Proper storage and handling of padel rackets are essential to maintain performance, extend product longevity, and reduce costly returns. This article provides expert-backed guidelines to ensure your high-performance padel rackets remain in top condition, offering practical solutions that align with manufacturing standards and industry best practices.

Padel rackets, especially those crafted with advanced materials like carbon fiber1 and fiberglass, require careful handling and optimal storage conditions to preserve their structural integrity and performance. The performance of your padel rackets can degrade if they are mishandled or stored in inappropriate environments. Exposure to extreme temperatures, intense sunlight, and high humidity can damage the delicate internal structure and surface of the racket, leading to issues like warping, delamination2 or reduced rebound capacity.

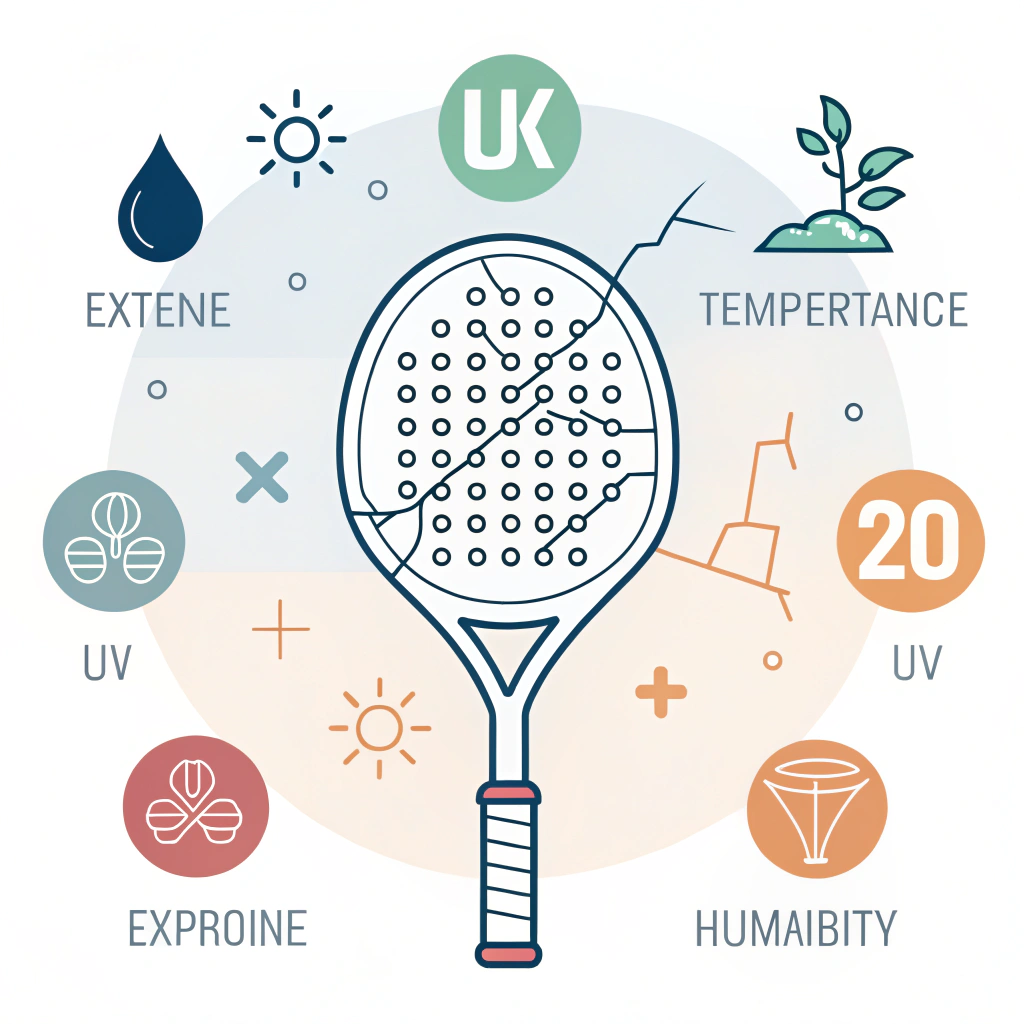

Key factors that affect racket quality include:

- Temperature Variations: Sudden changes in temperature can cause the materials to expand or contract, leading to deformation.

