In short: For next-season padel lines, prioritize a teardrop baseline for broad-market appeal, add diamond for power-focused releases and round for control/entry-level SKUs; specify 12K carbon1 or carbon–fiberglass hybrids as the primary face material for best cost‑to‑performance, pair with mid‑to‑high density EVA2 cores (30–38 kg/m³ range depending on feel), and work with an OEM that offers fast sampling, clear MOQs3 and predictable lead times4 — NEX Padel can deliver rapid prototyping, multiple fiber layups (fiberglass → 3K/12K/18K carbon), full printing/branding and controlled quality for brand-grade launches.

Why this matters (buyer context)

Product and procurement teams face three simultaneous pressures for next-season padel ranges: 1) the market is expanding fast and demands convincing differentiation; 2) players recognize subtle material/shape differences; 3) brand calendars leave little room for supplier unpredictability. This guide turns market and material choices into a practical sourcing roadmap: what to specify for each target segment, which trade-offs matter most, typical manufacturability limits, and how to work with an OEM like NEX Padel to de‑risk launch timing and quality.

Market and design drivers (brief)

- Padel continues rapid global growth (millions of new players yearly) — demand spans entry‑level, club/resale, and pro signature models.

- Player expectations are maturing: they seek specific feel, sweet spot behavior, and consistent weight/balance.

- Differentiation now combines material choices (carbon grades, fiberglass blends), surface texturing5, and bespoke graphics/paintwork.

- Sustainability and electronics (smart sensors) are emerging adjuncts but bring new BOM and QC implications.

Key material and shape trade-offs (quick summary)

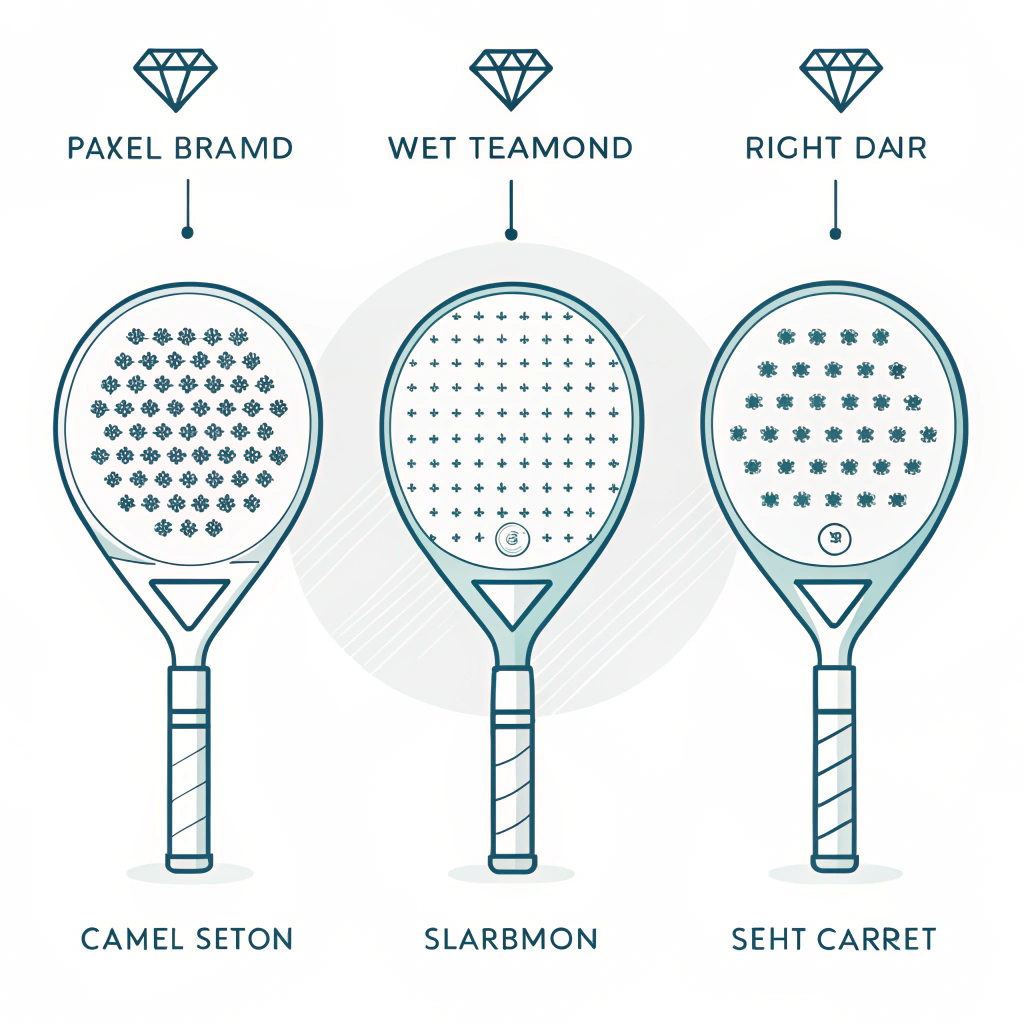

- Shapes: Diamond = power / smaller sweet spot; Teardrop = power + control balance; Round = control / larger sweet spot. Choose 2–3 shapes across a lineup.

