In today’s competitive sporting goods market, advanced Chinese padel racket manufacturers such as NEX Padel are setting new benchmarks by combining cutting-edge production methods with extensive customization options1. This article briefly explains how our advanced manufacturing processes, material expertise, and quality assurance measures2 help deliver high-performance padel rackets that meet the strict demands of B2B buyers.

Modern padel racket procurement demands more than just a product; it requires a partnership with a manufacturer that understands both the technical requirements and the market demands. NEX Padel leverages its expertise to produce pads that excel in performance by utilizing advanced materials—ranging from fiberglass to 3k, 12k, and 18k carbon fiber—and by offering diverse customizations. For procurement managers and business development professionals, the clarity of production techniques, rigorous quality controls, and customization possibilities are key factors in the decision-making process.

High-performance padel rackets rely on precision engineering and innovative production methodologies. At NEX Padel, our manufacturing process incorporates:

- Carbon Fiber Technology3: Utilizing 3k, 12k, and 18k carbon fiber provides increased strength-to-weight ratios and optimizes performance on the court.

- Quick Prototyping and Sampling4: Rapid development timelines ensure that our clients receive initial samples quickly, allowing for faster product iterations.

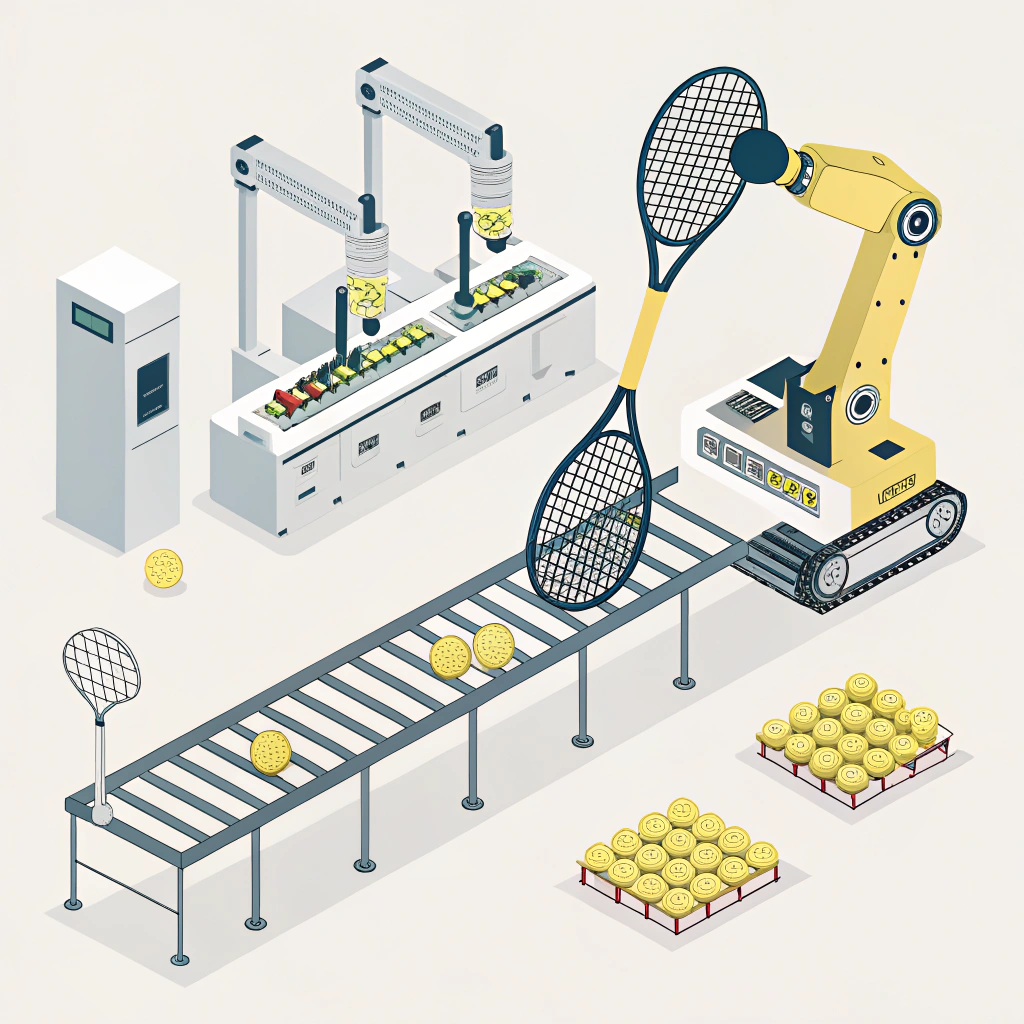

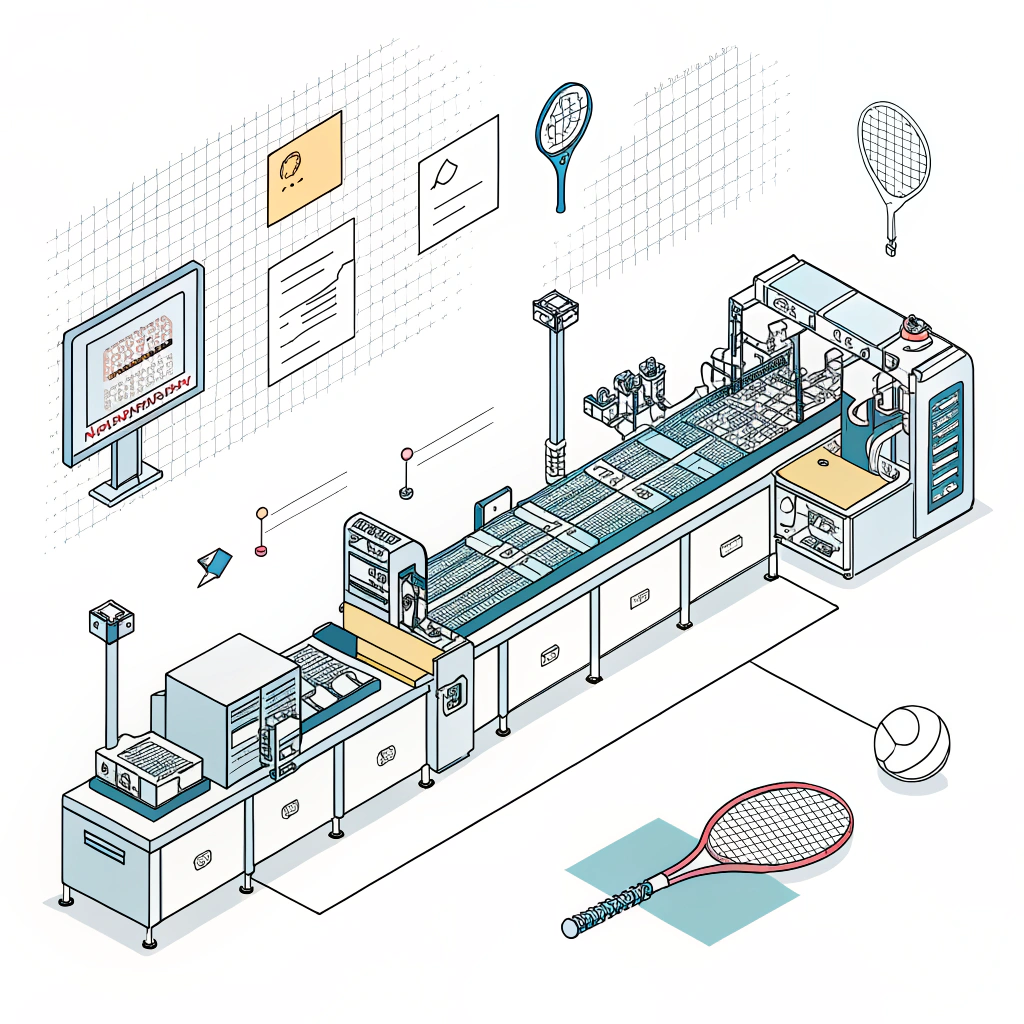

- State-of-the-Art Machinery: Automation and precision control ensure that every racket meets stringent tolerances.

These techniques help ensure not only durability and power but also consistent quality across batches.

A variety of raw materials, from traditional fiberglass to high-grade carbon fibers, are available to meet the needs of different market segments. Each material is selected based on:

- Durability: Ensuring long-term performance under rigorous play.

- Weight and Balance: Achieving optimal balance for enhanced control.

- Customization: Providing the flexibility to tailor racket properties based on buyer requirements.

This material diversity is critical for procurement managers who seek versatility in product offerings without compromising on quality.

NEX Padel distinguishes itself with robust customization options that set the stage for differentiated products in the marketplace. Buyers can choose among several racket shapes:

- Diamond

- Round

- Teardrop

Moreover, customization extends to:

- Logo and Color Customizations: From racket frames to hand grip covers, brand identity can be seamlessly integrated.

- Custom Shape Adjustments: Tailor-made designs that meet specific play style and performance criteria.

- Accessory Integration: Options to customize related accessories such as pressurized padel balls for quality assurance.

The ability to fine-tune these elements ensures that the final product aligns with a buyer's strategic market positioning.

Ensuring the highest quality standards during production is paramount. Our quality control process involves:

- Strict Material Testing: Raw materials undergo thorough testing cycles to confirm strength, durability, and performance characteristics.

- In-Process Inspections: Each stage of production is monitored to catch any deviations or defects early.

- Batch-to-Batch Consistency: High-precision machinery ensures minimal variation, so every racket produced meets the same high-quality standard.

- Timely Deliveries: Our efficient production scheduling and strong supply chain management guarantee on-time delivery, which is crucial for managing inventory and meeting market demands.

By adhering to these rigorous standards, we provide procurement managers with peace of mind and a solid basis for long-term partnerships.