- Humidity Levels: Excess moisture can compromise the integrity of the materials, particularly in composite structures3.

- Sunlight Exposure: Direct sunlight can weaken the adhesive bonds and degrade surface finishes.

- Physical Impacts: Improper handling or accidental drops can cause micro-cracks or breakage in both the frame and the surface coating.

Understanding these risks is the first step in ensuring that your high-performance padel rackets are stored and handled properly to maintain their competitive edge.

To effectively address the challenges of maintaining racket quality over time, it is important to analyze why these issues occur. Often, the degradation stems from a combination of environmental and operational factors such as improper storage facilities, lack of standardized handling protocols, or failure to perform routine maintenance.

Environmental Factors:

- Temperature Extremes: Both high and low temperatures impact the composite material properties.

- Moisture and Humidity: Environments with high moisture content cause gradual deterioration of the racket’s surface and internal binding agents.

- **Ultraviolet (UV) Exposure4: Constant UV exposure can break down polymer resins in the racket's construction.

Operational Factors:

- Inadequate Cleaning: Dirt, sweat, and grime can accumulate on the racket, leading to degradation.

- Neglected Maintenance: Failure to inspect for minor damages after each game might lead to compounded issues later.

- Transport and Handling: Rough handling during transit or storage can significantly damage the structure.

It is crucial for equipment managers and procurement professionals to integrate these insights into their storage protocols to minimize downtime and maintain the high performance expected from high-quality padel rackets.

Given the significant factors that affect your padel rackets, the following step-by-step solutions will help ensure that your equipment remains in peak condition:

-

Maintain a Controlled Environment:

- Temperature: Store rackets in a climate-controlled area to avoid extremes. A range between 18°C and 24°C (64°F to 75°F) is optimal.

- Humidity: Keep the storage area dry with humidity controlled ideally between 40% and 60%.

- Sunlight and Heat: Avoid placing rackets in areas that receive direct sunlight or near sources of heat.

-

Use Protective Covers:

- After each use, allow the rackets to dry completely and wipe off any moisture with a soft, dry cloth.

- Invest in high-quality protective covers that cushion the racket during storage and transport.

-

Implement Routine Maintenance Checks:

- Schedule regular inspections for any signs of damage such as cracks, delamination, or discoloration.

- Clean the racket surfaces using a gentle cleaning solution to remove sweat and debris.

- Record maintenance activities to monitor racket conditions over time.

-

Establish Standard Handling Protocols:

- Train staff on proper handling guidelines to reduce accidental impacts.

- Use padded transport cases designed to absorb shocks and prevent physical damage during transit.

The following table summarizes the essential storage and handling guidelines:

| Factor | Best Practice | Notes |

|---|---|---|

| Temperature Control | Maintain between 18°C and 24°C | Avoid rapid temperature fluctuations |

| Humidity Management | Keep humidity at 40%-60% | Use dehumidifiers if necessary |

| Sunlight Exposure | Store in a shaded area | Prevent UV-induced material degradation |

| Drying/Gentle Cleaning | Dry rackets immediately after use and wipe with soft cloth | Avoid abrasive cleaning agents |

| Protective Storage | Use padded, dedicated storage cases or covers | Protect against physical and environmental damage |

| Routine Inspections | Regular visual and hands-on inspections | Address issues early to prevent further damage |

Consider a scenario where a padel club implemented a robust storage policy. The club maintained controlled storage rooms where temperature and humidity conditions were strictly regulated, and every padel racket was cleaned and checked after each game.

Results Noticed:

- Extended Racket Lifespan: Rackets lasted over 18 months with consistent performance improvements compared to a previous lifespan of just over a year.

- Reduced Maintenance Costs: Regular checks helped identify minor issues before they escalated into major repairs, significantly lowering repair and replacement costs.

- Improved Player Satisfaction: Players experienced consistent performance from rackets, leading to positive feedback and reduced product returns.

By following these practices, the club demonstrated how proactive equipment maintenance not only preserves product integrity but also enables cost-effectiveness in the long run.

