A padel racket's surface texture1 directly influences playability by affecting friction, spin potential, and overall ball control. In short, a rough surface increases spin while a smooth surface enhances precision and control.

Padel racket performance is highly dependent on the intricate balance between material properties and surface texture. The surface texture of any padel racket not only determines the friction between the ball and the racket but also plays a decisive role in the shot's spin generation and overall control. Understanding these relationships is essential in optimizing performance for both casual players and competitive athletes.

Friction is the underlying force between the padel ball and the racket's hitting surface. When a ball makes contact with a rough surface, the increased friction creates more grip, which can help the player impart extra spin on the ball. In contrast, a smooth surface allows the ball to slide off more quickly, promoting a shot with greater precision and placement. These differences in interaction are crucial during high-speed exchanges on the court.

-

Rough Surface Benefits:

- Provides higher friction coefficients.

- Enhances the spin potential due to a “grab” effect.

- Beneficial in aggressive and spin-heavy gameplay.

-

Smooth Surface Benefits:

- Low friction leads to faster ball slippage.

- Offers improved control and accuracy for finesse shots.

- Ideal for players looking to emphasize placement over spin.

Research in material science2 and tribology3 (the study of friction) explains that the microscopic peaks and valleys on a surface create points of contact with the ball. These contact points lead to friction variation that can be engineered for specific playing outcomes. As a result, padel rackets can be customized to meet the performance needs of different player types.

At NEX Padel, understanding the importance of surface texture is core to our production philosophy. We employ advanced techniques to tailor the texture profiles to precise specifications that meet professional standards.

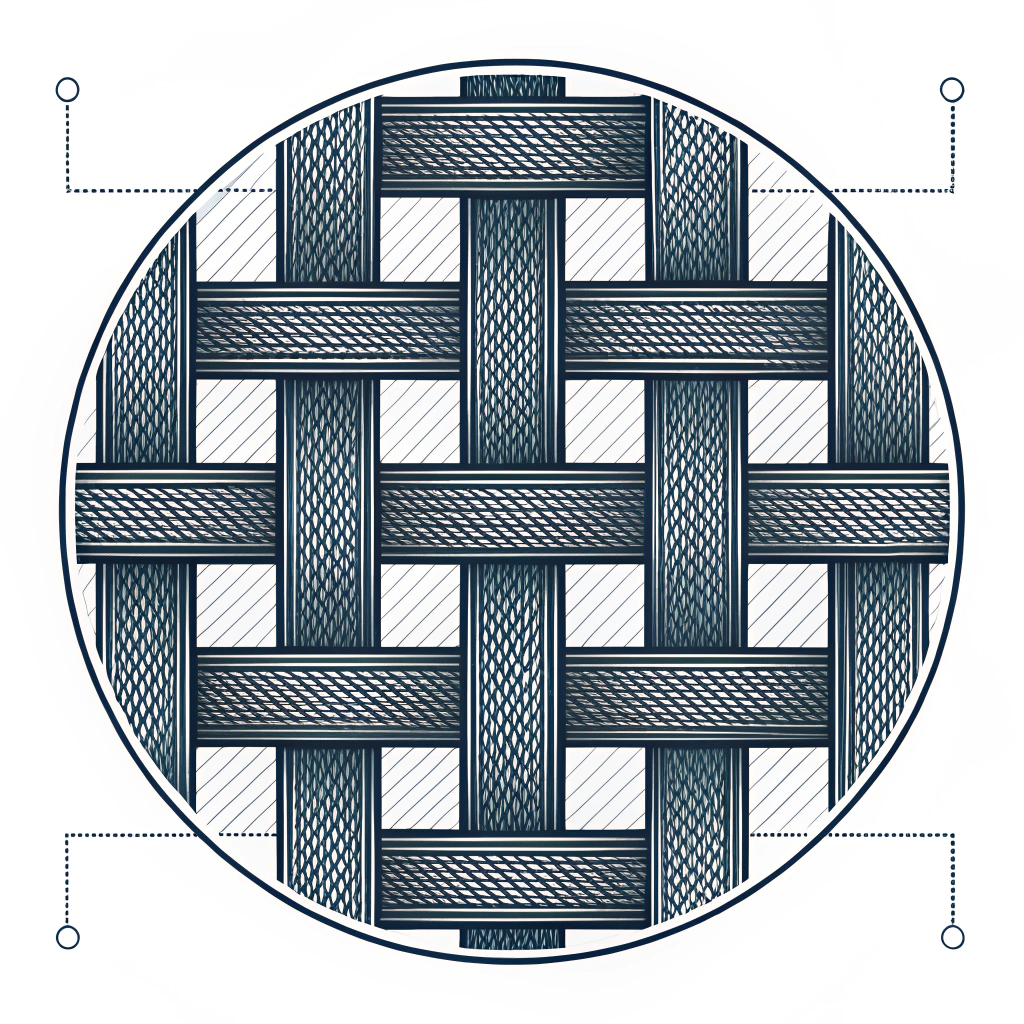

Our padel rackets are manufactured with a variety of high-performance materials such as carbon fiber4 with different weave patterns5 including 3k, 12k, and 18k weaves. The choice of weave directly affects the structural rigidity as well as the surface finish of the racket.

- 3k Weave: Offers a smooth finish that complements control-oriented players.

- 12k and 18k Weave: These denser weaves not only enhance durability and impact resistance but also provide a textured surface that can increase spin potential when intentionally roughened.

The decision to use a specific combination depends on the buyer’s target market and performance requirements. In practice, the material selection is made considering both mechanical properties and the ease of customization during surface processing.

The manufacturing process involves several stages where surface texture can be accurately controlled:

- Molding and Curing: The pre-designed mold influences the initial smoothness or roughness. Fine-tuning during the curing phase helps set the texture.

