Advanced production molds are a key investment that can significantly boost the quality and efficiency of padel racket manufacturing, leading to increased product performance and improved ROI1. In this article, we explore how upgrading to advanced, precision-molded solutions2 resolves production challenges, enhances product durability, and ultimately supports market competitiveness.

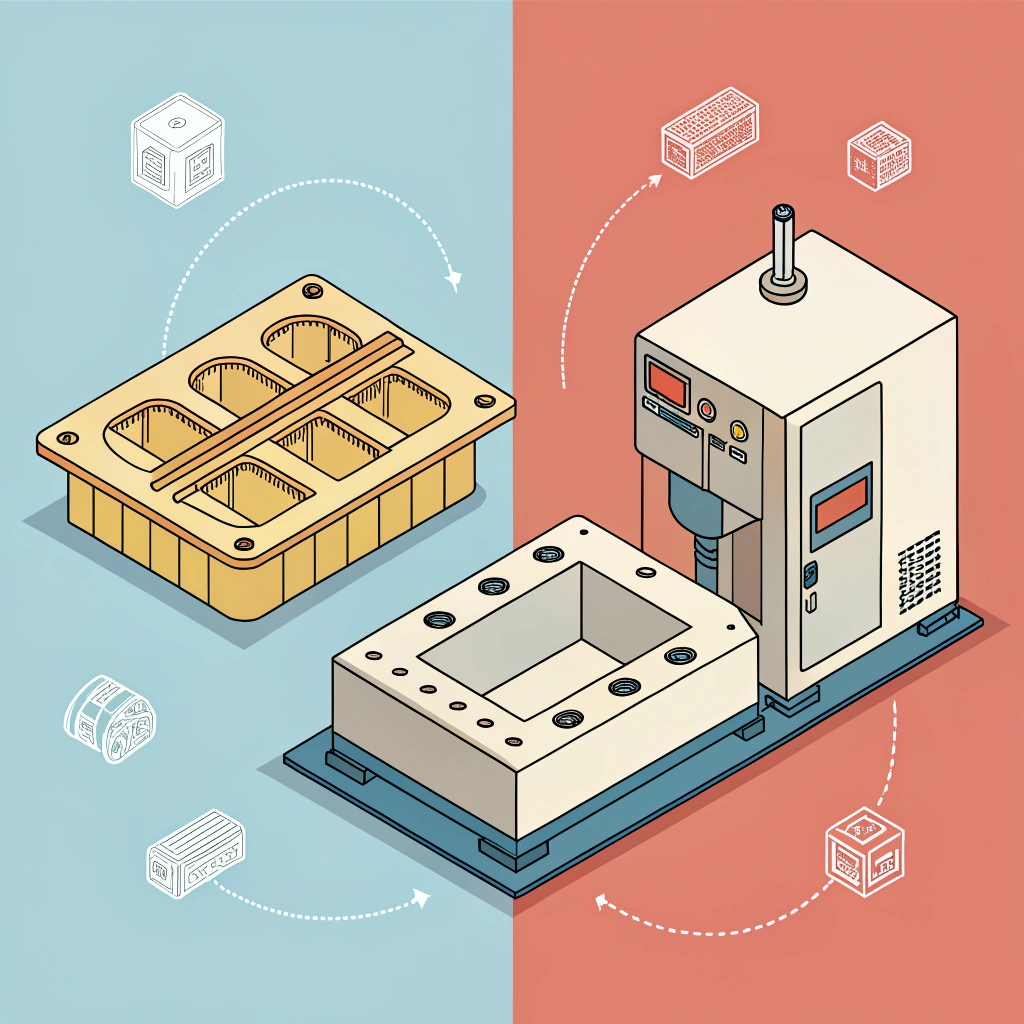

Manufacturers have long struggled with traditional molding techniques for producing padel rackets. Traditional molds often result in inconsistent shapes, variable product quality, and longer production cycles. These issues are particularly pronounced when producing high-performance rackets that require exacting standards in materials like carbon fiber3—whether 3k, 12k, or 18k types. Furthermore, outdated production molds can lead to production bottlenecks and increased waste, impacting both performance and profitability.

For companies aiming to serve leading brands such as Hirostar, Reebok, or Starvie—or even for B2B distributors sourcing reliable products—the pressure to deliver consistently high-quality sports equipment is critical. The increasing complexity of designs, including Diamond, Round, and Teardrop shapes and full customization options (from printing to handle customization), demands a manufacturing process that is both precise and agile.

