Quick Answer: Padel rackets differ from tennis rackets in several key ways: they have a solid, perforated structure without strings, use different materials and production techniques1, and follow distinct design and performance specifications.

For procurement managers, sports equipment distributors, and product designers, selecting the right racket technology for your target market involves a deep dive into design, materials, and performance elements. In today’s article, we explore the nuances of padel racket design compared to traditional tennis rackets. By understanding each product’s engineering and material composition, you can make informed decisions for product development, sourcing, and market positioning.

In the current sporting goods market, buyers often struggle with technology specifications. The challenge is not only in understanding the visual differences but also in grasping the underlying engineering principles behind each design. On one hand, padel rackets utilize a solid structure with a perforated surface and do not incorporate strings; on the other, tennis rackets feature a structured frame with inserted strings. This fundamental difference creates varied performance and safety parameters that must be clearly communicated to stakeholders.

Key issues for decision-makers include:

• Understanding material differences such as various grades of carbon fiber2 and fiberglass3.

• Recognizing how production techniques affect weight, durability, and overall performance.

• Distinguishing between product customization options from design to hand grip specifics.

An in-depth technical comparison is needed to simplify complex design aspects, ensuring that every procurement decision is backed by clear engineering insights.

Padel rackets are engineered differently from tennis rackets for several reasons:

- Solid Structure and Perforations: Unlike tennis rackets which have a network of strings, padel rackets are solid with strategically placed perforations. These holes help reduce air resistance and improve balance during play.

- Material Composition: Modern padel rackets are manufactured using a mix of high-tech materials—ranging from fiberglass for entry-level products to 3k, 12k, and 18k carbon fiber for high-performance models.

- Weight and Balance Considerations: The compact structure often results in a more evenly distributed weight, which is essential for fast reaction times on a smaller court.

- **Grip and customization4 Options: Manufacturers can offer higher levels of customization including logo engraving on hand grips and handle covers. This allows companies to distinguish themselves in competitive markets.

Tennis rackets, by contrast, emphasize string tension and frame design:

- String Network: The incorporation of strings in tennis rackets provides different play dynamics controlled by string tension. This flexibility allows adjustments that affect power and control.

- Frame Dimensions: Although tennis rackets may appear similar in overall size to padel rackets, the frame’s structure is optimized for the ball’s bounce and impact characteristics.

- Material and Production Techniques: Production techniques for tennis rackets prioritize string durability, shock absorption, and aerodynamics, which differ from the manufacturing priorities in padel rackets.

An important aspect for procurement managers is understanding how production techniques affect both performance and cost.

| Feature | Padel Rackets | Tennis Rackets |

|---|---|---|

| Main Materials | Fiberglass, 3k/12k/18k Carbon Fiber | Various alloys, composites, and sometimes carbon fiber |

| Production Techniques | Rapid prototyping with advanced molding techniques | Tensioning technology for strings, alloy shaping processes |

| Customization Options | Full customization for shape, printing, and grip design | Limited to string tension adjustments and grip customizations |

| Durability & Weight | Optimized for balance with a focus on impact resilience | Designed for a balance between power and string durability |

In padel rackets, the focus often lies on providing a uniformly distributed weight and enhancing durability via precision engineering. High-performance padel rackets use variants of carbon fiber which are manufactured for specific rigidity and flexibility profiles. This versatility allows these rackets to be tailored to different playing levels and styles.

