Padel racket materials greatly influence performance, and a quick answer is: if you value high durability and power, carbon fiber1 (especially in 12K or 18K variants) is ideal; if you prefer comfort and ease of use, fiberglass2 may better suit your needs. This article dives deep into the technical differences between these materials and guides you through selecting the right choice for high-performance padel equipment.

In the highly competitive world of padel equipment, the selection of materials for racket construction is paramount. Manufacturers and product managers face a challenge when balancing durability, precision engineering, and cost-effectiveness. At NEX Padel, we work at the intersection of advanced production techniques and premium material design. In this article, we explore how different materials—ranging from glass fiber to various types of carbon fiber (3K, 12K, 18K)—affect overall racket performance, helping you make informed procurement and product development decisions.

Materials are the backbone of any sporting equipment, and padel rackets are no exception. They not only determine the durability and weight of the racket but also directly influence vibration damping, impact resistance, and control. Understanding these aspects can help sports equipment companies decide on the optimal balance between performance and cost.

- Durability: Durability is essential because the racket must withstand high-impact collisions during intense matches. Carbon fiber, especially the 12K and 18K variants, provides excellent durability while ensuring a lightweight design.

- Weight Optimization: Lightweight materials improve maneuverability, which is crucial for quick reflexes and effective gameplay. Innovations in production techniques, including the use of advanced composites, have made it possible to reduce weight without sacrificing strength.

- vibration damping3: The absorption and diffusion of impact energy is vital for reducing vibration, which not only improves comfort for players but also helps in maintaining racket integrity over long periods.

- Precision and Control: Engineering precision in racket design ensures that the sweet spot—the optimal impact area—is maximized. This directly influences how accurately players can hit the ball, turning minute differences in material composition into significant competitive advantages.

