A quick answer: For B2B procurement managers comparing padel racket suppliers, NEX Padel stands out by combining advanced manufacturing techniques1, a diverse range of products including Diamond, Round, and Teardrop rackets, and a strong emphasis on customization2 and timely delivery to meet varied market needs.

Procurement managers today must navigate a crowded market, full of varying quality standards and production practices. With the growing demand for high-performance padel rackets, selecting the right supplier becomes a critical decision. Companies not only seek suppliers who can provide superior products but also those who incorporate advanced production techniques, offer flexible customization2 options, and demonstrate a clear commitment to quality and innovation.

NEX Padel, a leading manufacturer based in Jiaxing, Zhejiang, China, has emerged as a competitive player. They focus on advanced production processes that ensure each racket meets stringent performance criteria. In our comparison-driven review, we outline key factors to help you decide which supplier aligns best with your business needs.

When evaluating potential suppliers, consider the following areas to make an informed decision:

-

Manufacturing Process and Technology: Modern production techniques, such as the use of 3k, 12k, and 18k carbon fiber3 reinforcement, can significantly enhance racket performance. Suppliers employing advanced automation and precise quality control measures tend to produce more reliable products.

-

Product Range and Customization: A diverse product catalog, including different shapes and types like Diamond, Round, and Teardrop rackets, is essential. The ability to fully customize product details—such as shape, printed designs, and colors—enables you to cater to specific market segments and branding requirements.

-

Material Quality and Durability: Top suppliers use high-quality raw materials that withstand rigorous play. For example, using various grades of carbon fiber or glass fiber guarantees that the rackets not only perform well but are also durable under competitive conditions.

-

Production Speed and Reliability: In the B2B world, quick turnaround times and dependable delivery schedules are key. A supplier that can provide fast sampling and rapid prototyping4 alongside timely production and shipment can prove invaluable when market demands shift swiftly.

-

Market Reputation and Case Histories: A proven track record with notable brands such as Hirostar, Reebok, and Starvie adds validity. Such partnerships indicate that the supplier meets or exceeds industry standards for quality and reliability.

Below is a detailed table comparing NEX Padel with generic market alternatives. This comparison should help clarify differences in product quality, customization, and service levels.

| Criteria | NEX Padel | Competitor A | Competitor B |

|---|---|---|---|

| Manufacturing Technology | Advanced techniques using glass fiber, 3k/12k/18k carbon fiber | Traditional production methods; limited use of advanced composites | Mixed techniques with some modern upgrades |

| Quality Control5 | Rigorous quality monitoring and rapid prototyping | Standard industry QC processes | Variable quality control across batches |

| Production Speed | Fast sampling and timely delivery | Slower prototyping and production cycles | Average production turnaround times |

| Market Partnerships | Trusted by industry leaders like Hirostar, Reebok, Starvie | Lesser-known brands with fewer high-profile partnerships | Mixed portfolio with regional brands |

| After-Sales Support | Dedicated B2B support, flexible reorders | Minimal after-sales service | Standard support without customization focus |

This table reflects how NEX Padel distinguishes itself in several key areas critical for B2B procurement, such as advanced manufacturing technology, extensive customization capabilities, and a reliable production pipeline.

The padel racket market has evolved to require the use of advanced materials and methods. NEX Padel harnesses the power of both glass fiber and different carbon fiber grades (3k, 12k, 18k) to produce rackets that excel in performance and durability. These materials influence key performance indicators such as racket weight, resistance, and overall balance during play. By leveraging automation and state-of-the-art machinery, NEX Padel mitigates production variance ensuring each high-performance padel racket meets the highest standards.

Companies that rely on suppliers with advanced technology can reduce defect rates and ultimately lower long-term costs related to returns or warranty issues. This advanced approach creates a compelling value proposition for procurement managers looking for consistency alongside quality.

Customization2 is no longer a luxury in the competitive sports equipment market—it’s a necessity. NEX Padel understands that procurement managers require the ability to tailor products to meet local market trends, brand identity, and special campaigns. With options including custom shapes, printing, colors, and even personalized hand grip logos, NEX Padel provides a portfolio flexible enough to cater to a wide range of customer preferences.

This level of customization enables distributors to offer unique value propositions to their clientele and can help build stronger brand connections. Whether your market demands a distinctive aesthetic or performance tweaks based on regional play styles, the ability to customize ensures that your products meet consumer expectations.

