Advanced manufacturing techniques and design innovations revolutionize the way padel rackets are developed. In this article, we explore advanced production processes, material optimization—including the use of carbon fiber1 variants—and design customization that collectively drive enhanced performance, production efficiency, and market competitiveness for padel equipment. NEX Padel leads the way with state-of-the-art solutions that satisfy the demands of technical procurement managers, R&D engineers, and decision-makers in the sports equipment industry.

The padel industry is rapidly evolving, and competition has pushed manufacturers to adopt cutting-edge technologies. Technical procurement managers and R&D engineers are facing multiple challenges, which include:

- Balancing innovation with production efficiency while maintaining high quality.

- Integrating diverse materials such as fiberglass, 3k, 12k, and 18k carbon fiber to achieve both durability and performance.

- Customizing design features like Diamond, Round, and Teardrop shapes, along with bespoke logo printing and accessory personalization.

A significant challenge is to ensure a seamless production process that meets international standards without compromising on design flexibility. This challenge becomes increasingly complex when decisions involve scaling production while preserving the integrity of advanced materials and novel racket shapes.

Several factors contribute to the challenges seen in padel racket manufacturing:

-

Material Complexity:

The integration of advanced composites such as carbon fiber and fiberglass often requires precise calibration of production variables. Depending on the weave (3k, 12k, 18k), each material demands unique curing processes, pressure control, and precision in mold design. -

Design Customization Requirements:

Customers and brands now require highly customized designs including varied shapes (Diamond, Round, Teardrop) and personalization options like glove grip branding and handle covers. Each customization increases production variability and complexity, requiring agile prototyping and flexible tooling. -

Quality Assurance and Rapid Prototyping:

Custom orders and rapid prototyping put pressure on quality control measures. A robust quality assurance system is vital to ensure that every product not only meets safety regulations but also performs at a high competitive level in real-world usage. -

Integration of Advanced Production Techniques:

Modern manufacturing processes such as resin infusion2, vacuum consolidation3, and digital simulation4 demand significant investments in both technology and workforce training. Such investment requires a clear demonstration of improved performance or cost reduction to justify changes in long-established production lines.

To address these challenges, the implementation of advanced production techniques and design innovations is essential. At NEX Padel, a comprehensive strategy that spans material selection, production processes, and design optimization is deployed. Below is a detailed comparison of our approach and the resulting solutions:

| Aspect | Traditional Methods | Advanced Techniques at NEX Padel |

|---|---|---|

| Material Integration | Uniform material application with less precision control. | Utilizes varied grades of carbon fiber and fiberglass with precise calibration to optimize strength and weight. |

| Design Flexibility | Limited shape variations, standard designs. | Offers fully customizable shapes (Diamond, Round, Teardrop) to meet bespoke customer needs, with options for custom prints and logos. |

| Prototyping Speed | Lengthy cycle times due to manual adjustments. | Rapid prototyping using digital simulation4 coupled with automated tooling, allowing faster iterations and adjustments. |

| Quality Control | Traditional quality checks relying on human inspection. | Integrated Quality Control Systems with automated testing, ensuring consistency and compliance with international standards. |

| Production Scalability | Limited scalability without significant retooling. | Agile production lines that adapt quickly to different product specifications and order volumes without compromising quality. |

This table highlights how modern manufacturing approaches not only solve existing challenges but also provide a competitive edge in terms of design innovation and operational efficiency.

When evaluating and adopting advanced manufacturing techniques in padel racket production, several best practices and critical considerations should be taken into account:

-

Quality Over Quantity:

It is essential to choose materials that match the performance requirements. For instance, carbon fiber grades like 12k and 18k offer superior stiffness and strength properties, while fiberglass may be favored in applications where cost efficiency is key. -

Temperature and Pressure Control:

Advanced production processes such as resin infusion demand accurate control over curing conditions. Employing digital sensors and real-time monitoring ensures consistency across batches.

-

Customizable Molds:

To allow production of varying shapes and designs, investment in modular and reconfigurable molds is crucial. This flexibility helps in rapidly transitioning between styles like Diamond, Round, and Teardrop. -

Prototype Testing:

Leveraging digital simulation alongside physical prototypes helps in rapidly validating design changes. This dual approach minimizes the risk of post-production quality issues.