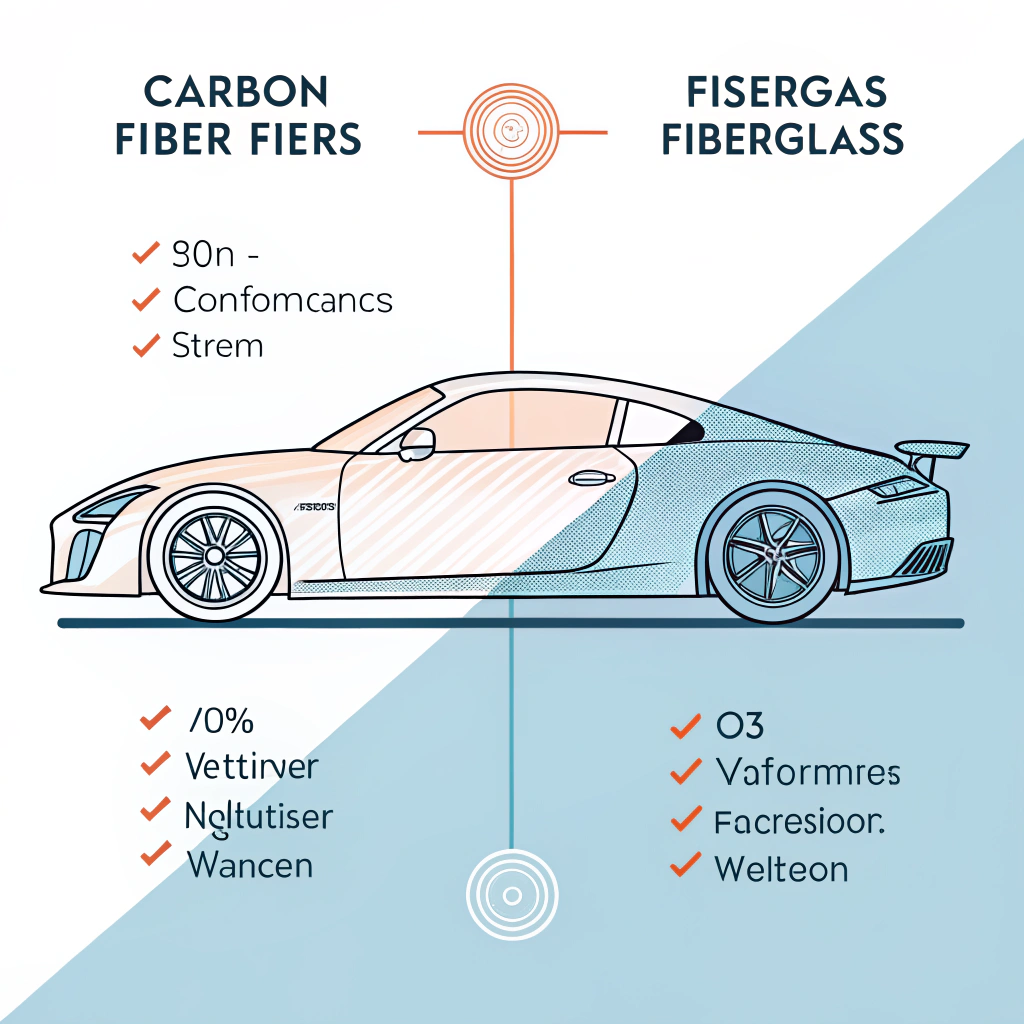

When comparing materials, the differences between carbon fiber and fiberglass are striking. Below is a comprehensive table that outlines the key technical and performance aspects of these materials:

| Material | Durability | Weight | Vibration Damping | Production Cost | Performance Feel |

|---|---|---|---|---|---|

| Fiberglass | Moderate | Heavier | Excellent | Lower | Softer, comfortable; ideal for beginners or recreational use |

| Carbon Fiber 3K | High | Lightweight | Good | Moderate | Balanced performance; suitable for intermediate players |

| Carbon Fiber 12K & 18K | Very High | Ultra-light | Moderate | Higher | Stiff, offers higher precision and power for professional play |

This table serves as a quick reference guide for technical buyers evaluating options based on performance needs and budget considerations.

At NEX Padel, the use of various carbon fiber types such as 3K, 12K, and 18K has allowed us to tailor racket performance to specific player needs. The numbers refer to the fiber count per bundle, which influences the material’s stiffness and stress distribution.

- 3K Carbon Fiber: Offers a well-balanced performance ideal for players looking for a combination of power and ease of handling. It is perfect for mid-level performance needs, where a slight trade-off in stiffness is acceptable to gain comfort.

- 12K and 18K Carbon Fiber: These options are favored when maximum strength, longevity, and precision are at the forefront. Their inherent rigidity results in enhanced power transmission and minimized deformation during high-impact plays. However, this may compromise the soft feel that beginners might prefer.

Fiberglass remains an important material in padel racket design due to its superior vibration damping properties, which make it especially appealing for players prioritizing comfort. Its softer impact feel reduces the risk of injury and is often a more affordable alternative for mass-market products. However, its higher weight can diminish maneuverability, which is why it is generally seen in rackets catering to less performance-intensive segments.

In today’s competitive market, customization is a crucial decision factor. NEX Padel offers fully customized racket designs where not only the shape but also the print and color schemes are adjustable. Customization extends to hand grips and handle covers, which can feature personalized logos, blending branding with performance. This level of detail is critical for companies looking to establish a unique market identity while providing top-notch equipment.

