The evolution of padel production through advanced manufacturing techniques1 has transformed the game equipment industry by integrating innovative materials and precision processes into every step of the production cycle. In this article, we explore the challenges and solutions that have emerged as manufacturers strive to meet the ever-growing demand for durable, high-performance, and customizable padel rackets.

Manufacturers in the padel industry have faced intense pressure to improve both product quality and production efficiency. As the sport has grown in popularity, procurement managers and product development leads have sought equipment that not only offers excellent performance but also stands up to the rigorous demands of competitive play. Traditional manufacturing methods that relied on basic materials like fiberglass do not adequately meet these expectations. The industry now demands innovations in material technology, precision manufacturing processes, and the ability to quickly adapt to market trends.

The main challenges include:

- Material Limitations: Historically, padel rackets were constructed using fiberglass or low-grade composites. With evolving play styles, these materials often fall short in providing necessary strength and weight balance.

- Customization Requirements: Demand for custom padel rackets, including tailored shapes like Diamond, Round, and Teardrop, as well as personalized prints and color options, necessitates flexible production processes.

- Quality Control: With higher performance expectations comes a stricter quality assurance regimen. Minimizing inconsistencies in lightweight yet resilient components, such as various grades of carbon fiber2 (3k, 12k, 18k), becomes crucial.

- Speed-to-Market: Rapid prototyping and quick turnaround times have become competitive differentiators in the B2B space.