-

Integration of Digital Simulation:

Prior to physical production, simulation can help identify potential weak points in design. It assists in optimizing material thickness and distribution, ultimately ensuring product durability and competitive performance. -

Automated Production Line:

Adopting industrial automation reduces cycle times and human error, enhancing both the throughput and reproducibility of high-quality outcomes. Furthermore, a robust automation process supports scalability for large volume orders.

-

Statistical Process Control (SPC)5:

Implementing SPC techniques throughout the production chain ensures continuous monitoring and prompt remediation of any inconsistencies. -

Certifications and Industry Standards:

Meeting ISO certifications and adhering to regulatory guidelines not only assures quality but also builds buyer confidence. Regular audits and standardized testing are critical components of a reliable quality assurance framework.

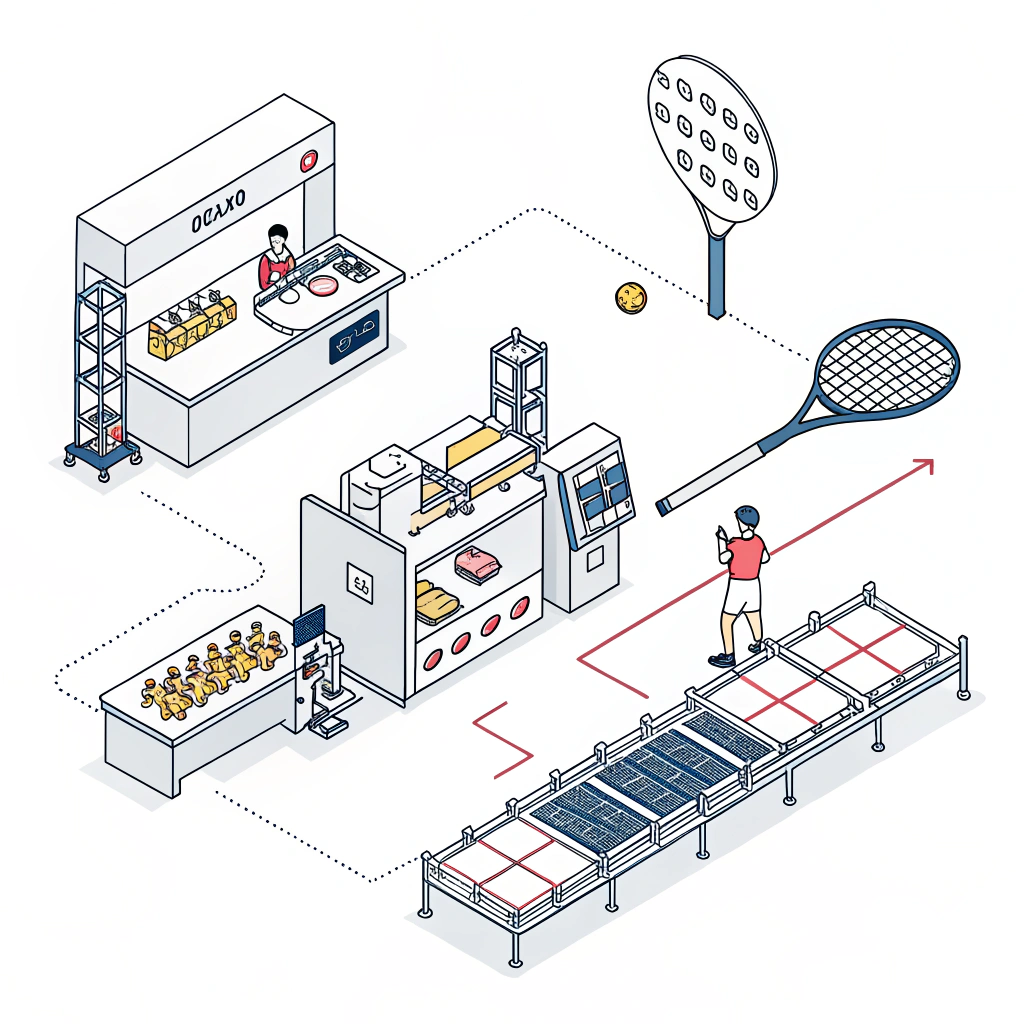

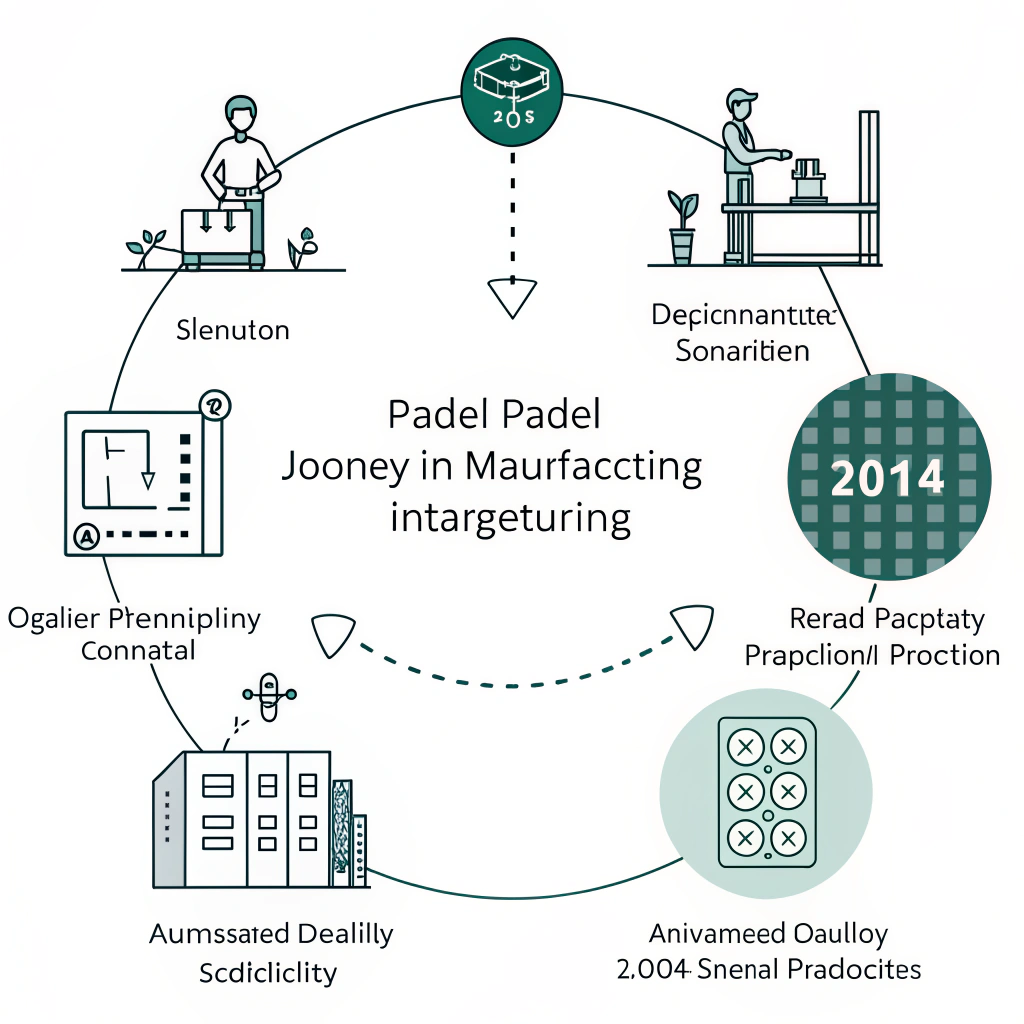

NEX Padel has successfully navigated the challenges of modern padel racket manufacturing by implementing these advanced techniques. Several key milestones in our journey include:

-

Material Integration Breakthroughs:

By adopting a diversified approach in material selection—from fiberglass to multiple grades of carbon fiber—we achieved a balance between traditional manufacturing strengths and innovative performance enhancements. This allowed us to tailor each racket to its intended purpose, ensuring optimal play performance. -

Revolutionized Prototyping Process:

Utilizing digital simulation tools alongside rapid prototyping, NEX Padel reduced development cycles by nearly 30%. This boost in speed not only satisfies fast-paced market demands but also provides customers with a clear demonstration of our commitment to quality and innovation. -

Adoption of Automated Production Lines:

Introducing automation in several stages, including material layup and quality checks, enhanced reproducibility and minimized human error. This approach led to production scalability, ensuring that even large orders with intricate customization requests are fulfilled with consistent quality. -

Comprehensive Quality Assurance:

Our rigorous quality control processes ensured compliance with international standards. Constant real-time monitoring and data analysis allowed us to quickly identify and adjust production parameters, maintaining the highest product standards.