The roots of these challenges lie in several factors:

-

Inconsistent Manufacturing Processes:

Traditional molds are often handmade or based on outdated engineering designs that do not fully account for modern performance requirements. This can lead to variability in the manufactured products. -

Limited Customization Flexibility:

Older mold technologies lack the versatility to easily switch between different racket shapes. For businesses that require frequent changes or customized designs, this limitation slows down the production process. -

Material Compatibility Issues:

The evolution from fiberglass to various grades of carbon fiber requires advanced production techniques to handle different material properties. Traditional molds may not be optimized for these modern materials, affecting both the durability and performance of the final product. -

Production Inefficiency:

Outmoded processes result in inefficiencies, higher production costs, and longer lead times. For companies that pride themselves on fast sampling and timely delivery, this lag can severely affect competitiveness in a fast-paced market. -

Quality Control Challenges:

Without precision molding techniques, ensuring that every padel racket meets strict quality assurance standards becomes difficult. This inconsistency affects both the product performance and the brand reputation of companies in the sports equipment industry.

Upgrading to advanced, precision-molded solutions addresses each of these challenges head-on. Let’s explore a detailed solution checklist that manufacturers can implement to reap the benefits of modern molding technology.

-

Implementing High-Precision Molds:

- Features:

Utilization of computer-aided design (CAD/CAM4) and computer-aided manufacturing (CAM) techniques allows for micrometer-level precision in designing molds tailored to the unique geometries of Diamond, Round, and Teardrop padel rackets. - Benefits:

Enhanced consistency across each produced batch, reduced variance in weight distribution, and improved overall product performance.

- Features:

-

Customizable Mold Designs:

- Features:

Advanced molds support complete customization, including the ability to alter shape, custom printing, and color adjustments. They can also accommodate logo customizations on components such as hand grips and handle caps. - Benefits:

Flexibility to meet bespoke customer requirements, faster iterations during product development, and streamlined production processes that reduce downtime.

- Features:

-

Material Optimization:

- Features:

New mold technologies are specifically designed to work with advanced materials like 3k, 12k, and 18k carbon fiber, ensuring better bonding, uniformity, and durability. - Benefits:

Superior strength-to-weight ratios, enhanced product performance under high stress, and longer lifespan of the racket.

- Features:

-

Enhanced Production Efficiency:

- Features:

The adoption of automated, robotic mold production lines can significantly reduce cycle times. Rapid prototyping combined with precision molding ensures that design iterations can be quickly and accurately tested. - Benefits:

Increased production throughput, lower operational costs per unit, and the ability to respond quickly to market demand fluctuations.

- Features:

-

Integrated Quality Assurance Systems5:

- Features:

Implementation of in-line inspection systems and automated quality control checkpoints during production. - Benefits:

Real-time detection of defects, reduced probability of defective batches, and consistent high-quality products which are essential for maintaining competitive edge.

- Features:

| Aspect | Traditional Molding | Advanced Precision Molding |

|---|---|---|

| Precision | Limited, manual adjustments required | High precision using CAD/CAM integration |

| Customization | Restricted design flexibility | Full custom capabilities including logos, colors, and shapes |

| Material Compatibility | Works best with basic materials | Optimized for modern carbon fiber types, e.g., 3k, 12k, 18k |

| Production Efficiency | Longer cycle times, high waste | Short cycle times with automated controls |

| Quality Assurance | Variable product quality | Consistent, rigorously monitored standards |

| ROI | Lower due to inefficiencies and waste | Higher due to improved quality and faster delivery |

To successfully transition to advanced molding technologies, companies must consider several strategic and operational factors. Below is a checklist of best practices:

-

Conduct a Cost-Benefit Analysis:

- Assess the initial investment against long-term savings from decreased waste, faster turnaround times, and reduced labor costs.

- Factor in potential increases in market share due to higher quality products and customer satisfaction.

-

Invest in Staff Training:

- Ensure that production teams are well-versed in the latest CAD/CAM systems and automated machinery.

- Provide continuous training to keep up with evolving techniques in material science and mold design.

-

Pilot Production Runs:

- Begin with small-scale pilot runs to validate the performance of advanced molds in real production conditions.

- Gather data on production cycle times, product consistency, and overall efficiency to inform full-scale implementation.