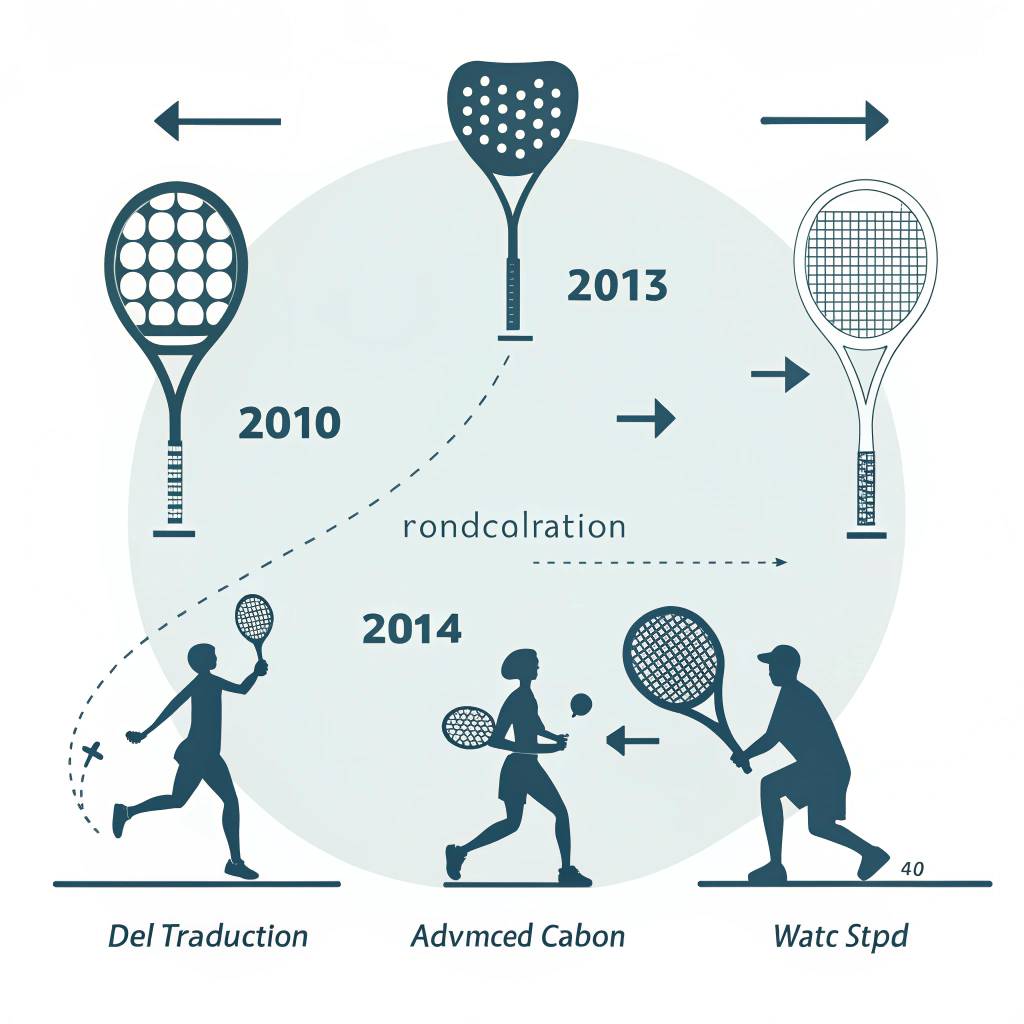

Understanding the evolution in padel production begins with a clear look at the drivers behind change:

-

Advances in Material Science:

The transition from fiberglass to modern carbon fiber2 (3k, 12k, 18k) has significantly boosted the durability and performance of rackets. Each type of carbon fiber offers a unique balance of strength, flexibility, and weight—a critical consideration for competitive players. -

Precision Manufacturing:

The incorporation of high-precision production techniques has allowed for the creation of more complex designs and shapes. This results in improved force distribution and enhanced player control on the court. Advanced methods, such as computer-aided manufacturing and consistent quality checks, minimize the typical variations associated with manual processes. -

Customization and Differentiation:

Today’s customers expect a high degree of personalization. Beyond basic design elements, modern manufacturing processes allow for custom padel rackets with company logos, unique imprinting on the hand grip or handle covers, and even fully custom shapes. This flexibility helps procurement managers serve niche markets more effectively. -

Global Competitiveness:

With the rising level of global competition in padel sports, meeting rapid delivery timelines without compromising quality is imperative. Manufacturers must streamline their production lines to support both high-volume orders and specialized customizations.

Adopting the following solutions can help companies overcome traditional manufacturing challenges and meet modern market demands:

Advanced materials such as carbon fiber2 in its various forms (3k, 12k, 18k) offer superior strength-to-weight ratios compared to fiberglass. These improvements translate into rackets that provide better performance while maintaining durability.

Integrating automation and precision tools in production ensures that each padel racket meets stringent quality standards. This includes:

- Computer-Aided Design (CAD)3: Facilitate the visualization and modification of custom designs.

- Automated Molding and Curing: Guarantee uniform curing times and temperatures for consistency.

- Digital quality control4: Utilize sensors and real-time feedback systems to catch defects early in the production process.

3. Develop flexible manufacturing lines5

Flexible manufacturing lines5 facilitate quick transition between different padel racket types (Diamond, Round, Teardrop) and support customization requirements. This approach not only increases efficiency but also provides manufacturers with the agility to respond to market shifts.

Enhanced quality control measures, such as multi-stage inspections and rigorous testing, ensure that each product meets the high-performance standards expected by competitive players. Investing in these protocols minimizes the risk of defects and ensures bulk orders meet consistent standards required by trusted brands.

Below is a table summarizing key factors and recommended solutions for enhancing padel racket production:

| Challenge | Root Cause | Recommended Solution | Considerations |

|---|---|---|---|

| Material Durability | Limited performance of fiberglass | Transition to advanced carbon fiber (3k, 12k, 18k) techniques | Ensure appropriate grade matches product design; balance weight and strength |

| Customization Demand | Market need for personalized products | Invest in flexible manufacturing lines and digital customization systems | Scale production ability to manage both custom and bulk orders |

| Quality Consistency | Variations in manual production processes | Automate quality control with digital sensors and automated inspections | Regular calibration of sensors; continuous staff training |

| Production Speed and Efficiency | Manual interventions extend turnaround times | Use automation and rapid prototyping techniques | Integrate lean manufacturing principles to minimize waste |

| Design Flexibility | Inability to adapt to player-specific requirements | Implement CAD and digital design tools | Maintain design libraries; update with emerging trends |

While the integration of advanced techniques brings many benefits, companies should keep the following points in mind:

-

Cost Implications:

Transitioning from traditional fiberglass to carbon fiber, and incorporating automated systems, requires significant upfront investment. It is important to perform a cost-benefit analysis to ensure the ROI aligns with market demands. -

Supply Chain Stability:

Relying on specialized materials like high-grade carbon fiber means ensuring a stable supply chain is critical. Procurement managers should establish long-term contracts with reliable suppliers to avoid production delays. -

Customization Complexity:

While fully customizable padel rackets offer a competitive edge, they also increase production complexity. Companies need robust project management and production planning systems to handle variable orders without compromising quality or speed. -

Regulatory Compliance:

Manufacturers must monitor industry standards and regulatory changes related to sports equipment. Compliance with safety and performance regulations must be continuously verified to maintain market credibility.

Consider the experience of leading brands such as Hirostar, Reebok, and Starvie, which have successfully adapted to these modern practices by partnering with advanced production facilities. A significant percentage of these brands have noted:

- A reduction in production defects by over 30% due to automated quality control measures.

- A shortened design-to-delivery cycle time by more than 25% through integrated CAD and automated molding processes.

- Improved product durability and performance consistency that, according to player feedback, enhances on-court competitiveness.

These examples underscore the direct benefits of adopting modern manufacturing techniques. By learning from these industry leaders, procurement managers and product developers can align their production strategies with proven practices, ensuring that every racket produced meets the evolving standards of competitive play.

In summary, the rapid evolution of padel production techniques is driven by advancements in material science, precision manufacturing, and the growing demand for customization. To stay competitive, companies must:

- Invest in advanced materials like various grades of carbon fiber.

- Leverage automated, precision-driven production techniques.

- Expand manufacturing line flexibility to support diverse racket shapes and custom designs.

- Strengthen quality assurance protocols to ensure consistent product performance.

- Consider supply chain and regulatory implications when planning production upgrades.

These strategies not only improve the performance and durability of padel rackets but also enable brands to meet customer expectations for personalized, high-quality equipment. Procurement managers and product development leads are encouraged to review current production lines, evaluate the potential for integrating these advanced techniques, and plan for a gradual transition toward more automated and flexible manufacturing processes.

Implementing these solutions will help companies not only stay ahead in a competitive market but also satisfy the nuances required by high-performance padel players. Embracing change in manufacturing strategies means building a foundation for lasting success and innovation in the padel sports equipment sector.

Q1: What advanced manufacturing techniques are commonly used in padel racket production?

A1: Advanced techniques include computer-aided design (CAD), automated molding and curing processes, and digital quality control systems that ensure consistency and precision. These methods facilitate the integration of high-performance materials like carbon fiber, allowing for both durability and customizable designs.

Q2: How does material selection impact the performance of padel rackets?

A2: Choosing the right materials is crucial because advanced carbon fiber (3k, 12k, 18k) offers superior strength-to-weight ratios compared to traditional fiberglass. This results in rackets that are not only lighter but also more durable and responsive during play, meeting the high-performance standards demanded by competitive players.

Q3: What are the benefits of customizable padel rackets in today’s market?

A3: Customizable padel rackets allow companies to meet specific player needs by offering tailored designs, personalized prints, and custom shapes (such as Diamond, Round, or Teardrop). This flexibility enhances the appeal of the product, allowing brands to cater to niche markets and differentiate their offerings in a competitive industry.

-

advanced manufacturing techniques: Click to read about how modern production processes integrate automation, robotics, and innovative material handling to improve product consistency, efficiency, and scalability in industrial manufacturing. ↩

-

carbon fiber: Click to learn more about the different grades of carbon fiber (3k, 12k, 18k), their unique properties, and how they enhance strength-to-weight ratios in high-performance sporting goods. ↩ ↩2 ↩3

-

Computer-Aided Design (CAD): Click to explore the fundamentals of CAD, a key technology that enables precise digital modeling and rapid iteration in modern product design. ↩

-

digital quality control: Click to see how digital quality control uses real-time sensor data and automated inspections to reduce defects and maintain consistent product quality in manufacturing. ↩

-

flexible manufacturing lines: Click to understand the benefits of flexible manufacturing lines, which allow companies to efficiently switch between product types and customization, meeting diverse market demands. ↩ ↩2