A padel racket’s construction requires a deep understanding of material science1 and precision engineering2—from selecting the right raw materials to incorporating advanced production techniques3 and customization4 techniques. This comprehensive guide provides procurement professionals with an in-depth look at how high-performance padel rackets are built, emphasizing materials, production processes, and quality assurance measures.

For B2B buyers and product development managers, understanding the construction process of padel rackets is crucial. Not only does it impact the final performance, but it also determines the durability and capacity for customization that high-performance products must meet. This article explains how NEX Padel leverages advanced production techniques and premium materials such as glass fiber, 3K Carbon Fiber5, 12K, 18K carbon fiber to create rackets that meet the highest industry standards. We will walk you through the core manufacturing steps, detail the customization process, and highlight quality assurance practices that ensure consistency and reliability, helping you make informed procurement decisions.

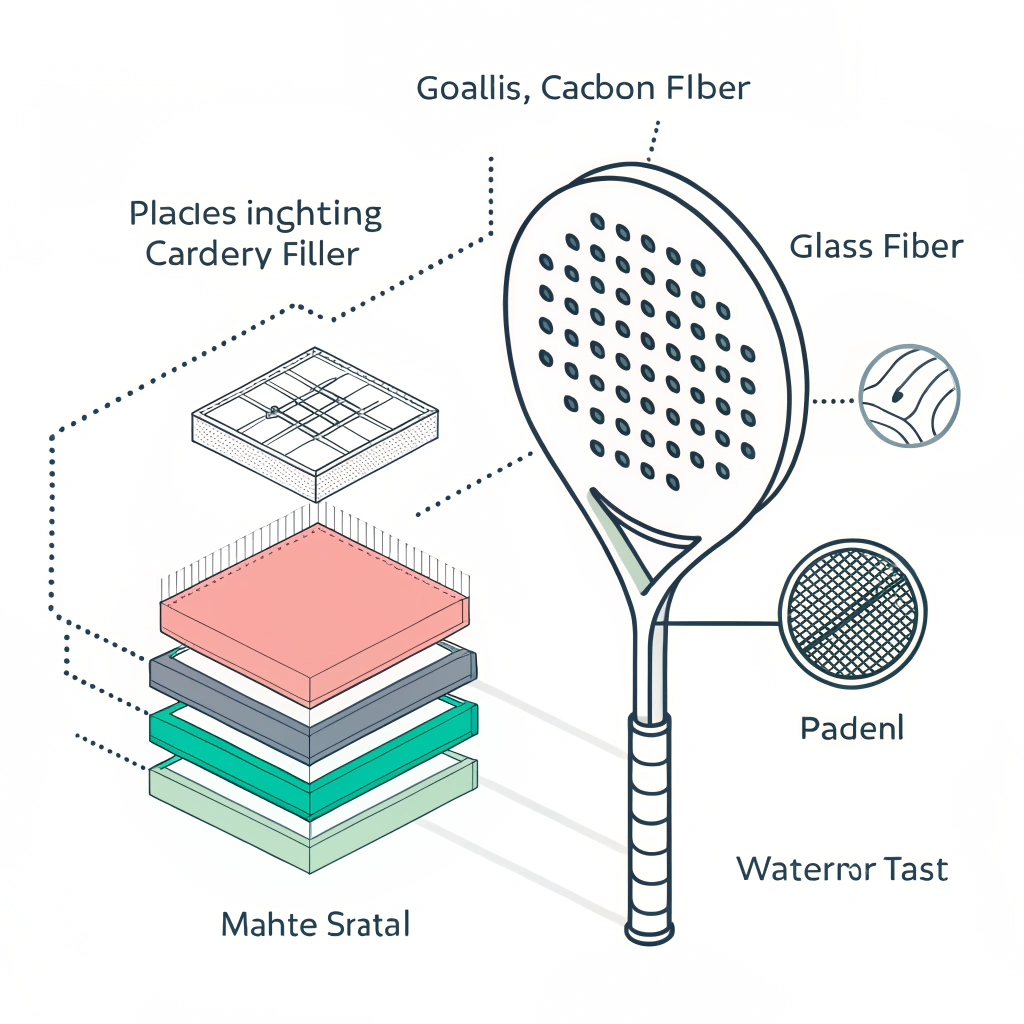

Selecting the right materials is the first step in constructing a padel racket. At NEX Padel, material selection is driven by both performance requirements and durability standards. Here’s a brief overview of each material used in our products:

-

Glass Fiber: Known for its flexibility and impact resistance, glass fiber forms the base layer in many rackets. It provides a good balance between performance and cost-effectiveness, making it ideal for beginners and intermediate-level equipment.

