Quick Answer: The latest padel racket technologies are revolutionizing performance through advanced materials like high-grade carbon fiber1, precision manufacturing techniques, and customizable designs that meet global market needs, ensuring durability and innovation for B2B decision-makers.

Introduction

In today’s competitive padel market, technological innovation is not just a trend—it is a necessity. Manufacturers and distributors must keep pace with evolving production techniques and material advancements to remain at the forefront. This article explores advanced padel racket technologies, detailing the challenges, production improvements, and tailored solutions that are transforming the industry. Our discussion is rooted in real-world factory experiences, emphasizing how materials such as glass fiber and various grades of carbon fiber (3k, 12k, 18k) are reshaping precision manufacturing.

Problem Description

The padel market is experiencing rapid growth, driven by increased global participation in the sport. However, this growth comes with significant challenges:

• Ensuring the durability and performance consistency of rackets.

• Integrating multiple advanced materials without compromising the design's integrity.

• Balancing cost efficiency with high-precision production.

• Meeting the demands for customization, including unique shapes and branded aesthetics.

B2B executives and technical managers face a common dilemma: how can production processes be upgraded to harness innovative materials while keeping lead times and quality control at optimal levels?

Cause Analysis

The challenges outlined are primarily due to legacy manufacturing practices that often rely on less advanced composite materials and outdated production techniques. Specific issues include:

-

Material Limitations:

Traditional materials like standard glass fiber can be cost-effective but may fall short in delivering the enhanced durability and lightweight performance achieved by higher-grade carbon fibers. -

Production Inflexibility:

Legacy machinery and design processes struggle to adapt to custom shapes such as Diamond, Round, or Teardrop designs, which are increasingly demanded by diverse market segments. -

Shortcomings in Quality Control:

Inconsistent quality assurance processes can lead to variations in racket performance—a serious concern for B2B buyers who base their decisions on reliability and durability metrics. -

Rigid Customization Options:

The pressure to quickly personalize features such as handles, logos, and grip components means that manufacturers must recalibrate production systems to support full customization without delaying lead times.

Solution-Oriented Approach: Advanced Racket Production Methods

The pathway to resolving these challenges involves an integrated solution that combines innovative materials, adaptive production techniques, and rigorous quality control. This article outlines a solution framework designed to meet current market demands.

-

Material Innovation

Manufacturers are now shifting from basic composites to advanced materials. For example, transitioning from traditional glass fiber to grades of carbon fiber like 3k, 12k, and 18k offers significant performance gains:

• 3k carbon fiber is ideal for lightweight designs with moderate strength.

• 12k and 18k variants provide superior rigidity and durability, essential for competitive play.Using a mix of these materials enables the creation of rackets that balance performance with cost-effectiveness. The incorporation of high-grade materials has also set the stage for precise customization based on customer requirements.