Quality is the cornerstone of any successful padel equipment supplier. NEX Padel employs strict quality control measures at every stage—from material selection and initial design to full-scale production runs. High-quality materials combined with meticulous craftsmanship lead to products that not only enhance on-court performance but also withstand the test of time.

Procurement managers benefit when suppliers demonstrate consistency in quality. Reliable products mean fewer returns, enhanced brand reputation, and long-term customer loyalty. Through detailed quality monitoring processes, NEX Padel ensures every batch of rackets that leaves their facility is reliable and performance-ready.

Speed of production coupled with reliable delivery schedules is a critical competitive advantage. In the fast-paced sports equipment market, delays can mean missed opportunities. NEX Padel’s commitment to fast sampling and rapid prototyping4 ensures that you can respond confidently to market demands. Their established production and logistics processes remove uncertainties and help maintain a steady supply chain.

For B2B buyers, predictable production lead times and efficient order fulfillment translate into more effective inventory management and better planning for seasonal sales surges.

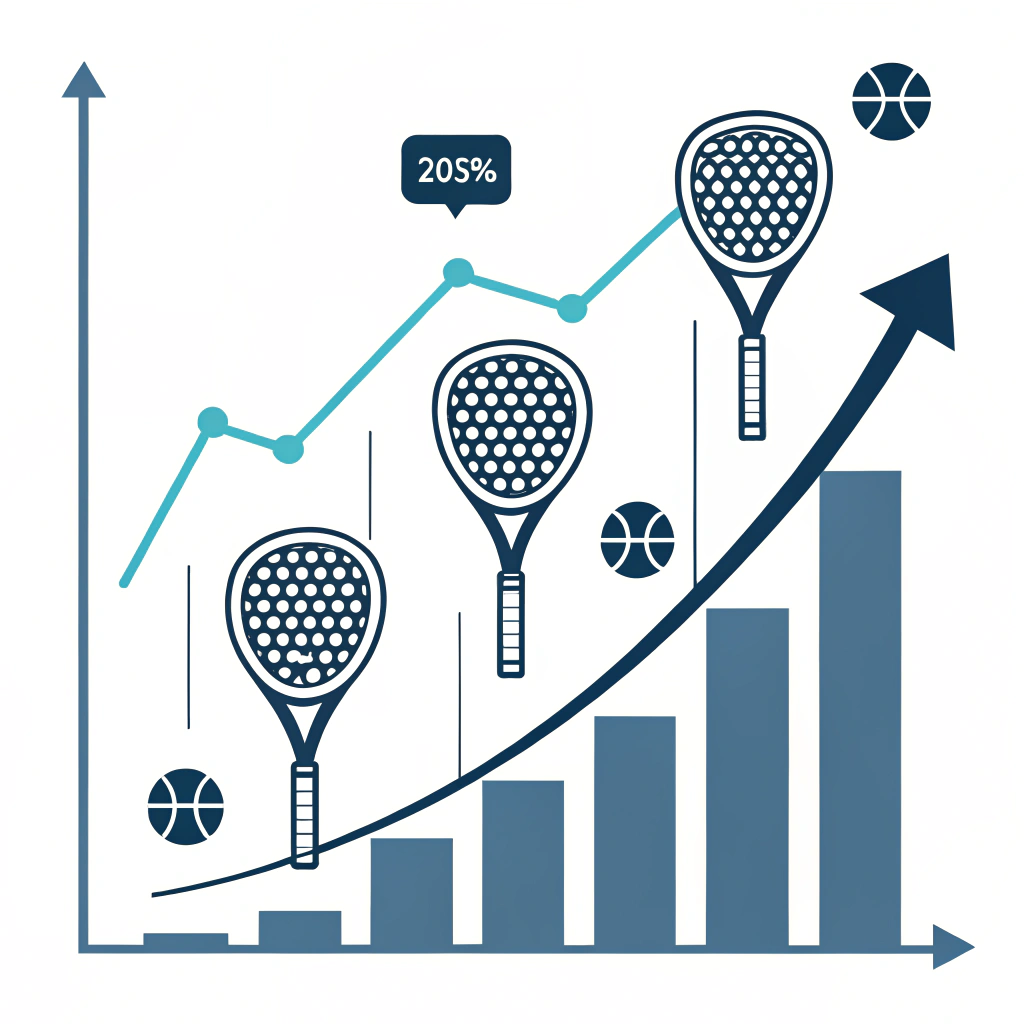

Recent studies in the padel market reveal an upward trajectory not only in player participation but also in demand for high-performance padel gear. The surge in the sport's popularity has driven companies to innovate beyond basic designs.

