Quick answer: For procurement teams vetting an OEM/ODM for padel rackets, require a standard set of mechanical, material, environmental and playability tests with defined acceptance criteria, sample sizes and traceable reports. These tests—covering impact resistance, durability, stiffness (flexural modulus1), balance & swing weight, material inspection and adhesive bond—reduce warranty risk, speed product qualification and make commercial comparisons measurable.

Why this matters (problem description)

Many sports brands shortlist manufacturers based on price and lead time, but insufficient technical requirements during supplier evaluation increases post-launch returns, performance complaints and reputational risk. Procurement and product managers need a clear, actionable testing protocol that ties lab results to on-court performance and to business metrics (warranty exposure, return rate, and time-to-market).

Key root causes of supplier risk

- Inconsistent raw materials: varying carbon/fiberglass layups and resin batches change stiffness and durability.

- Weak or undocumented QC: missing batch traceability and incomplete test records.

- Inadequate environmental testing: products pass room-temperature checks but fail after humidity/thermal cycles.

- Lack of playability validation: lab results don’t correlate to on-court play tests, leaving brands surprised by user feedback.

Recommended testing program (solution checklist)

Below is a concise list of tests every buyer should require from an OEM/ODM. For clarity the Purpose, Method, Typical acceptance, and Why it matters are shown.

| Test (priority) | Purpose | Method / Standard | Typical acceptance criteria (examples) | Why it matters |

|---|---|---|---|---|

| Impact / Shock resistance | Ensure racket withstands ball/edge impacts | Drop tests & pendulum impact; recorded peak force & dent depth | No structural crack; dent < X mm; force attenuation within spec | Prevents sudden failure in match play |

| Durability (fatigue) | Long-term resistance to repeated impacts | Repeated ball-strike cycles (e.g., 50k–200k cycles) | No delamination; <2% stiffness change | Relates to returns & warranty costs |

| Stiffness / Flexural modulus | Controls power and feel | 3-point bending, DMA (DMA (dynamic mechanical analysis2)) | +/- allowed range by model (e.g., 18k carbon target ±8%) | Drives power/comfort; must match spec |

| Balance & swing weight | Player feel and handling | Static balance measurement; swing weight analyzer | Balance within ±5 mm; SW within ±3% of spec | Directly maps to on-court handling expectations |

| Vibration analysis | Comfort and shock transfer | Accelerometer on impact, frequency response | RMS vibration below threshold; damping characteristics | Impacts perceived comfort and injury risk |

| Material inspection | Verify fiber/resin content & layup | FTIR, microscopy, mass/area, tensile tests | Fiber content matches spec; no voids >X% | Ensures repeatability and performance |

| Adhesive/bond testing | Verify shell-core lamination | Peel tests, shear strength | Bond strength > specified N/mm | Prevents delamination during play |

| Thermal & humidity cycling | Environmental durability | Cycling (e.g., -10°C to +60°C) & 95% RH exposures | No cracking/delamination; mechanical properties within tolerance | Simulates shipping/storage extremes |

| Playability validation | Correlate lab to court | Blind on-court panel tests, instrumented strikes | Player acceptance score; consistent ball rebound/feel | Final proof of product-market fit |

| Batch traceability & chemical compliance | Supply chain safety & recalls | Raw material certificates, batch IDs, RoHS/REACH checks | Full traceability; compliance certificates | Lowers regulatory & recall risk |

Detailed explanation of core tests and how to interpret results

- Impact resistance

- What it measures: structural integrity after a concentrated strike.

- How vendors run it: controlled pendulum or drop-hammer tests at defined energy levels (Joules). Record permanent deformation, surface cracking, and internal delamination via ultrasonic C-scan3.

- What to require: a defined energy per model type and an acceptance report with before/after C-scan images and dent depth measurements.

- Durability / fatigue testing

- What it measures: ability to endure repetitive strikes without failure.

- Method: actuator or robot that applies strike cycles at controlled intervals and forces; periodic inspections for delamination and stiffness change.

- Procurement spec: minimum cycle count tied to expected lifetime (e.g., 50k cycles for entry models, 150k for premium). Require log of cycle counts, failures, and a sample retention plan.

- Stiffness and flexural modulus

- What it measures: material flex under load, correlates to power and comfort.

- How to specify: target modulus for each model. Ask for both static (3-point bend) and dynamic (DMA) numbers, with tests performed at multiple temperatures (e.g., 20°C and 40°C).

- Balance & swing weight

- How to measure: static balance (distance from handle to center of mass) and moment of inertia (swing weight). Both affect player choice—procurement should set acceptable bands per SKU.

- Require batch reports showing mean and standard deviation across sampled units.

- Playability validation

- Combine instrumented lab tests (ball rebound speed, sweet spot response) with blinded player panels. Require the manufacturer to run these tests and provide normalized scores against a brand reference.