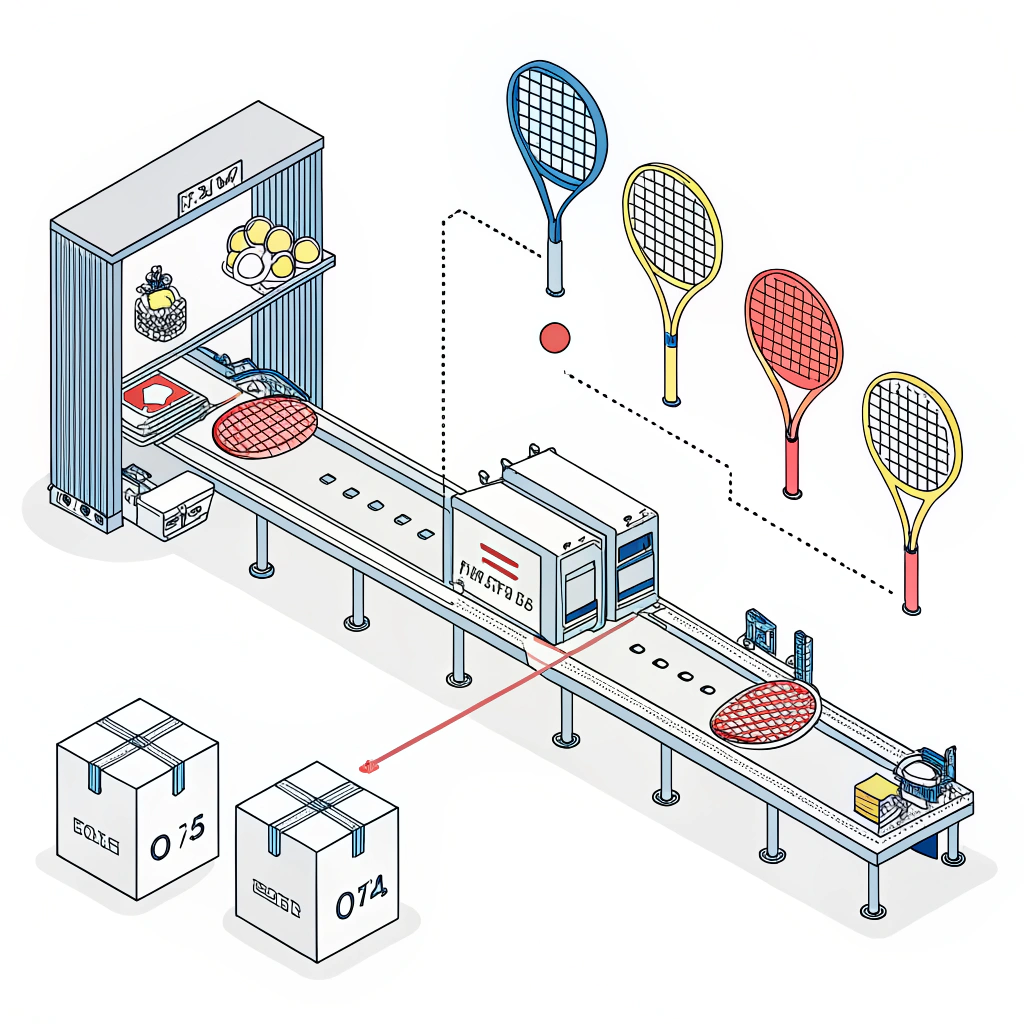

At NEX Padel, we use advanced production techniques to ensure that every paddle meets strict engineering standards:

-

- Rapid Prototyping5: Fast sampling and iterative testing allow us to refine racket designs efficiently.

- High-Precision Molding: This ensures uniformity in weight distribution and structural integrity.

- Customization Capabilities: From fully class-specific shapes like Diamond, Round, and Teardrop to custom prints and color schemes, our technology allows for wide-ranging adaptation based on client needs.

These techniques are essential to achieving the optimal balance between performance and durability. They also provide flexibility which is crucial in today's competitive sporting goods industry.

When evaluating rackets, performance metrics and user experience play a significant role:

- Padel Rackets: The consistent weight distribution enhances maneuverability, allowing players to react quickly during high-speed exchanges. The design, being solid, minimizes flexion, thereby increasing power consistency.

- Tennis Rackets: The tension of strings and the design of the frame allow for variations in power and precision. However, the lighter weight in some models might compromise stability under high impact conditions.

The hand grip design of a racket directly influences player performance. Padel rackets typically use the continental grip technique, making them accessible even for beginners while ensuring a strong foundation for all types of shots. In contrast, tennis rackets have evolved to accommodate more advanced grips that can be adjusted based on play style and preference.

Modern manufacturing offers extensive customization options:

- Customization for Brand Identity: Both padel and tennis products can be tailored with custom printing and color schemes.

- Technical Customization: Customizing the hand grip or handle covers with logos provides a unique selling proposition that can strengthen brand identity in a saturated market.

- Performance Customization: Adjustments in materials and design can lead to enhancements in racket performance. For example, changing the carbon fiber variant influences both the stiffness and vibration damping characteristics.

These options allow companies to better align their product specifications with market demand.

