularly 12k and 18k, necessitate meticulous production schedules.

- Customization Options: The ability to customize the racket, including the handle (hand grip and cover logos), is a unique selling point. Our capability in rapid sampling and timely deliveries supports agile market responses.

- Cost-Performance Tradeoff: The cost implications versus performance benefits of using higher-grade carbon fibers must be balanced against your market positioning strategy.

A summary table of OEM considerations is shown below:

| Consideration | Fiberglass | 3k Carbon Fiber | 12k Carbon Fiber | 18k Carbon Fiber |

|---|---|---|---|---|

| Production Speed | Faster (lower complexity) | Moderate | Slower (increased complexity) | Slow (highest precision required) |

| Customization Ease | High | High | Moderate | Moderate |

| Cost Efficiency | Excellent | Good | Moderate | Premium |

| Performance Demand | Suitable for casual to competitive play | Balanced performance | Optimal for advanced play | Only for elite performance |

When comparing the materials, it is essential to match your specific market requirements with the expected performance outcomes. Let’s break down the factors that matter most:

-

Fiberglass:

- Offers moderate performance suitable for recreational players.

- Its inherent flexibility allows for improved control in diverse swing types.

-

Carbon Fiber (3k, 12k, 18k):

- Increased stiffness contributes to greater energy transfer during ball impact.

- 3k presents an optimal profile for balanced performance.

- 12k and 18k excel in providing superior stiffness, which enhances power but demands precise production control to avoid brittleness.

Durability is a crucial consideration especially in sports equipment subjected to constant high-impact forces.

-

Fiberglass:

- Demonstrates good durability but may suffer from slight deformation under extreme impact.

-

Carbon Fiber Variants:

- Offer drastically improved impact resistance.

- The higher filament count (12k and 18k) results in a smoother energy dissipation, reducing the risk of micro-cracks over time.

Cost considerations are particularly pivotal in OEM manufacturing:

-

Fiberglass:

- Lower cost makes it ideal for larger production runs where budget efficiency is paramount.

- Simpler production processes result in faster turnaround times.

-

Carbon Fiber:

- Higher-grade variants are more expensive but justify the cost with enhanced performance.

- Production requires more advanced techniques, often resulting in longer sampling cycles and careful quality control, making them best suited for competitive markets demanding higher performance.

The material choice can be influenced by the target player demographic and market positioning:

-

Entry-Level to Recreational Products:

- Fiberglass provides sufficient performance without overextending production budgets.

-

Mid-Range High-Performance Products:

- 3k Carbon Fiber offers a balance between performance and cost.

-

Premium or Professional Series:

- 12k and 18k Carbon Fiber deliver top-tier performance that justifies their premium price tag through longevity and superior play qualities.

A summarized comparison is presented below:

| Factor | Fiberglass | 3k Carbon Fiber | 12k Carbon Fiber | 18k Carbon Fiber |

|---|---|---|---|---|

| Stiffness | Moderate | High | Very High | Maximum |

| Impact Resistance | Fair to Good | Good | Excellent | Superior |

| Production Complexity | Low | Moderate | High | Highest |

| Cost Efficiency | High | Moderate | Lower | Lowest |

| Best Suited For | Recreational products | Balanced performance products | Advanced performance products | Elite professional products |

Customization is not only about aesthetics but also performance tuning. As OEM partners, you may consider:

- Custom Shapes: Options such as Diamond, Round, and Teardrop shapes offer variable center of gravity adjustments.

- Graphic Customization: Incorporating bespoke colors, logos, and prints to enhance brand identity.

- Integrated Components: Besides racket frames, customization extends to hand grips and handle covers, ensuring a cohesive product design that enhances user comfort.

The trend in high-performance padel equipment leans heavily towards using advanced materials for longevity and competitive performance metrics. With increasing demand for precision-engineered rackets:

- Innovations in carbon fiber technology are set to redefine how racket stiffness and impact handling are optimized.

- Automated production techniques are increasingly being adopted to maintain quality consistency, critical for premium materials like 18k carbon fiber.

- OEM collaborations are moving towards integrated solutions where production techniques, material science, and customization converge to meet bespoke market demands.