While proper storage is crucial, handling plays an equally significant role in maximizing the lifespan of your padel rackets. Here are additional tips on handling that every sports equipment manager should consider:

- Avoid Sudden Forces: During use, ensure that rackets are not subjected to sudden or harsh impacts. Use appropriate techniques when swinging to avoid undue stress on the frame.

- Transport with Care: Use cases with sufficient padding when moving rackets from storage to courts. Avoid stacking rackets in ways that could cause pressure points.

- Educate End-Users: Hold training sessions for both players and staff to emphasize the importance of delicate handling and the proper techniques to avoid unnecessary strain on the equipment.

- Document Handling Procedures: Formalize the handling protocols in written guidelines. This not only helps new staff understand best practices but also ensures consistency across the organization.

At Nex Padel, we understand that every client has unique requirements. Our customization options extend beyond the design and build of the padel rackets to include specifications for handling accessories such as custom hand grips5 and handle covers. These protective additions are designed to complement the storage and care protocols by reducing the wear and tear on key contact points.

Customizable Features Include:

- Custom Hand Grips: Designed to reduce shock absorption and provide better grip, resulting in less impact on the racket frame.

- Logo Imprinting: For brand identity and added customization that underlines quality.

- Protective Cases: Engineered to meet specific organizational storage standards, ensuring your rackets are always stored in an optimal environment.

The ability to tailor these elements not only provides aesthetic value but also enhances the operational lifecycle of the rackets.

To summarize, the proper storage and handling of padel rackets are non-negotiable elements for ensuring product longevity and consistent performance. The guidelines we have covered include:

- Environmental Controls: Maintaining a controlled environment with stable temperature and humidity levels.

- Routine Maintenance and Inspections: Regular cleaning and inspection protocols to catch issues early.

- Protective Measures: Utilizing high-quality covers and padded cases to minimize physical damage.

- Education and Training: Ensuring staff and end-users understand the importance of proper handling techniques.

- Customization Opportunities: Leveraging custom components like hand grips and covers that further protect critical parts of the racket.

By adopting these strategies, equipment managers can significantly lower the risk of damage, reduce operational costs, and ultimately extend the life of their padel rackets. This proactive approach not only prevents performance issues but also provides confidence in the quality of the inventory.

Organizations seeking to optimize their inventory handling and extend the life of their products should integrate these guidelines into their standard operating procedures. Consider evaluating your current storage facilities and handling processes; small adjustments can yield significant long-term benefits for product durability and overall satisfaction.

Moving forward, we at Nex Padel are committed to supporting our partners with industry-leading products and expert guidance to ensure that your equipment performs at its best season after season.

-

How to store your padel racket?

Proper storage of your padel racket involves keeping it in a dry, temperature-controlled environment away from direct sunlight. It is important to avoid sudden temperature changes and to ensure the racket is completely dry after use before placing it in a protective cover. -

How to hold a padel racket properly?

Holding a padel racket properly involves maintaining a balanced grip, with the fingers comfortably wrapped around the handle. This not only ensures better control during play but also prevents undue strain on the racket frame, protecting it from damage over time. -

What is the shelf life of a padel racket?

The typical shelf life of a padel racket, especially for amateur play, is just over a year. With proper storage and handling, including regular maintenance and careful use, it is possible to extend this lifespan and retain performance close to the original state.

-

carbon fiber: Click here to learn about the advantages of advanced carbon fiber materials, including their lightweight and high-strength properties that benefit product performance and maintenance. ↩ ↩

-

delamination: Click here to explore the concept of delamination, which involves the separation of layers within composite materials, and understand its impact on structural integrity. ↩ ↩

-

composite structures: Click here to read about composite structures, the engineering behind combining multiple materials for superior performance, and best practices for handling them. ↩ ↩

-

Ultraviolet (UV) Exposure: Click here to discover how UV exposure can degrade materials, particularly polymers, and strategies to minimize its damaging effects on high-performance equipment. ↩ ↩

-

custom hand grips: Click here to delve into the benefits of custom hand grips, including improved user comfort and reduced equipment wear, which are vital for tailored B2B solutions in sports equipment. ↩ ↩