Factory QA workflow and traceability you should insist on

A supplier’s test capability is only useful when integrated with QC processes. Require this flow:

- Incoming inspection (IQC)

- Raw material certificates (carbon/fiberglass batch IDs, resin lot).

- Physical checks: grammage, weave orientation, resin content.

- In-line process control

- Temperature/humidity logs for curing.

- Adhesive pot-life records.

- Operator shift logs and machine calibration records.

- End-of-line (FQC)

- Visual, balance, weight, and initial impact checks on every unit.

- Statistical sampling for destructive tests (impact, peel, fatigue).

- Laboratory testing and batch release

- Destructive tests on representative samples per batch.

- Test reports indexed to production lot numbers and stored digitally.

- Retention and warranty support

- Retain samples for X months and provide full test datasets for warranty claims.

You should require defined sample sizes and acceptance rules based on batch size. Example sampling table:

| Batch size | Non‑destructive sampling | Destructive samples |

|---|---|---|

| 1–200 | 5% or min 5 | 1–2 |

| 201–1000 | 3% | 3–5 |

| >1000 | 1–2% | 5–10 |

Ask for SPC4 (statistical process control) charts, Cpk5 values for critical metrics, and digital traceability linking each pallet to raw material lots.

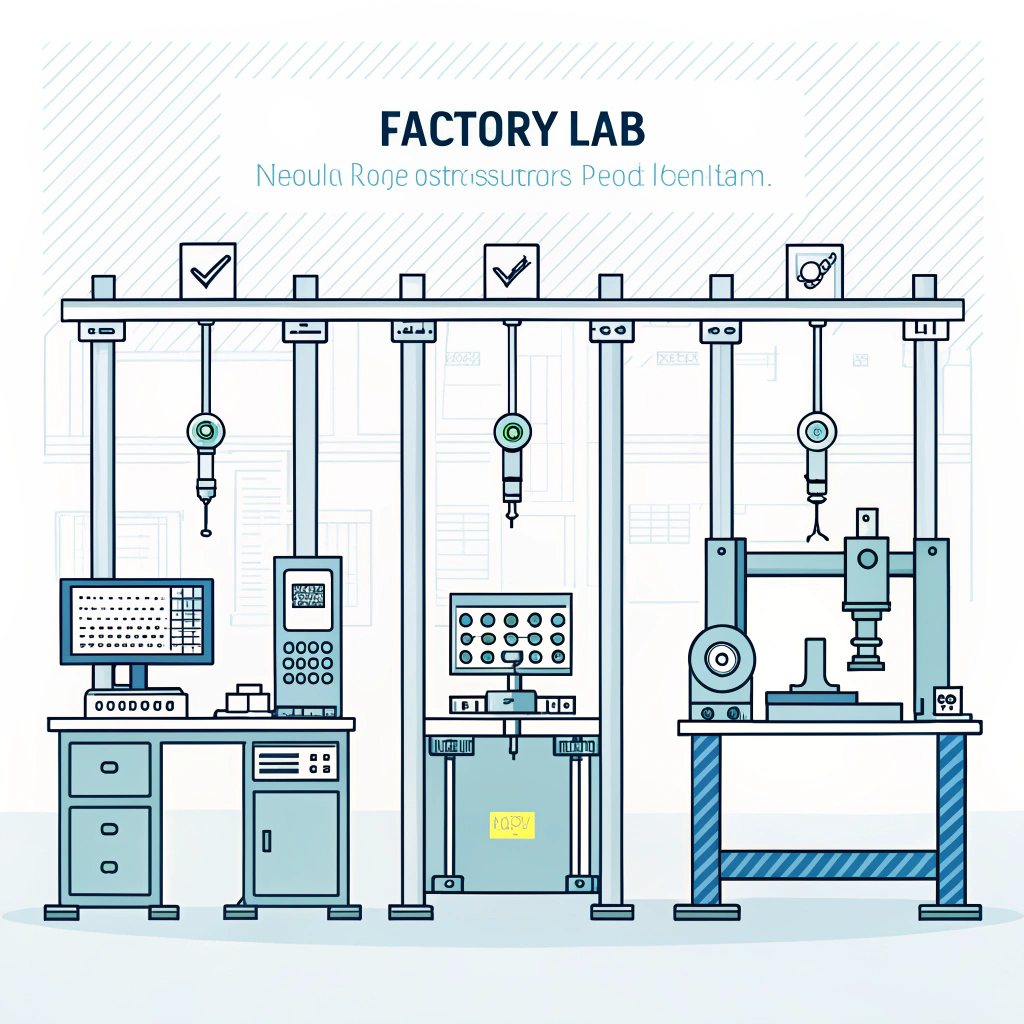

What equipment and lab capabilities reputable OEMs should have

Minimum in-factory equipment to verify claims:

- Drop hammer / pendulum impact rig

- 3-point bending rig and DMA

- Swing weight analyzer and precision scales

- Accelerometers and FFT analyzers for vibration

- Ultrasonic C-scan or X-ray for internal delamination

- Environmental chambers for thermal & humidity cycling

- Tensile testers for adhesive/peel strength

- Microscopy and FTIR for material confirmation

- Robot/actuator for fatigue testing

- On-court instrumented testing setup (radar, ball speed measurement)

When evaluating suppliers, request evidence of calibration records, method SOPs, and recent test reports tied to a product SKU.