At NEX Padel, our extensive experience in both design and OEM partnerships provides us with unique insights into these trends. Our commitment to rapid prototyping and reliable delivery has consistently supported our clients, including industry leaders such as Hirostar, Reebok, and Starvie.

When deciding on the optimal material for your next padel racket project, consider the following steps:

-

Define Your Market Segment:

Identify if you are targeting recreational players, mid-range competitors, or elite professionals. This will guide your material choice toward cost-effective solutions like fiberglass or premium options such as 12k/18k carbon fiber. -

Align Material Properties with Performance Needs:

Analyze the stiffness, durability, and impact resistance requirements. For adjusted performance, consider the balancing act between carbon fiber variants:- Choose 3k for a balance between cost and enhanced performance.

- Opt for 12k or 18k if ultimate durability and performance are non-negotiable.

-

Evaluate Customization Capabilities:

Ensure the manufacturing process supports custom shapes, graphics, and handle designs. Customization will not only strengthen your brand identity but also cater to specific user performance requirements. -

Consider OEM Production Efficiency:

Factor in production cycle times, quality control measures, and scalability. Our advanced production techniques ensure that regardless of whether you choose fiberglass or carbon fiber, the final product maintains high quality and consistency. -

Leverage Data and Testing:

Conduct and review comparative testing data. Use tables and performance metrics to decide which material yields the best performance for your specific needs. Collaboration with manufacturers like NEX Padel enables access to rigorous testing protocols and quality assurance data. -

Plan for Future Trends:

Stay abreast of technological advancements in material science and production methods. Future trends indicate a continuous push towards lighter, stronger, and more cost-effective solutions, ensuring your product portfolio remains competitive.

Selecting the right padel racket material is a multifaceted decision that integrates performance objectives, cost considerations, and production capabilities. By comparing fiberglass and carbon fiber variants (3k, 12k, 18k), OEM buyers can align their product strategy with specific market demands. With our detailed comparative analysis and actionable recommendations, you are now equipped to make informed procurement decisions, ensuring high-performance and durable padel rackets that resonate with your competitive market audience.

Embracing advanced production techniques and customization capabilities further elevates the potential of your product offerings. At NEX Padel, we are committed to delivering premium quality and innovative solutions tailored to your OEM needs.

Q: What is the performance difference between fiberglass and carbon fiber in padel rackets?

A: Fiberglass provides consistent, cost-effective performance with moderate stiffness and durability, making it suitable for recreational or entry-level play. In contrast, carbon fiber—especially in 3k, 12k, and 18k weaves—delivers higher stiffness, enhanced power transmission, and superior impact resistance, which are critical for advanced and professional-level play.

Q: How do different weaves like 3k, 12k, and 18k carbon fiber influence durability?

A: The filament count in carbon fiber directly correlates with durability and stiffness. A 3k weave offers balanced performance suitable for mid-range rackets; a 12k weave enhances durability and stiffness for advanced play, while an 18k weave maximizes both, making it ideal for elite-level, high-impact scenarios where maximum energy transfer and long-term durability are essential.

Q: What should OEM partners consider when selecting racket materials?

A: OEM partners should consider factors such as production speed, cost efficiency, customization capabilities, performance requirements, and long-term durability. By balancing these considerations with market positioning—whether choosing fiberglass for cost-sensitive applications or high-grade carbon fiber for premium performance—partners can optimize their procurement decisions and product offerings.

-

Fiberglass: Reading this article will provide insights into fiberglass’s cost efficiency, flexibility, and its role in ensuring consistent performance for scalable production. ↩

-

Carbon Fiber: Explore detailed explanations of various carbon fiber weaves (3k, 12k, 18k) to understand differences in stiffness, durability, and performance precision. ↩

-

OEM Manufacturing: Learn about the key considerations in OEM manufacturing, including production scalability, quality control, and customization strategies. ↩

-

Production Techniques: Discover advanced production techniques that are used to achieve precision, consistency, and high-performance standards in sports equipment manufacturing. ↩

-

Customization: Delve into how customization options can enhance product design and performance, allowing brands to tailor equipment to specific market demands. ↩