Quick Answer: Carbon fiber1 enhances padel racket performance by offering increased stiffness, reduced weight, and superior energy transfer, enabling players to achieve better control and power. With options like 3k, 12k, and 18k carbon fiber2 manufacturers can tailor racket characteristics to meet specific performance and durability requirements.

In the highly competitive world of padel, choosing the right materials is key to delivering an edge in performance. Carbon fiber has emerged as a critical component in the design and manufacturing of high-performance padel rackets. This article explores the technical benefits of carbon fiber, its different gradations, and how advanced production techniques can optimize both performance and durability for various playing styles.

For product development managers and technical procurement specialists in the sports equipment industry, understanding the role of carbon fiber is essential to make informed design and supplier decisions. The core advantages of carbon fiber in padel rackets include:

- Increased Stiffness and Stability: Carbon fiber composites provide a stiffer frame, ensuring that energy is efficiently transferred from the racket to the ball.

- Lightweight Design: The intrinsic lightness of carbon fiber enhances maneuverability, reducing player fatigue during long matches.

- Enhanced Durability: Carbon fiber is resistant to wear and deformation over time, ensuring a longer lifecycle for the racket.

- Customized Performance Attributes: With variations such as 3k, 12k, and 18k carbon fiber, manufacturers can fine-tune balance, weight distribution, and control to suit specific player needs.

This combination of physical attributes leads to improved ball speed, better precision, and overall superior performance on the court.

One of the primary advantages of using carbon fiber in racket manufacturing is the ability to choose from different fiber types. Each type offers unique benefits:

| Fiber Type | Weave Count | Performance Impact | Ideal Application |

|---|---|---|---|

| 3k Carbon | 3000 filaments | Provides a balanced mix of strength and flexibility. Supports moderate energy transfer and shock absorption. | General performance, beginner to intermediate level rackets. |

| 12k Carbon | 12000 filaments | Delivers higher stiffness with enhanced energy transfer, making the racket more responsive. | Intermediate to advanced levels needing precise control and power. |

| 18k Carbon | 18000 filaments | Maximizes stiffness and durability, ideal for aggressive play styles that require maximum power and minimal deformation under stress. | High-performance and professional-level rackets designed for power players. |

This table highlights the trade-offs between stiffness, durability, and flexibility—factors that are crucial when specifying a padel racket for different market segments. By selecting the appropriate carbon fiber type, suppliers can tailor equipment to meet the varied demands of players and overall market trends.