Cost, timeline and commercial implications

- Time-to-market: A basic qualification campaign (material checks + lab tests + small player panel) typically takes 3–6 weeks if the factory has ready labs; adding extensive fatigue or environmental cycles can add 2–6 weeks.

- Cost: Expect an incremental lab qualification cost per SKU (testing + destructive samples) — ranges vary widely; budget a few hundred to a few thousand USD depending on test scope. Factor this into landed cost rather than treating it as discretionary.

- Warranty & returns: Investing in upfront testing reduces returns and warranty claims. Quantify potential savings: a 1% reduction in returns on a SKU with 50k units/year at $60 ASP equals significant savings.

- MOQ and sampling: Larger MOQs require larger destructive sampling; negotiate a balance between acceptable risk and cost.

Acceptance criteria examples you can copy into RFQs

- Impact: No structural cracks and max dent <= 2 mm after a 60 J impact for midweight models.

- Fatigue: No delamination and <5% change in flexural modulus after 100k cycles.

- Balance: Center of mass within ±5 mm of declared value.

- Bond strength: Peel strength > 8 N/mm.

- Environmental: No visual defects and mechanical properties within ±8% after 5 cycles of -10°C/60°C and 95% RH for 72 hours each.

How to structure supplier qualification in procurement

- RFQ stage: Include required tests, sample sizes, acceptance limits, and request historical lab reports.

- Shortlist: Require photos of labs, equipment lists, calibration certificates and recent third-party audit reports.

- Pilot run: Produce 100–500 units, run full lab tests, and execute blind player panel.

- Approve: Only accept factories that pass both lab and on-court tests and provide a digital traceability system.

- Continuous monitoring: Periodic batch testing and yearly audits.

Why NEX Padel’s capabilities reduce your risk (factual)

NEX Padel is a manufacturer based in Jiaxing, Zhejiang with experience producing for brands such as Hirostar, Reebok and Starvie. We work with raw materials ranging from fiberglass to 3k, 12k and 18k carbon fiber, and support Diamond, Round and Teardrop shapes plus full custom tooling. Our in-house QA integrates material inspection, mechanical testing and playability checks, and we run batch traceability protocols to link each production run to raw material lots. We also manage padel ball supply with controlled wool blends and pressurized tube packaging, ensuring consistent quality for bundled products.

Practical next steps for procurement teams (action checklist)

- Add a mandatory testing annex to RFQs with specific test methods and acceptance criteria.

- Require lab photos, equipment lists, and calibration records during technical due diligence.

- Negotiate pilot-run testing timelines and costs upfront.

- Request digital batch traceability and retention of failed samples for 12 months.

- Insist on a combined lab + blind player panel validation before full production approval.

People Also Ask

Q: How to tell if a padel racket is good?

A: A good padel racket matches its declared weight, balance, and stiffness to the player profile; shows consistent build quality (no delamination or voids), passes basic impact and durability checks, and scores well in blind playability tests for control and power. For brands, insist on lab reports for impact, stiffness and maternal inspection plus a player validation step.

Q: Do expensive padel rackets make a difference?

A: Price often reflects materials, manufacturing precision and testing. Expensive rackets can offer better carbon layups, tighter tolerance on balance/swing weight and superior durability. However, price alone is not a guarantee; verify test data showing improved stiffness consistency, lower defect rates and better fatigue life to justify higher cost.

Q: What makes a padel racket better?

A: Technical factors include optimized weight distribution, appropriate stiffness for the target player, confirmed impact resistance, and quality of layup and bonding. These factors should be backed by measurable test results (flexural modulus, impact energy tolerance, swing weight) and validated by on-court player feedback.

-

Flexural modulus: Read to understand how flexural modulus is measured (3-point bend, DMA), how it ties to player feel and power, and how to set acceptance ranges and reporting formats for procurement. ↩

-

Dynamic mechanical analysis (DMA): Read to learn how DMA reports temperature-dependent viscoelastic properties, what test parameters matter (frequency, temperature sweep), and how DMA complements static bending numbers. ↩

-

C-scan: Read to learn how ultrasonic C-scan imaging detects internal delamination/voids, how to interpret before/after scans, and what image evidence to require in test reports. ↩

-

SPC (statistical process control): Read to learn how SPC charts (X̄, R, p-charts) monitor production variation, detect shifts, and support sampling plans and corrective actions during supplier monitoring. ↩

-

Cpk: Read to understand process capability indices (Cpk), how to calculate them against spec limits, and how Cpk thresholds map to acceptable supplier risk and sampling intensity. ↩