-

3K Carbon Fiber: This material offers an excellent balance between strength and weight. The term 3K refers to the number of filaments in the fiber bundle, ensuring moderate stiffness and stability.

-

12K Carbon Fiber: With a higher filament count, 12K carbon fiber delivers improved rigidity. This allows for better control and power, and it is often used in products aimed at high-performance players.

-

18K Carbon Fiber: The strongest and stiffest option among the commonly used fiber types, 18K carbon is ideal for players demanding maximum force transfer and precision. However, its increased stiffness requires careful handling during the manufacturing process.

Each material plays a distinct role in balancing racket performance with durability. Our production process optimizes these materials based on specific player demographics and use-case scenarios, combining them in unique ways to achieve desired characteristics.

Understanding the detailed production process is crucial for ensuring quality and consistency. The process from raw material to finished product is built on precision and advanced techniques. Below is an overview of the core steps:

-

Material Preparation and Selection

The manufacturing process begins with selecting high-quality raw materials. Each material is tested for consistency, tensile strength, and resistance to environmental factors.

a. Pre-treatment cleaning

b. Precision cutting to required dimensions

c. Quality verification before molding -

Lamination and Molding

In this step, multiple layers of materials are laminated to create a robust composite structure. The manufacturing process typically employs high-pressure and high-temperature molding to ensure proper bonding between fibers and resin.

a. Layer stacking according to design (Diamond, Round, or Teardrop profiles)

b. Application of resin and controlled curing

c. Use of molds that support full customization, including printing and shape adjustments -

Customization and Branding

A key advantage of working with our manufacturing facility is the ability to tailor products to specific client requirements. Customization includes:- Custom shapes: Along with standard profiles, rackets can be fully customized.

- Surface printing: Logos, color schemes, and other brand-specific details can be applied during the production process.

- Additional elements: Hand grip and handle covers can be customized with client logos.

This step is critical for distributors aiming to offer unique product lines that stand out in the competitive market.

-

Assembly and Finishing

After molding and customization, each racket undergoes an assembly stage. This involves attaching various components such as the grip, handle tape, and any additional protective coatings. A final quality check is performed before packaging. -

Packaging and Delivery

Once approved by our quality assurance team, the rackets are prepared for shipment. Our efficient sampling and quick turnaround times ensure that all products reach our partners on schedule.

The following flowchart summarizes our production process:

| Stage | Key Activities | Output |

|---|---|---|

| Material Preparation | Testing, cleaning, and cutting raw materials | High-quality material sheets |

| Lamination & Molding | Layer stacking, resin application, high-pressure curing | Composite racket structure |

| Customization | Shape modification, printing, and branding applications | Tailored racket design |

| Assembly & Finishing | Attaching grips, level finishing | Fully assembled padel racket |

| Packaging & Delivery | Final inspection, packing, and prompt shipment | Rackets delivered to clients |

One of the major competitive advantages in the padel industry is the ability to offer a high degree of customization. At NEX Padel, we believe that a product should not only meet performance criteria but also reflect the brand identity of our customers. Here are several key customization features:

-

Shape Customization:

Racket shapes such as Diamond, Round, and Teardrop each deliver different performance characteristics. We allow clients to select and even modify these profiles to fit specific market needs. -

Material Blend Selection:

Our manufacturing process can combine materials such as glass fiber with 3K, 12K, or 18K carbon fibers. By varying the ratios and layer placements, we create rackets optimized for various player types, ranging from beginners to professionals. -

Visual Branding and Printing:

Custom prints allow for unique color patterns and logos to be directly integrated into the racket’s surface. This not only enhances the aesthetic value but also reinforces brand recognition. -

Accessory Customization:

Beyond the racket frame itself, customization extends to hand grips (including logo imprinting on hand grip covers) and handle accessories. These minor details can significantly improve the user experience and appeal for retailers looking to offer a distinctive product.

These customization options provide an edge to distributors, allowing for product differentiation in a crowded market. The transparency of our process ensures that each custom order is executed with the highest technical precision.

Quality is paramount at every stage of production. Given the technical intricacies involved in using diverse materials, quality assurance is integrated into each phase. Here’s how we maintain excellence:

-

Incoming Material Inspection

Before production begins, raw materials such as glass fiber and carbon fiber are received and tested for consistency with specified quality standards. Only materials that pass stringent tests are approved for use. -

In-Process Quality Control

Our production facilities utilize state-of-the-art sensors and monitoring tools during the curing and molding process. This real-time monitoring helps detect defects early, ensuring process efficiency and high-quality output. -

Final Product Testing

Each completed padel racket undergoes mechanical testing to evaluate factors such as tensile strength, balance, and impact absorption. Products are compared against performance benchmarks to validate their durability and reliability. -

Certifications and Compliance

Our production processes comply with international standards for sports equipment manufacturing. This includes adherence to specific regulations concerning material safety and quality assurance.