When sourcing sporting goods, total cost of ownership is a significant consideration among procurement managers. Below are several factors that contribute to the overall value of a padel racket compared to a tennis racket:

| Metric | Padel Racket | Tennis Racket |

|---|---|---|

| Production Cost | Generally lower due to simpler construction | Higher due to string technology and frame complexity |

| Customization Flexibility | High customization options can drive added value | Customization mainly around grip and tension adjustments |

| End-User Performance | Consistent power and durability for fast-paced rallies | Versatile performance adjustments for power and control |

| Durability & Maintenance | Lower maintenance, robust design | Requires regular maintenance and string tension checks |

| Production Lead Time | Shorter lead cycles with rapid prototyping | Often longer due to stringing processes and material variability |

Procurement managers must weigh these factors with respect to their target market’s needs. A shorter lead time and robust design may favor padel racket production, particularly for high-volume orders where production consistency is crucial.

To effectively assess and decide which technology suits your business needs, consider the following best practices:

- Technical Review: Conduct thorough testing on prototypes to observe performance under real game conditions.

- Material Analysis: Leverage material testing to ensure the efficiency of carbon fiber types (3k, 12k, 18k) and fiberglass for padel rackets.

- Customization Capabilities: Evaluate the extent of possible customization. The ability to adjust shape, grip, and visual design can translate into better market differentiation.

- Supplier Reliability: Check track records of manufacturers like NEX Padel, who emphasize quick sampling, advanced production techniques, and reliable delivery.

- User Feedback: Incorporate end-user feedback from diverse skill levels to balance technical precision with player comfort.

These practices ensure that your procurement decisions are based on quantitative performance metrics and qualitative user satisfaction.

Consider a sporting goods distributor that faced declining sales due to outdated equipment design. They decided to partner with a manufacturer specializing in advanced production techniques. Here’s how they benefitted:

- Material Upgrade: The switch to high-grade carbon fiber (12k/18k) improved product durability and performance.

- Enhanced Customization: The distributor started offering custom-printed designs and logo-engraved handle grips. This resulted in increased brand engagement.

- Reduced Lead Times: With rapid prototyping and quick sampling from the manufacturer, new product lines hit the market faster than competitors.

- Market Differentiation: The technical superiority and customization options offered a clear call to action for retailers and consumers alike, leading to improved market share.

This case highlights the importance of detailed specification reviews and leveraging cutting-edge production techniques to drive business growth.

In conclusion, understanding the nuanced differences between padel and tennis rackets can significantly influence procurement and production strategies. Padel rackets, with their solid design, material versatility, and high customization potential, present a unique value proposition for B2B buyers looking to blend performance with production efficiency. In contrast, tennis rackets, though familiar with a long-standing tradition and technical variations in string tension, require more maintenance and present longer lead times.

Key takeaways include:

- A detailed technical comparison helps isolate the performance factors critical to your market segment.

- Material selection and production techniques are key drivers of performance and durability.

- Customization options, including ergonomic design and branding features, can differentiate products in a competitive landscape.

- Evaluating cost, production lead times, and supplier reliability should be central to any procurement decision.

Procurement managers, distributors, and design engineers should integrate these insights into their decision-making process, ensuring that the chosen technology aligns with the desired market position and performance expectations. Ultimately, using the right balance of engineering insights and manufacturing expertise will lead to products that not only meet but exceed end-user expectations.

Q: What is the difference between a padel racket and a tennis racket?

A: Padel rackets are solid with perforations and do not have strings, whereas tennis rackets utilize a strung network. Additionally, padel balls are designed with lower internal pressure, giving them a different bounce compared to tennis balls.

Q: What is the difference between padel and real tennis?

A: Although both sports appear similar, padel balls are slightly less pressurized and do not bounce as high or fast as tennis balls. Moreover, padel rackets have a perforated design made typically of carbon fiber or fiberglass, unlike the strung frames of tennis rackets.

Q: Do you hold a padel racket like a tennis racket?

A: Yes, the basic grip used is the continental grip. This grip is similar to holding a hammer and is essential in providing a stable foundation for executing various shots in padel.

-

production techniques: Click to learn how various production methods impact manufacturing efficiency, product performance, and quality assurance in sporting goods. ↩

-

carbon fiber: Click to explore the different grades and properties of carbon fiber used in high-performance equipment, including benefits for strength and weight reduction. ↩

-

fiberglass: Click for insights into fiberglass applications in sports manufacturing, including durability aspects and cost-effective production methods. ↩

-

customization: Click to discover strategies for product customization that enhance brand differentiation and meet diverse market needs in today’s competitive B2B landscape. ↩

-

Rapid Prototyping: Click to understand how rapid prototyping accelerates design iteration and product development, thereby reducing lead times and production costs. ↩