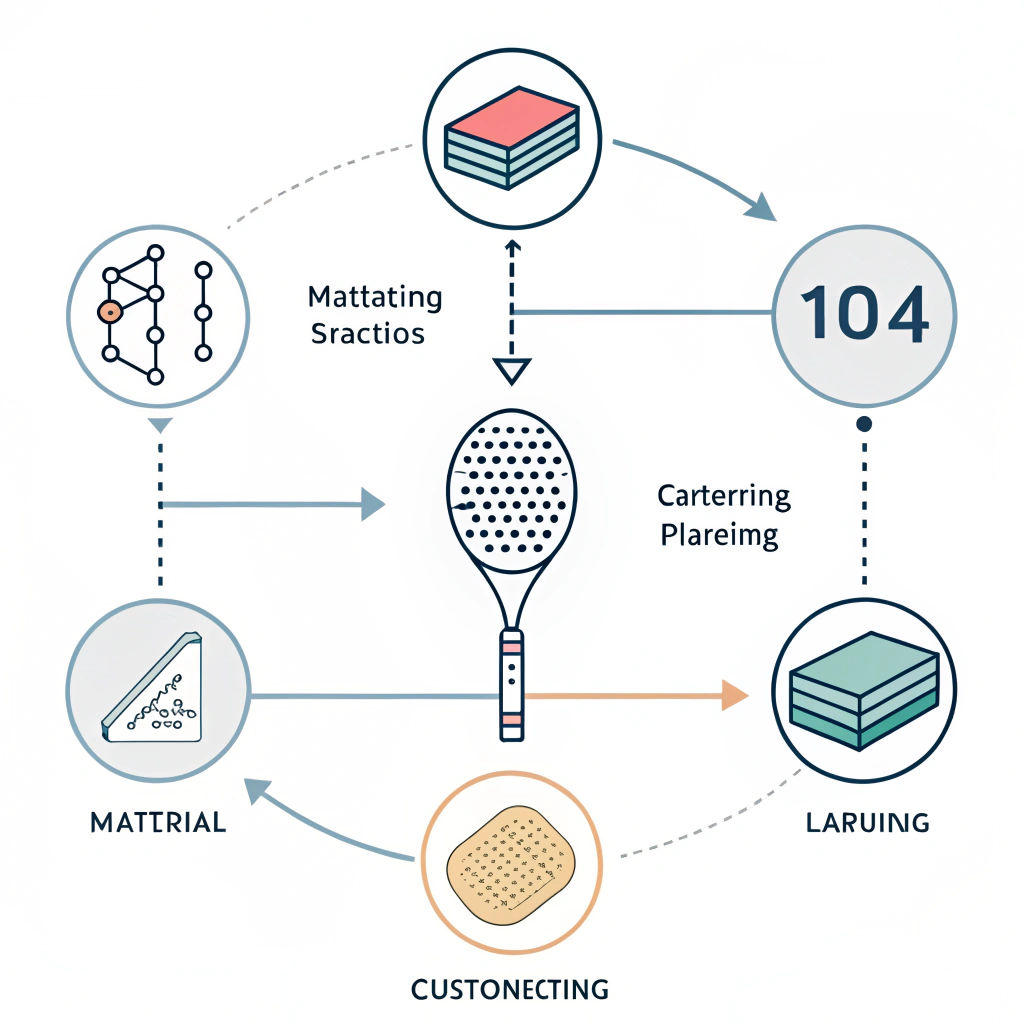

The advanced production techniques employed in padel racket manufacturing significantly affect the final product performance. Our process emphasizes precision and quality control from start to finish, ensuring that every racket meets high-performance standards. Let’s break down the key stages in the manufacturing process and how they influence material performance.

- Material Selection: The process begins with the careful selection of high-grade materials. Whether using varied carbon fiber types or superior fiberglass, the choice is driven by rigorous quality assessments and comparative analysis against standards.

-

- layering techniques4: Racket construction involves layering different materials to balance strength and flexibility. For instance, carbon fiber layers are strategically placed to ensure that stiffness is maximized at the impact zones, while softer layers might be added for enhanced vibration damping.

-

- curing process5: Advanced curing techniques help solidify the material matrix. Optimal curing is crucial for maintaining the structural integrity and longevity of the racket. Temperature, pressure, and time are carefully controlled to ensure that the composite materials fully integrate.

- Customization Integration: For orders requiring a fully customized design, digital printing and molding techniques are used to achieve specific shape and design requirements. This ensures that branding elements do not compromise the performance attributes of the racket.

The following flowchart summarizes our typical production process:

- Precision Engineering: By combining advanced materials with precision manufacturing techniques, NEX Padel ensures that each racket delivers on the promise of enhanced control and consistent performance.

- Durability and Strength: High-quality carbon fibers offer increased resistance to wear and tear. For B2B buyers, this translates into a lower warranty rate and greater customer satisfaction.

- Customization without Compromise: The ability to combine custom design elements with rigorous performance standards provides a unique competitive edge. This is particularly important for brands looking to differentiate themselves in a crowded marketplace.