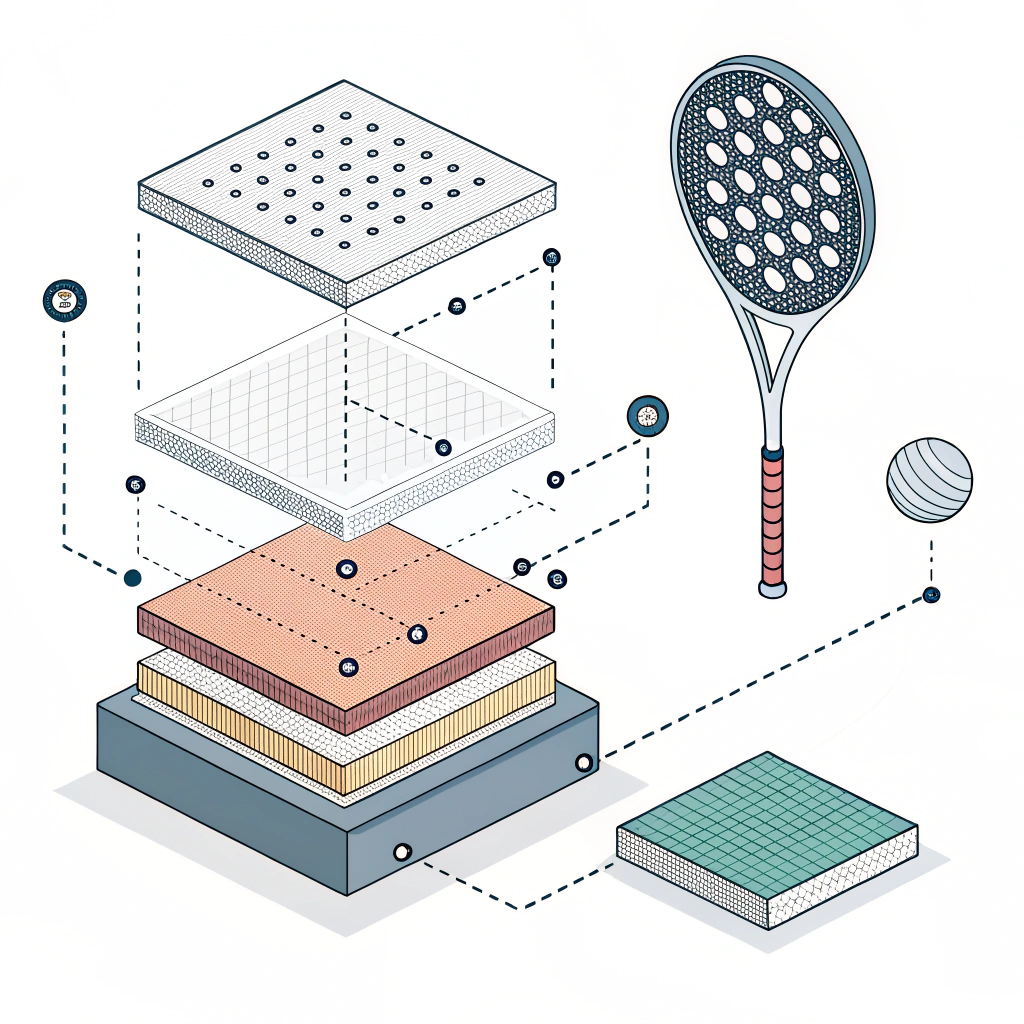

The incorporation of carbon fiber in racket manufacturing is not simply a matter of material substitution; it involves a high degree of precision in production processes. The key manufacturing techniques include:

-

- Composite Layering4: Multiple layers of carbon fiber are strategically laid up with resin to form a composite structure. Variations in lay-up allow for customized stiffness and flexibility zones within the racket.

-

- Precision Curing5: Using autoclave curing processes ensures that the resin fully permeates the carbon fiber layers, resulting in a solid bond that enhances durability and performance.

- Customized Molding: Advanced molding techniques adapt the racket shape to suit different playing styles. From the overall geometry to the handle design, precision molds enable complete customization.

- Quality Assurance & Testing: Rigorous testing regimens—covering flex, impact resistance, and longevity—ensure that each racket meets stringent performance criteria before reaching the market.

It is through these modern production techniques that manufacturers such as NEX Padel are able to provide products with high reliability. This level of process control is vital for producing rackets that not only meet but exceed performance expectations.

One of the main concerns for B2B procurement in the sports equipment market is the ability to customize products according to both performance criteria and brand identity. With carbon fiber, customization is not limited to the structural performance of the racket; it extends to aesthetic and ergonomic characteristics as well.

- Shape and Design Customization: Manufacturers offer three core racket shapes—Diamond, Round, and Teardrop—to accommodate various playing styles. Full customization is available to adjust balance, weight distribution, and even the curvature of the racket face.

- Logo and Color Customization: Beyond performance, companies often seek to enhance brand recognition. Custom printing on the racket surface, along with customizable hand grips and handle covers, ensures that each product reflects the brand’s image vividly.

- Optimizing Fiber Orientation: The orientation of carbon fiber layers can be adjusted to control stiffness and damping characteristics. This allows the design to be fine-tuned for specific energy transfer mechanisms, resulting in a racket that is responsive under power shots while maintaining adequate control for delicate plays.

This extensive level of customization sets high-performance brands apart in a crowded marketplace, allowing them to match specific consumer expectations with technical innovation.

While carbon fiber offers numerous benefits, its adoption in racket manufacturing comes with some challenges and limitations that need to be addressed:

- Cost Implications: Carbon fiber materials, especially higher-grade options like 18k carbon, are more expensive than traditional materials such as fiberglass. This has implications not only for the retail price but also for production costs at scale.

- Manufacturing Complexity: Working with carbon fiber requires sophisticated manufacturing technologies and high levels of skill. This is particularly important when ensuring consistency and quality control in customized production runs.

- Material Handling and Waste: The production process generates waste composite materials that must be handled responsibly. Innovations in recycling and waste management are ongoing but remain a critical factor for environmentally conscious companies.

- Performance Trade-offs: Although stiffer rackets provide better energy transfer, they can sometimes compromise on shock absorption and comfort. Engineers must balance these competing factors to deliver products that cater to a wide range of needs without sacrificing player comfort.

Addressing these challenges requires a deep understanding of both material science and advanced manufacturing processes. Companies that invest in research and development can turn these challenges into competitive advantages by offering innovative, high-performance products.