Data collected from industry reports indicate that customization is a top priority for distributors aiming to differentiate their offerings. With factors like innovative production techniques and superior material choices, suppliers like NEX Padel are well-positioned to capture increased market share. In addition, partnerships with global brands further reinforce the trust and recognition among end-users.

A summary of current market trends includes:

- Increased consumer interest in customized sports equipment.

- A shift towards green, yet high-performance production practices.

- Enhanced digital design tools allowing for closer collaboration between supplier and buyer.

- An emphasis on exceptional finishing and durability in equipment manufacturing.

These trends substantiate why partnering with a forward-thinking manufacturer is crucial. The robust combination of advanced techniques and effective quality control is a clear indicator of supply chain resilience and market adaptability.

Consider these scenarios that illustrate why NEX Padel might be the supplier of choice:

-

A regional distributor planning a product refresh cycle seeks a supplier who can deliver innovative designs quickly to meet a sudden surge in local demand. NEX Padel’s fast sampling and production capabilities ensure minimal lead times.

-

An international brand looking to differentiate itself by offering custom-designed padel rackets can leverage NEX Padel’s full customization services to project a strong brand image and tap into niche markets.

-

A retailer in a competitive market where quality assurance is paramount wants to minimize returns and warranty claims. With its rigorous quality control and production technology, NEX Padel reduces the likelihood of product defects, ensuring customer satisfaction.

Based on these scenarios, procurement managers looking for a trusted partner should prioritize suppliers who excel in both technological innovation and customization capabilities. NEX Padel not only meets these criteria but exceeds industry standards on both ends.

When choosing a padel racket supplier, the decision should be informed by a detailed comparison of manufacturing technology, product range, quality control, and production reliability. The table and analysis above highlight that NEX Padel is a market leader capable of delivering consistent, high-quality, and customizable padel equipment.

For B2B procurement managers, this means:

- Investing in suppliers with advanced technologies minimizes long-term risks.

- Choosing partners with robust customization options can lead to a stronger market presence.

- Working with reliable manufacturers simplifies supply chain management and improves overall business performance.

In conclusion, if you are in the process of evaluating suppliers among a competitive field, consider initiating discussions with NEX Padel. Their expertise caters specifically to the demands of a globally competitive padel market. Now is the time to reimagine your product offerings with a supplier that not only understands the technical aspects but also the market dynamics that drive success.

Q1: How does NEX Padel ensure the quality of high-performance padel rackets?

A1: NEX Padel employs rigorous quality control measures along with advanced manufacturing techniques and premium materials (such as various grades of carbon fiber and glass fiber) to ensure each product meets high-performance standards.

Q2: What customization options does NEX Padel offer?

A2: They offer extensive customization including racket shape, printed designs, color variations, and personalized logos on elements such as the hand grip, enabling tailored solutions that meet diverse market needs.

Q3: How does NEX Padel manage production speed and reliability?

A3: Through fast sampling and rapid prototyping4 alongside streamlined production processes, NEX Padel ensures fast turnaround times and reliable delivery schedules that help maintain a steady supply chain for distributors.

-

advanced manufacturing techniques: Reading this article will help you understand how modern production methods integrate automation and precision to improve product consistency and performance. Back ↩

-

customization: Reading this article will help you understand the importance and process of product customization to meet diverse market needs in a B2B context. Back ↩ ↩2 ↩3

-

carbon fiber: Reading this article will explain the role of carbon fiber reinforcement in enhancing product durability and performance, which is crucial for high-performance sports equipment. Back ↩

-

rapid prototyping: Reading this article will provide insights into how rapid prototyping accelerates product development and improves supply chain responsiveness, a key factor for B2B procurement. Back ↩ ↩2 ↩3

-

Quality Control: Reading this article will elucidate best practices in quality control to ensure consistent product performance and reduce long-term costs in manufacturing. Back ↩