- Face materials: Fiberglass = softer touch, lower cost; 3K carbon = affordable carbon look with good stiffness; 12K/18K carbon = higher stiffness, crisper response, higher cost.

- Core: EVA density controls dwell time and power—lower density = softer feel and more control; higher density = more power and less deformation.

- Surface: Textured/coated surfaces improve spin but require additional process steps (sandblasting, laser texture, or textured paints).

Material vs. performance vs. cost (concise table)

| Material / Feature | Player Impact | Typical Cost Delta | Manufacturability Notes |

|---|---|---|---|

| Fiberglass face | Softer feel, forgiving | Low | Easier layup, lower scrap |

| 3K Carbon face | Balanced stiffness, mid cost | Medium | Standard for hybrid models |

| 12K Carbon face | Stiffer, crisp response | High | Requires controlled layup for consistency |

| 18K Carbon face | Very stiff, pro feel | Very high | Demands precise curing; higher scrap risk |

| EVA low density (soft) | More control, less power | Low | Sensitive to temp during molding |

| EVA high density (firm) | More power, faster rebound | Low | Higher internal stress if overcured |

| Textured surface | More spin | Medium | Extra steps: texture tooling/paint |

Recommended SKUs and sample specs (actionable)

Below are three actionable specs you can use as starting points for tech packs or RFQs. These reflect common market segments and the manufacturability practices NEX Padel supports.

| SKU name | Target segment | Shape | Face | Core | Weight (g) | Balance (cm from butt) | Key notes |

|---|---|---|---|---|---|---|---|

| Club Control | Entry / club | Round | Fiberglass | EVA 28 (soft) | 350–365 | 26–27 (even) | Large sweet spot, low cost |

| All‑Round Pro | Mid / retail | Teardrop | 12K carbon + fiberglass hybrid | EVA 32 (mid) | 360–375 | 25.5–26.5 | Balanced power/control, textured surface option |

| Attack Elite | Advanced / signature | Diamond | 18K carbon + 12K carbon layer | EVA 36–38 (firm) | 360–370 | 24.5–25.5 (head‑heavy) | Max power, tighter sweet spot, pro feel |

Notes:

- Bold the face material like 12K carbon on the tech pack to lock supplier choices.

- Tight tolerances: +/- 5 g weight; balance +/- 0.3 cm.

- Provide target stiffness (RA values) if you require precise feel; NEX Padel can test RA on samples.

Manufacturing constraints and practical QA steps

- Layup complexity: Multi-layer carbon (e.g., 18K) increases time per unit and scrap rate. For cost-sensitive SKUs, a hybrid (carbon outer + fiberglass inner) gives a premium feel at lower yield risk.

- Curing: Oven profiles must be repeatable. Inconsistent curing changes bounce and internal stresses.

- Surface effects: Achieving uniform textured coatings or sandblasted finishes adds 3–7 days and requires tooling/fixtures.

- Painting and custom print: Full-color sublimation or pad printing requires masters and proofs; allow for color validation on finished units (not just samples).

- QC checkpoints to require in RFQ:

- Incoming fiber/resin certificates (batch traceability).

- Dimensional checks (thickness, diameter, weight, balance).

- Mechanical tests (RA, impact resilience).

- Visual and adhesion tests for paint/printing.

- Random play testing and pressure tests for ball pairing.

Typical MOQ and lead time expectations (what to plan)

- Sampling:

- Prototype/sample 1–3 units: 7–14 days depending on complexity (simple layups faster).

- Pre‑production pilot run (10–100 units): 2–4 weeks.

- Mass production:

- MOQ for standard SKUs: often 500–1,000 units per model/color. Full customization and lower MOQs are possible but add unit cost.

- Standard lead time after sign‑off: 6–9 weeks for most orders; complex carbon/texture/paint jobs 8–12+ weeks.

- NEX Padel notes: We offer rapid tooling and quick sample turnarounds and can scale to brand orders with predictable scheduling due to stabilized processes and experience with clients like Reebok and Starvie.

Cost/lead‑time tradeoffs (practical rules)

- If you need fast time-to-market: choose hybrid face (carbon + fiberglass), simpler paint (2-color print), and accept mid-density cores.

- If you need premium lineup: allocate extra lead time (add 2–4 weeks) for carbon layup control, textured finishes and additional QC.