-

Collaborate with Industry Leaders:

- Leverage partnerships with companies experienced in precision molding. For example, at NEX Padel, we collaborate with renowned brands to ensure our processes meet the highest standards.

- Utilize shared insights and best practices from leading industry players to optimize the transition process.

-

Implement Quality Monitoring Systems:

- Integrate automated inspection systems that can detect defects in real time.

- Use data analytics to continuously monitor process performance and make necessary adjustments quickly.

-

Plan for Scalability:

- Design the new molding system with future growth in mind. Modular, scalable machinery ensures that the production capacity can be increased without significant downtime or additional investments.

-

Maintain Transparent Communication with Stakeholders:

- Keep procurement managers and decision-makers informed about the benefits and performance metrics throughout the transition.

- Develop detailed reports and dashboards that showcase improvements in production efficiency, cost savings, and product quality.

Numerous case studies within the sports equipment manufacturing sector have shown that companies who upgrade their mold technology see dramatic improvements in both product quality and production efficiency. For instance, one leading manufacturer reported a 40% reduction in production cycle time and a 25% decrease in quality control issues after transitioning to precision molds. This not only improved customer satisfaction but also contributed significantly to their bottom line by ensuring a faster time-to-market for new product lines.

Data Insights:

- Cycle Time Reduction: Advanced molding techniques streamline the production process—allowing for faster output with the same or even lower resource usage.

- Quality Improvement: With precise dimensions and consistency, quality assurance becomes less labor-intensive and more reliable, decreasing the number of defective units.

- ROI Enhancement: Although the initial investment in modern molds is higher, the long-term ROI due to decreased operational costs and improved product performance justifies this upgrade.

Return on Investment Considerations:

When evaluating the ROI, decision-makers should consider not only the direct cost savings from more efficient production but also the strategic benefits of enhanced product reputation and customer loyalty in competitive markets.

Transitioning to advanced, precision-molded solutions is a strategic investment for padel racket manufacturers aiming to enhance their production capabilities. The benefits are multifaceted—ranging from improved product consistency and quality to faster production cycles and substantial savings in the long run.

Key takeaways include:

- The need for high-precision molds to ensure quality and consistency across all product lines.

- The value of customized design options that allow manufacturers to meet diverse customer requirements without compromising on speed or quality.

- The importance of integrated quality assurance systems to maintain rigorous production standards.

- Overall, moving to advanced molding technologies translates to a measurable increase in ROI, making it a critical investment for companies committed to competing at the highest levels in the industry.

For procurement managers and decision-makers, evaluating your current production processes against these industry benchmarks is essential. Consider conducting a pilot run or reaching out for a consultation to understand how advanced mold technology can be tailored to your production environment. By modernizing the production process with precision molds, companies can not only meet current market demands but also set a foundation for scalable growth and innovation in the competitive world of high-performance padel equipment.

People Also Ask

-

Do expensive padel rackets make a difference?

Yes, while more expensive rackets can offer enhanced performance features, they are not necessarily better for beginners or intermediate players. Expensive models often have smaller sweet spots and can be harder to maneuver, which may not suit all playing styles. -

What makes a padel racket better?

A padel racket's weight is a crucial factor in its performance. It affects power, speed, maneuverability, and comfort. Typically, a racket weighing between 340 and 375 grams strikes a balance, with a heavier racket offering more power for aggressive play. -

What to consider when buying a padel racket?

When choosing a padel racket, it is important to evaluate its shape for a comfortable fit, weight for balancing power and maneuverability, and balance to suit your playing style. Additionally, handle size and length, along with materials, directly impact performance and durability.

-

ROI: Learn about Return on Investment to understand how measuring efficiency gains and cost savings can justify capital expenditures in production technologies. ↩ ↩

-

precision-molded solutions: Discover how precision molding enhances manufacturing accuracy, reduces variability, and improves product durability through advanced production techniques. ↩ ↩

-

carbon fiber: Explore articles on carbon fiber materials, including differences between 3k, 12k, and 18k grades, and their impact on product performance and durability in high-performance equipment. ↩ ↩

-

CAD/CAM: Understand the role of computer-aided design and manufacturing (CAD/CAM) in achieving micrometer-level precision in mold production and how it streamlines the manufacturing process. ↩ ↩

-

Integrated Quality Assurance Systems: Read about integrated quality assurance systems that utilize in-line inspection and automated checkpoints to ensure consistent product quality and reduce defect rates. ↩ ↩