The following table outlines key quality control checkpoints:

| QA Stage | Description | Benefit |

|---|---|---|

| Material Inspection | Verification of raw material quality before production | Consistent material quality |

| In-Process Monitoring | Continuous measurement of curing, pressure, and temperature | Early detection of issues |

| Final Testing | Mechanical tests and performance evaluations | Assurance of product performance |

| Compliance Certification | Adherence to international standards and regulations | Increased market trust |

While the production of high-performance padel rackets is a refined process, it is not without its challenges. Addressing these challenges not only leads to production optimization but also improves overall product quality.

-

Material Variability:

Even slight inconsistencies in carbon fiber properties can influence performance. This is why strict quality assurance guidelines are in place during raw material inspection. -

Customization Complexity:

Tailoring a product on a micro-level—down to the shape or branding—can increase production complexity. Effective communication and clear specifications are crucial for ensuring that custom orders are produced accurately. -

Process Precision:

High-pressure molding and curing require exact environmental conditions. Any deviation might lead to an improperly set resin or weak adhesion between layers.

-

Robust Supplier Relationships:

By working closely with trusted suppliers, NEX Padel ensures that materials such as 18K carbon fiber meet specified performance and quality standards consistently. -

Advanced Production Technology:

Continuous investment in new production technology allows our manufacturing process to maintain precision, even when handling highly customized orders. -

Comprehensive Testing Regimes:

The implementation of rigorous testing during and after production has minimized defects in finished products, ensuring each racket performs at peak levels. -

Data-Driven Process Improvements:

Utilizing feedback from both in-house testing and customer performance data, we refine our production processes continuously. Data analysis helps pinpoint bottlenecks and areas for quality improvement.

In summary, each challenge encountered in the production process is met with a well-thought-out strategy that not only resolves the immediate issue but also contributes to the continuous optimization of manufacturing techniques.

In today’s competitive sports equipment market, a deep understanding of the production process—from material selection to final quality checks—is vital for making informed procurement decisions. High-performance padel rackets require precision engineering, advanced production techniques, and flexible customization options that allow the final product to meet rigorous performance standards.

For procurement professionals, it is essential to partner with manufacturers like NEX Padel who invest in both technology and quality assurance. Our expertise in using materials including glass fiber and various grades of carbon fiber (3K, 12K, 18K) ensures that every racket we produce is built for durability and performance. Additionally, our comprehensive customization options—ranging from shape modifications to branding elements—provide a unique competitive advantage in a crowded market.

By understanding the step-by-step process, the technical details, and the quality control measures discussed in this guide, B2B buyers can confidently assess and select a production partner capable of delivering rackets that fulfill both performance expectations and brand-specific requirements. We encourage you to leverage these insights when considering your supply chain needs and to inquire further about our advanced padel racket solutions.

-

What factors influence the quality of a padel racket?

Various factors such as the type of material used (glass fiber vs. various grades of carbon fiber), the precision of the molding process, customization details, and rigorous quality control measures all play a crucial role in the quality of a padel racket. -

How do carbon fiber compositions affect padel racket performance?

Carbon fiber compositions, including 3K, 12K, and 18K, determine the racket’s stiffness, weight distribution, and impact resistance. Higher filament counts generally offer greater rigidity and control, which is essential for high-performance play. -

What customization options are available for padel rackets?

Customization options include selecting the racket shape (Diamond, Round, Teardrop), combining different materials, and adding unique visual branding such as custom prints and logo placements on grips and covers.

-

Material Science: Click to learn how advancements in material science drive innovation in product development by exploring the properties, testing methods, and performance benefits of various raw materials. ↩

-

Precision Engineering: Click to discover the techniques behind precision engineering that ensure products meet exacting tolerances and deliver superior performance in competitive markets. ↩

-

Advanced Production Techniques: Click to uncover the modern production methods that streamline manufacturing processes, enhance efficiency, and improve product consistency. ↩

-

Customization: Click to explore how tailored product designs can meet specific market needs and help differentiate brands through unique design and branding strategies. ↩

-

Carbon Fiber: Click to delve into the world of carbon fiber, including the differences between 3K, 12K, and 18K grades, and how each variation impacts strength, weight, and performance in high-end products. ↩