-

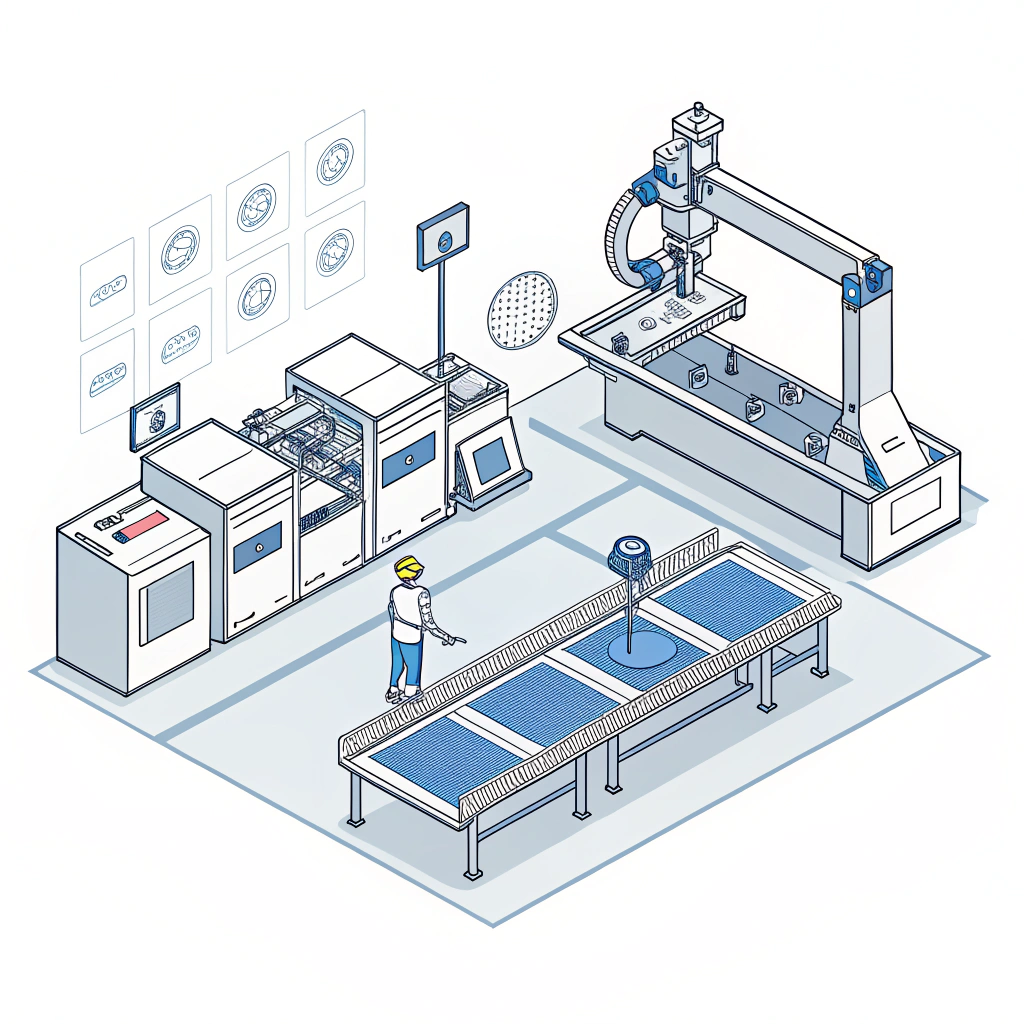

Precision Manufacturing Techniques

Modern production techniques such as computer numerical control (CNC machining2) and automated lay-up processes3 have streamlined the manufacturing of custom padel rackets. These advances help manufacturers achieve tighter tolerances and uniform quality across different product lines. The key factors driving these improvements include:

• Adoption of digital design tools that allow for rapid prototyping4 and virtual testing.

• Integration of advanced robotics in the production line, ensuring repeatability and consistency.

• Implementation of real-time quality control systems that monitor every production stage. -

Customization Capabilities

Businesses like NEX Padel have mastered the art of full customization. With diverse designs like Diamond, Round, and Teardrop, manufacturers can adapt rackets to suit various playing styles and market segments. Key customization options include:

• Custom shapes designed to maximize aerodynamics and balance.

• Personalized printing and color schemes that enable brand differentiation.

• Custom logos on hand grips and protective covers, reinforcing brand identity. -

Quality Assurance and Efficiency

Ensuring high quality in every product batch is fundamental. Quality control systems now integrate automated optical inspection5 and performance testing. This increased efficiency minimizes defective production and ensures that each padel racket meets internal standards and customer expectations.

Solution Implementation: A Detailed Look

Implementing these advanced production concepts requires a structured adaptation plan. Below, we present a table summarizing the key areas of transformation and the recommended strategies for each.

| Challenge Area | Traditional Approach | Advanced Production Solution | Benefits |

|---|---|---|---|

| Materials | Standard glass fiber | Use of multi-grade carbon fiber (3k, 12k, 18k) | Improved durability, performance, and lightweight design |

| Production Techniques | Manual assembly and outdated machinery | Automated CNC machining, robotic lay-up, digital prototyping | Enhanced precision and reduced production time |

| Customization | Limited design options | Full customization (Diamond, Round, Teardrop shapes, logo printing) | Tailored products meeting market-specific needs |

| Quality Control | Sporadic batch testing | Integrated real-time quality control systems | Consistent product quality and reduced waste |

| Lead Time | Long production cycles | Rapid prototyping and agile manufacturing processes | Faster delivery and higher customer satisfaction |

In this model, each upgrade addresses an existing shortfall in the production process. For manufacturers, the move to precision-driven technologies not only offers operational efficiency but also positions them competitively in the market.