The transformation at NEX Padel exemplifies an efficient and innovative production environment, where the integration of advanced manufacturing techniques drives overall quality, speed, and customization. This case study stands as evidence that when the right blend of technology and experience is applied, the results greatly benefit product performance and market success.

For procurement managers and R&D engineers looking to replicate or collaborate in similar technological advancements, consider the following actionable recommendations:

-

Invest in Training and Technology:

Equip your production teams with the latest digital tools and training on modern manufacturing techniques. This not only speeds up prototyping but also enhances overall quality control. -

Collaborate with Experts:

Engage with partners who have expertise in cutting-edge manufacturing processes. Collaborations can significantly reduce the learning curve, streamline integration, and share best practices across the industry. -

Adopt a Flexible Production Strategy:

Implementing agile methodologies in production planning ensures that scaling up for large orders or switching to custom designs does not halt efficiency. A flexible production strategy allows rapid adaptation to market trends and customer needs. -

Implement Advanced Quality Control Systems:

Utilize automation and real-time monitoring tools to maintain consistent checks throughout the production cycle. This is critical for safeguarding the durability and performance of each padel racket. -

Monitor Industry Trends and Data:

Stay updated on the latest trends in materials science, production technology, and design innovations. Regularly review industry standards and incorporate data-driven insights into your process upgrades.

By implementing these recommendations, procurement teams and manufacturers can not only achieve superior product performance but also secure a competitive advantage in the evolving padel industry.

Modern padel racket manufacturing requires a blend of precision, innovation, and agility. The strategic integration of advanced materials, rapid prototyping, and digital production controls are key factors driving improvements in quality, design, and efficiency. Manufacturers who invest in these advanced techniques stand to benefit from greater product customization, enhanced durability, and scalable production processes.

At NEX Padel, our experience in utilizing these cutting-edge methods has led to consistent industry-leading performance, fulfilling the stringent demands of global sports equipment markets. As technical procurement managers and R&D engineers evaluate new production technologies, we encourage further collaboration and consultation to explore tailored solutions for your brand's needs.

For more detailed insights and a personal consultation on how advanced manufacturing techniques can transform your padel racket production, please contact us.

Q1: What advanced manufacturing techniques are used in padel racket production?

A1: Advanced manufacturing in padel rackets involves the integration of high-performance carbon fiber and fiberglass, digital simulation for rapid prototyping, automated production lines, and precise quality control measures, all designed to improve durability and performance while allowing for custom designs.

Q2: How does NEX Padel ensure consistent quality in production?

A2: NEX Padel uses rigorous quality assurance practices including automated quality control, statistical process control, and constant monitoring of curing and production processes. This integrated approach assures each padel racket complies with international quality standards and delivers reliable performance.

Q3: What are the benefits of customizable padel racket designs?

A3: Customizable designs enable brands to create unique products that meet specific performance and aesthetic needs. Options such as shape variations (Diamond, Round, Teardrop) and personalized logo printing enhance market differentiation while maintaining high performance and durability.

-

carbon fiber: Reading this article will help you understand the material science behind carbon fiber composites, their performance benefits, and how they are integrated into modern manufacturing for high-end sports equipment. ↩ ↩

-

resin infusion: Discover how resin infusion techniques optimize material bonding and enhance the durability of composite structures, ensuring consistent product quality in advanced production environments. ↩ ↩

-

vacuum consolidation: Learn how vacuum consolidation is used to improve layer integration and minimize voids within composite materials, resulting in stronger and more reliable products. ↩ ↩

-

digital simulation: Understand the role of digital simulation in accelerating prototyping and optimizing design parameters, which contributes to faster and more efficient production cycles. ↩ ↩ ↩2

-

Statistical Process Control (SPC): Explore the fundamentals of SPC and how it is implemented in manufacturing to continuously monitor and improve product quality through data-driven insights. ↩ ↩