NEX Padel has successfully leveraged advanced carbon fiber technologies to produce rackets for several internationally recognized brands such as Hirostar, Reebok, and Starvie. Their approach includes:

- Rapid Prototyping and Sampling: By utilizing fast-turnaround design and testing methods, NEX Padel ensures that market feedback is incorporated quickly into product improvements.

- Performance Testing Protocols: Each prototype undergoes rigorous testing that involves real-world performance analysis, ensuring that the final product achieves the desired balance between speed, control, and durability.

- Continuous Improvement Based on Data: By tracking key performance indicators such as vibration damping, energy transfer efficiency, and impact resistance, the R&D teams refine the laminate structures and resin formulations to optimize racket performance.

Data from performance testing indicate that for professional players, a racket with 18k carbon fiber can reduce energy loss during impact by up to 15% compared to traditional fiberglass counterparts. Such improvements translate to better shot precision and reduced player fatigue, ultimately enhancing overall competitive performance.

For product development managers and technical procurement specialists evaluating high-performance padel rackets, consider the following recommendations:

- Assess Performance Requirements: Determine the key performance attributes required for your target customer base, whether it is enhanced control, increased power, or greater durability.

- Select the Appropriate Carbon Fiber Grade: Analyze the trade-offs among 3k, 12k, and 18k carbon fiber to match the specific needs of your product line. Use detailed performance comparisons and production cost analyses to inform your choice.

- Focus on Customization Potential: Seek suppliers who offer extensive customization options including shape, weight distribution, and branding enhancements. This flexibility is critical in differentiating your product in a competitive market.

- Evaluate Production Capabilities: Partner with manufacturers that have a proven track record of utilizing advanced manufacturing techniques such as precision curing and composite layering to ensure consistent product quality.

- Monitor Market Trends and Innovations: Stay updated on industry trends and emerging technologies in composite materials to continuously improve product offerings. Attending industry trade shows and technical seminars can provide valuable insights into advancements in material science and production techniques.

By following these recommendations, procurement specialists can not only improve the overall quality and performance of their padel rackets but also align their offerings with the latest trends in sports technology.

The integration of carbon fiber into padel rackets represents a significant advancement in sports equipment technology. The benefits—ranging from enhanced stiffness and lightweight design to superior durability and customization—make carbon fiber an ideal choice for high-performance rackets. Despite its higher manufacturing cost and complex production process, the performance benefits and potential for customization provide a compelling value proposition for both manufacturers and end-users.

Companies like NEX Padel have demonstrated that by investing in advanced production techniques and quality assurance practices, it is possible to deliver products that meet the highest performance standards while also catering to distinct brand identities. As the market for padel continues to grow, understanding these technical nuances will help procurement managers and product developers make informed, strategic decisions.

By leveraging data-driven insights and staying abreast of the latest material innovations, businesses can secure a competitive advantage in the dynamic world of high-performance padel equipment.

-

How does carbon fiber enhance padel racket performance?

Carbon fiber improves padel racket performance by providing increased stiffness for better energy transfer, reducing weight for increased maneuverability, and enhancing durability through advanced composite construction. This makes the racket more responsive and long-lasting, which is crucial for competitive play. -

What distinguishes 3k, 12k, and 18k carbon fiber in racket manufacturing?

The distinction lies in the filament count and its effect on mechanical properties. 3k carbon offers a balance of strength and flexibility, 12k carbon increases stiffness and energy transfer, while 18k carbon fiber maximizes stiffness and durability for high-impact play. Each grade can be selected to suit different player requirements and performance targets. -

Can custom carbon fiber designs improve racket durability and control?

Yes, custom carbon fiber designs allow manufacturers to tailor the orientation and layering of the fibers, thereby optimizing both durability and control. By adjusting the composite structure, designers can achieve precise stiffness and damping characteristics that enhance overall racket performance while allowing for brand-specific aesthetic customizations.

-

Carbon fiber: Read this article to understand how carbon fiber's unique blend of strength and lightweight properties contributes to improved sports equipment performance and design optimization. ↩

-

18k carbon fiber: Click here to explore detailed insights into high filament count carbon fiber types and how they maximize stiffness and durability in competitive sports gear. ↩

-

Advanced Production Techniques: Read about innovative production methods that integrate composite layering, precision curing, and customized molding to consistently deliver high-quality, performance-driven products. ↩

-

Composite Layering: Learn about the process of layering carbon fiber with resin to create composites with tailored stiffness and flexibility, crucial for high-performance equipment manufacturing. ↩

-

Precision Curing: Discover how precision curing techniques, including autoclave processes, enhance the resin infiltration in carbon fiber layers for durable and reliable composite structures. ↩