When evaluating a manufacturer, decision-makers must consider multiple factors. The table below summarizes key production capabilities and how NEX Padel’s offerings compare in the competitive landscape:

| Aspect | Description | NEX Padel Advantage |

|---|---|---|

| Material Quality | Variety from fiberglass to high-grade carbon fibers | Superior material selection ensures durability |

| Customization Options | Ability to design bespoke shapes, colors, and logo placements | Full customization including Diamond, Round, Teardrop |

| Production Efficiency | Speed of prototyping, sampling, and batch production | Fast turnaround and reliable delivery |

| Quality Control | In-process testing and final product inspections | Rigorous standards at every production stage |

| Industry Experience | History of producing products for notable brands | Trusted by industry leaders like Hirostar and Reebok |

This detailed comparison aids procurement professionals in aligning manufacturing capabilities with their sourcing needs, ensuring that the chosen partner can deliver both quality and value.

Industries such as sporting goods constantly evolve, with advancements in both player techniques and equipment technology. The increased demand for precision-engineered products means that manufacturers must:

- **Adopt Integrated Technologies5: Merging digital design with automated production lines.

- Focus on Continuous Improvement: Regularly updating production processes to incorporate the latest advancements in materials and manufacturing.

- Ensure Scalability: Balancing customization with large-scale production to meet diverse market requirements.

For instance, the integration of advanced carbon fiber technology not only improves racket performance but also enhances product lifecycle and customer satisfaction. Implementing these techniques allows companies like NEX Padel to adapt to changing market trends while maintaining high quality standards.

For B2B procurement managers considering the next step in sourcing high-performance padel rackets, here are actionable steps to facilitate an informed decision:

- Define Specific Requirements: Identify key performance metrics and desired customization options. Consider factors such as racket weight, balance, and aesthetic customization.

- Evaluate Manufacturing Capabilities: Assess the production techniques and quality control processes of potential manufacturing partners. A visit to the production facility or a review of performance certifications can provide critical insights.

- Review Customer Testimonials and Case Studies: Look for manufacturers with proven track records in delivering consistent quality. Case studies, especially in partnerships with well-known brands, provide a valuable reference.

- Request Sample Developments: Rapid prototyping and sample development are cornerstones of modern manufacturing. Ensure that your chosen supplier can offer a fast turnaround to align with your project timelines.

- Compare Customization Flexibility: Not all manufacturers offer the same level of customization. Verify that the production partner supports all your branding and design requirements, including specialized grips and accessory integrations.

- Analyze Pricing and Production Efficiency: While competitive pricing is important, do not compromise on quality. A well-balanced solution that offers both cost-effectiveness and high performance should be prioritized.

By following these steps, procurement managers can establish a clear roadmap for selecting a manufacturing partner that meets all technical and business requirements.

In the realm of high-performance sports equipment, particularly padel rackets, choosing a capable and reliable manufacturer is critical to maintaining competitive advantage. NEX Padel stands out by offering:

- Advanced production techniques that deliver superior performance.

- A diverse range of materials tailored to different performance needs.

- Extensive customization options to help brands differentiate in the market.

- Rigorous quality assurance protocols that ensure product consistency and durability.

For procurement managers and business developers, understanding these factors and comparing production capabilities across manufacturers is essential for making the best sourcing decision. With a focus on continuous improvement and strategic customization, partnering with a trusted manufacturer like NEX Padel not only meets current market demands but also paves the way for future innovation and growth.

Take the next step in your sourcing journey by exploring the comprehensive solutions that advanced manufacturing and customization can offer. For further insights or to arrange a facility visit, reach out to our business development team today.

Q: How do advanced carbon fiber technologies enhance padel racket performance?

A: Advanced carbon fiber technologies provide improved durability, increased strength-to-weight ratios, and enhanced power transfer, which results in a racket that is both lightweight and high-performing on the court.

Q: What quality control measures are essential for padel racket manufacturing?

A: Effective quality control measures include rigorous raw material testing, in-process inspections, and final product evaluations. These steps ensure that every padel racket meets the required performance standards and maintains consistency across production batches.

Q: Why choose a Chinese manufacturer for padel rackets?

A: Chinese manufacturers offer competitive pricing combined with state-of-the-art production technologies and extensive customization capabilities. This blend of efficiency and innovation makes them a preferred choice for businesses seeking high-quality, customizable padel rackets.

-

customization options: Read this article to understand different strategies for product personalization and how tailoring design choices can enhance market differentiation and customer engagement. Back to customization options ↩

-

quality assurance measures: Discover how implementing robust quality assurance protocols can improve product reliability, ensure compliance with industry standards, and foster long-term client trust. Back to quality assurance measures ↩

-

Carbon Fiber Technology: Learn about the properties of carbon fiber, its applications in sports equipment manufacturing, and how varying grades (3k, 12k, 18k) influence product performance. Back to Carbon Fiber Technology ↩

-

Quick Prototyping and Sampling: Explore the benefits of rapid prototyping and sampling in the manufacturing process, including faster iteration cycles and reduced time-to-market for new product designs. Back to Quick Prototyping and Sampling ↩

-

Integrated Technologies: Understand how integrating digital design and automated production systems can streamline manufacturing processes, enhance precision, and support scalable production. Back to Integrated Technologies ↩