- Surface Treatment: Techniques such as sandblasting or specialized sprays (for example, the HoneXP sand spray) are used to alter the surface. These treatments create a controlled roughness that can maximize ball spin while maintaining surface integrity.

- Quality Control: Advanced optical and tactile measurement tools ensure that the desired surface profile meets strict quality standards. This process is important to avoid inconsistencies that could lead to undesirable performance variations.

A detailed inspection at each stage helps our production team guarantee that every racket leaves the factory meeting the technical requirements demanded by professional padel players.

To better understand the performance implications, the following table demonstrates the key differences between rough and smooth surfaces:

| Feature | Rough Surface | Smooth Surface |

|---|---|---|

| Friction Level | High – enhances spin and ball grip | Low – facilitates faster ball release |

| Ball Control | Better for aggressive, spin-focused gameplay | Better for precision and shot placement |

| Suitability For Players | Advanced players seeking spin complexity | Beginners and control-focused players |

| Manufacturing Technique | Often treated with sandblasting or sprays | Result of a high-quality, controlled mold |

| Impact on Ball Behavior | Increases unpredictable spin variations | Offers consistent ball trajectory |

This comparison helps product development managers and procurement specialists to decide on the optimal texture based on the intended play style and market needs.

Our experience at NEX Padel reveals that even minor tweaks in surface texture during production can noticeably influence racket performance. Several field tests illustrate that a rough surface created by controlled treatments increases spin by up to 15% compared to untreated smooth surfaces. In addition, the enhanced grip provided by a rough finish has resulted in improved shot consistency for players in tournaments.

A recent project involved modifying a line of premium padel rackets with a tailored rough surface treatment. The field performance data showed:

- Improved ball spin rates during high-impact shots.

- Enhanced player feedback regarding shot control and comfort.

- Sustained durability even under repeated high-speed impacts.

These empirical results support the benefits of purposeful surface texturing and help inform best practices for both manufacturing and product marketing.

Flexibility in surface texture customization is one of NEX Padel’s key offerings. Beyond basic treatments, we also allow for:

- Full customization of racket shape and texture: Providing a competitive edge to brands seeking unique designs.

- Logo customization on additional components: Such as the hand grip and handle cover.

- Integration with advanced materials: Partnering with industry leaders to refine performance further.

These capabilities are essential for brands looking to innovate in padel equipment. The balance between aesthetic appeal and performance enhancement makes surface texture customization a powerful tool in design differentiation.

Given the complex interplay between surface texture and racket performance, here are a few recommendations for procurement specialists and product development managers when evaluating manufacturing partners:

-

Define Performance Priorities:

Clearly determine whether control or spin enhancement is the primary objective. For spin-focused products, opt for a controlled rough surface; for precise placements, a smooth surface is preferable. -

Evaluate Material and Weave Combinations:

Consider which material weave—be it 3k, 12k, or 18k carbon fiber—best aligns with your product’s performance targets. Each weave offers distinct texture possibilities. -

Inspect Manufacturing Capabilities:

Ensure that the production partner uses advanced surface treatment methods and has stringent quality control measures. This is vital to maintain consistency across large batches. -

Review Field Data and Case Studies:

Ask for empirical evidence or case studies from the manufacturer to validate how surface texture modifications translate to performance improvements. Data-backed insights can significantly support procurement decisions. -

Consider Customization as a Value-Add:

Look for manufacturing partners like NEX Padel that not only provide high-quality rackets but also offer comprehensive customization options. This flexibility can be a significant market differentiator.

Surface texture is a critical design parameter that directly impacts the performance of padel rackets. By engineering the texture profile, manufacturers can boost ball spin, control, and overall playability. For procurement specialists and product development managers, understanding these details is key to making informed decisions.

We recommend that brands evaluate their performance priorities—balancing spin against precision—and seek manufacturing partnerships that can deliver advanced material science solutions and reliable customization capabilities. At NEX Padel, our technical expertise and robust manufacturing practices ensure every racket meets the highest standards for competitive performance and durability.

In summary, deliberate management of the padel racket surface texture offers a clear competitive advantage. Whether your market demands aggressive spin or laser-precise control, the right surface treatment makes a difference. Use the above insights and production techniques as part of your procurement criteria to ensure the final product exceeds end-user expectations.

Q: Is a padel smooth or rough surface better?

A: A smooth surface on a padel racket offers superior ball control and precision, allowing the ball to slide off more easily for accurate shot placement. However, while it achieves precision, it does not generate as much spin as a rough surface, which increases friction and spin potential.

Q: How to make padel racket surface rough?

A: Manufacturers can achieve a rough surface through specific treatments such as using specialized sandblasting techniques or applying products like HoneXP sand spray. These methods create a controlled, durable roughness that enhances ball spin and overall control while maintaining the racket's aesthetic quality.

Q: Is a soft or hard racket better for padel?

A: The optimal racket hardness depends on player experience and playing style. Soft rackets tend to benefit beginners due to their larger sweet spot and forgiving nature, while hard rackets can deliver faster ball responses for experienced players who demand precision in shot speed variations.

-

surface texture: Click to learn how the microstructure of a padel racket’s surface can affect friction, spin, and ball control, offering insights into performance optimization. ↩

-

material science: Click to explore how material science investigates the properties and engineering of materials to enhance athletic equipment performance. ↩

-

tribology: Click to discover the fundamentals of tribology, the study of friction, lubrication, and wear, and its critical role in sports equipment design. ↩

-

carbon fiber: Click to learn about carbon fiber, a lightweight and strong material widely used in high-performance sports equipment due to its durability and versatility. ↩

-

weave patterns: Click to understand the significance of weave patterns in carbon fiber manufacturing, affecting both the strength and the surface characteristics of athletic equipment. ↩