Industry Trends and Case Study

Globally, the padel market is undergoing significant transformation as manufacturers adopt these advanced production techniques. A recent case study demonstrates how a leading manufacturer integrated these improvements into their workflow:

• The company began by overhauling its material sourcing strategy, choosing a blend of 12k and 18k carbon fiber to meet the increasing demand for high-strength rackets.

• Next, the integration of automated production lines allowed the company to reduce its turnaround time by 30%, ensuring that orders met tight lead deadlines.

• Finally, the introduction of customizable design capabilities resulted in even established brands offering bespoke products, significantly boosting their competitive edge.

This case study is not unique. Across the board, manufacturers that have embraced these changes have reported enhanced product consistency, reduced waste, and a stronger market position.

Key Technical Considerations

For decision-makers evaluating these advanced technologies, there are several technical aspects to consider:

-

Material Compatibility

It is essential to ensure that the materials chosen, whether glass fiber or various grades of carbon fiber, are compatible with existing production processes. Material compatibility directly affects the stability and performance of the final product. -

Production Scalability

Advanced techniques like CNC machining and robotic automation must scale to meet fluctuating market demands. A modular production setup can help maintain quality while increasing output. -

Customization Versatility

When offering fully customized products, manufacturers must design a production line that supports various order sizes—from prototypes to large-scale runs—without sacrificing precision or quality. -

Quality Inspection Protocol

Implementing an automated quality inspection process that includes both visual and performance tests can dramatically reduce the rate of rejected products while ensuring each racket meets performance standards. -

Regulatory Compliance

As the sports equipment market becomes more competitive, regulatory standards are continually updated. Manufacturers must ensure that any new production process complies with local and international industry regulations, especially regarding safety and material usage.

Actionable Recommendations

For B2B executives and technical managers considering an upgrade in production technology or looking to partner with leading manufacturers like NEX Padel, consider the following recommendations:

• Conduct a comprehensive audit of your current production methods to identify improvement areas, particularly in material usage and process automation.

• Invest in digital prototyping and simulation tools to mitigate risks during the transition to advanced production methods.

• Explore partnerships with experienced providers who have a proven track record in precision manufacturing and high-grade material handling.

• Pilot new technologies on a small scale to measure performance improvements before large-scale implementation.

• Stay updated on international regulatory changes to ensure that new processes and products remain compliant.

Conclusion

Innovation in padel racket technology is more than a competitive advantage—it's a strategic imperative. By adopting advanced materials like high-grade carbon fiber, leveraging state-of-the-art production techniques, and embracing customization, manufacturers can produce rackets that meet evolving market demands. These improvements not only enhance product performance but also drive efficiency and customer satisfaction.

As demonstrated by industry trends and real-world case studies, modernizing production processes is key to thriving in today’s competitive landscape. B2B decision-makers must view these advancements as essential investments that promise both immediate operational benefits and long-term market leadership.

For further insights into how these technologies can transform your production processes and boost your market competitiveness, consider reaching out—our team at NEX Padel is here to support your transition to a future-ready production environment.

People Also Ask

Q1: How does advanced carbon fiber enhance padel racket performance?

A1: Advanced carbon fiber, including 3k, 12k, and 18k variants, increases racket durability, reduces weight, and provides superior rigidity, resulting in improved handling and power during play.

Q2: What are the key differences between Diamond, Round, and Teardrop racket shapes?

A2: The Diamond shape typically focuses on a balance of power and control, the Round shape enhances maneuverability and balance, and the Teardrop design offers a blend of both with an emphasis on precision; each design can be customized further based on player needs.

Q3: How does NEX Padel ensure customization quality in its production?

A3: NEX Padel incorporates advanced production techniques, real-time quality control, and rigorous testing protocols to ensure that every custom design—from shape to grip detailing—meets the highest standards of performance and durability.

-

carbon fiber: Read this article to understand the benefits and applications of high-grade carbon fiber in enhancing product durability and performance in competitive manufacturing environments. ↩ ↩

-

CNC machining: Learn more about computerized numerical control machining, a precise manufacturing process that increases production efficiency and product consistency. ↩ ↩

-

automated lay-up processes: Discover how automated lay-up processes streamline composite material assembly and improve the overall quality of finished products. ↩ ↩

-

rapid prototyping: Explore rapid prototyping techniques that enable swift development and testing of design iterations in modern manufacturing. ↩ ↩

-

automated optical inspection: Find out how automated optical inspection systems enhance quality control by ensuring that every product meets strict performance standards. ↩ ↩