Every material property translates into a specific gameplay advantage. For example:

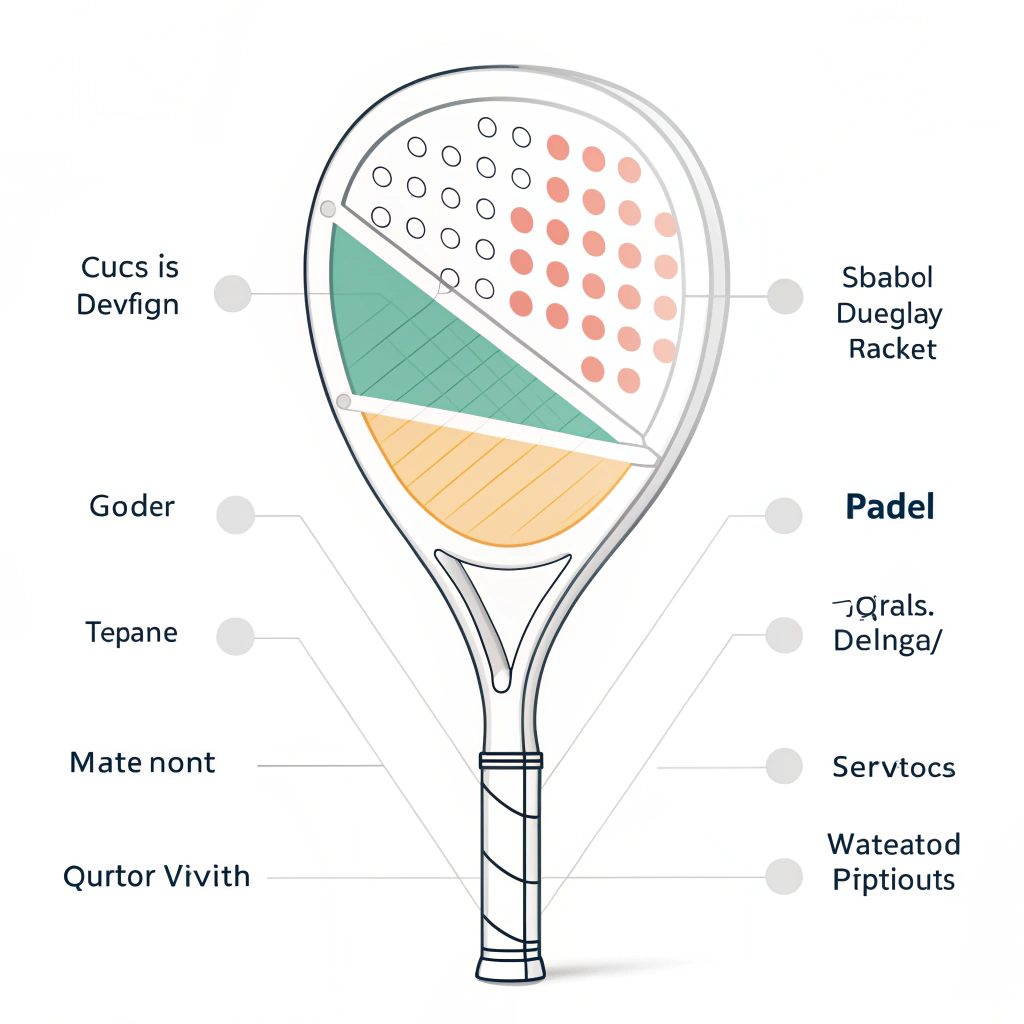

- Enhanced Sweet Spot and Control: The shape and materials of a racket directly influence the location and size of the sweet spot. Different designs, such as Diamond, Round, and Teardrop (all available through NEX Padel), are optimized for unique player styles. A properly designed sweet spot allows players to transfer energy more effectively, resulting in more powerful and accurate shots.

- Vibration and Comfort: While carbon fiber rackets offer remarkable power and precision, the inherent stiffness can lead to increased feedback to the hand on off-center hits. Conversely, fiberglass provides a softer feel, reducing the potential for discomfort over prolonged use.

Customizability isn’t just a marketing tool—it can directly affect performance. Our ability to offer a range of fiber types, handle customization, and printing options means that companies can tailor products to their target audience. For instance, a brand seeking to market a product line to amateur players might lean towards fiberglass-based rackets, emphasizing ergonomics and comfort rather than raw power.