- Lower MOQs? Expect 10–30% higher per-unit tooling/handling costs.

Testing, balls compatibility and pairing

- Ball compatibility: Most rackets are compatible with standard pressurized padel balls. If you want to bundle balls, NEX Padel can source pressurized balls with 45% or 57% wool, packed in pressurized tubes to preserve pressure.

- Pairing guidance: For controlled‑feel rackets (round), pair with 45% wool balls; for high‑power rackets (diamond), 57% wool gives more durability and consistent rebound.

- Recommend play-test protocol: 100‑hit durability test + player feedback across three playing styles (control, topspin, power).

Customization options NEX Padel supports

- Full custom shapes (beyond diamond/teardrop/round)

- Face layup options: fiberglass, 3K, 12K, 18K carbon combinations

- Graphic/print: full‑wrap sublimation, pad print, UV coat

- Grip and end‑cap branding (logoed hand grips and butt caps)

- Balls supply and co‑packaging

Smart sensors and sustainability: realistic integration path

- Smart sensor integration is feasible but adds tooling, electronics BOM, and separate QC for wireless performance. Start with modular add-ons (clip-in sensors) before embedding electronics into core.

- Sustainability: consider recycled fibers or bio‑resins, but note current tradeoffs — recycled carbon may reduce consistency and increase scrap. For marketing differentiation, minor sustainable changes (recycled packaging, water‑based paints) yield lower technical risk and good brand mileage.

Operational checklist for procurement teams (ready-to-use)

- Finalize three target SKUs (entry/mid/pro) with shape + face + core + weight bands.

- Request sample lead times and per‑unit cost for:

- Prototype (1–3 units)

- Pilot run (50–100 units)

- Mass production (500 units)

- Insist on suppliers’ QC plan and test report templates.

- Lock in color proofs and painting method on first sample: color consistency locks later schedule.

- Define warranty/defect thresholds and return logistics.

- If bundling balls or accessories, include joint packaging specs.

Case example (how a brand used this roadmap)

A mid‑sized European brand needed a 3-SKU seasonal launch with one signature player model. Using the above approach they:

- Picked a teardrop mid SKU with 12K carbon hybrid to maximize retail appeal.

- Approved samples within two weeks.

- Ran a 200‑unit pilot for retailer demos and an influencer campaign.

- Final mass order of 1,500 units shipped on schedule (lead time 8 weeks) with full QC documentation.

NEX Padel supported iterations to RA targets and delivered brand‑approved paint matches.

Final recommendations and next steps

- Aim for 2–3 core shapes for clarity; use material gradation (fiberglass → 12K → 18K) to tier pricing.

- Specify tolerances and test metrics in the RFQ to avoid late changes.

- Use rapid samples to lock paint/feel before committing to bulk.

- Engage an OEM with experience in carbon layups, predictable lead times and reference brand partnerships — NEX Padel offers these capabilities along with in‑house sourcing for pressurized balls and customization of grips and end caps.

People Also Ask

Q: What is the most popular padel racket?

A: Popularity varies by market and player level, but current best sellers tend to be hybrid or carbon models used by top pros (e.g., signature lines like AT10 or models labeled 12K carbon). For mass markets, balanced teardrop and hybrid (carbon+fiberglass) rackets are most commonly bought because they appeal to a wide range of players.

Q: How popular is padel in 2025?

A: As of 2025, padel has grown into a global sport with over 30 million players across 130+ countries. Growth is especially strong in the UK, US and parts of Latin America — creating a broad market for new racket SKUs and brands to capture.

Q: What shape padel racket is best?

A: There is no single “best” shape — it depends on player needs. Teardrop offers the best balance of power and control for most mid‑level and advanced players; diamond favors maximum power with a smaller sweet spot; round prioritizes control and a forgiving large sweet spot for beginners and club players. Choose shapes deliberately across your lineup to cover target play styles.

-

12K carbon: Read to understand what "12K" denotes (tow count), how weave count affects stiffness, weight and cost, and how to specify layup schedules and QA tolerances for consistent racket performance. ↩

-

EVA: Read to learn how EVA foam density (kg/m³) changes dwell time, rebound and feel, how to specify density and hardness in tech packs, and molding/temperature considerations that affect yield. ↩

-

MOQs: Read to learn strategies for negotiating minimum order quantities, how MOQs influence unit pricing, options for pilot runs and co‑packing to reduce risk, and clauses to include in RFQs. ↩

-

lead times: Read to get typical sampling and production timelines, the main drivers of delay (layup complexity, textured surfaces, painting), and how to write scheduling SLAs and buffer planning into contracts. ↩

-

surface texturing: Read to compare texture methods (sandblasting, laser engraving, textured paints), their impact on spin and feel, additional tooling/time/cost implications, and QA checks needed for uniform texture and adhesion. ↩