Recent market analyses indicate that while high-end players tend to favor carbon fiber rackets for their durability and precision, the majority of casual players appreciate the softer touch provided by fiberglass. Here’s a simplified case study outline:

- Case Study 1: A leading sports brand reported a 25% increase in customer satisfaction after switching to carbon fiber rackets with a 12K configuration. The upgrade provided players with a noticeable boost in power without sacrificing control.

- Case Study 2: An emerging B2B distributor catering to training academies prioritized the use of fiberglass rackets. Their products received positive feedback due to improved comfort and a lower incidence of stress-induced injuries among players.

These insights are backed by internal testing data at NEX Padel, where our prototypes undergo rigorous durability and performance testing before they are even considered for large-scale production.

When selecting padel racket materials for your product lineup, consider the following:

- Target Audience Needs: Identify whether your end-users prioritize speed and power over comfort, or vice versa. A sports equipment company must align its material selection with the users’ gameplay style.

- Budget Constraints: Material cost can have a significant impact on overall production expenses. While carbon fiber offers superior performance, its higher cost may not be justifiable for products aimed at entry-level players.

- Production Capabilities: Ensure that your manufacturing partners have the expertise and equipment necessary to handle advanced materials. Poor production techniques may undermine the advantages of even the best materials.

- Customization Options: To stand out in a competitive market, the ability to offer custom designs—both in terms of aesthetic elements and performance enhancements—is invaluable.

A decision matrix can be useful here. Consider the following simplified decision matrix as an example:

| Factor | Fiberglass Rackets | Carbon Fiber Rackets (12K/18K) |

|---|---|---|

| End-User Comfort | High | Moderate |

| Durability | Moderate | High |

| Production Cost | Low | High |

| Customization Flexibility | Good for general designs | Excellent for premium, performance-focused designs |

| Performance Precision | Adequate for casual play | Superior for competitive and professional play |

Using such a table helps your team visualize the trade-offs and choose the best option according to your market strategy.

For technical buyers and B2B product managers, selecting the right material for padel rackets is a critical decision that can influence overall product performance and user satisfaction. Our analysis shows that while fiberglass offers comfort and a softer feel ideal for beginners and casual players, carbon fiber — particularly the 12K and 18K variants — stands out for professionals who demand durability, power, and precision.

NEX Padel remains committed to continuous innovation, ensuring that our manufacturing expertise and precision engineering meet the evolving demands of the sports market. We recommend a careful evaluation of your target user’s needs, production capabilities, and cost constraints before making a decision. Should you need detailed technical support or wish to see our prototypes in action, please contact our team for further consultation.

By aligning your product strategy with material performance insights, you can deliver superior padel equipment that not only elevates gameplay but also positions your brand as a leader in sports technology.

Q: What material is best for a padel racket?

A: For optimal performance, carbon fiber is best for those needing high durability and strength, particularly using 12K or 18K variants. If comfort and ease of use are the primary requirements, fiberglass is a strong contender.

Q: Do different padel rackets make a difference?

A: Yes, different rackets greatly influence gameplay. Racket shape and material composition determine the sweet spot, control, and overall impact resistance, making a well-chosen design essential for performance.

Q: Which is better: graphite or fiberglass padel racquets?

A: Graphite (or carbon fiber) rackets provide a harder feel and superior durability, ideal for competitive play, whereas fiberglass rackets offer a softer feel with better vibration damping, making them suitable for players prioritizing comfort.

-

carbon fiber: Click to explore an in-depth article on carbon fiber, including its manufacturing process, material grades such as 12K and 18K, and how its structural benefits can provide enhanced durability and performance benefits in high-demand sporting equipment. ↩ ↩

-

fiberglass: Click to read about fiberglass’s properties, its advantages in vibration damping and comfort, and why it remains a cost-effective choice for equipment designed for casual or entry-level users. ↩ ↩

-

vibration damping: Click to learn more about vibration damping techniques, how they are measured, and their impact on user comfort and equipment longevity in high-performance sports gear. ↩ ↩

-

layering techniques: Click to discover how layering techniques in composite materials can optimize performance by balancing strength and flexibility, providing insights into advanced manufacturing methods used in sporting equipment. ↩ ↩

-

curing process: Click to delve into the curing process, an essential stage in composite material production, explaining how precise control of temperature, pressure, and time ensures superior material integration and durability in sports products. ↩ ↩